Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manufacturing Lecture

Caricato da

mohtram10370 valutazioniIl 0% ha trovato utile questo documento (0 voti)

105 visualizzazioni124 paginemanufacturing lecture

Titolo originale

manufacturing lecture

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentomanufacturing lecture

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

105 visualizzazioni124 pagineManufacturing Lecture

Caricato da

mohtram1037manufacturing lecture

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 124

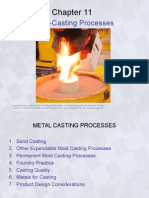

NON TRADITIONAL MACHINING AND

THERMAL CUTTING PROCESS

CHAPTER 26

Advanced Machining Processes

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

NON TRADITIONAL MACHINING

1. Mechanical energy process

1. Ultrasonic Machining

2. Water & Abrasive Jet

2. Electrochemical Machining( Deburring, Grinding)

3. Thermal Energy Process

1. Electric Discharge

2. Electron Beam

3. Laser Beam

4. Arc Cutting

5. Oxyfuel cutting

4. Chemical Machining

1. Mechanics and Chemistry of Chemical Machining

2. CHM Processes

5. Application Considerations

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

REQUIREMENT for NON TRADITIONAL

MACHINING

1. The need to machine newly developed metals and

non-metals.

These materials often have special properties (e.g.,

high strength, high hardness, high toughness) that

make them difficult or impossible to machine by

conventional methods.

2. The need for unusual and/or complex part

geometries that cannot easily be accomplished

and in some cases are impossible to achieve by

conventional machining.

3. The need to avoid surface damage that often

accompanies the stresses created by conventional

machining.

Many of these requirements are associated with the

aerospace and electronics industries.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Classification of non traditional Machining

The classification is based on principal form of

energy used

Mechanical

Electrical

Thermal

Chemical

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

MECHANICAL ENERGY PROCESSES

Several of the nontraditional processes that

use mechanical energy other than a sharp

cutting tool:

1. ultrasonic machining,

2. water jet processes,and

3. other abrasive processes.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Ultrasonic Machining (USM)

Used for Hard and Brittle Materials like Ceramics

and glass

Abrasive particles impacts on workpiece to

achieve metal removal

The tool drives the abrasives contained in a slurry

The tool oscillates perpendicular to work surface at

high frequency(20,000 HZ) and low

amplitude(0.075mm) and fed slowly in the work

surface

Tool Material is normally soft steel & Stainless

Steel

Abrasive slurry includes boron nitride, boron

carbide, Aluminum Oxide etc mixed with

water(20% ~60%) and the grit size is propotional

to amplitude

Tool and work both undergo abrasion with a ratio

of 100:1 to 1:1.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Ultrasonic Machining (USM)

Abrasives contained in a slurry are driven at

high velocity against the work by a tool

vibrating at low amplitude and high frequency.

The amplitudes are around 0.075 mm , and the

frequencies are approximately 20,000 Hz.

The tool oscillates perpendicular to the work

surface, and is fed slowly into the work,

the shape of the tool is formed in the part.

It is the action of the abrasives, impinging

against the work surface, that performs the

cutting.

Common tool materials are soft steel and

stainless steel.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Ultrasonic Machining (USM)

FIGURE 26.1

Ultrasonic machining.

Ultrasonic Machining (USM)

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Ultrasonic Machining (USM)

Abrasive materials in USM include

boron nitride,

boron carbide,

aluminum oxide,

silicon carbide, and

diamond.

Grit size ranges between 100 and 2000.

The vibration amplitude should be set

approximately equal to the grit size,

the gap size maintained at about twice grit size.

To a significant degree, grit size determines the

surface finish on the new work surface.

the material removal rate increases with increasing

frequency and amplitude of vibration.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Ultrasonic Machining (USM)

The slurry consists of a mixture of water and abrasive

particles.

Concentration of abrasives in water ranges from

20% to 60%.

The slurry must be continuously circulated to bring

fresh grains into action.

It also washes away chips and worn grits.

The cutting action operates on the tool as well as the

work.

As the abrasive erode the work surface, they also

erode the tool.

It is therefore important to know the relative volumes of

work material and tool material removed.

This ratio varies for different work materials,

100:1 for cutting glass

1:1 for cutting tool steel.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Ultrasonic Machining (USM)

Used for

hard, brittle work materials, such as ceramics,

glass, and carbides.

stainless steel and titanium.

Shapes obtained by USM

Shapes obtained include

non-round holes,

holes along a curved axis, and

coining operations,

in which an image pattern on the tool is

imparted to a flat work surface.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Water Jet Cutting (WJC)

Hydrodynamic or Water Jet cutting (WJC)

High Pressure (400 MPA)

High Velocity stream(900 m/s) from a nozzle

opening of 0.1 to 0.4 mm diameter

The nozzle unit consists of

a holder made of stainless steel, and

a jewel nozzle made of sapphire, ruby, or

diamond

Filtration systems is used to separate the swarf

produced during cutting.

Preferred cutting fluids are polymer solutions,

because of their tendency to produce a

coherent stream.

Water Jet Cutting (WJC)

FIGURE 26.2

Water jet cutting.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Water Jet Cutting (WJC)

Standoff distance: the separation between the

nozzle opening and the work surface.

generally desirable to be small to minimize

dispersion of the fluid stream ( typically 3.2

mm).

size of nozzle orifice affects the precision of cut;

smaller openings are used for finer cuts on

thinner materials.

thicker jet streams and higher pressures are

required to cut thicker stock.

Typical feed rates range from 5 to 500 mm/s,

depending on work material and its thickness

Used for plastics, leather, textiles, composites,

tile, carpet, cardboard etc

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Water Jet Cutting (WJC)

Applications / advantages include:

1. no crushing or burning of the work surface

typical in other mechanical or thermal

processes,

2. Minimum material loss because of the narrow

cut slit,

3. no environmental pollution, and

4. ease of automating the process.

A limitation of the process -- not suitable for

cutting brittle materials (e.g., glass)

because of their tendency to crack during

cutting.

Water-Jet

Cutting

Process

Figure 27.16 (a) Schematic illustration of the water-jet machining process. (b) A computer-controlled water-jet

cutting machine cutting a granite plate. (c) Examples of various nonmetallic parts produced by the water-jet

cutting process. (Enlarged on next slide). Source: Courtesy of Possis Corporation

Nonmetallic Parts Made by Water-Jet

Cutting

Enlargement of Fig. 27.16c. Examples of various nonmetallic parts produced by the water-jet cutting

process. Source: Courtesy of Possis Corporation

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Abrasive Water Jet Cutting (AWJC)

When WJC is used on metallic workparts,

abrasive particles must be added to facilitate

cutting.

