Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Yaba Elevator

Caricato da

Paolo OcampoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Yaba Elevator

Caricato da

Paolo OcampoCopyright:

Formati disponibili

Definition

History

Components of Elevators

How Elevators work?

Types of Elevators

Classification

Design Consideration

Control & Safety Devices

Modern Elevator

DEFINITION

An elevator (lift in British English) is a

type of vertical transport equipment

that efficiently moves people or

goods between floors

(levels, decks) of a building, vessel,

or other structure.

History

ELISHA GRAVES

OTIS

History

Components

The standard elevators will include the

following basic components:

1.Car

2.Hoistway

3.Machine/drive system

4.Safety system

5.Control System

The vehicle that travels between the different

elevator stops carrying passengers and/or goods.

usually A heavy steel frame surrounding a cage of

metal and wood panels.

The number of passengers shall be

obtained from the formula:

Number of passengers = rated load /75

*Where 75 represent the average weight of

a person in Kg.

3 TYPES:

Components

FIRST: ELEVATOR

CAR

The Standard Elevators Layouts: Standard elevators can be arranged in

the following four layouts:

Arrangement (A): Car with side

opening door and the

counterweight is located at the

back wall.

Arrangement (B): Car with

central opening door and the

counterweight is located at the

back wall.

Components

FIRST: ELEVATOR

CAR

Arrangement (C): Car with side

opening door and the

counterweight is located at one

side.

Arrangement (D): Car with

central opening door and the

counterweight is located at one

side.

The space enclosed by fireproof walls and

elevator doors for the travel of one or more

elevators, dumbwaiters or material lifts.

Components

SECOND: HOISTWAY

Roping system

Components

SECOND: HOISTWAY

ELECTRIC TRACTION MACHINE ABOVE AND BELOW

Components

SECOND: HOISTWAY

Driving machine, this is the power unit of

the elevator, and usually located at the

elevator machine room.

The Driving machine used to refer to the

collection of components that raise or

lower the elevator.

These include the drive motor, brake,

speed reduction unit, sheaves and

encoders.

Components

THIRD: ELEVATOR MACHINE & DRIVE

SYSTEM

Layout of Elevator Safety System

Components

FOURTH: SAFETY SYSTEM

The system responsible for

coordinating all aspects of

elevator service such as

travel, speed, and

accelerating, decelerating,

door opening speed and

delay, levelling and hall

lantern signals.

Simple Elevator Control System Inputs and Outputs

It accepts INPUTS

(e.g. button signals)

and produces

OUTPUTS (elevator

cars moving, doors

opening, etc.).

Components

FIFTH: ELEVATOR CONTROL SYSTEM

SAMPLE VIDEO

How does it work?

SHEAVE

SUSPENSION ROPE

COUNTERWEIGHT and

COUNTERWEIGHT

GUIDERAILS

GUIDERAILS

CALL BUTTONS

SENSORS

HOW ELEVATOR WORKS?: BASIC PARTS

BREAKS

GOVERNOR

TO HOIST

MECHANISM:

TO BUILDING

HEIGHT:

TO BUILDING

TYPE:

TO

ELEVATOR

LOCATION

TO

SPECIAL

USES

1. Traction

Geard

Gear-less

2. Hydraulic

Plunger/

Holed

hole-less

Roped

3. Climbing

4. Pneumatic

A- Low-Rise

buildings

B- Mid-Rise

buildings

C- High-

Rise buildings

1. Hospital

2. Residential

/Domestic

3. Agricultural

4. Industrial

5. Commercial

6. Parking

buildings

A- Outdoor

Elevators

A.1 Observation

elevator

A.2 Incline

Elevators

A.3 Platform

Elevators

A.4 Freight

Elevators

B- Indoor elevators

A- Handicap

Elevators

B- Grain Elevators

C- Double-deck

elevator

D- Sky Lobby

F- Limited use /

limited

application (LU/LA)

ELEVATOR TYPES

(ACCORDING TO: )

Types of Elevator

1. Passenger

2. Freight

3. Special Service

Classification

1.) TRACTION ELEVATOR

gearless

geared

2.) HYDRAULIC ELEVATOR

Holed

hole-less

roped

3.) CLIMBING ELEVATOR

4.) PNEUMATIC ELEVATOR

Types of Elevator

ACCORDING TO HOIST

MECHANISM

TRACTION

HYDRAULIC

CLIMBING

PNEUMATIC

TRACTION

GEARED & GEARLESS

Types of Elevator

ACCORDING TO HOIST

MECHANISM

Traction elevators are raised and

lowered through the elevator shaft by

cables operated by electric motors.

