Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.

Caricato da

NaniTalluriTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.

Caricato da

NaniTalluriCopyright:

Formati disponibili

How to Build a Hovercraft

October 2004

2

Patrick Wenzell

How to Build a Hovercraft

A Cobb County

Technology-Based Integration School

Special Thanks to

Mr. Joe Baker @

Dickerson Middle

School for the idea

October 2004

3

Patrick Wenzell

Primary Steps & Materials

Make Circular Platform

Work from Center to:

Drill holes per plan

Add riser for seating

Mount seating

Mount blower

Attach envelope

Duct Tape Edges

Cut & Attach Envelope

Paint as you wish

Required Materials:

4x4 Plywood

6x6 8mil Plastic

2x2 Plywood

12 Diameter Particle Bd.

1 x 3/8 Carriage Bolt/Nut

2 wood screws

Coffee Lid

Lots of Duct Tape

Sandpaper/Sanding Block

Paint

October 2004

4

Patrick Wenzell

Tape Measure

Tri-Square

Utility Knife

Chalk Line

Sandpaper/Block

and MATH SKILLS

Tools Required

Jig Saw

Circular Saw

String

Drill & Bits & Screws

Staple Gun & Staples

Paintbrush & guides

October 2004

5

Patrick Wenzell

Experimental Hovercraft

Goal:

Understand textual plans

Convert into a project plan

Manufacture components

Assemble components

Fine tune craft

Test and experiment

Create interactive experiments

What I learned:

How to outline a step by step plan

How to layout the plan on wood

How to use certain tools

How to make jigs to guide tools

How to troubleshoot problems

Not to get all my friends over to

see it work BEFORE I test it first

October 2004

6

Patrick Wenzell

Project Plan

Step 1

a. cut a 2 section of string (with a little extra).

b. tie the string to a pencil and the other to a tack or nail.

c. place the tack/nail in the center of the board.

d. keeping the string tight, draw a circle.

Step 2

a. cut a circle with a jigsaw.

Step 3

a. measure the diameter of your vacuums hose and drill the hole size accordingly.

b. drill a hole using the 1 or appropriately sized bit approximately 1 foot from the center of the hover craft.

Step 4

a. sand the edge of the disk on the top and bottom.

b. tape around the disk.

Step 5

a. drill a 11/4 hole in the center of the plywood for attaching the plastic skirt

b. cut the plastic sheet into a 54 x 54 square and lay it out on plywood disk

c. the carriage bolt washer coffee lid apparatus will be used to hold the plastic sheet to the plywood disk.

d. Poke small hole in the center of the plastic sheet.

e. Reinforce the hole with duct tape and then pass the bolt through the plastic sheet and bolt securely to the ply wood disk

October 2004

7

Patrick Wenzell

Project Plan (continued)

Step 6

a. trim the plastic sheet into a circle a little bit larger than the ply wood disk.

b. The plastic should be cut approximately 2 inches larger than the disk all the way around

Step 7

a. looking down on the hovercraft plastic side up draw 3 x3 squares on the plastic approximately 1 ft from

the center with 120-degree angles between each square.

b. The holes should not be directly above the hole where the shop vac will be attached

c. Space the shop vac hole between two of the square holes .

d. Use scissiors to cut

Step 8

a. over lap the plastic onto the opposite side of the ply wood disk leaving some play in the plastic .

b. staple the plastic to the ply wood on the top all the way around the disk leaving about 11/4 gap between

staples.

Step 9

a. wrap duct tape at least 2 times around the edges for protection.

Step 10

a. place chair centered on ply wood disk.

b. Place the shop vac or any blowing device (leaf blower/ air blower for air track behind the chair.

c. Connect the hose of the vacuum to blow the orifice and attach the other end of the hose to the hole on the

hovercraft.

October 2004

8

Patrick Wenzell

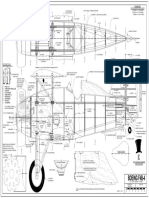

The Hovercraft Drawings

October 2004

9

Patrick Wenzell

Layout Circle on 4x4 Plywood

Find center of square

Tie pencil to nail in center of square

Adjust string to desired radius

2 = of diameter = 4 : 2*r = d

Draw Circle

Go ahead and layout:

Label Front/Back

Blower intake

Vent locations 120

o,

1 from center

At least 1 from Blower Intake

2 rear, 1 front

Lift Vents

Blower Intake

Center Point

120

o

120

o

120

o

BACK

FRONT

October 2004

10

Patrick Wenzell

Build a Jig to Guide Saw

Notch the end of a board to fit lip on

guide of saw

Drill hole to set blade at 2 from center

Hint, on a 4x4 square, center is exactly

2 from perpendicular sides

Nail to center of 4x4 sheet

Note: Safety Goggles & Mask

are required for protection!!!

