Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Product Knowledge Essar Metals

Caricato da

Naresh Narula0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni20 pagineCold Rolling is a process by which hot rolled strip or stock is introduced between rollers and then squeezed or compressed to the desired thickness. Pickling is done to remove scales and oxide layers present on the surface of hot rolled steel Make the steel surface suitable for Cold Rolling. If a steel surface is too hard for cold rolling, it may not be suitable for forming or bending.

Descrizione originale:

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCold Rolling is a process by which hot rolled strip or stock is introduced between rollers and then squeezed or compressed to the desired thickness. Pickling is done to remove scales and oxide layers present on the surface of hot rolled steel Make the steel surface suitable for Cold Rolling. If a steel surface is too hard for cold rolling, it may not be suitable for forming or bending.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni20 pagineProduct Knowledge Essar Metals

Caricato da

Naresh NarulaCold Rolling is a process by which hot rolled strip or stock is introduced between rollers and then squeezed or compressed to the desired thickness. Pickling is done to remove scales and oxide layers present on the surface of hot rolled steel Make the steel surface suitable for Cold Rolling. If a steel surface is too hard for cold rolling, it may not be suitable for forming or bending.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 20

PRODUCT KNOWLEDGE

An Introduction of Iron Making and Steel Making

Process Flow Diagram

Cold Rolled Steels

Introduction to Cold Rolling

Processing of CRCA and Essar Steel

Capability

Properties and Surface Characteristics of Cold Rolled Steel (CRCA)

Defects in Cold Rolled Steel

Applications of CRCA

Cold Rolled Steels

What is Cold Rolling ?

process by which hot rolled strip or stock is introduced between rollers

and then squeezed or compressed to the desired thickness

Amount of strain introduced determines the properties of the finished

product

Cold Rolled Steel

Introduction to Cold Rolling

Cold Rolled Steels

Why is Cold Rolling done ?

Good Formability

Superior Surface Finish

Reasonable Strength

Cold Rolled Steels

Commonly used Grades of Cold Rolled Steel

D/DD - Drawing/Deep Drawing Simple forming/bending

applications

EDD - Extra Deep Drawing Deep Drawn components

IF - Interstitial Free Critical Draw and Stretch

Components in terms of

geometry of the component,

type and depth of draw and

press parameters

Cold Rolled Steels

Chemical Composition Typical Ranges

%C %M

n

%Si %S %P %Al N,

ppm

%Ti %Nb

D/DD 0.05 0.3 0.02 0.01 0 0.05 70

EDD </=.04 0.2 0.02 0.01 0 0.03 50

IF 0.003 0.2 0.015 0.01 0 0.04 40 0.06 0.01

Cold Rolled Steels

Process flow of Cold Rolled Steel

Pickling (to remove oxides

and scales)

Cold Rolling in reversing or

tandem mill to desired

thickness

Annealing (batch or

continuous)for stress

relieving

Skin passing to remove Luder lines,

develop mech prop,impart desired

surface finish improve flatness

Inspection,

Finishing

Dispatch

Cold Rolled Steels

Pickling

Why is Pickling done ?

To remove scales and oxide layers present on the surface of hot rolled

steel

Make the steel surface suitable for cold rolling

Scales and oxide layers are harder than steel and hence hinder

the process of cold rolling of low carbon steel .

Cold Rolled Steels

Pickling

Hows scale and oxide removal are achieved?

Hot rolled strip is passed through tanks containing

hydrochloric acid wherein the acid dissolves the

oxide layer

The strip is then rinsed with water to remove any

excess acid. dried and the strip is ready for cold

rolling

Cold Rolled Steels

Cold Rolling

Hot rolled Pickled Coils are reduced to the desired thickness

Achieved either in;

Reversing Cold Rolling Mills : Thickness achieved by

repeated passes through the

same rolling stand back and

forth

or

Tandem Cold Rolling Mills : Thickness achieved through

series of rolling stands in

tandem

Cold Rolled Steels

Annealing

Why annealing is done?

Steel Coils are hard and brittle after Cold Rolling

Has Elongated grain Structure

Not suitable for end use

Cold Rolled Steels

Skin Passing

Why is Skin Passing Done ?

To remove Yield point by supplying load

To prevent occurrence of stretcher strains in annealed steel

To impart desired surface finish - matte on the strip surface

To improve strip shape

Cold Rolled Steels

Skin Passing

What are Stretcher Strains?

Generated due to the yield point phenomenon

exhibited by cold rolled and annealed low carbon

steel sheet/strip

Appears as discrete bands on the strip surface

Cold Rolled Steels

Defects in cold Rolled Steels

Surface Defects

Rolled in Scales

Left over oxides formed during hot rolling

Rolled into the sheet surface remaining unremoved even after pickling

Slivers

Defect mainly caused by alumina inclusions entrapped during steel

making/casting operations

Gets elongated linearly by rolling

Leads to cracking/failure during drawing operation

Cold Rolled Steels

Defects in cold Rolled Steels

Surface Defects

Roll Marks

Defect transferred to the strip from the rolls

Appears at regular intervals in the rolling directions

Caused due to scratches on rolls , foreign substance sticking to

rolls, metal pick up on rolls during strip breakage

Cold Rolled Steels

Defects in cold Rolled Steels

Surface Defects

Sticker Marks

Semi circular marks on the surface of the strip.

