Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sheet Metal Repair

Caricato da

Chirag DaveCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sheet Metal Repair

Caricato da

Chirag DaveCopyright:

Formati disponibili

1st Year Apprenticeship

Metal Work

In this block you will learn about:

Metals and their properties

Deformation effects after impact

Tools used for effective repair

Stretching and shrinking

Paintless dent removal

Body Steels

Hot rolled

thickness ranges 2-8

mm

generally used for

full frames, sub

frames (unibody)

and crossmembers

Cold rolled

hot rolled, acid

rinsed, cold rolled

thin, then annealed

better surface quality

good workability

most unibody panels

are cold rolled steel

stamping process

increases strength

Cold Rolling Mill to Stampings

Grain Structures of Steel

HSLA

Mild Steel

Properties of Steel

Mild Steel

HSS

HSLA

UHSS

AHSS

up to 30,000 psi yield strength

30 - 70,000 psi yield strength

75 - 100,000 psi yield strength

100- 160,000 psi yield strength

110 180,000 psi yield strength

HSS

Gets its initial strength

during the

heating/cooling

treatment from the

steel manufacturer

Is used mainly for load

bearing components in

the body structure,

however more

commonplace today

throughout entire body

structure

May be repaired cold or

with controlled heat

More difficult to repair

than mild steel

Yield strength of up to

70,000 psi.

Lack of available

identification for HSS

means treat all steel as

HSS!

HSLA

Like HSS except varying

alloying elements

(chemicals) are added

during the

manufacturing process

to increase its strength

(yield and tensile)

May be reworked cold

or with controlled heat

application

Found in areas such as:

Door intrusion beams

Bumper reinforcements

Lock pillars

Front and rear frame rails

Hinge pillars (A,B,C)

Yield strength up to

110,000 psi.

UHSS/AHSS

The strongest of the

structural steels found

in today's automobiles

Often referred to as

Boron, Martensitic, Dual

phase steels

Found in these areas:

Front and rear bumper

reinforcements

intrusion beams

A,B,C pillars (some

vehicles)

No heat whatsoever

is to be applied to

any component of

this designation!

These steels are

generally not repairable

Require special

considerations when

removing/sectioning

Identification of Steels

Location and application of HSS steels vary

widely from manufacturer to manufacturer

Sources of information include:

OEM body repair manuals

Internet sources (OEM approved)

Mitchell manuals (estimating manuals)

If you cannot positively identify the makeup

of a component, you must treat it as HSS!

HSS Locations

Part Loading

Tension:

a load that tries to pull parts straight apart

Compression

a load that forces parts straight into one another

Shear

A load that pulls sideways

Cleavage

a load that pulls parts away from each other at an angle

Peel

a load that pulls parts straight away from one another

Loads present during a

collision

Terminology

Yield strength:

The minimum amount of force any piece of metal

can resist without bending or deforming

permanently

Yield Point:

The amount of force that a piece of

metal can resist without tearing or breaking

Tensile strength

is measured as the maximum force per unit of

area that causes a complete fracture of break

Terminology

Work Hardening

Is the upper limit of plastic deformation, causing

the metal to become hard in the bent area

Malleability

is the property which allows deformation under

compression or upsetting (shrinking)

Elasticity

is the ability of the metal to be bent or stretched

and spring back to its original shape

Terminology

Plasticity:

The property that permits metal to change shape

when sufficient force is applied to it

Plastic Deformation:

The ability of the metal to be bent or formed into

different shapes ( bent beyond its elastic limit)

Elastic Deformation:

The ability of the metal to be stretched or bent

and return to its original state

Terminology

Torsional strength

is the property of a material to withstand a

twisting force

Shear Strength

is a measure of how well a material can

withstand forces acting to cut or slice it apart

Compressive Strength

is the property of a material to withstand being

crushed

Metal Strength Terminology

Elastic Deformation Plastic Deformation

Terminology

Rigidity:

Opposite of plasticity.

example: Cast iron will not bend or deform, it will only

break under load

Ductility:

ability of a metal to plastically deform without

breaking or fracturing, with the cohesion between

the molecules remaining sufficient to hold them

together

Heat and Sheet Metal

The point at which Steel melts is 2600

Degrees F

We should know the effects of the

temperature change between 400 - 1600

degrees F.

