Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sequencing

Caricato da

Sundaramali Govindaswamy GDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sequencing

Caricato da

Sundaramali Govindaswamy GCopyright:

Formati disponibili

1 2 3

INTRODUCTION

Sequencing problem is the problem of determining an

appropriate order (sequence) for a series of jobs to be

done on a finite number of service facilities so as to

minimize the total time taken for finishing all the jobs.

If there are n jobs and m machines then the sequencing

problem is to determine the optimum sequence selected

among (n!)m theoretical alternatives, that is

technologically feasible.

ASSUMPTIONS

1. Only one operation is carried out on a machine at a time.

2. Processing times are known and do not change.

3. Each operation as well as the job once started must be

completed

4. Only one machine of each type is available

5. No inventory aspect of the problem is considered

6. An operation must be completed before its succeeding

operation can start.

7. Transportation time in moving jobs from one machine to

another is negligible.

IMPORTANT DEFINITIONS

Total elapsed time () is the between starting the first job and

completing the last one.

Idle time on a machine is the time the machine remains

idle during the total elapsed time.

No passing rule in a sequencing problem :

If each of then jobs is to be processed through two machines

M

1

and M

2

in the order M

1

M

2

then this rule means that each

job will go to machine M

1

first and then to Machine M

2

PROCESSING n JOBS on 2 MACHINES

(Johnsons method)

Let A

11

, A

21

, A

31

An1

be processing times of n jobs on Machine 1 and Let A

21

, A

22

,

A

32

. A

n2

be processing times of n jobs on Machine 2.

Step 1

Find the minimum processing hours in M

1

and M

2

Step 2

If the minimum is in M

1

machine write the Job sequence No in the Optimal

sequence table (write the sequence from left to right in the Optimal sequence

table) If the minimum is in M

2

machine write the job sequence No in the Optimal

sequence table (write the sequence from right to left in the optimal sequence table)

If there is a tie (i.e both M

1

and M

2

is equal then compare the lowest with other M

1

& M2 hours, which one is lower give the preference.

Step 3

Cancel the jobs already assigned in the optimal sequence table and repeat steps 1

to 2 until all the jobs have been assigned.

PROCESSING n JOBS ON 3 MACHINES

Let A

1

, A

2

, A

3

be the three machines. Let the order of operations be

A

13

, A

21

, A

3

. This problem can be converted into a two machine problem

if any one of the following conditions is satisfied.

Condition 1

Min A

i1

Max A

i2

(mini. time on machine 1 max. time on

machine 2)

Condition 2

Min A

i3

Max A

i2

(mini. time on machine 3 max. time on

machine 2)

The method fails if none of these conditions is satisfied. If one of the

conditions is satisfied , then the processing times on H and K machines are

given by

Hi = A

i1

+ A

i2

, i = 1,2,3.., n-1

Ki = A

i2

+ A

i3

, i = 1,2,3,., n

Now proceed to determine the optimal sequence as we discussed early

PROCESSING n JOBS ON m MACHINES

Let there be m machines A

1

, A

2

,., A

m

. This problem can be converted

in to a two machine problem if one of the following condition is satisfied..

CONDITIONS

If Min A

i1

Max Aij j = 1,2,3. m-1

or Min Aim Max Aij j = 2,3.., m

If any one of the condition is satisfies then

Hi = Mi1+Mi2+Mi3+..Mm-1

(Add from first machine to last before the machine)

Ki = Mi2+Mi3+Mi4+.Mij

(Excluding first machine then add up to last machine)

After getting the two machine type equations, then proceed the problem

like what we discussed in earlier methods.

MATHEMATICALLY APPLICATIONS

n JOBS 2 MACHINES

Find the sequence that minimizes the total elapsed time required

to complete the following tasks on machines M and M in the

order M , M. Also find the minimum total elapsed time

TASKS A B C D E F G H I

M1 2 5 4 9 6 8 7 5 4

M2 6 8 7 4 3 9 3 8 11

OPTIMAL SEQUENCE

MACHINE 1 MACHINE 2

MACHINE/

TASKS

M1 M2 ORDER OF

CANCELLATION

A 2 6 1

B 5 8 7

C 4 7 4

D 9 4 6

E 6 3 2

F 8 9 9

G 7 3 3

H 5 8 8

I 4 11 5

A C I B H F D G E

To find the minimum total elapsed time

Minimum total elapsed time = 61 time units

Idle time for machine M1 = 61-50 = 11 time units

Idle time for machine M2 = 2 time units

n JOBS 3 MACHINES

Find the sequence that minimizes the total elapsed time required

to complete the following tasks on the machines in the order

1-2-3.Find also the minimum total elapsed time (hours) and the

idle times on the machines.