Guide Rails

Counterweigh

t

Buffers

Car Frame &

Safety

Hoistway Door

Door Operator

Car

Machine Room

HOW DOES IT

WORK?

Elevator cars are pulled

up by means of rolling

steel ropes over a deeply

grooved pulley,

commonly called a

sheave in the industry.

The weight of the car is

balanced by a

counterweight.

Sometimes two elevators

are built so that their

cars always move

synchronously in

opposite directions, and

are each other's

counterweight.

Nowadays, some

traction elevators are

using flat steel belts

instead of conventional

steel ropes. Flat steel

belts are extremely light

due to its carbon fiber

core and a high-friction

coating, and does not

require any oil or

lubricant. Because of

these qualities, elevator

energy consumption in

high-rise buildings can

be cut significantly.

TRACTION

GEARED & GEARLESS

ACCORDING TO HOIST

MECHANISM

Types of Elevator

25

Traction Changes

Geared

Gearless

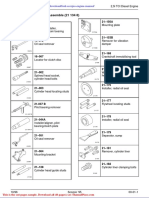

COMPONENTS

Traction Elevator

car

cables

elevator machine

controls

counterweight

hoistway

rails

penthouse

pit

TRACTION

GEARED & GEARLESS

ACCORDING TO HOIST

MECHANISM

Types of Elevator

COMPONENTS

TRACTION

GEARED & GEARLESS

ACCORDING TO HOIST

MECHANISM

Types of Elevator

Machine room

8-6 minimum clear

Bottom of Beam

(OH)

17-6 206

Travel

number of floors

Pit (P)

10-1 11-5

TRACTION

GEARED & GEARLESS

ACCORDING TO HOIST

MECHANISM

Types of Elevator

Rise Limitations: ~ 300 feet (Geared)

unlimited (Gearless)

Cost: $150,000 - $200,000 (Geared) : $200,000 + (Gearless)

Speeds: 350 - 500 fpm (Geared) : 500 - 1800+

(Gearless)

Advantages of Gearless:

smoother

approx. twice machine life

HYDRAULIC

HOLED, HOLE-LESS & ROPED

ACCORDING TO HOIST

MECHANISM

Types of Elevator

20

Hydraulic Code Changes

Holeless Hydraulic Holed Hydraulic Roped Hydraulic

Consists of three

parts:

Tank

Pump

Valve

The car is moved up and down using a fluid piston

mounted inside a cylinder

SAMPLE VIDEO

HYDRAULIC

HOLED, HOLE-LESS & ROPED

ACCORDING TO HOIST

MECHANISM

Types of Elevator

Hydraulic elevator systems lift

a car using a hydraulic ram, a

fluid-driven piston mounted

inside a cylinder.

HYDRAULIC

HOLED, HOLE-LESS & ROPED

ACCORDING TO HOIST

MECHANISM

Types of Elevator

HOW DOES IT

WORK?

HYDRAULIC

HOLED

ACCORDING TO HOIST

MECHANISM

Types of Elevator

Guide Rails

Plunger &

Cylinder

Controller &

Pumping Unit

To & From Oil

Pipe

Hoistway

Door

Door

Operator

Rise Limitations: ~ 60

feet

Speeds: 100/125/150 fpm

Cost: $35 - $85K

Advantages:

low cost

no penthouse

no structural load on

building

Disadvantages

slow

energy inefficient

HYDRAULIC

HOLELESS

ACCORDING TO HOIST

MECHANISM

Types of Elevator

Controller &

Pumping Unit

To & From Oil

Pipe

Plungers &

Cylinders

Guide Rails

Hoistway

Door

Door

Operator

Rise Limitations: 20 feet

Speeds: 100/125 fpm

Cost: $35 - $45K

Advantages:

no well hole

minimizes

environmental

contamination

Disadvantages:

limited travel

HYDRAULIC

ROPED

ACCORDING TO HOIST

MECHANISM

Types of Elevator

Rise Limitations: 60 feet

Cost: $45k - $75k

Speeds: 100 - 125 - 150 fpm

Advantages:

Eliminates well hole

Same 60 travel range as holed

hydro

Existing Building

Disadvantages:

More costly than conventional holed

hydraulic

HYDRAULIC

HOLED, HOLE-LESS & ROPED

ACCORDING TO HOIST

MECHANISM

Types of Elevator

COMPONENT

S

Hydraulic

car

plunger/piston/jack

elevator machine

controls

hoistway

rails

penthouse/headway

pit

HYDRAULIC

HOLED, HOLE-LESS & ROPED

ACCORDING TO HOIST

MECHANISM

Types of Elevator

COMPONENT

S

Machine room

7-9 minimum clear

Bottom of Beam

(OH)

12-0 123

Pit (P)/Plunger

4-0

Travel +2-6

CLIMBING

ACCORDING TO HOIST

MECHANISM

Types of Elevator

They hold their own power

device on them, mostly

electric or combustion engine.

