Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Measurement Text Book

Caricato da

harim_me0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

90 visualizzazioni70 pagineMetrology

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMetrology

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

90 visualizzazioni70 pagineMeasurement Text Book

Caricato da

harim_meMetrology

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 70

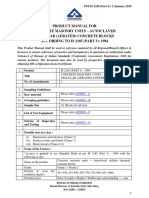

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

PowerPoint to accompany

Krar Gill Smid

Technology of Machine Tools

6

th

Edition

Measurement

Section 5

History

Egyptians used length called cubit

Equal to length of forearm (middle finger to

elbow)

James Watt measured tolerances of steam

engine with thickness of thin shilling

International System of Units (SI)

developed in 1960

Two major systems of measurement

Inch system in US and Canada

Metric system for 90% of world

Metric (Decimal) Systems

Jan 16, 1970, Canada adopted SI for

implementation throughout Canada by 1980

Dec 8, 1975, US Senate passed Metric Bill

Will take long time to convert

All machine tools and measuring devices will

have to be redesigned

Long life expectancy of costly machine tools

People resistant to change

Fractional/Inch System

Increased use of CNC and digital data

make fractional sizes impractical

ANSI recommends decimal dimensions

Fractional dimensions still used to identify

sizes of holes produced by drills, standard

taps, and screw thread sizes

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

PowerPoint to accompany

Krar Gill Smid

Technology of Machine Tools

6

th

Edition

Basic Measurement

UNIT 7

Objectives

Identify several types of steel rules

Measure round and flat work to 1/64-in.

accuracy with a rule

Measure with spring calipers and a rule

Inch System

Unit of length is the inch

May be divided into fractional or decimal

fractions

Fractional system based on binary system

Common fractions: 1/2, 1/4, 1/8, 1/16, 1/32, 1/64

Decimal-fraction system uses base 10

Number written as product of 10 or fraction of 10

Inch System

Value Fraction Decimal

one-tenth 110 .1

one-hundredth 1100 .01

one-thousandth 11000 .001

one ten-thousandth 110,000 .0001

one hundred-thousandth 1100,000 .00001

one millionth 11,000,000 .000001

Inch/Metric Conversion

Metric Size

mm cm dm m

1 in. 25.4 2.54 0.254 0.0254

1 ft 304.8 30.48 3.048 0.3048

1 yd 914.4 91.44 9.144 0.9144

Fractional Measurement

Measured with rulers or calipers

Steel rules graduated

Binary-fractional divisions

1, , , 1/8, 1/16, 1/32, 1/64

Decimal fractional divisions

decimeters, centimeters, millimeters, half-millimeters

1/64 in. or 0.50 mm. smallest used

Precision instruments

Micrometers and verniers used for dimensions

of less than 0.50 mm

Steel Rules

Metric steel rules graduated in millimeters

and half-millimeters

Linear measurement without great accuracy

Lengths from 15 c. to 1 m.

Factional steel rules graduated in common

binary fractions (1/8 1/64 in.)

Several varieties (spring-tempered, flexible,

narrow, and hook)

Lengths range from 1 to 72 in.

Fractional Steel Rules

Spring-tempered quick reading 6 in. rules

Most frequently used in shop work

Hook rules

Used to make accurate measurements from edge

of workpiece and also flanges and circular pieces

Use for setting inside calipers to a dimension

Decimal rules

Used for linear measurements smaller

than 1/64 in.

Fractional Steel Rules

Short-length rules

Used to measure small openings and hard-to-reach

locations

Five small rules in set: range between and 1 in.

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

Measuring Lengths

Fairly accurate measure with steel rules

Butt end of rule against shoulder or step

Steel rules become worn with constant use

Can make measurements taken from end inaccurate

Compensate by measuring from 1-in or 1-cm mark and

subtracting 1 from measurement

Keep edge of rule parallel to edge of work

Rule used as straightedge to test flatness of

workpieces

Edges ground flat: place, hold to light and view

Outside Calipers

Not precision tools

Used to approximately measure outside

surface of either round or flat work

Several styles

spring joint

firm joint

Do not use when accuracy < .015 in.needed

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Using Outside Calipers

Hold both legs of caliper parallel to edge of rule.