This complicates the process by adding a number

of parameters that must be controlled.

Additional parameters are

abrasive type,

grit size, and

flow rate.

Typical abrasive are

Aluminum oxide,

silicon dioxide, and

garnet (a silicate mineral)

grit sizes range between 60 and 120.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Abrasive Water Jet Cutting (AWJC)

The abrasive particles are added to the water

stream at about 0.25 kg/min as it exits the

nozzle.

Nozzle orifice diameters are 0.25 to 0.63 mm

somewhat larger than in WJC to permit

higher flow rates and

more energy contained in the stream.

Typical standoff distances are between 1/4

and 1/2 of those in WJC.

Abrasive Water Jet Cutting (AWJC)

Abrasive Water Jet

Cutting (AWJC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Abrasive Jet Machining (AJM)

Abrasive particles with Gas is used

The gas is dry and pressure is about 0.2 ~ 1.4

MPA

Gas Velocity is about 2.5 to 5 m/s

nozzle orifice diameter range from 0.075 to 1.0

mm.

Gases include dry air, nitrogen, carbon dioxide,

and helium.

Typical distances between nozzle tip and work

surface range between 3 and 75 mm.

The workstation must be set up to provide proper

ventilation for the operator.

It is generally a finishing process rather than a

production cutting process

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Abrasive Jet Machining (AJM)

FIGURE 26.3

Abrasive jet machining (AJM).

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Abrasive Jet Machining (AJM)

Applications include

deburring,

trimming and deflashing,

cleaning, and

polishing.

Cutting is accomplished on thin flat stock of hard,

brittle materials (e.g., glass, silicon, mica, and

ceramics)

Typical abrasives used include

aluminum oxide (for aluminum and brass),

silicon carbide (for stainless steel and

ceramics), and

glass beads (for polishing).

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Abrasive Jet Machining (AJM)

Grit sizes are small, 15 to 40 m in diameter,

must be uniform in size.

It is important not to recycle the abrasives

because used grains become fractured (and

therefore smaller in size), worn, and

contaminated.

Abrasive-Jet

Machining

Figure 27.17 (a) Schematic illustration of the abrasive-jet machining process. (b) Examples of parts

produced through abrasive-jet machining, produced in 50-mm (2-in.) thick 304 stainless steel. Source:

Courtesy of OMAX Corporation.

(b)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Abrasive Flow Machining (AFM)

This process is used to deburr and polish difficult-

to-reach areas

abrasive particles mixed in a viscoelastic polymer

(called the media) is forced to flow through or

around the part surfaces and edges.

The polymer has the consistency of putty.

Silicon carbide is a typical abrasive.

particularly well-suited for internal passageways

that are often inaccessible by conventional

methods.

The media flows past the target regions of the

part under pressures ranging between 0.7 and 20

MPa.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Abrasive Flow Machining (AFM)

Other applications include

forming radii on sharp edges,

removing rough surfaces on castings, and

other finishing operations.

The process can be automated economically for

mass production.

A common setup is to position the workpart

between two opposing cylinders, one containing

media and the other empty.

The media is forced to flow to and fro through the

part between the two cylinders, as many times as

necessary to achieve the desired material

removal and finish.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Electrochemical Machining (ECM)

Remove material by anodic dissolution

the shape of the workpiece is obtained by a

formed electrode tool in close proximity to the

work by a rapidly flowing electrolyte.

The machining process is similar to de-plating

Tool is Cathode(-) & Workpiece is Anode(+)

The principle underlying the process is

material is deplated from the anode and

deposited onto the cathode in an electrolyte

bath.

In ECM the electrolyte bath flows rapidly

between the two poles to carry off the deplated

material, so that it does not become plated

onto the tool.

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

Electrochemical Machining (ECM)

FIGURE 26.4

Electrochemical machining (ECM).

Electrochemical Machining

Figure 27.6 Schematic illustration of the electrochemical machining process.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Machining (ECM)

The electrode tool,

usually made of copper, brass, or stainless

steel,

possess the inverse of the desired final shape

of the part.

an allowance is provided for the gap between

the tool and the work.

the electrode is fed into the work at a rate equal to

the rate of metal removal.

MRR depends upon Faradays First Law

the amount of chemical change produced by

an electric current (i.e., the amount of metal

dissolved) is proportional to the quantity of

electricity passed (current x time).

V= CIt,

where is C is constant i.e: specific removal rate

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Machining (ECM)

Feed rate:

We should note that this equation assumes 100%

efficiency of metal removal.

The actual efficiency is 90% to 100%

It depends on

tool shape,

voltage and current density, and

other factors.

Gap distance needs to be controlled closely.

If g becomes too large, the electrochemical process

slows down.

if the electrode touches the work, a short circuit

occurs, & process stops altogether.

Typical gap range between 0.075 to 0.75 mm.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Machining (ECM)

ECM requires large amounts of electrical power.

rate of metal removal is determined by electrical

power, specifically the current density.

The voltage is kept relatively low to minimize

arcing across the gap.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Machining (ECM)

Water is used as the base for the electrolyte.

To reduce electrolyte resistivity, salts such as NaCl

or NaNO

3

are added.

the flowing electrolyte removes

the material from the workpiece,

heat and

hydrogen bubbles created in the chemical

reactions.

The removed microscopic material particles must

be separated from the electrolyte through

centrifuge,

sedimentation, or

other means.

The disposal of separated particles (thick sludge)

is an environmental problem.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Machining (ECM)

Generally used in applications in which

the work metal is very hard or difficult to

machine, or

the workpart geometry is difficult (or impossible)

to accomplish by conventional machining.

Work hardness makes no difference in ECM.

Typical ECM applications include:

1. die sinking, which involves the machining of

irregular shapes and contours into forging dies,

plastic molds, and other shaping tools;

2. multiple hole drilling, in which many holes can be

drilled simultaneously with ECM;

3. holes that are not round; and

4. deburring.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Machining (ECM)

Advantages include:

1. little surface damage to the workpart,

2. no burrs as in conventional machining,

low tool wear (the only tool wear results from the

flowing electrolyte), and

1. relatively high metal removal rates for hard and

difficult-to-machine metals.