Minimum time on Machine 1 = 3

Maximum time on Machine 2 = 5

Minimum time on Machine 3 = 5

Condition 1 Minimum time on Machine 1 Maximum time on Machine 2

Condition 2 Minimum time on Machine 3 Maximum time on Machine 2

Condition 2 is satisfying, hence we can convert this into 2 machine problem.

H = Machine 1 + Machine 2

K = Machine 2 + Machine 3

Optimal sequence

MACHINE H MACHINE K

A D G F B C E

To find the total elapsed time

The Minimum total elapsed time = 59 hrs.

Idle time on Machine 1 = 59-46 = 13 hrs

Idle time on Machine 2 = 3+2+5+4+4+7+12 = 37 hrs

Idle time on Machine 3 = 7 hrs

n JOBS m MACHINES

Solve the following sequencing problem giving an optimal solution

if passing is not allowed

CONDITIONS

Min M1 = 8 Min M4 = 14

Max M2 = 8 Max M3 = 8

Condition 1 Min M1 Max M2 &M3 condition is satisfied

Condition 2 Min M4 Max M2 & M3 Condition is satisfied

(if any one is satisfied proceed to next step)

Hi = Mi1+Mi2+Mi3 (except last machine) = 28, 26, 24,19

Ki = Mi2+Mi3+Mi4 (except first machine) = 29,33,30,26

Optimal sequence

Machine H Machine K

To find the total elapsed time

Minimum total elapsed time = 82 time units

Idle time on M1 = 82-42 = 40 time units

Idle time on M2 = 8+4+5+7+(82-50) = 56 time units

Idle time on M3 = 13+5+3+7+(82-57) = 53 time units

Idle time on M4 = 19 time units

Potrebbero piacerti anche

- ApexDocumento23 pagineApexMadhava PadiyarNessuna valutazione finora

- Sequencing ProblemDocumento27 pagineSequencing ProblemSaurabh MishraNessuna valutazione finora

- SEQUENCINGDocumento34 pagineSEQUENCINGmayureshk776Nessuna valutazione finora

- Operations Research VII SEMESTER (18ME735) Module - 5: Department of Collegiate and Technical EducationDocumento29 pagineOperations Research VII SEMESTER (18ME735) Module - 5: Department of Collegiate and Technical Educationjhansi lakshmiNessuna valutazione finora

- Scheduling & Sequencing Njobs 2 Machines 2012Documento80 pagineScheduling & Sequencing Njobs 2 Machines 2012gay mojicaNessuna valutazione finora

- KMB 206 OR Unit - 4Documento21 pagineKMB 206 OR Unit - 4Prashant SharmaNessuna valutazione finora

- Sequencing ModelDocumento10 pagineSequencing ModelBisoyeNessuna valutazione finora

- Operations Research: Department of MathematicsDocumento9 pagineOperations Research: Department of MathematicsAhmad Zia YaqoobiNessuna valutazione finora

- Or Notes (Unit Iv)Documento24 pagineOr Notes (Unit Iv)Vinayak Mishra100% (1)

- Journal On SequenceDocumento8 pagineJournal On SequenceDevaraj AstroNessuna valutazione finora

- Lecture-3 Flow Shop 3 MC Problem 23aug22Documento40 pagineLecture-3 Flow Shop 3 MC Problem 23aug22motted groupNessuna valutazione finora

- IJSRDV7I10123Documento3 pagineIJSRDV7I10123uzmanoureenaNessuna valutazione finora

- Production Planning and ControlDocumento27 pagineProduction Planning and Controlsagar09Nessuna valutazione finora

- Chapter 6 Job SchedulingDocumento25 pagineChapter 6 Job Schedulingnescafe okNessuna valutazione finora

- 7 Sequencing ProblemsDocumento40 pagine7 Sequencing Problemschaitanya mudlapurNessuna valutazione finora

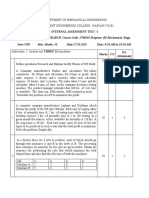

- Course: OERATIONS RESEARCH Course Code: 17ME81 Program: BE Mechanical Engg. Sem - VIII Max. Marks: 30 Date:27.05.2020 Time: 9:30 AM To 10:30 AMDocumento2 pagineCourse: OERATIONS RESEARCH Course Code: 17ME81 Program: BE Mechanical Engg. Sem - VIII Max. Marks: 30 Date:27.05.2020 Time: 9:30 AM To 10:30 AMLokesh Lokesh D SNessuna valutazione finora