Three Effects:

scaling

changes in grain structure

expansion and contraction

Temperature and Colour Change

Light film of scale (iron oxide) 430 F

Pale yellow / Straw / Brown / Purple / Light Blue

Dark Blue / 600 degrees F

Reddish Glow / 900 degrees F

Blood Red / Dark Cherry 1200 F

Cherry Red 1550 degrees F

Critical Point 1600 degrees F

Low Crown

High Crown

Reverse Crown

Buckles

Buckles occur when metal has been bent past

its elastic limit

Work hardening has occurred and a new

shape is formed

The buckles found in indirect damage are as

follows:

simple hinge

collapsed hinge

simple rolled

collapsed rolled

Direct and Indirect Damage

Impact effect on a High Crown

Effect of damage on a Low Crown Panel

Effect of impact on a combination High / Low

Crowned Panel

Tension can only be removed by unlocking the

pressure areas

Combination of Buckles

simple

hinge

buckle

two types

of rolled

buckles

Collapsed hinge

buckle

Steps in Unlocking Damage

First in last out

Collapsed Roll Buckle

What happens to the Steel upon impact?

In this case, the damage (Hinged Buckle) has

caused severe damage to the molecular structure

Hammering helps the atoms to vibrate back

into shape, or order

Tools

Hammers

Dollies

Spoons

Dent pullers

Body picks

Oxy-Acetylene

Body files

Body Hammers

Hammers

Holding the Body

Hammer

Dollies

Holding the Dolly

Using the Corner of the Dolly

Using the Edge of the Dolly

Using the Dolly as

a tool for bumping

Spoons

Uses of the Body Spoon

Can be used as a

dolly in hard to reach

areas

When used with

due care, can be

used for leverage

Great tool for

dispersing the force

of a hammer blow

Body Picks

Body Puller Set

(Slide Hammer)

Pull Rods

Other Body Working Tools

Pry Bars

Suction Cups

Stud Welders

Porta-spot Dent Pullers

Body Files

Slap Files

Hydraulic Porta-Power

Dent Removal Tools

Dent Removal Systems

Hammer Maintenance

Depending on the

condition of your

hammer, several

steps may need to

be taken to restore

the mirror finish

to the surface on

the face of the

hammer.

From filing to

wet sanding and

polishing.

Locating Damage

Visually

Physically

Mechanically

Use your sense

of sight and the

reflection of a

light source as a

means of damage

identification

If a visual reference

is not possible, feeling

for damage will be

more than satisfactory

Mechanical Methods

Hammer and Dolly

Variables:

Force of hammer blow

Force of Dolly rebound

Shape of Dolly

Working distance

Hammer on Dolly

Hammer off Dolly

Metal Fundamentals

Properties of steel

Working the metal

Heat Shrinking

Detecting an Oil Can or stretched area

Time to Shrink!

Shrinking

Shrinking Procedure

- Hold torch

at right angle

to panel

- heat metal

to desired

degree

- place dolly

behind area

to be shrunk

- hammer area

from centre out

- quench

immediately with

wet sponge

Cold Shrinking

Using a Carbon Rod for heat shrinking

Repair Plan

Determine the extent of

the damage

Removal of moulding,

emblems, or sound

deadening materials

from behind panels

Roughing out dents

with hammer, puller, or

pry bar

Metal finishing with

hammer, dolly and

body file

Panel shrinking

Removal of small

dents and bulges

Filling with body filler

Filing, sanding, and

priming the fill area

Rustproofing the back

side of panels

Completion of repairs

End of Metal Repair Fundamentals

Potrebbero piacerti anche

- The Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)Documento69 pagineThe Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)wulfgang2498100% (11)

- Sheet Metal Handbook PDFDocumento127 pagineSheet Metal Handbook PDFcat6313100% (3)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- A Beginners Guide To Paintless Dent RepairDocumento16 pagineA Beginners Guide To Paintless Dent Repairpapipapii100% (5)