Disadvantages are:

1. significant cost of electrical power to drive the

operation and

2. problems of disposing of the electrolyte sludge.

Parts Made by Electrochemical Machining

Figure 27.7 Typical parts made by electrochemical machining. (a) Turbine blade made of nickel alloy of

360 HB. Note the shape of the electrode on the right. (b) Thin slots on a 4340-steel roller-bearing cage.

(c) Integral airfoils on a compressor disk.

Knee Implants

Figure 27.8 (a) Two total knee replacement systems showing metal implants (top pieces) with an

ultra-high molecular-weight polyethylene insert (bottom pieces). (b) Cross-section of the ECM

process as applies to the metal implant. Source: Courtesy of Biomet, Inc.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Deburing (ECD)

It is an adaptation of ECM designed to

remove burrs or to

round sharp corners

by anodic dissolution.

The hole in the workpart has a sharp burr.

The tool is designed to focus on the burr.

Portions of the tool not being used for machining

are insulated.

The electrolyte flows through the hole to carry

away the burr.

The same operation principles of ECM also apply

to ECD. However, cycle times are much shorter.

A typical cycle time is less than a minute.

The time can be increased if it is desired to round

the corner.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Deburing (ECD)

FIGURE 26.5

Electrochemical deburring (ECD).

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Grinding (ECG)

A special form of ECM

a rotating grinding wheel with a conductive bond

material is used for the anodic dissolution of the

workpart surface.

Abrasives used in ECG include aluminum oxide

and diamond.

The bond material is

metallic (for diamond abrasives) or

resin bond impregnated with metal particles

(for aluminum oxide).

The abrasive grits protruding from the grinding

wheel at the contact with the workpart establish

the gap distance in ECG.

The electrolyte flows through the gap between the

grains to play its role in electrolysis.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Grinding (ECG)

FIGURE 26.6

Electrochemical grinding (ECG).

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electrochemical Grinding (ECG)

Metal removal in ECG

deplating is responsible for 95% or more, and

the abrasive action of grinding wheel removes

the remaining 5%or less,

mostly in the form of salt films.

Therefore the grinding wheel lasts much longer

than in conventional grinding.

a much higher grinding ratio.

dressing of the grinding wheel is required much

less frequently.

Applications include:

sharpening of cemented carbide tools and

grinding of surgical needles, other thin wall

tubes, and fragile parts.

Electrochemical-Grinding Process

Figure 27.9 (a) Schematic illustration of the electrochemical-grinding process. (b) Thin slot

produced on a round nickel-alloy tube by this process.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Thermal energy Process

characterized by very high local temperatures

hot enough to remove material by fusion or

vaporization.

the high temperatures, cause physical and

metallurgical damage to the new work surface.

1. Electric discharge Processes

Die sink

Wirecut

2. Electron Beam Machining

3. Laser Machining & cutting

4. Plasma Arc Machining

5. Oxyfuel cutting

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

ELECTRIC DISCHARGE PROCESSES

remove metal by a series of discrete electrical

discharges (sparks)

these cause localized temperatures high

enough to melt or vaporize the metal in the

immediate vicinity.

used only on electrically conducting work

materials.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

The shape of the finished work surface is

produced by a formed electrode tool.

The sparks occur across a small gap between

tool and work surface.

The process takes place in a dielectric fluid.

The discharges are generated by a pulsating

direct current power supply.

The region in which discharge occurs is heated

to extremely high temperatures.

a small portion of the work surface is

suddenly melted and removed.

The flowing dielectric flushes away the small

particle.

Electric Discharge Machining (EDM)

FIGURE 26.7

Electric discharge machining (EDM): (a) overall setup, and (b) close-up view of

gap, showing discharge and metal removal.

Electrical-Discharge Machining Process

Figure 27.10 (a) Schematic illustration of the electrical-discharge machining process. This is one of the most widely used

machining processes, particularly for die-sinking applications. (b) Examples of cavities produced by the electrical-discharge

machining process, using shaped electrodes. Two round parts (rear) are the set of dies for extruding the aluminum piece shown

in front (see also Fig. 19.9b). (c) A spiral cavity produced by EDM using a slowly rotating electrode similar to a screw thread. (d)

Holes in a fuel-injection nozzle made by EDM; the material is heat-treated steel. Source: (b) Courtesy of AGIE USA Ltd.

Stepped Cavities Produced by EDM

Process

Figure 27.11 Stepped cavities produced with a square electrode by the EDM process. The workpiece

moves in the two principle horizontal directions (x y), and its motion is synchronized with the

downward movement of the electrode to produce these cavities. Also shown is a round electrode

capable of producing round or elliptical cavities. Source: Courtesy of AGIE USA Ltd.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

The removal of material increases the gap at

that location,

thus it is less likely to be the site of another

spark.

the individual discharges remove metal at very

localized points,

they occur hundreds or thousands of times

per second

a gradual erosion of the entire surface

occurs in the area of the gap.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

Two important process parameters are

discharge current and

frequency of discharges.

The best surface finish is obtained at high

frequencies and low discharge currents.

As the tool penetrates into the work,

overcutting occurs.

the distance by which the machined cavity

exceeds the size of the tool on each side.

Overcut is a function of current and frequency

(amount to several hundredths of a millimeter).

The high spark temperatures that melt the work

also melt the tool.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

FIGURE 26.8

(a) Surface finish in EDM as a function of discharge current and frequency of

discharges. (b) Overcut in EDM as a function of discharge current and frequency

of discharges.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

Tool wear is measured as the ratio of work

material removed to tool material removed

(similar to the grinding ratio).

ranges between 1.0 and 100.

Electrodes are made of graphite, copper, brass,

copper tungsten, silver tungsten, and other

materials.

The selection depends on

the type of power supply circuit,

the type of work material, and

whether roughing or finishing is to be done.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

Graphite is preferred for many applications

because it does not melt.

It vaporizes at very high temperatures, and

the cavity created by the spark is generally

smaller than for most other materials.

a high ratio of work material removed to tool

wear.

The hardness and strength of the work material

are not factors in EDM.

The melting point of the work material is an

important property.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

metal removal rate can be related to melting

point approximately by the following empirical

formula,

where

RMR = metal removal rate, mm

3

/s;

K = constant of proportionality whose value= 664

in SI units;

I = discharge current,amps; and

T

m

= melting temperature of work metal, C.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

Dielectric fluids used include

hydrocarbon oils,

kerosene, and

distilled or deionized water.

