Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 12: Plastic (Plastik) : Materials Technology 1

Caricato da

anipcatalyzerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter 12: Plastic (Plastik) : Materials Technology 1

Caricato da

anipcatalyzerCopyright:

Formati disponibili

CHAPTER 12 : PLASTIC

(Plastik)

MATERIALS TECHNOLOGY 1

J3022

PREPARED BY : LIM YEE KAI

DEPARTMENT of MECHANICAL ENGINEERING

12.0 Introduction

Monomer : A molecule that can combine with others to form a polymer

Polymers : are a large class of materials consisting of many small molecules

(called monomer) ) that can be linked together to form long chains

(polymerization), thus they are known as macromolecules . Polymer are a

group of organic, semiorganic or inorganic.

Plastic : Polymer that have been or can be readily formed or molded into a

useful shape.

Monomer

Resin

Plastic

Polyme

r

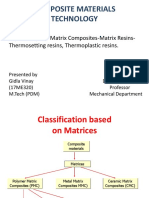

12.2 Classification Of Polymer

Polymers

Thermoplastics

Crystalline

Amorphous

Thermosets Elastomers

12.3 Polymer Structure

Polymers are large molecules with strong intermolecular forces

and tangled chains

Crystalline and semi-crystalline have an arrangement of their

chains that comes from packing

Crystal region strengthen the polymer

The percentage of the polymer that is crystalline is called the

percent crystallinity, has an important influence on the

properties of the polymer.

Degree of crystallinity depends on the density.

12.5 Polymerization (Proses Pempolimeran)

POLYMERIZATION: Forming large molecules from small

molecules OR the process by which polymers are formed.

Types: Additional & Condensation Polymerization

12.5.1 Additional Polymerization

(Polyaddition or chain growth polymerization)

Definition:

*A polymerization technique where monomer

molecules add on to a growing polymer chain

one at a time.

The monomers quickly combine by an addition

reaction without losing any atoms, so that the polymer

has the same basic formula as the monomer.

nM ----> -(-M-)n-

(monomer) (polymer)

12.5.1 Additional Polymerization (Continued)

Vinyl polymers are addition polymers, which have the same atoms as

the monomer in their repeat units.

12.5.2 Condensation Polymerization

(step-reaction polymerization)

Definition:

*Covalent bonds are rearranged in such a way

that two monomers are connected and water is

"condensed" out.

12.5.2 Condensation Polymerization (Continued)

A few types of condensation polymers are listed below.

In the table, R and R' stand for organic groups.

12.6 Types of Polymer

Thermoplastic

Polystyrene (PS)

Polyethylene (PE)

Polyamides (PA)

Polycarbonate (PC)

Polyvinyl chloride (PVC)

Polyester (PET)

Thermosets

Epoxy

Urea formaldehyde

Melamine

Phenolics (Bakelite)

Polyurethane (PU)

Silicone

Thermoplastics Thermoset plastics

1. Addition polymerization.

2. Softens on heating and retaining the same

chain on cooling.

3. They are along chain linear polymers

without any branched or cross linked chain.

4. On repeated heating and cooling, there is no

change in chemical nature.

5. These plastics undergo purely physical

process.

6. By heating the plastics, they can be proceed.

7. Waste thermoplastics can be recovered.

1. Condensation polymerization.

2.Heat resistance.(infusible and insoluble

mass on heating )

3. They are branched or cross-linked

Polymer.

4. Some sort of chemical changes occur

On heating.

5.These Plastics undergo physical as well

as chemical process.

6. These plastics cannot be proceed by heating.

7. Waste thermosetting cannot be recovered.

8/12/2014 14

12.6.1 Thermoplastic (cont)

Polyethylene (PE)

Clear to whitish translucent thermoplastic.

LD: low glass transition temperature, Tg (very

attractive), used for plastic bags, coatings, and

squeeze bottles.

HD: more crystalline linear polymer with

improved strength, stiffness, and chemical

inertness.