- Machines Jobs: 1 2 3 4 A B C D EDocumento3 pagineMachines Jobs: 1 2 3 4 A B C D EPritiNessuna valutazione finora

- Operations Research: Department of MathematicsDocumento13 pagineOperations Research: Department of MathematicsNaga AvinashNessuna valutazione finora

- Job Sequencing On 3 Machines.: - Two Conditions For A Easy SolutionDocumento16 pagineJob Sequencing On 3 Machines.: - Two Conditions For A Easy SolutionSegarta AntoniusNessuna valutazione finora

- Job Sequencing On 3 Machines.: - Two Conditions For A Easy SolutionDocumento16 pagineJob Sequencing On 3 Machines.: - Two Conditions For A Easy SolutionSegarta AntoniusNessuna valutazione finora

- Concept of Logical Sort For Idle Time Minimization of Rental/Critical Machine in FlowshopDocumento6 pagineConcept of Logical Sort For Idle Time Minimization of Rental/Critical Machine in FlowshopTJPRC PublicationsNessuna valutazione finora

- QTM (Unit - 4)Documento7 pagineQTM (Unit - 4)Arkhitekton DesignNessuna valutazione finora

- Or M3 Ktunotes - inDocumento62 pagineOr M3 Ktunotes - inJaya sankarNessuna valutazione finora

- Operation Research IIDocumento14 pagineOperation Research IISSC PREETHIKA R.VNessuna valutazione finora

- Course: OERATIONS RESEARCH Course Code: 17ME81 Program: BE Mechanical Engg. Sem - VIII Max. Marks: 30 Date:01.07.2020 Time: 10:30 AM To 11:30 AMDocumento3 pagineCourse: OERATIONS RESEARCH Course Code: 17ME81 Program: BE Mechanical Engg. Sem - VIII Max. Marks: 30 Date:01.07.2020 Time: 10:30 AM To 11:30 AMLokesh Lokesh D SNessuna valutazione finora

- Sequencing ProblemsDocumento2 pagineSequencing ProblemsSubramani Lakshmaiha100% (1)

- 5.2 Processing N Jobs K MachinesDocumento15 pagine5.2 Processing N Jobs K MachinesPreethiNessuna valutazione finora

- Sequenceing: Processing N Jobs Through Two MachinesDocumento8 pagineSequenceing: Processing N Jobs Through Two MachineskhaledawarsiNessuna valutazione finora

- Unit - II: Sequencing Problems Johnson's RuleDocumento30 pagineUnit - II: Sequencing Problems Johnson's RuleRakib KhanNessuna valutazione finora

- Moore's Procedure & Johnson's Procedure: Session 12Documento16 pagineMoore's Procedure & Johnson's Procedure: Session 12Easwar KumarNessuna valutazione finora

- Flow Shop Scheduling: Chapter ContentsDocumento33 pagineFlow Shop Scheduling: Chapter ContentsRajendra Prasad DashNessuna valutazione finora

- Thuật toán JohnsonDocumento8 pagineThuật toán JohnsonBabyCoder HvhNessuna valutazione finora

- Job Shop SchedulingDocumento28 pagineJob Shop Schedulinganmol6237Nessuna valutazione finora

- OR Tutorial Sheet 4Documento1 paginaOR Tutorial Sheet 4Aditya KumarNessuna valutazione finora

- Unit - 3 Assignment ProblemsDocumento23 pagineUnit - 3 Assignment ProblemsIsha NatuNessuna valutazione finora

- Two MachineDocumento5 pagineTwo MachineIAEME PublicationNessuna valutazione finora

- Chapter 7 Scheduling1Documento39 pagineChapter 7 Scheduling1daftpunk915Nessuna valutazione finora

- Assignment No 1 (Sequence Problem)Documento6 pagineAssignment No 1 (Sequence Problem)yadu nairNessuna valutazione finora

- Sequencing: The Assumptions There Are Some General Assumptions Made To Solve The SequencingDocumento2 pagineSequencing: The Assumptions There Are Some General Assumptions Made To Solve The Sequencingtejashraj93Nessuna valutazione finora

- Multi MachineDocumento33 pagineMulti MachineSeviye KoseNessuna valutazione finora

- Assignment - 4Documento2 pagineAssignment - 4ranjeet singhNessuna valutazione finora