It serves as

an insulator in the gap (except when ionization

occurs in the presence of a spark).

flush debris out of the gap and

remove heat from tool and workpart.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Machining (EDM)

Applications include

tool fabrication and

parts production.

The tooling for many of the mechanical processes

are often made by EDM, including

molds for plastic injection molding,

extrusion dies,

wire drawing dies,

forging and heading dies, and

sheet metal stamping dies.

Electric Discharge Machining (EDM)

As in ECM, the term die sinking used for

producing a mold cavity, is sometimes referred to

as ram EDM.

the materials used to fabricate the tooling are

difficult (or impossible) to machine by

conventional methods.

Certain production parts also call for application

of EDM.

delicate parts that are not rigid enough to

withstand conventional cutting forces,

hole drilling where the axis of the hole is at an

acute angle to the surface, and

production machining of hard and exotic

metals.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Wire Cutting (EDWC)

Commonly called wire EDM,

It uses a small diameter wire as the electrode to

cut a narrow kerf in the work.

The cutting action is achieved by thermal energy

from electric discharges between the wire and the

workpiece.

The workpiece is fed past the wire along the

desired path, similar to a bandsaw operation.

the wire is slowly and continuously advanced

between a supply and take-up spool to present a

fresh electrode of constant diameter to the work.

This maintains a constant kerf width during

cutting.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Wire Cutting (EDWC)

FIGURE 26.9

Electric discharge wire cutting (EDWC), also called wire EDM.

The Wire EDM Process

Figure 27.12 Schematic illustration of the wire EDM

process. As many as 50 hours of machining can be

performed with one reel of wire, which is then discarded.

Metal removal rate:

MRR= 4x10

4

IT

w

1. 23

where

I=current in amperes

T

w

= melting temperature of workpiece, C

Wire EDM

(a) (b)

Figure 27.13 (a) Cutting a thick plate with wire EDM. (b) A computer-controlled wire EDM

machine. Source: Courtesy of AGIE USA Ltd.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Wire Cutting (EDWC)

A dielectric is applied by nozzles directed at the

toolwork interface, or the workpart is submerged

in a its bath.

Wire diameters range from 0.076 to 0.30 mm,

depending on kerf width.

Materials used for the wire include brass, copper,

tungsten, and molybdenum.

Dielectric fluids include deionized water or oil.

As in EDM, an overcut exists that makes the kerf

larger than the wire diameter.

overcut is in the range 0.020 to 0.050 mm.

Once cutting conditions are established, overcut

remains fairly constant and predictable.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Wire Cutting (EDWC)

FIGURE 26.10

Denition of kerf and overcut in electric discharge wire cutting.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Wire Cutting (EDWC)

Although EDWC seems similar to a bandsaw

operation, its precision far exceeds that of a

bandsaw.

The kerf is much narrower,

corners can be made much sharper, and

the cutting forces against the work are nil.

hardness and toughness of the work material

do not affect cutting performance.

The only requirement is that the work material

must be electrically conductive.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Electric Discharge Wire Cutting (EDWC)

The special features make it ideal for making

stamping dies.

Because of narrow kerf, it is often possible to

fabricate punch and die in a single cut.

Other applications include, tools and parts with

intricate outline shapes

lathe form tools,

extrusion dies, and

flat templates.

Electric Discharge Wire Cutting (EDWC)

FIGURE 26.11

Irregular outline cut from a solid metal slab by

wire EDM. (Photo courtesy of LeBlond

Makino Machine Tool Company, Amelia,

Ohio.)

2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

ELECTRON BEAM MACHINING (EBM)

One of several industrial processes that use

electron beams.

other applications include heat treating,

welding and free form fabrication.

It uses a high velocity stream of electrons

focused on the workpiece to remove material by

melting and vaporization.

An electron beam gun generates a continuous

stream of electrons

accelerated to approximately 75% of the

speed of light

focused through an electromagnetic lens on

the work surface.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

ELECTRON BEAM MACHINING (EBM)

FIGURE 26.12

Electron beam machining (EBM).

Electron-Beam Machining Process

Figure 27.15 Schematic illustration of the electron-beam machining process.

Unlike LBM, this process requires a vacuum, so workpiece size is limited to the

size of the vacuum chamber.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

ELECTRON BEAM MACHINING (EBM)

The lens is capable of reducing the area of the

beam to a diameter as small as 0.025 mm.

On impinging, the kinetic energy of the electrons

is converted into thermal energy of extremely

high density that melts or vaporizes the material

in a very localized area.

Applications include

high-precision cutting of any known material.

drilling extremely small diameter holes; down

to 0.05 mm,

drilling of holes with very high depth-to-

diameter ratiosmore than 100:1, and

cutting slots that are about 0.025 mm wide

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

ELECTRON BEAM MACHINING (EBM)

cuts can be made to very close tolerances with

no cutting forces or tool wear.

The process is ideal for micromachining.

limitations:

carried out in a vacuum chamber to eliminate

collision of the electrons with gas molecules.

high energy requirement and

expensive equipment.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

The term laser stands for light amplification by

stimulated emission of radiation.

It is an optical transducer that converts electrical

energy into a highly coherent light beam.

A laser light beam

is monochromatic (single wave length) and

highly collimated (the light rays in the beam

are almost perfectly parallel).

using conventional optical lenses, a laser can be

focused onto a very small spot with high power

densities.

Laser Beam Machining (LBM)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Laser Beam Machining (LBM)

FIGURE 26.13

Laser beam machining

(LBM).

Laser-Beam

Machining

(LBM)

Figure 27.14 (a) Schematic illustration of

the laser-beam machining process. (b)

and (c) Examples of holes produced in

nonmetallic parts by LBM. (d) Cutting

sheet metal with a laser beam. Source:

(d) Courtesy of Rofin-Sinar, Inc.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

LBM uses the light energy from a laser to remove

material by vaporization and ablation.

The types of lasers used are

carbon dioxide gas lasers and

solid-state lasers.

the energy of the coherent light beam is

concentrated not only optically but also in terms

of time.

The light beam is pulsed so that the released

energy results in an impulse against the work

surface

the melted material evacuating the surface at

high velocity.

Laser Beam Machining (LBM)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

It is used to perform various types of drilling,

slitting, slotting, scribing, and marking operations.

Drilling small diameter holes is possibledown to

0.025 mm.

For larger holes (above 0.50-mm) the laser beam

cut the outline of the hole.

not considered a mass production process.

generally used on thin stock.

