Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Just in Time: Operational Systems For Manufacturing JIT and Lean Production

Caricato da

Ronald De Castro0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

70 visualizzazioni27 pagineJIT

Titolo originale

1.JIT Solution

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoJIT

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

70 visualizzazioni27 pagineJust in Time: Operational Systems For Manufacturing JIT and Lean Production

Caricato da

Ronald De CastroJIT

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 27

JUST IN TIME

Operational Systems for

Manufacturing JIT and Lean

Production

Informal review

Work on this during

class today. Thanks

for your inputs

As a Manufacturing Leader...

You will play a

critical role in the

management and

control of the

companies critical

information.

The Problem of

Manufacturing

Getting the right material and physical

resources together at the right place

and at the right time to meet the

customers requirements.

Desired features, On time delivery, High

Quality, at the best price

Breaking down the problem

Getting the material

needed

Having enough

inventory of material

to support

production

Not having too

much inventory and

extra costs

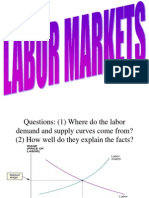

ROP

E

O

Q

time

I

n

v

e

n

t

o

r

y

lead

time

demand

(constant rate)

Economic Order Quantity and Reorder Point Planning Model

saw tooth pattern

A very limited model

Manufacturing and CIM

Systems

Where the action is!

Background reading

JUST IN TIME:

Only what is needed, nothing

more...

To have only the right materials, parts

and products in the

right place at the right time.

THE SEVEN WASTES

from Shigeo Shingo in Robert W. Halls book

Attaining Manufacturing Excellence, 1987

Waste of over production

Waste of waiting

Waste of transportation

Waste of processing itself

Waste of stocks

Waste of motion

Waste of making defective products

Claims for JIT:

reduced inventory

reduced WIP

shorter lead times

not too early, not to late...

JIT is the result businesses want,

not a starting point

What happens with JIT

Eliminate non-value added activities

less time spent and less money spent...

Involve your suppliers and customers

eliminate duplications, non value addded activ.

Shorter Set-up time and less WIP

Faster through-put, less time, higher quality

JIT Action Areas

Develop people - increase

skills,productivity, morale

Eliminate waste in all areas

Optimize materials handling and production

flow

Control Tooling

Increase quality

Improve continuously!

Develop the pipeline

flow... then work to

shorten it!

Eliminate multiple locations

Contract the plant layout

Eliminate the "pipeline failures"

Reliability

Quality

People

Reduce "changeover times and lot sizes"

significantly

Use "mind technology" before applying high

technology!

Arvin Cell with 6 operators

Bend Pipe and

trim inlet end

Heat and form

inlet end

Size and

inspect/test

flange and product

assembly

Weld flange

brackets and

assembly

Dimension check

and leak test

Traditional Production Line 6 people

First pass work cell design 3 people

Second try work cell design 1 person

Floor Space

Reduction

nearly 50%

Documented savings

Customer rejects reduced 95%

Scrap reduced 62%

Work in process reduced 91%

Changeover time reduced by 78%

Labor cost as % of sales reduced 41%

The Name Game

JIT

Short Cycle Mfg.

Toyota Production

System

Synchronous Mfg.

Lean Manufacturing

Lean Production

Common Sense Mfg.

The Vision of Lean in the USA

Perhaps best stated by

James Womack, and

Daniel Jones in two

popular books

First

The Machine That Changed

the World (1990)

Unlocking the power of Lean

requires more than just

tools:

James Womack, and

Daniel Jones second

book

Lean Thinking (1996)

Lean Thinking presents

An Americanized view of lean production

Precisely specifying value by product

Identifying the value stream for each product

Making the value-creating steps flow without

interruptions

Letting the customer pull value from the

producer

Pursuing perfection (continuously improving)

Lean Production Challenges

Developing beyond the tools

Inculcating the concepts and values

of lean production into the fabric of an

organization

Working to truly improve continuously

Expanding lean efforts out to your

customers and to all your suppliers

Lean Production can lead to

lots of open questions

Thanks for your attention

Potrebbero piacerti anche

- Lean ClassDocumento425 pagineLean ClassElena Montero CarrascoNessuna valutazione finora

- Lean Manufacturing Just-In-TimeDocumento26 pagineLean Manufacturing Just-In-TimeTạ Ngọc HuyNessuna valutazione finora

- Lean Manufacturing - Group PresentationDocumento41 pagineLean Manufacturing - Group PresentationXMBA 24 ITM VashiNessuna valutazione finora

- Manufacturing: By: Arsalan NajmiDocumento35 pagineManufacturing: By: Arsalan NajmiMuhammad Naveed IkramNessuna valutazione finora

- Lean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Documento35 pagineLean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Vineeta KanwalNessuna valutazione finora