Climbing elevators are often

used in work and construction

areas.

PNEUMATIC

ACCORDING TO HOIST

MECHANISM

Types of Elevator

Pneumatic elevators are raised

and lowered by controlling air

pressure in a chamber in which

the elevator sits.

Matanglawin to

PNEUMATIC

ACCORDING TO HOIST

MECHANISM

TRIVIA

A rendering of the Guangzhou CTF Finance Centre

China to Get the World's

Fastest Elevators: 95 Floors

in 43 Seconds

ACCORDING TO BUILDING

HEIGHT

Types of Elevator

A- Low-Rise buildings

typically use hydraulic elevators

because

of their lower initial cost

B- Mid-Rise buildings

typically use Geared Traction

Elevators

C- High-Rise buildings

typically use Gear-Less Traction

Elevators

ACCORDING TO BUILDING TYPE

Types of Elevator

1- Hospital Elevators

2- Residential /Domestic Elevators

ACCORDING TO BUILDING TYPE

Types of Elevator

3. Agricultural applications: 4- Industrial Elevators 5- Parking Elevators

ACCORDING TO BUILDING TYPE

Types of Elevator

6- Commercial Elevators

A- Commercial passenger elevators

B- Freight elevators

C- Commercial Dumbwaiter

ACCORDING TO ELEVATOR

LOCATION

Types of Elevator

A- Outdoor Elevators

Common types of outdoor elevators are cargo elevators, platform elevators, and incline and vertical

elevators.

A.1 Observation elevator

A.2 Incline Elevators

A.3 Freight Elevators

B- Indoor Elevators

ACCORDING TO SPECIAL USE

Types of Elevator

A- Handicap Elevators

B- Grain Elevators

C- Double-deck elevator

ACCORDING TO SPECIAL USE

Types of Elevator

D- Sky Lobby

F- Limited use / limited application (LU/LA)

Classification

1. Passenger A passenger elevator is designed to move people between a building's floors.

2. Freight A freight elevator, or goods lift, is an elevator designed to carry goods, rather

thanpassengers.

Classification

3. Special Service

Sidewalk elevators

Stage lifts

Vehicle elevators

Boat lift

Residential elevator

Paternoster

Rack-and-pinion elevator

Design Considerations

Design Considerations

Key-operated elevators should be used only in private facilities or when an elevator operator is present.

Wide elevator cabs are preferable to long ones.

The minimum internal elevator dimensions, allowing for one wheelchair passenger alone, are 1.00 m x 1.30

m

The door opening should not be less than 0.80 m.

The inside of the elevator should have a handrail on three sides mounted 0.80 to 0.85 m from the floor

The accessible elevator should serve all floors normally reached by the public.

Control panel

The control panel can be mounted at one of the alternative locations shown in figure 3.

For ease of reach, the control panel should be mounted 0.90 m to 1.20 m from the floor

Design Considerations

The numerals on the floor selector buttons should be embossed so as to be easily

identifiable by touch.

Control buttons should be in an accessible location and illuminated. Their diameter should

be no smaller than 20 mm.

Call buttons

For ease of reach, call buttons should be mounted 0.90 m to 1.20 m from the floor

Design Considerations

Floor identifiers

Tactile numerals should be placed on both sides

of the door jambs at an approximate height of

1.50 m to help a lone sightless passenger to

identify the floor reached

Hall signal

The elevator hall signal should be placed at an

approximate height of 1.80 m

Door re-opening activators

The door opening interval should be no less

than five seconds. Re-opening activators should

be provided.

Design Considerations

Audiovisual signals

The elevator should signal arrival at each floor by means of a bell and a light to alert

sightless and hearing-impaired passengers simultaneously.

Colour

The colour of the elevator door should

contrast with the surrounding surface so as

to be easily distinguishable by person with

visual impairments.