Laser Beam Machining (LBM)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

The range of work materials that can be

machined is virtually unlimited.

Ideal properties of a material for LBM include

high light energy absorption,

poor reflectivity,

good thermal conductivity,

low specific heat, low heat of fusion, and

low heat of vaporization.

Of course, no material has this ideal combination of properties.

The actual list of work materials includes metals

with high hardness and strength, soft metals,

ceramics, glass and glass epoxy, plastics, rubber,

cloth, and wood.

Laser Beam Machining (LBM)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Most arc-cutting processes use the heat

generated by an arc between an electrode and a

metallic workpart (usually a flat plate or sheet) to

melt a kerf that separates the part.

The most common arc-cutting processes are

1.plasma arc cutting and

2.air carbon arc cutting.

3.other Arc-cutting processes

ARC-CUTTING PROCESSES

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

A plasma is a superheated, electrically ionized

gas.

PAC uses a plasma stream operating at

temperatures in the range 10,000

o

C to

14,000

o

C to cut metal by melting.

operates by directing the high-velocity plasma

stream at the work,

thus melting it and

blowing the molten metal through the kerf.

The arc is generated between an electrode and

the anode workpiece.

The plasma flows through a water-cooled nozzle.

Plasma Arc Cutting (PAC)

FIGURE 26.14

Plasma arc cutting (PAC).

Plasma Arc Cutting (PAC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

The plasma jet is a high-velocity, collimated

stream with extremely high temperatures at its

center,

hot enough to cut through metal in some

cases 150 mm (6 in) thick.

Gases used in PAC include nitrogen, argon,

hydrogen, or mixtures of these gases.

These are referred to as the primary gases.

Secondary gases or water are often directed to

surround the plasma jet to confine the arc and

clean the kerf of molten metal as it forms.

Plasma Arc Cutting (PAC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Application: cutting of flat metal sheets and

plates.

Operations:

manually by hand-held torch, or

by the torch under numerical control (NC).

can be used to cut nearly any electrically

conductive metal.

Metals frequently cut include plain carbon

steel, stainless steel,and aluminum.

For NC applications feed rates for 6-mm thick

plate can be as high as

200 mm/s aluminum and

85 mm/s steel plate.

Plasma Arc Cutting (PAC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Feed rates must be reduced for thicker stock.

e.g. the maximum feed rate for cutting 100-

mm thick aluminum stock is around 8 mm/s.

Disadvantages:

1.the cut surface is rough, and

2.metallurgical damage at the surface is the

most severe among the nontraditional

metalworking processes.

Plasma Arc Cutting (PAC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

In this process,

the arc is generated between a carbon

electrode and the metallic work, and

a high-velocity air jet is used to blow away the

melted portion of the metal.

It can be used

to form a kerf for cut the piece, or

to gouge a cavity in the part.

Gouging is used to prepare the edges of

plates for welding.

Air Carbon Arc Cutting

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

used on a variety of metals, including

cast iron,

carbon steel,

low alloy,

stainless steels, and

various nonferrous alloys.

Spattering of the molten metal is a hazard and a

disadvantage of the process.

Air Carbon Arc Cutting

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

1. gas metal arc cutting,

2. shielded metal arc cutting,

3. gas tungsten arc cutting, and

4. carbon arc cutting.

Other Arc-Cutting Processes

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

A widely used family of thermal cutting processes,

popularly known as flame cutting.

use the heat of combustion of certain fuel

gases combined with

the exothermic reaction of the metal with

oxygen (primary mechanism)

The cutting torch deliver a mixture of fuel gas and

oxygen in the proper amounts, and direct a

stream of oxygen to the cutting region.

The purpose of the oxyfuel combustion is to raise

the temperature in the region of cutting to support

the reaction.

It is performed either manually or by machine.

OXYFUEL-CUTTING PROCESSES

(OFC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

commonly used to cut ferrous metal plates, with

the following reactions:

The second reaction is the most significant in

terms of heat generation.

OXYFUEL-CUTTING PROCESSES

(OFC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

cutting of nonferrous metals is different.

generally characterized by lower melting

temperatures than the ferrous metals, and

more oxidation resistant.

the heat of combustion plays a more important

role in creating the kerf.

to promote the metal oxidation reaction, chemical

fluxes or metallic powders are added to the

oxygen stream.

OXYFUEL-CUTTING PROCESSES

(OFC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Fuels used in OFC include

acetylene (C

2

H

2

),

MAPP (methylacetylene-propadiene C

3

H

4

),

propylene (C

3

H

6

), and

propane (C

3

H

8

).

Acetylene burns at the highest flame temperature

and is the most widely used fuel for welding and

cutting.

However, there are storage and handling

hazards

OXYFUEL-CUTTING PROCESSES

(OFC)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

material is removed by means of a strong

chemical etchant.

include

chemical milling,

chemical blanking,

chemical engraving, and

photochemical machining (PCM).

CHEMICAL MACHINING (CHM)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

1. Cleaning.

first step

ensures that material will be removed

uniformly.

2. Masking.

A protective coating called a maskant, made of

a material chemically resistant to the etchant.

applied to those portions of the work surface

that are not to be etched.

Maskant materials include neoprene,

polyvinylchloride, polyethylene, and other

polymers.

Mechanics and Chemistry of CHM

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

1. Etching.

material removal step.

part is immersed in an etchant that chemically

attacks portions that are not masked.

When the desired amount of material has been

removed, the part is withdrawn from the etchant

and washed.

2. Demasking.

The maskant is removed from the part.

Mechanics and Chemistry of CHM

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Masking can be accomplished by any of three

methods:

1. cut and peel,

2. photographic resist, and

3. screen resist.

1- Cut and peel

maskant is applied over the entire part by

dipping,

painting, or

spraying.

The resulting thickness of the maskant is 0.025 to

0.125 mm.

Masking Methods

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

After it has hardened, the maskant peeled by a

knife in the areas to be etched.

performed by hand, usually guiding the knife

with a template.

generally used for

large workparts,

low production quantities, and

where accuracy is not critical.

cannot hold tolerances tighter than 0.125 mm.

1- Cut and peel

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

It uses photographic techniques to perform

masking.

contain photosensitive chemicals.

applied to the work surface and exposed to

light through a negative.

These areas can then be removed from the

surface using developing techniques.

This leaves desired surfaces of the part

protected by the maskant and

the remaining areas unprotected, vulnerable to

chemical etching.