8/12/2014 15

12.6.1 Thermoplastic (cont)

Polyethylene (PE)

Types

Low density (LDPE)

High Density (HDPE)

Linear low density (LLDPE)

8/12/2014 16

12.6.1 Thermoplastic (cont)

Polyethylene (PE)

Applications: containers,

insulation,

chemical tubing, bottles,

water pond liners etc

8/12/2014 17

12.6.1 Thermoplastic (cont)

Polyvinyl Chloride (PVC)

PVC is amorphous, does not recrystallize.

PVC homopolymer has high strength (7.5 to 9

ksi) and is brittle.

Compounding of PVC: Modifies and improves

properties.

Application: Clothing, Electric wires, Pipes,

Portable electronic accessories, Signs, Joining,

Ceiling tiles, Unplasticized polyvinyl chloride

(uPVC)

Products of PVC

PVC pipes, fittings, flexible hoses and gaskets

PVC Cement

PVC Ceiling Tiles

Credit card

PVC Products

PVC footwear PVC costume PVC car sticker & decal

PVC sign

8/12/2014 20

12.6.1 Thermoplastic (cont)

Polypropylene (PP)

Isotactic form is crystalline and has the most applications

Higher strength and stiffness than PE.

High melting (165-177

0

C)and heat deflection

temperature.

Low density, good chemical resistance, moisture

resistance , heat resistance, good surface hardness and

dimensional stability.

Applications: Useful in many application involving boiling

water or steam, house wares, appliances, packaging,

laboratory ware, bottles, etc.

Product of PP

Document Boxes & PP Folders

PP knife handle

PP rope

OPP Tape

PP Chair

Toys

8/12/2014 22

12.6.1 THERMOPLASTIC (cont)

Polystyrene (PS)

Transparent, brittle and chemically inert

By heating polystyrene with a foaming agent,

expanded polystyrene can be made. Expanded

beads create excellent thermal insulation properties

(Styrofoam).

Styrofoam is extremely light, white solid foam. It

mainly used to make light-weight ceiling tiles in

buildings, and food boxes and shock absorbers

for packaging.

Polystyrene (PS) continue..

Poor weatherability and easily attacked by chemicals.

Low processing cost and good dimensional stability.

Applications: Automobile interior parts, dials and knobs of

appliances and housewares

1939: Wood TV Cabinet

1948: Phenolic TV Cabinet

1970: HIPS TV Cabinet

8/12/2014 24

12.6.1 Thermoplastic (cont)

Polymethyl Methacrylate (PMMA)/

Acrylic

Rigid and relatively strong.

Completely amorphous and very

transparent.

Good outdoor weatherability and is

more impact-resistant than glass.

An acrylic commonly known as

Plexiglas.

Applications: Glazing of aircraft,

boats, skylights, advertising signs etc.

Automotive lamps

8/12/2014 25

12.6.1 Thermoplastic (cont)

Polyamides (PA)

High strength due to hydrogen bonding between molecular

chain

Flexibility of carbon chain contributes to molecular flexibility,

low melt viscosity and high lubricity.

8/12/2014 26

12.6.1 THERMOPLASTIC (cont)

Tough, opaque solids with moderate melting points.

Outstanding characteristic is the ability to draw into fibers,

becoming tough, transparent materials of relatively high

strength.

High strength, toughness and dimensional stability.

Very high impact strength.

High heat deflection temperature.

Engineering applications:

Widely used in the textile industry: Armor, personal protection,

sport equipment.

Audio equipment, drumheads woodwind reeds.

Others used: rope, cable, sheath, electricity generation, building

construction, brakes, expansion joints and hoses, composite

material.

Products of Polyamides (PA)

Kevlar Ballistic vests

Inner lining of tubeless tyres

Reinforcing composite

materials (combination

with carbon fiber, glass

fiber) used in body of

gitar, cricket bats, boat.

Nylon Stocking

8/12/2014 28

12.6.1 THERMOPLASTIC

Thermoplastic Polyesters

Primarily used as fibers and films with the most important

being polyethylene terephthalate (PET)

Phenylene ring provides rigidity

Good insulator: independent of temperature and

humidity.