- IOSR JournalsDocumento6 pagineIOSR JournalsInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- N Jobs and M - Machine ProblemDocumento9 pagineN Jobs and M - Machine ProblemHarsha KasaragodNessuna valutazione finora

- Operations SchedulingDocumento4 pagineOperations SchedulingModather SalahNessuna valutazione finora

- Op Scheduling Lesson 8Documento36 pagineOp Scheduling Lesson 8Balraj AnandNessuna valutazione finora

- Lecture-2 Flow Shop Scheduling Johnson's Method 22aug22Documento29 pagineLecture-2 Flow Shop Scheduling Johnson's Method 22aug22motted groupNessuna valutazione finora

- Sequencing ProblemDocumento32 pagineSequencing ProblemSanjal DesaiNessuna valutazione finora

- Example 1: - Vinay Chhabra & Manish DewanDocumento4 pagineExample 1: - Vinay Chhabra & Manish DewansharadgggNessuna valutazione finora

- Scheduling NotesDocumento26 pagineScheduling NotesIshpreet SinghNessuna valutazione finora

- 24 8 18 POR Question Bank Unit I II IIIDocumento10 pagine24 8 18 POR Question Bank Unit I II IIIddownload 1Nessuna valutazione finora

- Bsor Project Application of Job Shop SchedulingDocumento47 pagineBsor Project Application of Job Shop SchedulingAditya SapraNessuna valutazione finora

- Unit III 2 SPDocumento9 pagineUnit III 2 SPPravah ShuklaNessuna valutazione finora

- Flow-Shop Sequencing Model Using Genetic Algorithm: Smita Verma and Paheli SinghalDocumento4 pagineFlow-Shop Sequencing Model Using Genetic Algorithm: Smita Verma and Paheli SinghalSaravanan GopalNessuna valutazione finora

- Multistage Flow-Shop Scheduling With Weighted Jobs: DR Neeru ChaudharyDocumento4 pagineMultistage Flow-Shop Scheduling With Weighted Jobs: DR Neeru ChaudharyinventionjournalsNessuna valutazione finora

- Sequencing Problems Processing N Jobs Through 3 Machines Problem Example PDFDocumento2 pagineSequencing Problems Processing N Jobs Through 3 Machines Problem Example PDFSaravana SelvakumarNessuna valutazione finora

- Scheduling Jobs in Parallel Machines To Minimise Total TardinessDocumento44 pagineScheduling Jobs in Parallel Machines To Minimise Total TardinessSaurabh SrivastavaNessuna valutazione finora

- Sequencing Problems 1Documento24 pagineSequencing Problems 1Div SavaliyaNessuna valutazione finora

- Remote Projects Follow-up with Scrum-Excel Burn Down Chart: Scrum and Jira, #1Da EverandRemote Projects Follow-up with Scrum-Excel Burn Down Chart: Scrum and Jira, #1Nessuna valutazione finora

- Random - Number GeneratorsDocumento37 pagineRandom - Number GeneratorsSundaramali Govindaswamy GNessuna valutazione finora

- Random No GenerationDocumento13 pagineRandom No GenerationSundaramali Govindaswamy GNessuna valutazione finora

- Random GenDocumento31 pagineRandom GenSundaramali Govindaswamy GNessuna valutazione finora

- Lesson-1 Modeling and SimulationDocumento24 pagineLesson-1 Modeling and SimulationSundaramali Govindaswamy GNessuna valutazione finora

- Maintenance SimulationDocumento43 pagineMaintenance SimulationSundaramali Govindaswamy GNessuna valutazione finora

- Six Big LossesDocumento25 pagineSix Big LossesSundaramali Govindaswamy GNessuna valutazione finora

- Unit-5 Game TheoryDocumento15 pagineUnit-5 Game TheorySundaramali Govindaswamy GNessuna valutazione finora

- Iterative Dominance in Game Theory-IDocumento19 pagineIterative Dominance in Game Theory-ISundaramali Govindaswamy GNessuna valutazione finora

- Simplex MethodDocumento29 pagineSimplex MethodSundaramali Govindaswamy GNessuna valutazione finora

- LPP - Big M MethodDocumento6 pagineLPP - Big M MethodSundaramali Govindaswamy G50% (2)

- Merchant's Circle DiagramDocumento42 pagineMerchant's Circle DiagramSundaramali Govindaswamy GNessuna valutazione finora