- 2884-Panel Beating PDFDocumento1 pagina2884-Panel Beating PDFsyllavethyjim100% (1)

- Car Spray PaintingDocumento16 pagineCar Spray PaintingFabricio100% (2)

- DIY Wooden Guitar Stand With Basic Power Tools - Woodwork JunkieDocumento7 pagineDIY Wooden Guitar Stand With Basic Power Tools - Woodwork JunkieJosé Luis Rodríguez VargasNessuna valutazione finora

- Sheet MetalDocumento75 pagineSheet MetalVenkata ChakradharNessuna valutazione finora

- Build A 10 Ton Hydraulic PressDocumento10 pagineBuild A 10 Ton Hydraulic PressManuel SterlingNessuna valutazione finora

- Car Body Painting ProcessDocumento19 pagineCar Body Painting ProcessPritam Patnaik100% (1)

- Sheetmetal FabricationDocumento18 pagineSheetmetal FabricationSumeet Saini100% (1)

- AutomotiveDocumento259 pagineAutomotiveNavasca RandeeNessuna valutazione finora

- Sheet Metal FormingDocumento16 pagineSheet Metal FormingSabur Mythin Abdul AzeesNessuna valutazione finora

- Sheet Metal Guide (Mate)Documento72 pagineSheet Metal Guide (Mate)aushad3m100% (5)

- Paint Defect Troubleshooting Guide PDFDocumento16 paginePaint Defect Troubleshooting Guide PDFRavi KhoseNessuna valutazione finora

- How To Build A Fuel LineDocumento15 pagineHow To Build A Fuel LineMech EngrNessuna valutazione finora

- Sheet Metal Stamping in Automotive Industry IgnoreDocumento48 pagineSheet Metal Stamping in Automotive Industry IgnoreSalil GhateNessuna valutazione finora

- CHAPTER-3 Body Working ToolsDocumento10 pagineCHAPTER-3 Body Working ToolsAmanuelNessuna valutazione finora

- Chopper Jig-Plans PDFDocumento10 pagineChopper Jig-Plans PDFMphilipTNessuna valutazione finora

- 03 Welding Imperfections 29-11-03Documento17 pagine03 Welding Imperfections 29-11-03bizhanjNessuna valutazione finora

- AutomotivePlasticPart Design PDFDocumento5 pagineAutomotivePlasticPart Design PDFVinothkumargkNessuna valutazione finora

- IC Learning Series 2013 - Sheet Metal FabricationDocumento19 pagineIC Learning Series 2013 - Sheet Metal FabricationnskumarmNessuna valutazione finora

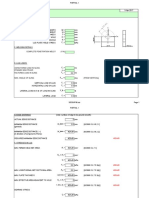

- Fabrication Formulas - SheetMetal PDFDocumento4 pagineFabrication Formulas - SheetMetal PDFsunilbhol85% (20)

- Milling MachineDocumento47 pagineMilling MachineCt Costales DangaranNessuna valutazione finora

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarDa EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarNessuna valutazione finora

- Lifting Lug Design B 01Documento22 pagineLifting Lug Design B 01bakellyNessuna valutazione finora

- Design and Build An English WheelDocumento18 pagineDesign and Build An English WheelWita100% (1)

- Tempering SteelDocumento28 pagineTempering SteelMartin OngNessuna valutazione finora

- Media Blasting & Metal Preparation: A Complete GuideDa EverandMedia Blasting & Metal Preparation: A Complete GuideValutazione: 4.5 su 5 stelle4.5/5 (10)

- Injection MoldingDocumento45 pagineInjection MoldingJagdeep SinghNessuna valutazione finora

- Manufacturing Technology - MachiningDocumento61 pagineManufacturing Technology - Machiningviverefelice100% (1)

- Understanding Metal Stamping - Design To Prototyping To ProductionDocumento11 pagineUnderstanding Metal Stamping - Design To Prototyping To ProductionRAKHEE RICHHARIA100% (2)