2- Photographic Resist (Photoresist)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

normally applied where small parts are produced

in high quantities, and

Close tolerances are required.

Tolerances closer than 0.0125 mm can be

held

2- Photographic Resist (Photoresist)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

The maskant is applied by means of silk

screening methods.

the maskant is painted onto the workpart

surface through a silk or stainless steel mesh.

Embedded in the mesh is a stencil.

The maskant is thus painted onto the work

areas that are not to be etched.

generally used in applications in between the

other two methods in terms of accuracy, part size,

and production quantities.

Tolerances of 0.075 mm can be achieved.

3- Screen Resist

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Material removal rates are generally indicated as

penetration rates, mm/min,

because rate of chemical attack of the work

material by the etchant is directed into the

surface.

The penetration rate is unaffected by surface

area.

Depths of cut are as much as 12.5 mm.

However, many applications require depths

only several hundredths of a millimeter.

Mechanics and Chemistry of CHM

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Along with penetration into the work, etching also

occurs sideways under the maskant.

The effect is referred to as the undercut, and

it must be accounted for in the design of the

mask.

the undercut is directly related to the depth of cut.

etch factor:

Mechanics and Chemistry of CHM

Chemical-Machining

Figure 27.3 (a) Schematic illustration of the chemical-machining process. Note that no forces or machine

tools are involved in this process. (b) Stages in producing a profiled cavity by chemical machining; note the

undercut.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

It is used largely to remove material from aircraft

wing and fuselage panels for weight reduction.

applicable to large parts where substantial metal

is removed.

surface finish varies with different work materials.

Surface finish depends on depth of penetration.

As depth increases, finish becomes worse,

Metallurgical damage from chemical milling is

very small, perhaps around 0.005 mm into the

work surface.

The cut and peel maskant method is employed

Chemical Milling

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Chemical Milling

FIGURE 26.16

Sequence of processing steps in chemical milling: (1) clean raw part, (2) apply

maskant, (3) scribe, cut, and peel the maskant from areas to be etched, (4) etch,

and (5) remove maskant and clean to yield finished part.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Chemical Milling

Chemical Milling

Figure 27.2 (a) Missile skin-panel section contoured by chemical milling to improve the stiffness-to-weight ratio

of the part. (b) Weight reduction of space-launch vehicles by the chemical milling of aluminum-alloy plates.

These panels are chemically milled after the plates first have been formed into shape by a process such as roll

forming or stretch forming. The design of the chemically machined rib patterns can be modified readily at minimal

cost.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

It uses chemical erosion to cut

very thin sheetmetal partsdown to 0.025 mm

thick and/or

for intricate cutting patterns.

In both instances, conventional punch-and-die

methods do not work because

the stamping forces damage the sheet metal,

the tooling cost would be prohibitive, or

both.

It produces burr free parts.

Maximum stock thickness is around 0.75 mm.

Also, hardened and brittle materials can be

processed.

Chemical Blanking

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Chemical Blanking

FIGURE 26.17

Sequence of processing steps in chemical milling: (1) clean raw part, (2) apply

maskant, (3) scribe, cut, and peel the maskant from areas to be etched, (4)

etch, and (5) remove maskant and clean to yield finished part.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Maskant is applied either by the photoresist

method or the screen resist method.

Tolerances as close as 0.0025 mm can be held

on 0.025mm thick stock

As stock thickness increases, more generous

tolerances must be allowed.

Because chemical etching takes place on both

sides, it is important that the masking procedure

provides accurate registration between the two

sides.

Otherwise, the erosion into the part from

opposite directions will not line up.

This is especially critical with small part sizes and

intricate patterns.

Chemical Blanking

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

FIGURE 26.18 Parts made by chemical blanking. (Courtesy of Buckbee-

Mears, St.Paul.)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

It is a chemical machining process for making

name plates and other flat panels that have

lettering and/or artwork on one side.

It can be used to make either recessed lettering

or raised lettering.

Masking is done by either the photoresist or

screen resist methods.

Chemical Engraving

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Chemical machining in which the photoresist

method is used.

The term can be applied correctly to chemical

blanking and chemical engraving when these

photographic resist method.

employed in metalworking when close tolerances

and/or intricate patterns are required.

These processes are also used extensively in

the electronics industry to produce intricate circuit

designs on semi-conductor wafers.

the term etch factor here correspond to

anisotropy,

defined as the depth of cut d divided by the

undercut

Photochemical Machining (PCM)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

Photochemical Machining (PCM)

FIGURE 26.19

Sequence of processing steps in photochemical machining: (1) clean raw part; (2) apply resist (maskant) by dipping, spraying,

or painting; (3) place negative on resist; (4) expose to ultraviolet light; (5) develop to remove resist from areas to be etched; (6)

etch (shown partially etched); (7) etch (completed); (8) remove resist and clean to yield nished part.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

There are various ways to photographic exposure

The figure shows the negative in contact with the

surface of the resist during exposure.

This is contact printing,

but other methods expose the negative through a

lens system to enlarge or reduce the size of the

pattern printed on the resist surface.

Photoresist materials in current use are sensitive

to ultraviolet light but not to light of other

wavelengths.

Therefore, no need to carry out the processing

steps in dark

Photochemical Machining (PCM)

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

APPLICATION CONSIDERATIONS

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

APPLICATION CONSIDERATIONS

A, Good application;

B, fair application,

C, poor application;

D, not applicable; and

blank entries indicate no data available during compilation.

2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e

APPLICATION CONSIDERATIONS

A, Excellent;

B, good,

C, fair,

D, poor.

