Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Coconut Fibered Green Asphalt

Caricato da

Vanny Joyce BaluyutCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Coconut Fibered Green Asphalt

Caricato da

Vanny Joyce BaluyutCopyright:

Formati disponibili

COCONUT

FIBERED

GREEN

ASPHALT

Chapter I- Introduction

Background of the Study

Puerto Princesa is a popular tourist city with many beach

resorts and seafood restaurants. It has been acclaimed several

times as the cleanest and greenest city in the Philippines.

There are too many mineral resources that can be seen in

Palawan such as nickel, copper ,manganese and also

bitumen. Bitumen is a term applied to native substances;

petroleum, native asphalt, mineral, waxes, and asphaltites of

variable colors, hardness and volatility.

Coconut fibers can be used as a mixture to the

asphalt to lessen the cracking; the fibers will

lessen the void spaces which are the primary

cause of the cracking.

The leaves from the Indian mango can be

extracted to get the color green pigment which

will be used to color the asphalt. These

innovations will improve the quality of the

asphalt that is used here in Puerto Princesa City.

The researchers would like to provide a study

regarding the use of Indian mango leaves and

coconut fibers as organic materials as

components for green asphalt innovation which

may be the solution for the cracking. Also these

organic materials can easily be found and its

cheaper than the other chemical which can also

be used as coloring.

Statement of the Problem

General: Will the mixing of bitumen and other

organic component provide a good quality of

asphalt?

Specific:

Does the use of coconut fiber lessen the possible

cracking of asphalt?

Will the use of the extracted Mangifera

indica(Indian mango) leaves reduce the heat of

the asphalt?

Do the use of organic component increase or

decrease the possible cost of the asphalt?

Objective of the Study

General: To provide a good quality of green asphalt

Specific:

To lessen the possibility of cracking of the asphalt

To lessen the heat absorption by the asphalt

To lessen the CO

2

that release from the asphalt

To reduce the probable cost of the asphalt mixtures

Significance of the Study

This experiment aims to enhance the quality of

cold mix asphalt by making it an ecofriendly green

asphalt, It reduces the chemical volume that is

being release by the asphalt and it will be good for

the health of the community, it also strengthens the

quality of the asphalt by the use of other

aggregates.

Scope and Delimitation

The experiment will be conducted in three

different clean container, one with the CMA(Cold

Mix Asphalt), second is the asphalt with coconut

fiber and the third is the green asphalt with the

green pigment of Mangifera indica(Indian

mango) and coconut fiber. The researchers will

differentiate the three asphalts and it will be

checked by the PEO after 29 days for the

measurement of temperature and strength of the

asphalt. This experiment does not cover the

durability of the asphalt.

Assumption of the Study

The researchers assumption of the study is to

obtain the objectives that is been proposed. First is

to lessen the heat applied in the asphalt and to

obtain a higher strength and also to reduce the

possibility of cracking through the use of coconut

fibers and mango leaves.

Chapter II - Review of Related

Literature

Coconut fiber

The asphalt-fiber characteristics are tested to

determine such characteristics as the

penetration, softening point, burning point,

ductility, density, and Marshall immersion. This

condition creates a softer asphalt mixture,

which is prone to rutting (Fontes et al, 2010)

Fiber size affects the ease of mixing between the asphalt

and fiber: the smaller the fiber, the easier the mixing

process. (Civil and Environmental Research, 2012)

The results had shown that for mixtures of type SMA

(Stone Mastic Asphalt) the incorporated percentage of

coconut staple fibers, to a temperature of 70C, varied

between 0.5 and 0.7%. (Vale et al., 2006)

Green asphalt

Some say that dark-colored surfaces absorb

solar radiation instead of reflecting it. It has

been shown, however, that the UHI (Urban

Heat Island) effect is not a black and white

issue. Density, heat capacity, thickness,

porosity, and a myriad of other factors affect

pavement surface temperature as well.

(LEED and Construction Building, 2009).

Natural sand

Excessive natural sand contents can

increase the susceptibility of asphalt

concrete to permanent deformation-type

distresses. ( Reed B. Freeman and Chun-Yi

Kuo,1999)

Chapter III -

Conceptual Framework

Independent variables

Total cost

Mixing ratio of the

materials

Time that will be

consume

Dependent variables

Ductility

Density

Heat

Chapter IV - Material and

Methods

Material

Coconut fiber

Mangifera indica (Indian mango)

Natural sand

Mortar and Pestel

Container

Aggregates

Bitumen

Admixture

Procedures for project

implementation

Preparation for Mangifera indica(Indian

mango) leaves pigment

Gathering the materials

Cleaning the leaves

Pulverizing the leaves

Extracting the leaves

Preparation for clean container

Buying a container

Steaming the container

Drying and cleaning the container

Preparation for coconut fiber

Buying the coconut fiber

Drying the coconut fiber

Cutting the coconut fiber to 1mm

Asphalt making

Buying the materials

Loading the materials at batch plant

Mixing the asphalt mixtures

Putting the asphalt in a clean container

Checking the materials after 29 days

THANK YOU

PREPARED BY

BARCENAS, RYAN N.