- Crossing the Line Baja 1000: What Secrets Starts as Fortune Might Cost Him His LifeDa EverandCrossing the Line Baja 1000: What Secrets Starts as Fortune Might Cost Him His LifeNessuna valutazione finora

- Red Wing Steel Works 5x8 Utility Trailer Plans 01022015 PDFDocumento32 pagineRed Wing Steel Works 5x8 Utility Trailer Plans 01022015 PDFpiper1234Nessuna valutazione finora

- Using Sheet Metal Bodies in SOLIDWORKS Simulation: Model CreationDocumento6 pagineUsing Sheet Metal Bodies in SOLIDWORKS Simulation: Model CreationBlashko GjorgjievNessuna valutazione finora

- Metalman Product Catalogue PDFDocumento8 pagineMetalman Product Catalogue PDFwilly0366Nessuna valutazione finora

- WP - FDM - Metal Forming - 0420aDocumento8 pagineWP - FDM - Metal Forming - 0420aBAF BafConsultingNessuna valutazione finora

- Sheet Metal OperationsDocumento3 pagineSheet Metal OperationsDineshNessuna valutazione finora

- A Multi-Link Suspension System PDFDocumento8 pagineA Multi-Link Suspension System PDFmikael bezerra cotias dos santos0% (1)

- Dog Tag/ Key ChainDocumento13 pagineDog Tag/ Key ChainAidan O'HaraNessuna valutazione finora

- WHEELINGDocumento57 pagineWHEELINGEcone666Nessuna valutazione finora

- Automotive Painting Processes - Today and Tomorrow - Dr. Michael Hilt, Fraunhofer Institute, Germany PDFDocumento21 pagineAutomotive Painting Processes - Today and Tomorrow - Dr. Michael Hilt, Fraunhofer Institute, Germany PDFfatahkaryadiNessuna valutazione finora

- How To Make Springs Web in PDFDocumento191 pagineHow To Make Springs Web in PDFEng-JR100% (3)

- Workbook: Your CL Assi C Car Rest Orat I OnDocumento10 pagineWorkbook: Your CL Assi C Car Rest Orat I OnMarcelo Araujo RodriguesNessuna valutazione finora

- PLANS Lamborghini CountachDocumento33 paginePLANS Lamborghini CountachRichard NevilleNessuna valutazione finora

- 12 - Sheet Metalworking (Chapter 16)Documento51 pagine12 - Sheet Metalworking (Chapter 16)Taher al suhamiNessuna valutazione finora

- Sheet Metal FabricationDocumento70 pagineSheet Metal Fabricationnjsoffice33% (6)

- Painting Automotive Plastics PartsDocumento16 paginePainting Automotive Plastics Partsraj100% (2)

- Sheet Metal Forming ProcessesDocumento34 pagineSheet Metal Forming ProcessesIzi100% (12)

- As 1720.1-1988 PDFDocumento87 pagineAs 1720.1-1988 PDFIvan LiewNessuna valutazione finora

- Detailers Dictionary Volume 2: The Industry StandardDa EverandDetailers Dictionary Volume 2: The Industry StandardNessuna valutazione finora

- SolidWorks 2018 Learn by doing - Part 2: Surface Design, Mold Tools, WeldmentsDa EverandSolidWorks 2018 Learn by doing - Part 2: Surface Design, Mold Tools, WeldmentsValutazione: 2 su 5 stelle2/5 (1)

- Sheet Metal Stamping 101 - Art HedrickDocumento18 pagineSheet Metal Stamping 101 - Art Hedricktrollforge100% (1)

- Automotive Body Painting NC IIIDocumento82 pagineAutomotive Body Painting NC IIIHonrada-Remoto JunrielNessuna valutazione finora

- Vintage Speed Parts: The Equipment That Fueled the IndustryDa EverandVintage Speed Parts: The Equipment That Fueled the IndustryNessuna valutazione finora

- Basic Knowledge of Sheet MetalDocumento36 pagineBasic Knowledge of Sheet MetalHemang Shah33% (3)

- Designing of Stamping DiesDocumento28 pagineDesigning of Stamping DiesSumeshKrishnanNessuna valutazione finora