Applications: Switches, relays, TV tuner components,

circuit boards, impellers, housing and handles

Products of Polyester

Photographic film

polyester cellophane tape

Polyester backpack

Polyester tie

Mens polo

T-shirt

Polyester sarees

100% Polyester

Coral Short Robes

Polyester

pants

Recycle Polyester

recycled polyester fiber

On July 20, 1969 the human race accomplished its greatest technological

achievement of all time when Neil Armstrong set foot on the moon. This

feat would not have been possible without many materials science

developments. Plastics played an important roll. For example, the Apollo

A7L space suits were a multi-layer plastic structure comprised of nylon

fabric, neoprene coated nylon fabric, Dacron (PET) fabric, aluminized

Mylar (PET) film, Kapton (PI) film, and Teflon (PTFE) coated fabric.

The fish bowl helmet was produced from transparent polycarbonate.

The space suits of today make even more extensive use of plastics.

8/12/2014 32

12.6.2 Thermosets (cont)

Epoxy Resins

Good adhesion, chemical resistance and

mechanical properties

High molecular mobility, low shrinkage during

hardening

Applications: Protective and decorative coating,

drum lining, high voltage insulators and

laminates

Commercial/Industrial Epoxy Floor Coating

(a) (b) (c)

Products of Epoxy

Epoxy printed circuit board (PCB)

Double-Sided Printed Circuit Boards (PCBs)

Epoxy Surfboards

8/12/2014 35

12.6.2 Thermosets (cont)

Phenolics

Low cost, good insulating and mechanical properties.

Produced by polymerization of phenol and

formaldehyde.

General purpose compounds: Usually wood flour filled to

increase impact resistance.

High impact strength compounds: Filled with cellulose

and glass fibers.

High electrical insulating compounds: Mineral (Mica)

filled.

Heat resistant compounds: Mineral filled.

Applications: Wiring devices, auto transmission parts,

plywood lamination, adhesives, shell molding.

Products of Phenolics

Bakelite

letter opener

Bakelite radio Bakelite pool ball

Phenolic Plywood

1948: Phenolic TV Cabinet

Cookware with phenolic

handle

Melamine

Application: Molded dinnerware, buttons, control

buttons, & knobs

Melamine dinnerware Melamine Faced MDF / Chipboard

Melamine Milk

Staff members of the local quality supervision bureau empty

melamine tainted milk powder packets at a garbage dump site in

Shenzhen

Which companies are affected?

8/12/2014 40

12.6.2 Thermosets (cont)

Polyurethanes (PU)

Primarly used as faoms

Depending on cross-linking, urethanes may behave as

thermosets, thermoplastic, or elastomers

Application include

Fibers

Coatings

Foams for furniture

Mattresses

Insulation

Packing or shipping material

Products of Polyurethanes (PU)

PU foams

In-line skate wheels

PU foodbed

and midsole

Products of Polyurethanes (PU)

PU condom

Cool room PU panel

PU panel

PU Foam

Plastic Moulding

Extrusion Moulding

Injection Moulding

Blow Moulding

Transfer/Compression

Moulding

Extrusion Blow Moulding

Injection Blow Moulding

Stretch Blow Moulding

Pengacuanan Penyemperitan

Pengacuanan Penyuntikan

Pengacuanan Pindah/Mampatan

Pembentukan Bahan Plastik

Stretch Blow Moulding

Pengacuanan Peniupan

Extrusion Moulding (Pengacuanan Penyemperitan)

- Feed section- stock comes in from hopper and preheated,

- Compression section- resin transformed into liquid form,

entrapped air forced out via compression

- Metering section- homogen melt, sufficient pressure to

pump through the die.

Injection Moulding (Pengacuanan Penyuntikan)

This schematic illustrates the basics of plastic injection molding

system.

A hot, molten polymer is injected into a cold mold.

A screw apparatus can be used to inject the polymer into the

mold.

After the part is solidifies, the mold is opened and part is ejected.

Cycle Time of Injection Moulding Machine

Injection Moulding is a CYCLIC process:

Injection: polymer is injected into the mold cavity

Hold on time: once the cavity is filled, a holding pressure is maintained to

compensate for material shrinkage

Cooling: the molding cools and solidifies.