Potrebbero piacerti anche

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocumento40 pagineMachining Processes Used To Produce Round Shapes: Turning and Hole MakingSaurabh ChoudhariNessuna valutazione finora

- On TweelDocumento21 pagineOn TweelRaju UpparapellyNessuna valutazione finora

- Bhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429Documento51 pagineBhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429PreethamBAsaravalliMohanNessuna valutazione finora

- Couplings PDFDocumento34 pagineCouplings PDFAhmed El-Shafei100% (1)

- Bearing For Cement Industry - NDocumento20 pagineBearing For Cement Industry - NAjanta Bearing100% (1)

- SKF PriceDocumento156 pagineSKF Priceparesh singhalNessuna valutazione finora

- Screw Conveyor O&M ManualDocumento20 pagineScrew Conveyor O&M Manualjay b100% (1)

- Vibration IsolationDocumento7 pagineVibration IsolationSyed AkramNessuna valutazione finora

- Minimac - ProfileDocumento40 pagineMinimac - ProfileAnshuman AgrawalNessuna valutazione finora

- Elements OF Technology: BearingsDocumento12 pagineElements OF Technology: BearingsRAHUL16398100% (1)

- Abrasive ProcessesDocumento63 pagineAbrasive ProcessesmohdhmNessuna valutazione finora

- Design and Fabrication of Hammering and Grinding Machine-1Documento16 pagineDesign and Fabrication of Hammering and Grinding Machine-1Viswaragavan.NNessuna valutazione finora

- Radial Shaft Seals ManualDocumento68 pagineRadial Shaft Seals ManualPieter van der WaltNessuna valutazione finora

- Predictive Maintenance in Paper IndustryDocumento14 paginePredictive Maintenance in Paper IndustryInfiniteUptimeNessuna valutazione finora

- ME 551 - 08 Flexures (Rev. 1.1)Documento15 pagineME 551 - 08 Flexures (Rev. 1.1)Vishal PawarNessuna valutazione finora

- Pulveriseren Atriton PDFDocumento8 paginePulveriseren Atriton PDFAntonNessuna valutazione finora

- Process Monitoring in GrindingDocumento47 pagineProcess Monitoring in GrindingBhargav ParsaNessuna valutazione finora

- CPS Vayeron Smart-Idler - Case StudyDocumento13 pagineCPS Vayeron Smart-Idler - Case StudyAshok RaoNessuna valutazione finora

- CH 13Documento102 pagineCH 13Alex BjNessuna valutazione finora

- ThesisDocumento248 pagineThesisrussell_mahmood100% (1)

- Presentación Equipo 2Documento62 paginePresentación Equipo 2Ruben Lopez RicoNessuna valutazione finora

- The - Role - of - Vibration - Monitoring - Schaeffler (UK) - (2009) PDFDocumento20 pagineThe - Role - of - Vibration - Monitoring - Schaeffler (UK) - (2009) PDFjuanarcos_778612Nessuna valutazione finora

- Design and Fabrication of Abbtasive Belt Grinding Attachment For LatheDocumento3 pagineDesign and Fabrication of Abbtasive Belt Grinding Attachment For LathePrashant BachhavNessuna valutazione finora

- Design GuideDocumento68 pagineDesign GuiderdsrajNessuna valutazione finora

- Analysis and Design of Air-Jet Pumps For Pneumatic TransportationDocumento302 pagineAnalysis and Design of Air-Jet Pumps For Pneumatic TransportationMusheer BashaNessuna valutazione finora

- PresentationDocumento36 paginePresentationsdNessuna valutazione finora

- Gears: by Aknath MishraDocumento20 pagineGears: by Aknath Mishrasamurai7_77Nessuna valutazione finora

- Belt Drive: Prof. H. D. Mhatre 1Documento22 pagineBelt Drive: Prof. H. D. Mhatre 1PHOOL KUMAR PATELNessuna valutazione finora

- Belt ConveyorsDocumento10 pagineBelt ConveyorsRaja PalasaNessuna valutazione finora

- Pulveriseren Atriton PDFDocumento8 paginePulveriseren Atriton PDFEmre AfacanNessuna valutazione finora

- Belt Cleaner: Head PulleyDocumento7 pagineBelt Cleaner: Head PulleyAgung Pandega PutraNessuna valutazione finora

- 2nd UnitDocumento60 pagine2nd UnitPradeepvenugopalNessuna valutazione finora

- Selection of MotorsDocumento51 pagineSelection of MotorsGohar GujjarNessuna valutazione finora

- Mahindra Gears Transmiision Training ReportDocumento32 pagineMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- E - 7403-9000 - Table of ContentsDocumento4 pagineE - 7403-9000 - Table of Contentsraobabar21Nessuna valutazione finora

- RepairDocumento4 pagineRepairaaa2175Nessuna valutazione finora

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFDocumento9 pagineFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresNessuna valutazione finora

- Conveyor Belting - Manual For Mechanical EngineersDocumento70 pagineConveyor Belting - Manual For Mechanical Engineersmzarei_1982Nessuna valutazione finora

- Gravity ConveyorsDocumento49 pagineGravity ConveyorsAdriel Aron DiazNessuna valutazione finora

- Plasma Oxy Fuel: Metal CuttingDocumento20 paginePlasma Oxy Fuel: Metal CuttingRIDHAMNessuna valutazione finora

- Recommended FitsDocumento10 pagineRecommended FitsZiad AkmalNessuna valutazione finora

- SpringDocumento30 pagineSpringlin_meckylogiNessuna valutazione finora

- Triz40princ - Part 1Documento46 pagineTriz40princ - Part 1Students MAHDUM AFDHA SAKHINessuna valutazione finora

- 5) Bearing Fundamentals PDFDocumento123 pagine5) Bearing Fundamentals PDFRizal Gunawan100% (1)

- Types of GearsDocumento22 pagineTypes of GearsAnonymous 2RbW9dNessuna valutazione finora

- Operating Principle of Diesel and Petrol EnginesDocumento8 pagineOperating Principle of Diesel and Petrol EnginesJonathan MalamulaNessuna valutazione finora

- Laser Bending PresentationDocumento109 pagineLaser Bending PresentationVivek SharmaNessuna valutazione finora

- SMC Air Unit Catalog - นิวเมติกDocumento15 pagineSMC Air Unit Catalog - นิวเมติกmon012100% (1)

- Du Dub PDFDocumento55 pagineDu Dub PDFSURESH100% (1)

- 4 Dtic: Reliability and Life Prediction Methodology M60 Torsion BarsDocumento60 pagine4 Dtic: Reliability and Life Prediction Methodology M60 Torsion BarsTabiXh AahilNessuna valutazione finora

- Design Exploration - Judd KaiserDocumento30 pagineDesign Exploration - Judd KaiserSangbum KimNessuna valutazione finora

- ANSYS 18.2 Mechanical Products UpdateDocumento112 pagineANSYS 18.2 Mechanical Products UpdateAnonymous hprsT3WlP100% (1)

- Rootcause Failure AnalysisDocumento3 pagineRootcause Failure Analysiskannan25% (4)

- Jurusan Teknik Mesin Universitas Diponegoro 2011Documento27 pagineJurusan Teknik Mesin Universitas Diponegoro 2011BaraSeptianKusumandanaNessuna valutazione finora

- OKS Katalog 84 en 1712 ViewDocumento84 pagineOKS Katalog 84 en 1712 ViewmadhanacdcNessuna valutazione finora