October 2004

11

Patrick Wenzell

Cut a 4 Diameter Circle

Start at the edge

Slowly and evenly cut

the circle using the guide

Repeat to make even

October 2004

12

Patrick Wenzell

Smooth and Tape the Circle Edge

Sand the edges

100 grit

Round edges to protect plastic

Apply 3 layers of duct tape

Cut about 1 sections

Apply tangentially to Top

Fold over edges

Repeat from Bottom

Final layer center around edge

and seal top and bottom

October 2004

13

Patrick Wenzell

Everything Must Fit Smoothly

Drill 3/8 hole for carriage bolt in

center of circle

Drill hole for intake slightly

smaller than the diameter of the

blower

Sand the inside of the intake hole

to widen and make a very tight fit

Insert blower attachment

October 2004

14

Patrick Wenzell

Make Template, Build & Attach Riser

Riser is 2 pieces of scrap wood

Model with cardboard, first

Layout and cut notches to

provide access to center bolt

Notch both pieces to interlock

for strength and stability

Screw in from bottom

October 2004

15

Patrick Wenzell

Center Seat on Riser

Sand Interlock between Riser

components

Must be smooth

Must be level

Center 12 Seat on Riser

Attach with Screws into the riser

Can cover seat with foam

or just paint

October 2004

16

Patrick Wenzell

Cut Plastic 2-3 Larger than Platform

Plastic provides the Envelope

to provide lift for hovering

Set the platform on plastic

Cut circle around platform

about 3 from the edge

Use scissors or utility knife

October 2004

17

Patrick Wenzell

Attach Plastic Envelope

Fold edges a couple of times for

strength

Staple every to edge

Reinforce center and perimeter of

plastic with duct tape

Puncture small hole to receive 3/8

carriage bolt

Attach Coffee Lid

Secure with coffee lid, washer & nut

October 2004

18

Patrick Wenzell

More Duct Tape

Duct tape, same as before

over the stapled plastic

Mount 100mph blower

October 2004

19

Patrick Wenzell

Cut Holes for Lift Factor

Place platform upside down

Center plastic over platform

Draw 3 - 3 squares on the

plastic approximately 1 ft from

the center at 120-degree angles.

The holes should not be directly

above the intake hole where the

blower will be attached 1

away

Use 3 square template tied to

1 string & utility knife

October 2004

20

Patrick Wenzell

Reinforce Holes More Duct Tape

Tape edges of square cutouts

Tape front and back of edges

3 pieces of tape

Tape edge of cutout, then fold

over to reinforce inside

Especially the corners of the

cutouts

Tape Coffee Lid Washer

Around and across

October 2004

21

Patrick Wenzell

Ready for Testing & Tuning

Do Not Call Your Friends, Yet!

Two people lift platform

Another removes sawhorses

Place gently on clean floor

Test first w/o pilot

Test next w/light weight pilot

UP & DOWN ONLY!!!!!!!!!!

For now..

October 2004

22

Patrick Wenzell

Problems Encountered

Problem

Coffee can lid washer

collapsed

Blow out on side

5 lift in back, 3 in front

Bumper creates imbalance

Blow out creates imbalance

Solution

Re-attached/Re-inforced w/

Duct Tape

Patched with Duct Tape

Reduced back to 3 lift

Removed bumper

Fixed blowout with tape

October 2004

23

Patrick Wenzell

The Hardest Part of this Project was

October 2004

24

Patrick Wenzell

The Most Fun I Had With This Project was:

Potrebbero piacerti anche

- Civil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334Documento1 paginaCivil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334NaniTalluriNessuna valutazione finora

- Staad (1) Civil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334Documento1 paginaStaad (1) Civil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334NaniTalluriNessuna valutazione finora

- Instrument Profilestaad (1) Civil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334Documento3 pagineInstrument Profilestaad (1) Civil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334NaniTalluriNessuna valutazione finora

- MECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.Documento13 pagineMECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.NaniTalluriNessuna valutazione finora

- Civil InstrumInstrument Profilestaad (1) Civil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334entsDocumento2 pagineCivil InstrumInstrument Profilestaad (1) Civil Engineering Projects For Students at Mech Wind Technologies Hyderabad PH 9542878334entsNaniTalluriNessuna valutazione finora

- MECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.Documento17 pagineMECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.NaniTalluriNessuna valutazione finora

- MECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.way TrackpptDocumento13 pagineMECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.way TrackpptNaniTalluriNessuna valutazione finora

- MECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.Documento13 pagineMECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.NaniTalluriNessuna valutazione finora

- MECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.Documento23 pagineMECHANICAL LIVE PROJECTS at MECH WIND TECHNOLOGIES, HYDERABAD, PH 9542878334.NaniTalluriNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Fundamentals of Airliner Performance Part 6 The EngineDocumento9 pagineFundamentals of Airliner Performance Part 6 The EngineupsasaNessuna valutazione finora

- Ata 38 L1 Water & WasteDocumento27 pagineAta 38 L1 Water & WastejimbokhepelNessuna valutazione finora

- AirworpaDocumento96 pagineAirworpaMd. Pabel AhmedNessuna valutazione finora

- Sopwith Camel: 2 Operational HistoryDocumento11 pagineSopwith Camel: 2 Operational Historybill100% (1)

- Easa Airworthiness Directive: AD No.: 2011-0197Documento3 pagineEasa Airworthiness Directive: AD No.: 2011-0197Carlos VarrentiNessuna valutazione finora

- Condor Electric Remote COntrol AirplaneDocumento7 pagineCondor Electric Remote COntrol AirplaneedissontNessuna valutazione finora

- SL 30Documento90 pagineSL 30Eric DirksenNessuna valutazione finora

- Aviation 4Documento4 pagineAviation 4Huzaifa IftikharNessuna valutazione finora

- Smiths Aerospace: Presentation To Investors DR John FerrieDocumento20 pagineSmiths Aerospace: Presentation To Investors DR John FerriesanazhNessuna valutazione finora

- Mildtl 38999 FullcatalogDocumento36 pagineMildtl 38999 FullcatalogC S KumarNessuna valutazione finora

- CID FanDocumento2 pagineCID FanIrfan AhmedNessuna valutazione finora

- SimTecT 2010 HandbookDocumento60 pagineSimTecT 2010 HandbookLeonardo QuevedoNessuna valutazione finora

- C-Fly Obtain F803 User ManualDocumento18 pagineC-Fly Obtain F803 User Manualdwi89Nessuna valutazione finora

- Compare Specifications and Performance of Private Jet AircraftDocumento5 pagineCompare Specifications and Performance of Private Jet AircraftAnonymous TedqS0h6ZkNessuna valutazione finora

- Pacific Aerospace: CT:4 Airtrainer Updated On 12 Jan 2018 PDFDocumento4 paginePacific Aerospace: CT:4 Airtrainer Updated On 12 Jan 2018 PDFChatchai Prasertsuk100% (5)

- 121-169PM - 33-300BDocumento2 pagine121-169PM - 33-300BDanielAlejandroRamosQueroNessuna valutazione finora

- CenkoDocumento12 pagineCenkoSavio VargheseNessuna valutazione finora

- The Adventures of A Reluctant Student by Bach RichardDocumento73 pagineThe Adventures of A Reluctant Student by Bach Richardmesame semestriNessuna valutazione finora

- Sealing in TurbomachineryDocumento62 pagineSealing in Turbomachineryjparmar100% (1)

- History of The George C. Marshall Space Flight Center, 1 Jan. - 31 Dec. 1965, Volume 1Documento379 pagineHistory of The George C. Marshall Space Flight Center, 1 Jan. - 31 Dec. 1965, Volume 1Bob AndrepontNessuna valutazione finora

- DataDocumento1.278 pagineDataEsther SastraningsihNessuna valutazione finora

- Jet Engine - 1Documento21 pagineJet Engine - 1MuhammedNayeemNessuna valutazione finora

- PID For Fixed-Wing UAV PDFDocumento6 paginePID For Fixed-Wing UAV PDFMUVNNessuna valutazione finora

- Ojt ReportDocumento75 pagineOjt Reportpranav dixitNessuna valutazione finora

- CG (Initial) : Designed by Plans byDocumento1 paginaCG (Initial) : Designed by Plans byFarooq AhmadNessuna valutazione finora

- l1676 10 Type Rating Single Pilot HelicopterDocumento8 paginel1676 10 Type Rating Single Pilot HelicopterFidel ArellanoNessuna valutazione finora

- PC 21 Bi PDFDocumento58 paginePC 21 Bi PDFTheGuilioNessuna valutazione finora

- Drag Reduction by Microbubble - ShipDocumento6 pagineDrag Reduction by Microbubble - ShipKURNIAWANNessuna valutazione finora

- Stokes' Law and The Coffee Filters: A ProblemDocumento3 pagineStokes' Law and The Coffee Filters: A Problemabdul_azemiNessuna valutazione finora

- 190 00837 01 - 02Documento36 pagine190 00837 01 - 02Haroon Javed QureshiNessuna valutazione finora