Screw Back: at the same time, the screw retracts and turns, feeding the next shot

in towards the front.

Mold Opening: once part is sufficiently cool, the mold opens and the part is

ejected

The mold closes and clamps in preparation for another cycle.

Test Your Understanding

Plastic model

Products of Injection Moulding

Compression Moulding

Compression molding is an old and widely used molding process for

thermosetting plastics.

Its applications also include thermoplastic phonograph records,

rubber tires, and various polymer matrix composite parts.

Materials for compression molding include phenolics, melamine,

urea-formaldehyde, epoxies, urethanes, and elastomers. Typical TS

plastic moldings include electric plugs, sockets, and housings; pot

handles, and dinnerware plates.

The process, consists of:

(1) loading a precise amount of molding compound, called the charge,

into the bottom half of a heated mold.

(2) bringing the mold halves together to compress the charge, forcing it

to flow and conform to the shape of the cavity

(3) heating the charge by means of the hot mold to polymerize and cure

the material into a solidified part.

(4) opening the mold halves and removing the part from the cavity.

Compression Moulding

Advantages

molds that are simpler, less expensive, and

require low maintenance

less scrap

low residual stresses in the molded parts (thus

favoring this process for flat thin parts such as

phonograph records).

Disadvantages

longer cycle times and therefore lower

production rates than injection molding.

Injection Blow Moulding Process

2 different process.

Parison formed from injection blow moulding system is called a preform.

It is not a finished part but subjected to subsequent steps that forms the

final shape.

Proven to be economical.

Extrusion Blow Moulding

In Extrusion Blow Molding

(EBM), plastic is melted and

extruded into a hollow tube (a

parison).

This parison is then captured by

closing it into a cooled metal

mold.

Air is then blown into the

parison, inflating it into the

shape of the hollow bottle,

container or part.

After the plastic has cooled

sufficiently, the mold is opened

and the part is ejected.

Stretch Blow Molding

Plastic is first molded into a "preform" using the Injection Molded Process.

These preforms are later fed (after cooling) into an EBM blow molding machine.

In the SBM process, the preforms are heated (typically using infrared heaters)

above their glass transition temperature, then blown using high pressure air into

bottles using metal blow molds.

Usually the preform is stretched with a core rod as part of the process.

The stretching of some polymers, such as PET (PolyEthylene Terepthalate)

results in strain hardening of the resin, allowing the bottles to resist deforming

under the pressures formed by carbonated beverages, which typically approach

60 psi.

Blown Film Extrusion

Plastic pellets are fed and melt in the extruder.

Resin enters annular die and forced inside a mandrel where it is shaped into

sleeves, extruded into a die opening in form of thick walled tube.

Using pressure of internal air introduced from center of mandrel, molten tube

will expend into bubble of desired diameter and lower the film thickness.

Air is maintained at constant pressure.

Nip rollers are used to collapse the bubble, stretch the film and serve as take-

off device for the line.

Blown Film Extrusion

REFERENCES

William D.Callister, Jr, Materials Science and

Engineering an Introduction, 2003, 5

th

edition,John

Wiley & sons,Inc.

Smith W.F & Hashemi J. (2004) Foundation of

material science and engineering third edition.

NY:McGraw-Hill Company, inc.

Serope Kalpakjian and Steven R. Schmid,

Manufacturing Engineering and Technology, 2001,

4

th

edition, Prentice Hall,Inc.

Potrebbero piacerti anche

- Polymers: 5.1 PlasticsDocumento8 paginePolymers: 5.1 PlasticsCh. Muhammad UsamaNessuna valutazione finora

- Applied Chemistry Lecture 4Documento66 pagineApplied Chemistry Lecture 4Muhammad RafayNessuna valutazione finora

- PolymersDocumento35 paginePolymersYash AwatadeNessuna valutazione finora

- PolymersDocumento35 paginePolymersYash AwatadeNessuna valutazione finora

- PolymersDocumento35 paginePolymersYash AwatadeNessuna valutazione finora

- UNIT IV 20ME403 EMM (Non Metallic Materials) New 02.05.2022 (1) (2578)Documento116 pagineUNIT IV 20ME403 EMM (Non Metallic Materials) New 02.05.2022 (1) (2578)Dark ranger YtNessuna valutazione finora