Generates due to sticking tendency of subsequent coil wraps

Sticking tendency is due to any of the following reasons

Higher tension of the coils being taken for annealing

Higher soaking time/temperature

Poor shape of the strip

Cold Rolled Steels

Application of Cold Rolled Steel (low Carbon)

Automobile components

Panels for White Goods/Appliances

Packaging (Drums ,Barrels and Containers)

Furniture

Electrical Panels

General Engineering

Cold Rolled Steels

Application of Cold Rolled Steel (low Carbon)

Exposed Component

UN-exposed Component Critical draw Components

Potrebbero piacerti anche

- Tecnical Data Crupe PDFDocumento23 pagineTecnical Data Crupe PDFNaresh NarulaNessuna valutazione finora

- Architects in FaridabadDocumento2 pagineArchitects in FaridabadNaresh Narula100% (1)

- Power2SME Proposal KBLDocumento24 paginePower2SME Proposal KBLNaresh Narula0% (1)

- Power2SME Proposal 21st May 2014Documento27 paginePower2SME Proposal 21st May 2014Naresh NarulaNessuna valutazione finora

- Banc AssuranceDocumento11 pagineBanc AssurancerishikeshpandeyNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- C Exam13Documento4 pagineC Exam13gauravsoni1991Nessuna valutazione finora

- WassiDocumento12 pagineWassiwaseem0808Nessuna valutazione finora

- Master of Commerce: 1 YearDocumento8 pagineMaster of Commerce: 1 YearAston Rahul PintoNessuna valutazione finora

- Robocon 2010 ReportDocumento46 pagineRobocon 2010 ReportDebal Saha100% (1)

- General Separator 1636422026Documento55 pagineGeneral Separator 1636422026mohamed abdelazizNessuna valutazione finora

- Benjie Reyes SbarDocumento6 pagineBenjie Reyes Sbarnoronisa talusobNessuna valutazione finora

- Emergency Room Delivery RecordDocumento7 pagineEmergency Room Delivery RecordMariel VillamorNessuna valutazione finora

- Vehicle Registration Renewal Form DetailsDocumento1 paginaVehicle Registration Renewal Form Detailsabe lincolnNessuna valutazione finora

- Digital Communication Quantization OverviewDocumento5 pagineDigital Communication Quantization OverviewNiharika KorukondaNessuna valutazione finora

- Lecture 1 Family PlanningDocumento84 pagineLecture 1 Family PlanningAlfie Adam Ramillano100% (4)

- 2002, Vol.86, Issues 4, Hospital MedicineDocumento221 pagine2002, Vol.86, Issues 4, Hospital MedicineFaisal H RanaNessuna valutazione finora

- Username: Password:: 4193 Votes 9 Days OldDocumento6 pagineUsername: Password:: 4193 Votes 9 Days OldΘώμηΜπουμπαρηNessuna valutazione finora

- Reservoir Rock TypingDocumento56 pagineReservoir Rock TypingAffan HasanNessuna valutazione finora

- Cinema 4D ShortcutsDocumento8 pagineCinema 4D ShortcutsAnonymous 0lRguGNessuna valutazione finora

- Standard Deviation IntroductionDocumento3 pagineStandard Deviation IntroductionShyam ShresthaNessuna valutazione finora

- Doe v. Myspace, Inc. Et Al - Document No. 37Documento2 pagineDoe v. Myspace, Inc. Et Al - Document No. 37Justia.comNessuna valutazione finora

- Jazan Refinery and Terminal ProjectDocumento3 pagineJazan Refinery and Terminal ProjectkhsaeedNessuna valutazione finora

- Tender34 MSSDSDocumento76 pagineTender34 MSSDSAjay SinghNessuna valutazione finora

- Environment ManagerDocumento234 pagineEnvironment ManagerAbhishek kumarNessuna valutazione finora

- Steps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersDocumento5 pagineSteps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersruhelanikNessuna valutazione finora

- Reflection Paper #1 - Introduction To Action ResearchDocumento1 paginaReflection Paper #1 - Introduction To Action Researchronan.villagonzaloNessuna valutazione finora

- Weekly Choice - Section B - February 16, 2012Documento10 pagineWeekly Choice - Section B - February 16, 2012Baragrey DaveNessuna valutazione finora

- Measuring Renilla Luciferase Luminescence in Living CellsDocumento5 pagineMeasuring Renilla Luciferase Luminescence in Living CellsMoritz ListNessuna valutazione finora

- Ramdump Memshare GPS 2019-04-01 09-39-17 PropsDocumento11 pagineRamdump Memshare GPS 2019-04-01 09-39-17 PropsArdillaNessuna valutazione finora

- Numerical Methods: Jeffrey R. ChasnovDocumento60 pagineNumerical Methods: Jeffrey R. Chasnov2120 sanika GaikwadNessuna valutazione finora

- Self Team Assessment Form - Revised 5-2-20Documento6 pagineSelf Team Assessment Form - Revised 5-2-20api-630312626Nessuna valutazione finora

- The Online Medical Booking Store Project ReportDocumento4 pagineThe Online Medical Booking Store Project Reportharshal chogle100% (2)

- Easa Ad Us-2017-09-04 1Documento7 pagineEasa Ad Us-2017-09-04 1Jose Miguel Atehortua ArenasNessuna valutazione finora

- Planview Innovation Management Maturity Model PDFDocumento1 paginaPlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaNessuna valutazione finora

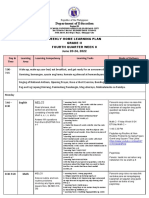

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Documento8 pagineDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIONessuna valutazione finora