Turn adjusting nut until end of lower leg just splits

desired graduation line on rule

Place caliper on work

with both legs of caliper

at right angles to

centerline of the work

Diameter correct when

caliper just slides over

work by own weight

Inside Calipers

Used to measure diameter of holes or width of

keyways and slots

Several styles

Spring joint

Firm Joint

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Measuring An Inside Diameter

Place 1 leg of caliper near hole's bottom edge

Hold caliper leg in position with finger

Keep caliper legs vertical or parallel to hole

Move top leg in direction of arrows and turn

adjusting nut until slight drag felt on leg

Find size of setting by placing end of rule and

one leg against flat surface

Hold legs of caliper parallel to edge of rule

and note reading

Transferring Measurements

Check caliper setting with outside micrometer

for accurate measurement

Hold micrometer in right hand

Place one leg of caliper

on micrometer anvil

and hold position

Rock top leg of caliper

in direction of arrows

Adjust thimble until

slight drag felt as caliper leg passed over

measuring face

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

PowerPoint to accompany

Krar Gill Smid

Technology of Machine Tools

6

th

Edition

Squares and

Surface Plates

Unit 8

8-21

Objectives

The machinists combination square

Three types of solid and adjustable squares

Two types of surface plates

8-22

Square

Used for layout, inspection and setup

Manufactured to various degrees of

accuracy

Range from semiprecision to precision squares

Precision squares are hardened and

accurately ground

8-23

Machinist's Combination Square

Used for quick check of 90 and 45 degree

angles and measure of length

Part of combination set that includes square

head, center head, bevel protractor and

graduated grooved rule

8-24

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

8-25

Precision Square

Used chiefly for inspection and setup

purposes

Hardened and accurately ground

Must be handled carefully to preserve

accuracy

Great variety manufactured but all variations

of either solid square or adjustable square

8-26

Beveled-Edge Square

Better quality standard squares used in

inspection

Beveled edge allows blade to make line

contact with work

More accurate check

Work is square (90 degrees) if both sides

touch surface of work

8-27

Toolmaker's Surface

Plate Square

Provides convenient method of checking

work for squareness on surface plate

One-piece construction

Little chance of any inaccuracy developing

8-28

Adjustable Squares

Not as accurate as good solid square

Used where impossible to use fixed square

Diemaker's square

Used to check clearance angle on dies

Blade adjusted to angle of workpiece by blade-

adjusting screw, then angle checked with

protractor

Direct-reading type indicates angle of blade

8-29

Adjustable Micrometer Square

Used to check part for squareness accurately

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

8-30

Straightedges

Used to check surfaces for flatness and act

as guide for scribing long, straight lines in

layout work

Rectangular bars of hardened and accurately

ground steel

Edges flat and parallel

Plain or beveled edges

Generally made of cast iron with ribs

8-31

Surface Plates

Rigid block of granite or cast iron

Flat surface used as reference plane for layout

Generally have three-point suspension to

prevent rocking when mounted on uneven

surface

Two types

Cast-iron plates

Granite surface plates

Trivia (Extra Credit)

Why is a granite surface plate preferred?

8-33

Surface Plates

Cast-iron plates

Well ribbed and high strength

Good wear-resistance qualities

After machined, surface scraped by hand to flat

Operation long and cost high

Granite surface plates

Manufactured from gray, pink, or black granite

Several degrees of accuracy

Extremely flat finishes produced by lapping

8-34

Advantages of Granite Plates

Not appreciably affected by temperature

change

Will not burr, therefore, accuracy not

impaired

Nonmagnetic

Rustproof

Abrasives will not embed themselves as

easily in the surface

8-35

Care of Surface Plates

Keep surface plates clean at all times

Clean occasionally with solvent to remove film

Protect with wooden cover when not in use

Use parallels whenever possible to prevent

damage to plates by rough parts or castings

Remove burrs from workpiece before placing

it on plate

8-36

Care of Surface Plates

Slide heavy parts onto the plate rather than

place them directly on the plate

Remove all burrs from cast-iron plates by

honing

When not in regular use, cover cast-iron

plates with thin film of oil to prevent rusting

Center punching or prick punching layout

lines should not be done on a surface plate

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

PowerPoint to accompany

Krar Gill Smid

Technology of Machine Tools

6

th

Edition

Micrometers

Unit 9

9-38

Objectives

Identify the most common types of outside

micrometers and their uses

Measure the size of a variety of objects to

within .001-in. accuracy

Read vernier micrometers to .0001-in.

accuracy

Measure the size of a variety of objects to

within 0.01-mm accuracy

9-39

Precision Measuring Tools

Five categories of tools based on the

dimension being measured

Outside

Inside

Depth

Thread

Height

9-40

Micrometer Caliper

Standard inch micrometer accurate to .001 in.

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

9-41

Principle of the Inch Micrometer

Zero line on thimble lined up with index

line on sleeve (barrel)

Measuring faces just touch

Pitch is 1/40 (.025) in.since 40 threads

One complete revolution of spindle, one line

appears

Every fourth line longer (represents .100 in.)