- KAIZENDocumento74 pagineKAIZENKaushik Biswas100% (2)

- Lean ManufacturingDocumento90 pagineLean ManufacturingSasa TesijaNessuna valutazione finora

- Lean Project 1Documento14 pagineLean Project 1Siddharth SinghNessuna valutazione finora

- Just-in-Time and Lean Systems: Operations Management R. Dan Reid & Nada R. SanderDocumento33 pagineJust-in-Time and Lean Systems: Operations Management R. Dan Reid & Nada R. Sandertamilselvan nNessuna valutazione finora

- Lean OverviewDocumento23 pagineLean OverviewSanjib BiswasNessuna valutazione finora

- Leanu3apresentation 1Documento54 pagineLeanu3apresentation 1Tato FloresNessuna valutazione finora

- Chapter 1 Introduction To Lean ManufacturingDocumento37 pagineChapter 1 Introduction To Lean Manufacturingelin chanNessuna valutazione finora

- An OverviewDocumento37 pagineAn OverviewRahmat UllahNessuna valutazione finora

- Agile & Lean ManufacturingDocumento39 pagineAgile & Lean ManufacturingHassan Aziz100% (1)

- Jit MbaDocumento24 pagineJit MbaAnkit Pasahan100% (1)

- Lean Manufacturing and It's Implementation in Automotive IndustryDocumento48 pagineLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshNessuna valutazione finora

- Basics of LeanDocumento22 pagineBasics of LeanWarren RiveraNessuna valutazione finora

- Facility PlanningDocumento34 pagineFacility Planningsashi99100% (1)

- Kaizen PDFDocumento74 pagineKaizen PDFKaushik BiswasNessuna valutazione finora

- Lean Manufacturing 2017Documento15 pagineLean Manufacturing 2017Relu CosteaNessuna valutazione finora

- Lean Supply ChainDocumento45 pagineLean Supply ChainHenra HalimNessuna valutazione finora

- Analisis de Procesos: Administracion de La ProduccionDocumento59 pagineAnalisis de Procesos: Administracion de La ProduccionCamilo Collao GómezNessuna valutazione finora

- Stores ManagementDocumento45 pagineStores Managementgurudarshan67% (3)

- T3.lean Manufacturing - Part IDocumento42 pagineT3.lean Manufacturing - Part IAl AidenNessuna valutazione finora

- Lean Manufacturing Just in TimeDocumento28 pagineLean Manufacturing Just in TimePam G.Nessuna valutazione finora

- Lean Manufacturing Just-In-TimeDocumento26 pagineLean Manufacturing Just-In-TimeNARENDER SINGHNessuna valutazione finora

- Lean Manufacturing and It's Implementation in Automotive IndustryDocumento48 pagineLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshNessuna valutazione finora

- Pull System, JITDocumento12 paginePull System, JIThendmeNessuna valutazione finora

- Introduction To Lean Manufacturing: Achieving World-Class Organizational ResultsDocumento75 pagineIntroduction To Lean Manufacturing: Achieving World-Class Organizational ResultsAshokNessuna valutazione finora

- Lean Management Chapter 1Documento33 pagineLean Management Chapter 1Diya DuttaNessuna valutazione finora

- 08 Lean OperationsDocumento16 pagine08 Lean OperationsAshwin MathewNessuna valutazione finora

- Operations ManagementDocumento39 pagineOperations ManagementShilpi JainNessuna valutazione finora

- Lean Six Sigma HistoryDocumento43 pagineLean Six Sigma HistoryPedro Boanerges Paz Romero0% (1)

- Lean Manufacturing Just-In-TimeDocumento26 pagineLean Manufacturing Just-In-TimeDeepakBharathiNessuna valutazione finora

- Operations ManagementjjjDocumento29 pagineOperations ManagementjjjHarish AgarwalNessuna valutazione finora

- GBE KPO 2 001 00 Lean Basics 1Documento75 pagineGBE KPO 2 001 00 Lean Basics 1hondacarNessuna valutazione finora

- 4.GSI 2022 - The Automobile Industry - BDocumento36 pagine4.GSI 2022 - The Automobile Industry - Bw4kprtrn9vNessuna valutazione finora

- TQM - Principles and Principles - JITDocumento17 pagineTQM - Principles and Principles - JITRinju DuttNessuna valutazione finora

- Just in Time ReluDocumento16 pagineJust in Time ReluRelu CosteaNessuna valutazione finora

- Lean PresentationDocumento82 pagineLean PresentationEkasuthan RastaNessuna valutazione finora

- Chapter 7 - Operations ManagementDocumento31 pagineChapter 7 - Operations ManagementMaryjanedbn DlaminiNessuna valutazione finora

- Lean Manufacturing & VSMDocumento131 pagineLean Manufacturing & VSMRa Balamurugan100% (1)