Floor surface

The floor of the elevator and the

area in front of the elevator on

each floor should have a non skid

resilient surface or a low-pile fixed

carpet.

Design Considerations

Doors

single slide (24-36)

center opening (42-60)

two-speed, side opening (42)

two-speed, center opening (60)

Design Considerations

Planning guide

Four Car Group

Three Car Group

ELEVATOR GROUPINGS

Six Car Group

Eight Car Group

ELEVATOR ZONING

Control & Safety Devices

When engaged, emergency

elevator brakes wedge up

against the rails guiding the

elevator car, slowing it to a stop.

When the elevator car is in the

correct position, the door

operating system unlocks and

pulls open both the car doors

and the elevator shaft doors.

CONTROL & SAFETY DEVICE

The elevator system

can respond to

signals from other

building systems to

add calls, control

access, and change

elevator operating

modes.

Telephones or similar two-

way communication devices

are installed inside elevator

cars

for emergencies.

Inputs from access control systems

can be used by elevator controllers to

anticipate waiting passengers and

automatically call elevators to certain

floors.

Elevator controllers

are connected to

numerous elevator-

specific control

devices to operate

the elevator system

independently.

Call buttons are the typical

method for passengers to

select their desired travel

direction or floor.

In emergency fire situations, the fire alarm control panel signals to

the elevator controller to recall the elevator car(s) to a

designated floor.

Phase two fire service mode

functions are activated by a

keyswitch, typically inside the

elevator car.

Access control systems

can be used to admit only

authorized personnel to

elevators serving secure

building areas.

Elevators can be used to control

access to certain areas of a building

by either controlling the access to the

elevator or controlling where the

elevator can stop.

Martanglawin to

One of the "must sees" of St.

Louis, Missouri, is the

Gateway Arch.

SLANT ELEVATORS

To go to the top of the Arch,

passengers in groups of five

enter an egg-shaped

compartment containing five

seats and a flat floor. Eight

compartments are linked

to form a train. These

compartments individually

retain an appropriate level by

periodically rotating every 5

degrees, which allows them

to maintain the correct

orientation while the entire

train follows curved tracks

up one leg of the arch. The

trip to the top of the Arch

takes four minutes, and the

trip back down takes three

minutes. The car doors have

narrow glass panes, allowing

passengers to see the interior

stairways and structure of

the Arch during the trip

This controversial 326

metre high elevator takes

you up the side of one of the

many enormous cliffs in

Zhangjiajie, China

The elevator inside

the louvre, paris,

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Food Processing Equipment DesignDocumento6 pagineFood Processing Equipment DesignPaolo Ocampo67% (3)

- Roman ArchitectureDocumento9 pagineRoman Architecturewhojackie88Nessuna valutazione finora

- EquipmentDocumento2 pagineEquipmentPaolo OcampoNessuna valutazione finora

- B - PreHistoric - Egypt 01 - 13 RevisedDocumento15 pagineB - PreHistoric - Egypt 01 - 13 RevisedPaolo OcampoNessuna valutazione finora

- C - Mesopotamia To Greek 14 - 30 RevisedDocumento20 pagineC - Mesopotamia To Greek 14 - 30 RevisedPaolo OcampoNessuna valutazione finora

- 04 Greek ArchitectureDocumento7 pagine04 Greek ArchitecturePaolo OcampoNessuna valutazione finora

- Final Plumbing 2Documento215 pagineFinal Plumbing 2Paolo Ocampo88% (8)

- 02 Near East ArchitectureDocumento10 pagine02 Near East ArchitecturePaolo OcampoNessuna valutazione finora

- 03 Egyptian ArchitectureDocumento8 pagine03 Egyptian ArchitecturePaolo OcampoNessuna valutazione finora

- Pre-Historic Architecture PUPDocumento7 paginePre-Historic Architecture PUPPaolo OcampoNessuna valutazione finora

- PANTONE Color ReferenceDocumento19 paginePANTONE Color ReferencePaolo Ocampo100% (3)

- PANTONE Color ReferenceDocumento19 paginePANTONE Color ReferencePaolo Ocampo100% (3)

- PANTONE Color ReferenceDocumento19 paginePANTONE Color ReferencePaolo Ocampo100% (3)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- ProSep Project and Company PicturesDocumento35 pagineProSep Project and Company PicturesRiu100% (1)

- SingaporeNon ConventionshipsDocumento102 pagineSingaporeNon Conventionshipsmohdfirdausmokhtar100% (1)