- Metal Properties and Destructive TestingDocumento84 pagineMetal Properties and Destructive Testingtuvu100% (3)

- Corrosion ResistanceDocumento482 pagineCorrosion ResistanceJosé Ramírez100% (1)

- Sifat Dan Pengujian RefraktoriDocumento28 pagineSifat Dan Pengujian RefraktoriAnggi ApriansyahNessuna valutazione finora

- Automobile Body Materials Trim and MechanicsDocumento8 pagineAutomobile Body Materials Trim and MechanicsHarshdeepsinh Padhiyar100% (1)

- Girder Fork Renovation Tech TalkDocumento4 pagineGirder Fork Renovation Tech TalkBimal Amarnath Menon100% (1)

- Speeds and Feeds - Wikipedia, The Free EncyclopediaDocumento10 pagineSpeeds and Feeds - Wikipedia, The Free EncyclopediarajeshjvarmaNessuna valutazione finora

- Chevy High Performance - January 2020 USA PDFDocumento76 pagineChevy High Performance - January 2020 USA PDFErc3Nessuna valutazione finora

- EscortsDocumento2 pagineEscortspratikNessuna valutazione finora

- SE - ML - 109 - GSM Based Digital Notice Board With Display On GLCD DisplayDocumento1 paginaSE - ML - 109 - GSM Based Digital Notice Board With Display On GLCD DisplayChirag DaveNessuna valutazione finora

- TESTPAPERSANDSYLLABUSFORBINSACHIVALAYCLERKDocumento15 pagineTESTPAPERSANDSYLLABUSFORBINSACHIVALAYCLERKSamir DesaiNessuna valutazione finora

- SE - ML - 111 - Phase Irrigation Motor Monitoring & Auto-Controlling Based OnDocumento1 paginaSE - ML - 111 - Phase Irrigation Motor Monitoring & Auto-Controlling Based OnChirag DaveNessuna valutazione finora

- SE - ML - 108 - Micro Controller To Ethernet InterfaceDocumento1 paginaSE - ML - 108 - Micro Controller To Ethernet InterfaceChirag DaveNessuna valutazione finora

- SE - ML - 106 Hybrid RFID-GPS-Based Terminal System in VehicularDocumento1 paginaSE - ML - 106 Hybrid RFID-GPS-Based Terminal System in VehicularChirag DaveNessuna valutazione finora

- SE ML 107 U.S.B. Connectivity To MicrocontrollerDocumento1 paginaSE ML 107 U.S.B. Connectivity To MicrocontrollerChirag DaveNessuna valutazione finora

- Se - ML - 100 Temperature and Humidity Control System Using Graphical LCD and ArmDocumento1 paginaSe - ML - 100 Temperature and Humidity Control System Using Graphical LCD and ArmChirag DaveNessuna valutazione finora

- Uttam ProjectDocumento18 pagineUttam ProjectChirag DaveNessuna valutazione finora

- Se - ML - 103 - Pic Based Remote Temperature Controller With EthernetDocumento1 paginaSe - ML - 103 - Pic Based Remote Temperature Controller With EthernetChirag DaveNessuna valutazione finora

- SE - GP - 106 Embedded and GSM Based Vehicle Tracing SystemDocumento1 paginaSE - GP - 106 Embedded and GSM Based Vehicle Tracing SystemChirag DaveNessuna valutazione finora

- Se - ML - 101 - Internet Based Home Automation System Using ArmDocumento1 paginaSe - ML - 101 - Internet Based Home Automation System Using ArmChirag DaveNessuna valutazione finora

- Estestofreasoningsolvede Book666pages3rdeditionDocumento666 pagineEstestofreasoningsolvede Book666pages3rdeditionChirag DaveNessuna valutazione finora

- SE - GP - 101 Virtual Distance Measuring Tape With GPS & Graphical LCDDocumento1 paginaSE - GP - 101 Virtual Distance Measuring Tape With GPS & Graphical LCDChirag DaveNessuna valutazione finora