- UNIT-IV-Non MetallicDocumento112 pagineUNIT-IV-Non MetallicSethu ramNessuna valutazione finora

- Thermoplasti &thermosetDocumento25 pagineThermoplasti &thermosetabasoudaNessuna valutazione finora

- 1 ThermoplasticDocumento8 pagine1 ThermoplasticabasoudaNessuna valutazione finora

- Lecture1 2Documento7 pagineLecture1 2Rahmeh EL saaiedehNessuna valutazione finora

- Plastics 140928093734 Phpapp02Documento27 paginePlastics 140928093734 Phpapp02Siyyadula Chandra SekharNessuna valutazione finora

- Consumer Goods - Low Cost and Easy Processability Make HDPE A Material of Choice inDocumento5 pagineConsumer Goods - Low Cost and Easy Processability Make HDPE A Material of Choice inDwi YuliantoNessuna valutazione finora

- PLASTICSDocumento72 paginePLASTICSKalyan RamavathNessuna valutazione finora

- PlasticsDocumento41 paginePlasticsZorbaNessuna valutazione finora

- Mec131 Topic Report Last.Documento17 pagineMec131 Topic Report Last.mansang.mc62Nessuna valutazione finora

- 2nd Unit - PlasticDocumento31 pagine2nd Unit - PlasticAvantikaNessuna valutazione finora

- PMT Module 1Documento73 paginePMT Module 1Palliyil UjwalNessuna valutazione finora

- PolymersDocumento18 paginePolymersmaria.olivaaa.rossNessuna valutazione finora

- Polymers Wps OfficeDocumento4 paginePolymers Wps OfficeEJ DizonNessuna valutazione finora

- Unit IV PolymerDocumento25 pagineUnit IV PolymerYugandhar PatilNessuna valutazione finora

- Sandeep ChemistryDocumento21 pagineSandeep ChemistrySandeep Nandan MishraNessuna valutazione finora

- Plastic Presentation...Documento24 paginePlastic Presentation...Asela Wimukthi100% (1)

- Apllied ChemistryDocumento11 pagineApllied ChemistryG-20 Papai ShahaNessuna valutazione finora

- Thermoplastic - WikipediaDocumento5 pagineThermoplastic - Wikipediakirthi83Nessuna valutazione finora

- PolymersDocumento33 paginePolymerssundara ramanNessuna valutazione finora

- Rida Tahir Plastic 13Documento10 pagineRida Tahir Plastic 13AyeshaNessuna valutazione finora

- Portfolio PlasticDocumento5 paginePortfolio PlasticGabrielaNessuna valutazione finora

- Polymer NoteDocumento9 paginePolymer NoteNdidiamaka Nwosu AmadiNessuna valutazione finora

- Polymer Processing-2Documento62 paginePolymer Processing-2andrijanto123Nessuna valutazione finora

- 1.types of Plastic Material SelectedDocumento10 pagine1.types of Plastic Material SelectedPavan Kumar IBNessuna valutazione finora

- ThermoplasticDocumento10 pagineThermoplasticvaniakash294Nessuna valutazione finora

- Branched Polymers Occur When Groups of Units Branch Off From TheDocumento2 pagineBranched Polymers Occur When Groups of Units Branch Off From ThedummyNessuna valutazione finora

- UNIT-2 Engg. Materials 2019 ModifiedDocumento67 pagineUNIT-2 Engg. Materials 2019 ModifiedANABOINA SHIVRAJNessuna valutazione finora

- PolymersDocumento47 paginePolymersVishal KhandelwalNessuna valutazione finora

- Module 7 PolymersDocumento53 pagineModule 7 PolymersVarsha VarmaNessuna valutazione finora

- Design and Development of Plastic Parts For Car Interior: Project TitleDocumento56 pagineDesign and Development of Plastic Parts For Car Interior: Project TitleJyoti KaleNessuna valutazione finora