- Iterative Dominance in Game TheoryDocumento19 pagineIterative Dominance in Game TheorySundaramali Govindaswamy GNessuna valutazione finora

- FORM Module IpsDocumento10 pagineFORM Module IpsRizalNessuna valutazione finora

- The Roti Canai StoryDocumento5 pagineThe Roti Canai StoryDr Bugs TanNessuna valutazione finora

- Safe Motherhood Ao2016-0035 Quality Antenatal Care PDFDocumento9 pagineSafe Motherhood Ao2016-0035 Quality Antenatal Care PDFGa B B OrlonganNessuna valutazione finora

- History of The Hadith, Dr. Muhammad HameedullahDocumento0 pagineHistory of The Hadith, Dr. Muhammad HameedullahAMEEN AKBAR100% (4)

- Iso 16232 10 2007 en PDFDocumento8 pagineIso 16232 10 2007 en PDFyağmurNessuna valutazione finora

- ArticleDocumento9 pagineArticleElly SufriadiNessuna valutazione finora

- 2012 Karshaniya YavaguDocumento4 pagine2012 Karshaniya YavaguRANJEET SAWANTNessuna valutazione finora

- 32 Forms of God GaneshaDocumento16 pagine32 Forms of God Ganeshasudhakarpk2011100% (2)

- Science: BiologyDocumento22 pagineScience: BiologyMike RollideNessuna valutazione finora

- RG-RAP6260 (G) Hardware InstallationDocumento26 pagineRG-RAP6260 (G) Hardware InstallationrazuetNessuna valutazione finora

- Web Programming: GET / HTTP/1.1 ..Documento16 pagineWeb Programming: GET / HTTP/1.1 ..Alecu IlieNessuna valutazione finora

- Auditing BasicsDocumento197 pagineAuditing BasicsMajanja AsheryNessuna valutazione finora

- ASC 2020-21 Questionnaire PDFDocumento11 pagineASC 2020-21 Questionnaire PDFShama PhotoNessuna valutazione finora

- Climate Declaration: For White Corex PlasterboardDocumento1 paginaClimate Declaration: For White Corex PlasterboardAbdullah BeckerNessuna valutazione finora

- Periodicity Review SL KeyDocumento4 paginePeriodicity Review SL KeyYeyoung ParkNessuna valutazione finora

- Cause List 2.1.2023Documento4 pagineCause List 2.1.2023あいうえおかきくけこNessuna valutazione finora

- Gita Ananda SDocumento10 pagineGita Ananda Srosaanggita76Nessuna valutazione finora

- Service Marketing - Term End Examination 2021 School of Business Management Narsee Monjee Institute of Management Studies, HyderabadDocumento2 pagineService Marketing - Term End Examination 2021 School of Business Management Narsee Monjee Institute of Management Studies, Hyderabadnatasha bennyNessuna valutazione finora

- LEARNING ACTIVITY SHEET in Oral CommDocumento4 pagineLEARNING ACTIVITY SHEET in Oral CommTinTin100% (1)

- British Airways Culture and StructureDocumento29 pagineBritish Airways Culture and Structure陆奕敏Nessuna valutazione finora

- CIT 811 TMA 4 Quiz QuestionDocumento3 pagineCIT 811 TMA 4 Quiz QuestionjohnNessuna valutazione finora

- Goal SettingDocumento11 pagineGoal Settingraul_mahadikNessuna valutazione finora

- Bluesil Ep 150 A3: Insulator Grade Silicone RubberDocumento2 pagineBluesil Ep 150 A3: Insulator Grade Silicone RubberNagendra KumarNessuna valutazione finora

- Course Information2009 2010Documento4 pagineCourse Information2009 2010shihabnittNessuna valutazione finora

- Ias Book 2015Documento49 pagineIas Book 2015Rahul SharmaNessuna valutazione finora

- Discover India, January 2018Documento51 pagineDiscover India, January 2018calebfriesenNessuna valutazione finora

- Fluid Mechanics HydraulicsDocumento420 pagineFluid Mechanics Hydraulicsanonymousdi3noNessuna valutazione finora

- Homeopatia Vibracional RatesDocumento45 pagineHomeopatia Vibracional RatesAugusto Bd100% (4)

- Manual Daily Calorie Log: MyfitnesspalDocumento4 pagineManual Daily Calorie Log: MyfitnesspalAzariah Burnside100% (2)

- SWAMINATHAN Ajanta RhapsodyDocumento227 pagineSWAMINATHAN Ajanta RhapsodyRoberto E. García100% (1)