- SE - GP - 104 GPS and GSM Based Office Cab Monitoring, Alerting and Logging SystemDocumento1 paginaSE - GP - 104 GPS and GSM Based Office Cab Monitoring, Alerting and Logging SystemChirag DaveNessuna valutazione finora

- Arch15 Chapter 15Documento47 pagineArch15 Chapter 15Chirag DaveNessuna valutazione finora

- SE - GP - 100 GPS Based Train Location Tracking System With SMS FacilityDocumento1 paginaSE - GP - 100 GPS Based Train Location Tracking System With SMS FacilityChirag DaveNessuna valutazione finora

- Daikin FCQG - F - Thin Body Round Flow Cassette 950 X 950Documento32 pagineDaikin FCQG - F - Thin Body Round Flow Cassette 950 X 950PrestoneKNessuna valutazione finora

- Columns and StrutsDocumento10 pagineColumns and StrutsamitsagaNessuna valutazione finora

- GE Panle BoardDocumento52 pagineGE Panle Boardchandrakanth0083396Nessuna valutazione finora

- Interview Questions 1 TCSDocumento3 pagineInterview Questions 1 TCSSrinivas TumpalaNessuna valutazione finora

- 16 ConstructionDocumento28 pagine16 Constructionalcibiades romeroNessuna valutazione finora

- C Staehle Kalt Datenblatt EN 1511Documento7 pagineC Staehle Kalt Datenblatt EN 1511pierocarnelociNessuna valutazione finora

- Gi Conduit LayingDocumento5 pagineGi Conduit LayingPrasad PanchatsaramNessuna valutazione finora

- Split Type Air Conditioner Ceiling Type (60Hz) : Indoor Unit Outdoor UnitDocumento11 pagineSplit Type Air Conditioner Ceiling Type (60Hz) : Indoor Unit Outdoor UnitThiago FrazãoNessuna valutazione finora

- IP Rating HagerDocumento20 pagineIP Rating Hagervinesh_viswanathan_3Nessuna valutazione finora

- Kovan Grandeur BrochureDocumento14 pagineKovan Grandeur BrochureMax KohNessuna valutazione finora

- Dev. 9-Garden and Landscape.: DescriptionDocumento9 pagineDev. 9-Garden and Landscape.: DescriptionrafabdNessuna valutazione finora

- Mep ManualDocumento108 pagineMep ManualNiyas TkNessuna valutazione finora

- Effect of Slag, NaturalDocumento10 pagineEffect of Slag, Naturaljklo12Nessuna valutazione finora

- JL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Documento20 pagineJL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Dong-Yong KimNessuna valutazione finora

- Alloy Steel Pipe Price List IndonesiaDocumento14 pagineAlloy Steel Pipe Price List Indonesiaiandegs2010Nessuna valutazione finora

- 7th - Building & ArchitectureDocumento9 pagine7th - Building & ArchitectureRamchandra YadavNessuna valutazione finora

- Swimming Pool Heat PumpDocumento2 pagineSwimming Pool Heat PumpMohammed ErshadNessuna valutazione finora

- Premium Wall Mounted SeriesDocumento5 paginePremium Wall Mounted SeriesjohnNessuna valutazione finora

- Polystone P Homopolymer: Technical Data SheetDocumento1 paginaPolystone P Homopolymer: Technical Data Sheetmuchamad yasinNessuna valutazione finora

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Documento1 paginaA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Vivek MishraNessuna valutazione finora

- Thermal ComfortDocumento25 pagineThermal Comfortshahzadali0786Nessuna valutazione finora

- PRIMOTECH - Solar Water HeaterDocumento14 paginePRIMOTECH - Solar Water HeaterPrimotech EnergyNessuna valutazione finora

- Api 579 Asme Ffs Sell Sheet 1 PDFDocumento6 pagineApi 579 Asme Ffs Sell Sheet 1 PDFNelson AlvarezNessuna valutazione finora

- Versatility & Durability: Engineered Liquid Level SolutionsDocumento12 pagineVersatility & Durability: Engineered Liquid Level SolutionsnovriNessuna valutazione finora