Thimble has 25 equal divisions

Represents .001 in.

9-42

To Read Standard Inch

Micrometer

Note last number showing on sleeve and

multiply by .100

Note number of small lines visible to right

and multiply by .025

Note number of divisions on thimble from

zero to line that coincides with index line on

sleeve and multiply by .001

Add three products to get total reading

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

9-43

Sample Reading

Note last number showing on sleeve and

multiply by .100

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

2 x .100

.200

9-44

Sample Reading

Note number of small lines visible to right

and multiply by .025

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

3

3 x .025

.075

9-45

Sample Reading

Note number of divisions on thimble from

zero to line that coincides with index line on

sleeve and multiply by .001

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

13 x .001

.013

9-46

Sample Reading

Add three products to get total reading

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

.200

.075

.013

.288 in.

9-47

Vernier

Micrometer

Added to sleeve

Each division on vernier

scale has a value of .0001 in.

Scale consists of 10 divisions

that run parallel to index line.

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

Friction thimble

9-48

To Read Vernier Micrometer

Read as would a standard micrometer

Note line on vernier scale that coincides with

one on thimble

Indicates number of ten-thousandths

Multiple the line number times .0001

Add to total of the other readings

9-49

Micrometer Adjustments:

Remove Play in Threads

Back off the thimble

Insert C-spanner into slot or hole of

adjusting nut

Turn adjusting nut clockwise until play

between threads has been eliminated

Note: After adjusting, spindle should advance freely

while ratchet stop or friction thimble is being turned

9-50

Testing Accuracy of Micrometers

Test periodically to ensure accuracy

Clean measuring faces before testing

Turn thimble using friction thimble or

ratchet stop until measuring faces contact

each other

Zero line on thimble coincides with center index

line on sleeve = accuracy

Can also check by measuring gage block or

other known standard

9-51

Adjusting Accuracy of a

Micrometer

Clean measuring faces; inspect for damage

Close measuring faces carefully by turning

ratchet stop or friction thimble

Insert C-spanner into hole or slot in sleeve

Carefully turn sleeve until index line on

sleeve coincides with zero line on thimble

Recheck accuracy

9-52

Special-Purpose Micrometers

Direct-reading micrometer

Additional digital readout

built into frame

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

Large-frame micrometer

Made for measuring large

outside diameters up to 60 in.

Interchangeable anvils give

range of 6 in.

9-53

Other Micrometers

Indicating micrometer

Uses indicating dial and movable anvil

Accurate to ten-thousandths of an inch

Can be used as a comparator with gage blocks

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

Mul-T-Anvil

micrometer

Used for measuring tubing

and distances from a slot to

an edge

Round and flat anvils

9-54

Digi-Matic Micrometer

Used as hand gage for inspecting small parts

Accurate up to 50 millionths of an inch and

displays both inch or metric sizes

Statistical process

control when added

provides stand-alone

inspection system

Interface with PC

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

9-55

Screw Thread Micrometers

Measures pitch diameter of threads

Pointed spindle and double-V swivel anvil

Shaped to contact pitch diameter of thread

Equal to outside diameter less depth of one thread

Limited to certain range

Four ranges for one-inch

8-13 TPI

14-20 TPI

22-30 TPI

32-40 TPI

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

PowerPoint to accompany

Krar Gill Smid

Technology of Machine Tools

6

th

Edition

Vernier Calipers

Unit 10

10-57

Objectives

Measure workpieces to within an accuracy

of .001 in. using a 25-division inch vernier

caliper

Measure workpieces to within an accuracy

of .001 in. using a 50-division inch vernier

caliper

Measure workpieces to within an accuracy

of 0.02 mm using a metric vernier caliper

10-58

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Used to lock readings into place

Parts of the Vernier Caliper

Manufactured with both 25- and

50-division vernier scales

Bar of 25-division

vernier scale graduated

same as micrometer

10-59

Measuring a Workpiece

Remove all burrs from workpiece

Clean surface to be measured

Open jaws enough to pass over work

Close jaws against work and lock right-hand

clamp screw

Turn adjusting screw until jaws just touch

work surface

Lock clamp screw on movable jaw

Read measurement

10-60

Reading the Measurement

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

A 50-division inch vernier caliper reading of 1.464 in.

1 x 1.000= 1.000

4 x 0.100= .400

1 x 0.050= .050

14 x 0.001= .014

1.464 in.