- Linear Combustion Engine As Main Energy Unit For Hybrid VehiclesDocumento9 pagineLinear Combustion Engine As Main Energy Unit For Hybrid Vehiclesgamer777Nessuna valutazione finora

- 4-2 SyllabusDocumento4 pagine4-2 SyllabussimalaraviNessuna valutazione finora

- Ford Scorpio Engine ManualDocumento4 pagineFord Scorpio Engine Manualkristy100% (49)

- Volvo-FH-Series Specifications UK PDFDocumento18 pagineVolvo-FH-Series Specifications UK PDFmatab33Nessuna valutazione finora

- SC530 50HZ Cummins Generator STAMFORDDocumento4 pagineSC530 50HZ Cummins Generator STAMFORDChen CarolineNessuna valutazione finora

- Diesel and Petrol Engines ReportDocumento8 pagineDiesel and Petrol Engines ReportJonathan MalamulaNessuna valutazione finora

- Safeguarding Philosophy PDFDocumento47 pagineSafeguarding Philosophy PDFahmed ramadanNessuna valutazione finora

- BP Flowback ProceduresDocumento10 pagineBP Flowback ProceduresAlexander KlmNessuna valutazione finora

- MarPower (Basic Marine Engineering)Documento124 pagineMarPower (Basic Marine Engineering)Renefrid Tejero100% (4)

- JGM767KNDocumento6 pagineJGM767KNJosh FereiraNessuna valutazione finora

- Mine Locomotives: Thursday, December 20, 2018Documento202 pagineMine Locomotives: Thursday, December 20, 2018SunilNessuna valutazione finora

- Ammann Asphalt Mixing-Plant EasyBatch en PDFDocumento12 pagineAmmann Asphalt Mixing-Plant EasyBatch en PDFWillian MazaNessuna valutazione finora

- PumpsDocumento35 paginePumpsMuhammad Ahmed Saleem100% (2)

- FAQ-Revitalizants en SDocumento24 pagineFAQ-Revitalizants en SsyafiqNessuna valutazione finora

- Mahindra, Yuvo 575 Di TractorDocumento8 pagineMahindra, Yuvo 575 Di TractorSk IbrahimNessuna valutazione finora

- Battery Charger With Stirling EngineDocumento14 pagineBattery Charger With Stirling EngineSivaNessuna valutazione finora

- Quibiztec - Proposal For GAS Conversion Plants To Lagos State Government Ver 02Documento17 pagineQuibiztec - Proposal For GAS Conversion Plants To Lagos State Government Ver 02sylviaaim2Nessuna valutazione finora

- Electrical Power Generation MCQ PDF FreeDocumento37 pagineElectrical Power Generation MCQ PDF FreesabilashNessuna valutazione finora

- C 968 - 99 - Standard Test Methods For Analysis of Sintered Gadolinium Oxide-Uranium Dioxide PelletsDocumento12 pagineC 968 - 99 - Standard Test Methods For Analysis of Sintered Gadolinium Oxide-Uranium Dioxide Pelletslywu2000Nessuna valutazione finora

- 190097Documento13 pagine190097weldsaidiNessuna valutazione finora

- Bobcat 753 Service ManualDocumento404 pagineBobcat 753 Service ManualUtilaje AgrinNessuna valutazione finora

- Most Complete List For Dodge Check Engine Light CodesDocumento10 pagineMost Complete List For Dodge Check Engine Light CodesMvh3rNessuna valutazione finora

- Process CheckLists P&ID Rev 3Documento3 pagineProcess CheckLists P&ID Rev 3Farhan AhmedNessuna valutazione finora

- ASTM D86-11a (Metodo de Prueba Estandar para Destilación de Productos Del Petroleo A Presión Atmosferica)Documento27 pagineASTM D86-11a (Metodo de Prueba Estandar para Destilación de Productos Del Petroleo A Presión Atmosferica)Anonymous gBMz178Nessuna valutazione finora

- EMD DD40X Operating ManualDocumento58 pagineEMD DD40X Operating ManualE.r. Blanco100% (1)

- Single Cylinder Ohv Briggs & StrattonDocumento179 pagineSingle Cylinder Ohv Briggs & Strattonkerusacba_2011100% (2)

- Webasto Golf 7Documento30 pagineWebasto Golf 7NPNessuna valutazione finora

- Avro ARJ Manual by Mathhias Lieberecht PDFDocumento147 pagineAvro ARJ Manual by Mathhias Lieberecht PDFali4957270Nessuna valutazione finora