- Bearing TypesDocumento7 pagineBearing TypesMaintenance Circle100% (1)

- CH-5, Advanced (Nano-Traditional) Machining ProcessDocumento22 pagineCH-5, Advanced (Nano-Traditional) Machining ProcessAbreham DerejeNessuna valutazione finora

- Chapter 1 - 012010Documento93 pagineChapter 1 - 012010muhamadsaidiNessuna valutazione finora

- Chemical Machining ProcessesDocumento2 pagineChemical Machining ProcessesMuhammadHamzaNessuna valutazione finora

- Manufacturing LectureDocumento35 pagineManufacturing Lecturemohtram1037Nessuna valutazione finora

- Manufacturing LectureDocumento44 pagineManufacturing Lecturemohtram1037Nessuna valutazione finora

- Manufacturing LectureDocumento22 pagineManufacturing Lecturemohtram1037Nessuna valutazione finora

- Manufacturing LectureDocumento43 pagineManufacturing Lecturemohtram1037Nessuna valutazione finora

- Manufacturing LectureDocumento25 pagineManufacturing Lecturemohtram1037Nessuna valutazione finora

- Manufacturing Technology - I ME 303Documento105 pagineManufacturing Technology - I ME 303mohtram1037100% (1)

- Manufacturing LectureDocumento149 pagineManufacturing Lecturemohtram1037Nessuna valutazione finora

- Geometrical Dimensioning & Tolerancing: Based On The ASME Y14.5M - 1994 Dimensioning and Tolerancing StandardDocumento86 pagineGeometrical Dimensioning & Tolerancing: Based On The ASME Y14.5M - 1994 Dimensioning and Tolerancing Standardmohtram1037100% (4)

- C-4, Homemade C-4 - Ragnar Benson - Paladin PressDocumento28 pagineC-4, Homemade C-4 - Ragnar Benson - Paladin Pressalwaysalone83% (52)

- Explosives EngineeringDocumento476 pagineExplosives Engineeringl209100% (4)

- Guerilla's Arsenal - David Harber - Paladin PressDocumento82 pagineGuerilla's Arsenal - David Harber - Paladin PressAntiFascistMilitant89% (19)

- How To Make PCBs With A Laser PrinterDocumento11 pagineHow To Make PCBs With A Laser PrinterYacullsNessuna valutazione finora

- Macroetching Metals and Alloys: Standard Test Method ForDocumento11 pagineMacroetching Metals and Alloys: Standard Test Method ForMaxNessuna valutazione finora

- Etching and Pedal Finishing Tutorial!: 1. Warnings!Documento18 pagineEtching and Pedal Finishing Tutorial!: 1. Warnings!Jesse BélangerNessuna valutazione finora

- L1 Microstructure ExaminationDocumento5 pagineL1 Microstructure ExaminationDarshan ShaarmaNessuna valutazione finora

- New Microsoft PowerPoint PresentationDocumento158 pagineNew Microsoft PowerPoint PresentationSutapa Roy100% (1)

- Chapter 27 Advanced Machining Processes1Documento37 pagineChapter 27 Advanced Machining Processes1vaniNessuna valutazione finora

- JSS 52300-1992 PDFDocumento68 pagineJSS 52300-1992 PDFNaga Prasad100% (2)

- Corrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F (360°C) or in Steam at 750°F (400°C)Documento8 pagineCorrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F (360°C) or in Steam at 750°F (400°C)Partth VachhaniNessuna valutazione finora

- Broco Catalogue 110214Documento6 pagineBroco Catalogue 110214Admiiral PramadyaNessuna valutazione finora

- ACList 20180808Documento3 pagineACList 20180808mahmood750Nessuna valutazione finora

- BS Iso 4386-3-2018Documento18 pagineBS Iso 4386-3-2018ismaelarchilacastilloNessuna valutazione finora

- MultiCore FlowDocumento48 pagineMultiCore FlowPoy ParinphornNessuna valutazione finora

- Ab2 Naval Standard PDFDocumento52 pagineAb2 Naval Standard PDFSSFPLNessuna valutazione finora

- Principles of AdhesionDocumento44 paginePrinciples of AdhesionOmar Hesham SalahNessuna valutazione finora

- 304 Chromic Acid AnodizingDocumento6 pagine304 Chromic Acid AnodizingPuguh Cahpordjo BaeNessuna valutazione finora

- Sur Tec 650Documento17 pagineSur Tec 650donhan91Nessuna valutazione finora

- DJJ 3123 Expriment 1Documento6 pagineDJJ 3123 Expriment 1Apet GriffinNessuna valutazione finora

- How To Paint Lines On A Concrete Floor1 PDFDocumento12 pagineHow To Paint Lines On A Concrete Floor1 PDFdang2172014100% (1)

- Astm E340 2015 PDFDocumento11 pagineAstm E340 2015 PDFnantha kumar100% (1)

- Bright Dip Manual PDFDocumento47 pagineBright Dip Manual PDFCicero Gomes de Souza100% (1)

- 1 in General: Marking of Parts Fitted On Iveco Products General RequirementsDocumento4 pagine1 in General: Marking of Parts Fitted On Iveco Products General RequirementsRafa Lopez PuigdollersNessuna valutazione finora

- Exp 2 - MSMDocumento4 pagineExp 2 - MSMAmratPatelNessuna valutazione finora

- Non-Traditional MachiningDocumento48 pagineNon-Traditional MachiningSyedZameerNessuna valutazione finora

- Thermal Science and Engineering ProgressDocumento10 pagineThermal Science and Engineering ProgressAmirNessuna valutazione finora

- Section 6. Corrosion Removal ProceduresDocumento3 pagineSection 6. Corrosion Removal ProceduresblackhawkNessuna valutazione finora

- Unconventional Machining ProcessDocumento39 pagineUnconventional Machining Processuday bavandla100% (1)

- Cmci Cmci: High Performance Epoxy Grout SystemDocumento2 pagineCmci Cmci: High Performance Epoxy Grout Systempravi3434Nessuna valutazione finora

- Photochemical MachiningDocumento15 paginePhotochemical MachiningHeineken Ya Praneetpongrung0% (1)

- HW 8 Non Traditional Machining Ch26Documento2 pagineHW 8 Non Traditional Machining Ch26BobNessuna valutazione finora

- Damascus NotesDocumento13 pagineDamascus NotesuchoaNessuna valutazione finora