10-61

Metric Vernier Caliper

Many have both metric and inch graduations

Parts same as inch vernier

Main scale graduated in millimeters

Every main division numbered, equal to 10 mm

Fifty graduations on sliding scale with every fifth

one numbered

50 graduations occupy same space as 49 graduations

on main scale (49 mm)

1 vernier division = 0.98 mm so difference between 1

main scale division and 1 vernier division = .02 mm

10-62

Reading a Metric Vernier Caliper

Last numbered division on bar to left of

vernier scale represents number of

millimeters multiplied by 10

Note how many full graduations showing

between this numbered division and zero

Multiply number by 1 mm

Find line on vernier scale that coincides with

line on bar and multiply by 0.02 mm

Add for total reading

10-63

Direct-Reading Dial Caliper

Dial indicator, hand attached to pinion,

mounted on sliding jaw

Metric: 1 revolution of hand = 2 mm of travel

Inch: 1 revolution = .100 or .200 in. of travel

Depends on manufacturer

Most have narrow sliding blade attached to

sliding jaw (and dial) used depth gage

10-64

Digital Electronic Caliper

Can provide readings to resolution of

.0005 in. or 0.01 mm at touch of button

No rack, pinion or glass scale

Can connect to Statistical Process Control (SPC)

equipment for inspection purposes

Measurements

Inside diameter

Outside diameter

Step

Depth

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

PowerPoint to accompany

Krar Gill Smid

Technology of Machine Tools

6

th

Edition

Inside-, Depth-, and Height-

Measuring Instruments

Unit 11

11-66

Transfer-Type Instruments

Size of object taken with instrument not

capable of giving direct reading

Small hole gages for small measures

Sets of four

Range: .125 - .500 in.

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Have small, round end or ball Have flat bottom

11-67

Transfer-Type Instruments

Telescope Gages

Used to obtain size of holes, slots, and recesses

from .3125 to 6.000 in.

(8 to 152 mm)

T-shaped: pair of telescoping

tubes connected to handle

Knurled knob on handle end

locks plungers into position

11-68

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Vernier Height Gage

Precision instrument

Variety of sizes:

12-72 in. or 300-1000 mm.

Height within .001 in (0.02 mm)

Digital height gage

zero function, display .0001 in.

Offset scriber

Attachment that permits

setting heights from face of plate

Depth gage attachment

11-69

To Measure with a Vernier Height

Gage and Dial Indicator

1. Thoroughly clean plate, base, work surface

2. Place finished edge of work on surface

plate

3. Clamp against angle plate if necessary

4. Insert snug-fitting plug into hole with .500

in projecting

5. Mount dial indicator on movable jaw

6. Adjust movable jaw until indicator almost

touches surface plate

11-70

To Measure with a Vernier Height

Gage and Dial Indicator

7. Lock upper slide of height gage, use

adjusting nut to move indicator until dial

registers turn

8. Set indicator dial to zero

9. Adjust vernier height gage until indicator

registers zero on top of plug

10. Subtract initial reading plus half diameter

of plug

Potrebbero piacerti anche

- 8 - Solid SolutionsDocumento9 pagine8 - Solid Solutionstaak41Nessuna valutazione finora

- LMD Tga DSCDocumento18 pagineLMD Tga DSCharim_meNessuna valutazione finora

- Group Technology and Cellular Manufacturing2Documento83 pagineGroup Technology and Cellular Manufacturing2harim_meNessuna valutazione finora

- Comparator Types - HKKDocumento28 pagineComparator Types - HKKharim_meNessuna valutazione finora

- DSC PDFDocumento18 pagineDSC PDFMinh TranNessuna valutazione finora

- Quick guide to precision measuring instrumentsDocumento4 pagineQuick guide to precision measuring instrumentsharim_meNessuna valutazione finora

- Group Technology and Cellular Manufacturing-IDocumento20 pagineGroup Technology and Cellular Manufacturing-Isiva_karthidpm100% (1)

- CIMDocumento20 pagineCIMharim_meNessuna valutazione finora

- Auto CollimatorDocumento38 pagineAuto Collimatorharim_meNessuna valutazione finora

- Linear MeasurementDocumento58 pagineLinear Measurementpdpantawane100% (2)

- Monitoring The Progress of The Jobs Is An Integrated Part of CIMDocumento3 pagineMonitoring The Progress of The Jobs Is An Integrated Part of CIMharim_meNessuna valutazione finora

- Neurocomputing: P.K. Kankar, Satish C. Sharma, S.P. HarshaDocumento8 pagineNeurocomputing: P.K. Kankar, Satish C. Sharma, S.P. Harshaharim_meNessuna valutazione finora