FANGON, MATTHEW THEODORE V.

INOCENCIO, NESTY PAUL C.

VENTILACION, RYAN JOHN T.

ADVISER : ENGR. DARVIN LARDIZABAL

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- CADTDocumento24 pagineCADTVanny Joyce Baluyut100% (1)

- Insular Life Assurance Co., Ltd. v. Serafin D. Feliciano, Et Al. - 074 Phil 468Documento8 pagineInsular Life Assurance Co., Ltd. v. Serafin D. Feliciano, Et Al. - 074 Phil 468Vanny Joyce BaluyutNessuna valutazione finora

- Youth Amba 2014 Application Form FinalDocumento2 pagineYouth Amba 2014 Application Form FinalVanny Joyce BaluyutNessuna valutazione finora

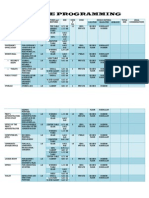

- Space ProgrammingDocumento4 pagineSpace ProgrammingVanny Joyce Baluyut0% (1)

- 2143 4646 1 PBDocumento19 pagine2143 4646 1 PBjayrenzo26Nessuna valutazione finora

- Chainsaw ActDocumento12 pagineChainsaw ActolofuzyatotzNessuna valutazione finora

- RA 7277 - Magna Carta of Disabled PersonsDocumento18 pagineRA 7277 - Magna Carta of Disabled PersonsVanny Joyce Baluyut100% (3)

- Bill of Rights Reviewer FullDocumento31 pagineBill of Rights Reviewer Fullroansalanga100% (22)

- UST GN 2011 Criminal Law ProperDocumento262 pagineUST GN 2011 Criminal Law ProperLariza AidieNessuna valutazione finora

- G.R. No. 47593 September 13, 1941 - The Insular Life Assurance Co. v. Serafin D. Feliciano, Et Al. - 073 Phil 201Documento14 pagineG.R. No. 47593 September 13, 1941 - The Insular Life Assurance Co. v. Serafin D. Feliciano, Et Al. - 073 Phil 201Vanny Joyce BaluyutNessuna valutazione finora

- The Wake of Typhoon YolandaDocumento2 pagineThe Wake of Typhoon YolandaVanny Joyce BaluyutNessuna valutazione finora

- G.R. No. 171035 - William Ong Genato v. Benjamin Bayhon, Et Al.Documento9 pagineG.R. No. 171035 - William Ong Genato v. Benjamin Bayhon, Et Al.Vanny Joyce BaluyutNessuna valutazione finora

- Ordinance No. 506: An Ordinance Providing Guidelines For The Implementation of Ordinance No. 501Documento10 pagineOrdinance No. 506: An Ordinance Providing Guidelines For The Implementation of Ordinance No. 501Vanny Joyce BaluyutNessuna valutazione finora

- Cases of Insurable InterestDocumento10 pagineCases of Insurable InterestVanny Joyce BaluyutNessuna valutazione finora

- Different Economic SystemsDocumento24 pagineDifferent Economic SystemsVanny Joyce BaluyutNessuna valutazione finora

- G.R. No. 92492 June 17, 1993 - Thelma Vda. de Canilang v. Court of Appeals, Et Al.Documento11 pagineG.R. No. 92492 June 17, 1993 - Thelma Vda. de Canilang v. Court of Appeals, Et Al.Vanny Joyce BaluyutNessuna valutazione finora

- G.R. No. 131622. November 27, 1998 Medel, Medel and Franco vs. Court of Appeals, Spouses Gonzales - 299 SCRA 481Documento8 pagineG.R. No. 131622. November 27, 1998 Medel, Medel and Franco vs. Court of Appeals, Spouses Gonzales - 299 SCRA 481Vanny Joyce BaluyutNessuna valutazione finora

- Monitoring and Assessment Quality Objectives - Form - Admin.2Documento3 pagineMonitoring and Assessment Quality Objectives - Form - Admin.2Vanny Joyce BaluyutNessuna valutazione finora

- Cases of Insurable InterestDocumento10 pagineCases of Insurable InterestVanny Joyce BaluyutNessuna valutazione finora

- Finals Reviewer - Labor StandardsDocumento36 pagineFinals Reviewer - Labor StandardsAldrich Alvaera100% (2)

- Balanced Scorecard TemplateDocumento3 pagineBalanced Scorecard TemplateVanny Joyce BaluyutNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- How To Restring An Acoustic Guitar Nicholas OngkowijayaDocumento9 pagineHow To Restring An Acoustic Guitar Nicholas Ongkowijayaplebeius31Nessuna valutazione finora