- BMFP 3423 Lean P1 - Dec2022Documento31 pagineBMFP 3423 Lean P1 - Dec2022Idham NasrulNessuna valutazione finora

- Glovia Lean ManufacturingDocumento16 pagineGlovia Lean ManufacturingALEJANDRANessuna valutazione finora

- (2012.04.28) Principles of Lean Six Sigma 2012Documento88 pagine(2012.04.28) Principles of Lean Six Sigma 2012JeanNessuna valutazione finora

- 5 Herramientas Lean ManufacturingDocumento22 pagine5 Herramientas Lean ManufacturingJose Morataya Barrios100% (1)

- KaizenDocumento40 pagineKaizenAshish KulkarniNessuna valutazione finora

- Lean Manufacturing OverviewDocumento29 pagineLean Manufacturing OverviewKrunalNessuna valutazione finora

- Concept of Lean Manufacturing For Supervisor and Middle ManagemntDocumento25 pagineConcept of Lean Manufacturing For Supervisor and Middle ManagemntAdnan HameedNessuna valutazione finora

- A Presentation On Lean ShipbuildingDocumento32 pagineA Presentation On Lean ShipbuildingAndre BlueNessuna valutazione finora

- Time Compression TechnologiesDocumento28 pagineTime Compression TechnologiesAmit BedareNessuna valutazione finora

- Session V, Two RevolutionsDocumento27 pagineSession V, Two RevolutionsrehanroxNessuna valutazione finora

- 5.3 Lean Production and Quality MNGDocumento71 pagine5.3 Lean Production and Quality MNGfm017225Nessuna valutazione finora

- Supply Chain and Inventory Management Seminar Paper Presented ToDocumento17 pagineSupply Chain and Inventory Management Seminar Paper Presented Toankitjain1104Nessuna valutazione finora

- Lean ManufacturingDocumento20 pagineLean ManufacturingPranav SharmaNessuna valutazione finora

- Toyota Inventory ManagementDocumento26 pagineToyota Inventory ManagementHarshGarbyal63% (16)

- What The Heck You Should Know About Quality Engineering?Da EverandWhat The Heck You Should Know About Quality Engineering?Nessuna valutazione finora

- Application of Lean in Non-manufacturing Environments - Series Books 18 to 19: Toyota Production System ConceptsDa EverandApplication of Lean in Non-manufacturing Environments - Series Books 18 to 19: Toyota Production System ConceptsNessuna valutazione finora

- Kanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryDa EverandKanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryValutazione: 5 su 5 stelle5/5 (1)

- Lecture11 (Ch12)Documento22 pagineLecture11 (Ch12)Ronald De CastroNessuna valutazione finora

- Chapter21 Solutions Hansen6eDocumento24 pagineChapter21 Solutions Hansen6eMauricio Rodriguez PeraltillaNessuna valutazione finora

- JITfinalDocumento32 pagineJITfinalRonald De CastroNessuna valutazione finora

- White Light Corporation Vs City of Manila DigestDocumento1 paginaWhite Light Corporation Vs City of Manila Digestcess5655Nessuna valutazione finora

- Affidavit of Loss SampleDocumento1 paginaAffidavit of Loss SampleDranreb AgurrabNessuna valutazione finora

- Chapter 12Documento35 pagineChapter 12Ronald De CastroNessuna valutazione finora

- Just-in-Time and Lean Systems: Operations Management R. Dan Reid & Nada R. SandersDocumento37 pagineJust-in-Time and Lean Systems: Operations Management R. Dan Reid & Nada R. SandersAshok DargarNessuna valutazione finora

- White Ligth Corp. vs. City of ManilaDocumento15 pagineWhite Ligth Corp. vs. City of ManilaGeorgette V. SalinasNessuna valutazione finora

- Knowledge, Perception and Attitude of Community Pharmacists Towards Generic Medicines in Karachi, Pakistan: A Qualitative InsightDocumento7 pagineKnowledge, Perception and Attitude of Community Pharmacists Towards Generic Medicines in Karachi, Pakistan: A Qualitative InsightRonald De CastroNessuna valutazione finora

- Just-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaDocumento24 pagineJust-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaRonald De CastroNessuna valutazione finora

- MCN 2Documento15 pagineMCN 2Ronald De CastroNessuna valutazione finora

- Funda 1Documento19 pagineFunda 1Ronald De CastroNessuna valutazione finora

- Chapt 014 ENTREPDocumento25 pagineChapt 014 ENTREPRonald De CastroNessuna valutazione finora

- Crossword Puzzle: Cross DownDocumento3 pagineCrossword Puzzle: Cross DownRonald De CastroNessuna valutazione finora

- Chap 013Documento25 pagineChap 013Sadaf IftikharNessuna valutazione finora

- Sections, Parts and ChaptersDocumento3 pagineSections, Parts and ChaptersRonald De CastroNessuna valutazione finora