- Thermosets Can Melt and Take Shape Once After They Have Solidified, They Stay Solid. in TheDocumento4 pagineThermosets Can Melt and Take Shape Once After They Have Solidified, They Stay Solid. in TheRazaNessuna valutazione finora

- Thermoplastics and Thermosetting PlasticDocumento24 pagineThermoplastics and Thermosetting PlasticKAPIL SINGHNessuna valutazione finora

- Plastics PPPTDocumento10 paginePlastics PPPTfebishmbaNessuna valutazione finora

- Polymer Notes 2017Documento10 paginePolymer Notes 2017Bikram YadavNessuna valutazione finora

- CH 5 Plastic ProcessingDocumento23 pagineCH 5 Plastic ProcessingSahibsartaj Dhaliwal83% (6)

- PlasticsDocumento9 paginePlasticsAliyu Ibrahim SalihuNessuna valutazione finora

- Plastics Injection Moulding ProcessDocumento16 paginePlastics Injection Moulding Processरोहित मदानNessuna valutazione finora

- Science of Materials Science of Materials C: Dr. Andres MarquezDocumento45 pagineScience of Materials Science of Materials C: Dr. Andres MarquezAPNessuna valutazione finora

- Program: B.Tech Subject Name: Manufacturing Technology Subject Code: ME-405 Semester: 4thDocumento22 pagineProgram: B.Tech Subject Name: Manufacturing Technology Subject Code: ME-405 Semester: 4thROHIT MEHRANessuna valutazione finora

- PlasticsDocumento23 paginePlasticsIsaac JebNessuna valutazione finora

- Lecture 4Documento16 pagineLecture 4Rahmeh EL saaiedehNessuna valutazione finora

- Polymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic ResinsDocumento27 paginePolymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic Resinsgidlavinay100% (1)

- What Is Polymer??: PropertiesDocumento10 pagineWhat Is Polymer??: PropertiesG-20 Papai ShahaNessuna valutazione finora

- Plastic PDFDocumento32 paginePlastic PDFMuhammad Fathin100% (1)

- Assignment 03 by AlemuDocumento11 pagineAssignment 03 by AlemuAlemu MergaNessuna valutazione finora

- 2016 Technical ManualDocumento68 pagine2016 Technical ManualNemanja SusicNessuna valutazione finora

- CHAPTER 10 - PolymerDocumento8 pagineCHAPTER 10 - PolymerVilla, Rheysha LynNessuna valutazione finora

- Thermoplastics: Group III Cayabyab, Shield R. Espiritu, Micoh L. Mendoza, Maynard T. Radia, Rezvani MDocumento20 pagineThermoplastics: Group III Cayabyab, Shield R. Espiritu, Micoh L. Mendoza, Maynard T. Radia, Rezvani MMaynard Trinidad MendozaNessuna valutazione finora

- Green Vintage Illustration Laboratory Business PresentationDocumento31 pagineGreen Vintage Illustration Laboratory Business Presentationmarcmaglaqui30Nessuna valutazione finora

- PolyetheneDocumento11 paginePolyetheneUshanth SivalingamNessuna valutazione finora

- Condensation Polymerization ProductsDocumento7 pagineCondensation Polymerization ProductsemascuñanaNessuna valutazione finora

- 3 PolymersDocumento36 pagine3 PolymersMuhammad TanweerNessuna valutazione finora

- Types of PolymersDocumento9 pagineTypes of PolymersFaiq ElNessuna valutazione finora

- Clear and Plastic Danger: The Alien in your KitchenDa EverandClear and Plastic Danger: The Alien in your KitchenValutazione: 4 su 5 stelle4/5 (1)

- 05dtp12f1003 Arc Welding AsrulDocumento10 pagine05dtp12f1003 Arc Welding AsrulanipcatalyzerNessuna valutazione finora

- Injection MouldingDocumento4 pagineInjection MouldinganipcatalyzerNessuna valutazione finora

- Injection MouldingDocumento4 pagineInjection MouldinganipcatalyzerNessuna valutazione finora