- Energy Cable Accessories Epp1984 EngDocumento156 pagineEnergy Cable Accessories Epp1984 EngSathiyanathan ManiNessuna valutazione finora

- E 321 - 96 - Rtmymq - PDFDocumento9 pagineE 321 - 96 - Rtmymq - PDFPrakash MakadiaNessuna valutazione finora

- Performance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsDocumento4 paginePerformance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsFredrick IshengomaNessuna valutazione finora

- Cooling Tower 3DTrasar ManualDocumento90 pagineCooling Tower 3DTrasar ManualArevaLemaNessuna valutazione finora

- Zeal High Precision Wet Test Gas Flow Meters 2022Documento5 pagineZeal High Precision Wet Test Gas Flow Meters 2022Hiran ChathurangaNessuna valutazione finora

- Rcfe Contract SSHDocumento240 pagineRcfe Contract SSHJeanne MarshNessuna valutazione finora

- View/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordDocumento2 pagineView/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordlakshmilavanyaNessuna valutazione finora

- Fault and Alarm Indicators: Planning and Installation Guide For Trident v2 SystemsDocumento27 pagineFault and Alarm Indicators: Planning and Installation Guide For Trident v2 SystemsDeepikaNessuna valutazione finora

- Pressure-Controlled Pumps CascadeDocumento2 paginePressure-Controlled Pumps Cascadecc_bauNessuna valutazione finora

- CMA Building Foundation Beams PDFDocumento13 pagineCMA Building Foundation Beams PDFRegie NojaldaNessuna valutazione finora

- The Beginner's Guide To SynthsDocumento11 pagineThe Beginner's Guide To SynthsAnda75% (4)

- ProductBrochure A35F A40F en 30A1006561Documento24 pagineProductBrochure A35F A40F en 30A1006561Ji UvexNessuna valutazione finora

- Resistive Capacitive Inductive and Magnetic Sensor Technologies by Winncy Y Du PDFDocumento400 pagineResistive Capacitive Inductive and Magnetic Sensor Technologies by Winncy Y Du PDFlocthaiquoc83% (6)

- BOB SO Information HandoutDocumento5 pagineBOB SO Information HandoutKabya SrivastavaNessuna valutazione finora

- 01 SQL ErrorsDocumento2.085 pagine01 SQL ErrorsM. temNessuna valutazione finora

- Evaluasi Keandalan PLTA Bakaru: Akbar Tanjung, Arman Jaya, Suryanto, ApolloDocumento8 pagineEvaluasi Keandalan PLTA Bakaru: Akbar Tanjung, Arman Jaya, Suryanto, Apollohilda tangkeNessuna valutazione finora

- Rishabh SharmaDocumento72 pagineRishabh SharmaAmitt MalhotraNessuna valutazione finora

- CatalogDocumento42 pagineCatalogOnerom LeuhanNessuna valutazione finora

- Toshiba NB520 Compal LA-6859PDocumento38 pagineToshiba NB520 Compal LA-6859Pash thonNessuna valutazione finora

- 6802988C45 ADocumento26 pagine6802988C45 AJose Luis Pardo FigueroaNessuna valutazione finora

- HDR-HC1 Hc1e HC1K Hc1ek Ver.1.3 2006.07 Service Manual Suplemento 1Documento8 pagineHDR-HC1 Hc1e HC1K Hc1ek Ver.1.3 2006.07 Service Manual Suplemento 1Javier GutiérrezNessuna valutazione finora

- Seguridad en Reactores de Investigación PDFDocumento152 pagineSeguridad en Reactores de Investigación PDFJorge PáezNessuna valutazione finora

- Kumbh Mela 2019 Presentation Mela AuthorityDocumento35 pagineKumbh Mela 2019 Presentation Mela AuthorityBanibrataChoudhuryNessuna valutazione finora

- SBI Clerk Mains Bolt 2023 OliveboardDocumento160 pagineSBI Clerk Mains Bolt 2023 OliveboardMaahi ThakorNessuna valutazione finora

- Group 2 (Oacc39)Documento3 pagineGroup 2 (Oacc39)viernazanne.viadoNessuna valutazione finora

- BS EN 12536-2000 Gas Welding Creep Resistant, Non-Alloy and Fine Grain PDFDocumento11 pagineBS EN 12536-2000 Gas Welding Creep Resistant, Non-Alloy and Fine Grain PDFo_l_0Nessuna valutazione finora

- Unit Ii Construction Practice - 10Documento94 pagineUnit Ii Construction Practice - 10Arun KumarNessuna valutazione finora

- RAC D Expansion DevicesDocumento21 pagineRAC D Expansion DevicesSohaib IrfanNessuna valutazione finora

- RS232STATUSMONDocumento1 paginaRS232STATUSMONashish.boradNessuna valutazione finora