- Passport, Application FormDocumento1 paginaPassport, Application Formmjdc_12Nessuna valutazione finora

- Passport, Application FormDocumento1 paginaPassport, Application Formmjdc_12Nessuna valutazione finora

- Food Wastage ManagementDocumento3 pagineFood Wastage ManagementUnagar Shifa HasanNessuna valutazione finora

- 07 Electrical SymbolsDocumento4 pagine07 Electrical SymbolsNad EemNessuna valutazione finora

- Study and Partial Replacement of Fine Material (Sand) in Concrete Use of Silica SandDocumento11 pagineStudy and Partial Replacement of Fine Material (Sand) in Concrete Use of Silica Sandshivanand hippargaNessuna valutazione finora

- En Scroll Replacement Guidelines 0Documento10 pagineEn Scroll Replacement Guidelines 0Ferdie FernandezNessuna valutazione finora

- Planetary NetworksDocumento2 paginePlanetary NetworksNiñabeth David100% (1)

- Solid Waste Management Opportunities Challenges GujaratDocumento14 pagineSolid Waste Management Opportunities Challenges GujaratRahul Kumar AwadeNessuna valutazione finora

- Cold Forming of Metals SafetyDocumento19 pagineCold Forming of Metals SafetyHari KoneruNessuna valutazione finora

- 5070 MSDSDocumento5 pagine5070 MSDSAhmed Emad AhmedNessuna valutazione finora

- Indesit IWC 6105Documento72 pagineIndesit IWC 6105Carlos Garcia GarciaNessuna valutazione finora

- 2 Ingles, Week 19, 20, 21 Project 3Documento4 pagine2 Ingles, Week 19, 20, 21 Project 3Kuri AlvaradoNessuna valutazione finora

- Applications of Value EngineeringDocumento6 pagineApplications of Value EngineeringJohn Ray CuevasNessuna valutazione finora

- Clarifiers & ThickenersDocumento8 pagineClarifiers & ThickenersSuhas JadhavNessuna valutazione finora

- World of Darkness - Three Shades of NightDocumento290 pagineWorld of Darkness - Three Shades of NightBilly Mott86% (7)

- Instructions For Use: AR4W07PDocumento18 pagineInstructions For Use: AR4W07Pnoxy58Nessuna valutazione finora

- Electronic Waste 1 1Documento12 pagineElectronic Waste 1 1Harsha vardhanNessuna valutazione finora

- Bag TechniqueDocumento23 pagineBag TechniqueMamta Rajput83% (12)

- Soal Lus 2021 - Bahasa Inggris - Paket 1Documento20 pagineSoal Lus 2021 - Bahasa Inggris - Paket 1AmbariCaesarNessuna valutazione finora

- Apurva KhedagiDocumento5 pagineApurva KhedagiScott KhamphouneNessuna valutazione finora

- 01.03.07 Specification For Combustion Gas TR 3017 - enDocumento16 pagine01.03.07 Specification For Combustion Gas TR 3017 - enCandiano PopescuNessuna valutazione finora

- 58MoM SEACDocumento186 pagine58MoM SEACamoNessuna valutazione finora

- New 8Documento3 pagineNew 8Punit BedmuthaNessuna valutazione finora

- Water and Waste Management SystemDocumento7 pagineWater and Waste Management SystemRhoselle Mae GenandaNessuna valutazione finora

- Industrial ChemistryDocumento5 pagineIndustrial ChemistryMuhammad Adnan100% (1)

- Event Sustainability Management SystemsDocumento24 pagineEvent Sustainability Management SystemsIbnu HassanNessuna valutazione finora

- 1science5 Week 1Documento12 pagine1science5 Week 1Annie LouNessuna valutazione finora

- Slaughter House by Eluru Municipality, ELR (1) - 221029 - 174130Documento4 pagineSlaughter House by Eluru Municipality, ELR (1) - 221029 - 174130Rao GNessuna valutazione finora

- Biomanagement of Distillery Solid Waste Using Earthworm Eudrilus Eugeniae 169 172Documento4 pagineBiomanagement of Distillery Solid Waste Using Earthworm Eudrilus Eugeniae 169 172ARAVIND K N 2020 ME EENessuna valutazione finora

- Design of 50 KG/HR Controlled-Air Hospital Waste IncineratorDocumento14 pagineDesign of 50 KG/HR Controlled-Air Hospital Waste IncineratorMargaret DaughertyNessuna valutazione finora

- 196 - Water Unit 6 Waste Water TreatmentDocumento19 pagine196 - Water Unit 6 Waste Water TreatmentAbdullah MofarrahNessuna valutazione finora

- World Environment DayDocumento3 pagineWorld Environment DaySomya MishraNessuna valutazione finora