- Injection MouldingDocumento4 pagineInjection MouldinganipcatalyzerNessuna valutazione finora

- 02 VF10 Appliance Information enDocumento2 pagine02 VF10 Appliance Information enGabriel ZorattiNessuna valutazione finora

- CHE317 Intro LectureDocumento32 pagineCHE317 Intro LectureKevin MulkernNessuna valutazione finora

- ZondST2D Eng PDFDocumento148 pagineZondST2D Eng PDFLilyOhhNessuna valutazione finora

- How To Carry Out Tack WeldingDocumento2 pagineHow To Carry Out Tack WeldingwentropremNessuna valutazione finora

- Photodegradation and Photostabilization of PSDocumento32 paginePhotodegradation and Photostabilization of PSMinhAnhNessuna valutazione finora

- 121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFDocumento87 pagine121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFkumarnpccNessuna valutazione finora

- CH 10 Lecture 3 Angular Overlap: I. Ligand Field Theory and Square Planar ComplexesDocumento16 pagineCH 10 Lecture 3 Angular Overlap: I. Ligand Field Theory and Square Planar ComplexesIsrael PobleteNessuna valutazione finora

- Visual Design Elements and PrinciplesDocumento9 pagineVisual Design Elements and PrinciplesgamerootNessuna valutazione finora

- InggrissinkholeDocumento2 pagineInggrissinkholeRika Rika SilvianaNessuna valutazione finora

- Phys 1011 Final SAMPLEDocumento10 paginePhys 1011 Final SAMPLEJonah the mixerNessuna valutazione finora

- Enki CleanARC BrochureDocumento2 pagineEnki CleanARC BrochurebrenorbrophyNessuna valutazione finora

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocumento11 pagineDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanNessuna valutazione finora

- Testing of Transformer Oil and Winding Temperature IndicatorsDocumento6 pagineTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyNessuna valutazione finora

- BLANCO2Documento2 pagineBLANCO2Alejandro PérezNessuna valutazione finora

- Vectors DPPDocumento13 pagineVectors DPPAchyuth DaggumatiNessuna valutazione finora

- The Klein-Gordon EquationDocumento22 pagineThe Klein-Gordon EquationAnderson CalistroNessuna valutazione finora

- Using The CONVAL Software For The Petrochemical Plant Control Valve Checking Case StudyDocumento6 pagineUsing The CONVAL Software For The Petrochemical Plant Control Valve Checking Case Studychem_taNessuna valutazione finora

- Aperture 3Documento355 pagineAperture 3Edu José MarínNessuna valutazione finora

- Assignment 3Documento3 pagineAssignment 3VenkatGollaNessuna valutazione finora

- 1 s2.0 S2352484722007922 MainDocumento21 pagine1 s2.0 S2352484722007922 MainEspinoza Payano Blas RussNessuna valutazione finora

- STAT219syllabus PDFDocumento3 pagineSTAT219syllabus PDFakbar03Nessuna valutazione finora

- REFERENCESDocumento3 pagineREFERENCESCaye AregladoNessuna valutazione finora

- Enthalpy 2Documento11 pagineEnthalpy 2SB KPNessuna valutazione finora

- 7PPX0 2021 2022 AM Exercise BookDocumento131 pagine7PPX0 2021 2022 AM Exercise BookTeun JenniskensNessuna valutazione finora

- Permanent WayDocumento7 paginePermanent Wayaishwarya mundraNessuna valutazione finora

- Spring 2011 Portfolio Unit PlanDocumento48 pagineSpring 2011 Portfolio Unit PlanJack MoselNessuna valutazione finora

- A Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiDocumento25 pagineA Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiIridian ÁvilaNessuna valutazione finora

- Johor-Answer P2-Trial SPM 2007Documento8 pagineJohor-Answer P2-Trial SPM 2007kamalharmozaNessuna valutazione finora

- D6937 4047 PDFDocumento2 pagineD6937 4047 PDFEmily MurilloNessuna valutazione finora

- Lec# 8 (Higher Order DE)Documento22 pagineLec# 8 (Higher Order DE)Faraz KashifNessuna valutazione finora