- Machine VisionDocumento4 pagineMachine Visionharim_meNessuna valutazione finora

- Me2304 Emm QBDocumento14 pagineMe2304 Emm QBharim_meNessuna valutazione finora

- Measurement Concepts and SystemsDocumento33 pagineMeasurement Concepts and Systemsharim_meNessuna valutazione finora

- Hot Cold WorkingDocumento40 pagineHot Cold Workingpatel ketanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Metrology Lab ManualDocumento36 pagineMetrology Lab Manualuvrsunil_kumar100% (2)

- SC Ch1 f1 StudywithadminDocumento8 pagineSC Ch1 f1 StudywithadminNur dini FauziNessuna valutazione finora

- Physics Notes Class 9: Phase 1 CHAPTER (1to5)Documento77 paginePhysics Notes Class 9: Phase 1 CHAPTER (1to5)Nasir SaleemNessuna valutazione finora

- IAAF Calibration and Testing ManualDocumento31 pagineIAAF Calibration and Testing ManualmeongNessuna valutazione finora

- An Accurate Eye PDFDocumento92 pagineAn Accurate Eye PDFRock Tiger83% (6)

- Lesson Plan: Sampoerna Academy BogorDocumento4 pagineLesson Plan: Sampoerna Academy Bogorlissinussi0% (1)

- Experiment 1 Physics FinalDocumento8 pagineExperiment 1 Physics FinalBenjo DimaculanganNessuna valutazione finora

- Astm D-4166Documento2 pagineAstm D-4166ader paredesNessuna valutazione finora

- Aws Visual InspectionDocumento54 pagineAws Visual Inspectionoluninjaa100% (1)

- 9th Physics Chapter 1Documento8 pagine9th Physics Chapter 1Shakeel Ahmad Kasuri100% (2)

- The Micrometer: V. Ryan © 2004 - 2009Documento6 pagineThe Micrometer: V. Ryan © 2004 - 2009shrishtiNessuna valutazione finora

- 9th Science EM - WWW - Tntextbooks.inDocumento328 pagine9th Science EM - WWW - Tntextbooks.inRagavi JoNessuna valutazione finora

- Uncertainties and Significant FiguresDocumento4 pagineUncertainties and Significant FiguresgraceNessuna valutazione finora

- IAL Physics Unit 3 NoteDocumento22 pagineIAL Physics Unit 3 NoteÅzmâñ KhäñNessuna valutazione finora

- IS 2185 PART 3 Product ManualDocumento7 pagineIS 2185 PART 3 Product ManualRajat Raj VermaNessuna valutazione finora

- Fitting ShopDocumento45 pagineFitting ShopRishabh SharmaNessuna valutazione finora

- 03 Marking ToolsDocumento26 pagine03 Marking ToolsArun PrasadNessuna valutazione finora

- Errors - (1 To 50) VERNIER, SCREW GAUGEDocumento6 pagineErrors - (1 To 50) VERNIER, SCREW GAUGEadvaitkshirasgar786Nessuna valutazione finora

- Vernier CalipersDocumento40 pagineVernier CalipersBalaji BaluNessuna valutazione finora

- Heritage Institute of Technology: Fitting ShopDocumento18 pagineHeritage Institute of Technology: Fitting ShopAnurag MukherjeeNessuna valutazione finora

- Completed Physics ManualDocumento120 pagineCompleted Physics ManualShanmugam RameshNessuna valutazione finora

- Metrics For MechanicsDocumento63 pagineMetrics For Mechanicseduardorojas007Nessuna valutazione finora

- Catalogo2012 INSIZEDocumento288 pagineCatalogo2012 INSIZEKaki GonzalezNessuna valutazione finora

- Measuring Instruments: StructureDocumento11 pagineMeasuring Instruments: StructureAkash SinghNessuna valutazione finora

- Measurement Instruments and ToolsDocumento91 pagineMeasurement Instruments and ToolsNishanth Shannmugam100% (2)

- Acf 21 Students FileDocumento6 pagineAcf 21 Students FileElizabeth JadeNessuna valutazione finora

- D4564 Densidad de Suelos en Sitio Con Sleeve MethodDocumento9 pagineD4564 Densidad de Suelos en Sitio Con Sleeve MethodtomashdzNessuna valutazione finora

- Nabl 129Documento138 pagineNabl 129Ashish DubeyNessuna valutazione finora

- Basic Measurement 2Documento9 pagineBasic Measurement 2irghazaliNessuna valutazione finora

- WPH06 01 Que 20190128daDocumento20 pagineWPH06 01 Que 20190128daHamza Tahir IqbalNessuna valutazione finora