Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gas Safety

Caricato da

Syed Safiur RahmanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gas Safety

Caricato da

Syed Safiur RahmanCopyright:

Formati disponibili

Gas safety

In

P&bs2

introduction

THE FATAL ACCIDENT THAT HAS OCCURRED

IN BHILAI STEEL PLANT IS AN EYE-OPENER

FOR ALL OF US. WE MUST DRAW LESSONS

FROM THE INCIDENT. THIS PRESNTATION

IS TO RE-LOOK AT OUR SYSTEM, FINDING

ANY UNSAFE POSSIBILITIES AT OUR GAS

AND RELATED WATER NETWORKS AND

TAKING MEASURES ACCORDINGLY

CO GAS U-SEAL

AND

SEAL POT

Gas composition

Constituents Unit COG BFG BOF

Mixed

Gas(BFG+BOF)

CBM

CO2 % vol 3-4 23.3 16.2 22.38 1-2

CO % vol 6-7 26.9 69.3 32.4

N2 % vol 4-7 46.2 14.5 42.1

H2 % vol 52-59 -- -- --

CH4 % vol 24-28 -- -- -- 95-97

Other gases % vol 1.5-2.5 3.6 -- 3.14 2-4

Calorific Values Kcal/Nm3 4250 914 2000 1054

8300

(NCV)

Gas properties

SN COG BFG

Source

Coke oven gas, is the gas

obtained when coal is

heated in an air tight

place

Blast furnace gas, a by-

product of blast furnaces,

is generated when the iron

ore is reduced

with coke to metallic iron

Hazardous or

Not

Categorized as

hazardous/toxic gas

Categorized as

hazardous/toxic gas

Colour Yellowish Colourless

Odour Pungent Odourless

Density

Lighter than air (0.45

times lighter).

Heavier than air

Schematic arrangement of CO GAS U-SEAL AND

drain POT & water supply lines

Salient points of our cog water seal

There are one goggle valve at the COG inlet line at PBS2.

There are 2 drain pots in COG common header.

There are total 3 U-seal one in each individual gas lines taken

from COG header.

There are one drain-pot connected to each U-seal of

individual boiler.

Color code for gas line is yellow and color code for water line

is sea green.

Our U-seal water line has been taken from ACW pump header.

Our U-seal water filling line is having U-seal to restrict back

flow of gas to water circuit in case of water pressure loss.

Backflow of gas in the drain-pot water filling line will be

restricted by drain-pot water column itself

CO GAS U-SEAL

AND

SEAL POT

CO GAS U-SEAL

1. In main gas line the effective height of

the U seal shall be 2.5 times of the

working gas pressure.

2. The effective height of gas line is

overflow point of the water pipe in gas

line to the top of the U bend in gas line.

3. Inlet water line U seal is TO BE provided

to avoid flow of gas in water line if the

pumps gets dry or water line is empty.

U-SEAL facts

CO GAS

SEAL POT

1. Drain pot is a device to collect

the Condensate accumulated in gas

pipe line.

2. It also helps in releasing the

pressure in gas pipe line if the gas

pressure becomes TOO high .

3. It works on the principal of U-

Tube manometer.

At Normal Condition P < 2000mm WC

it remains in stable condition.

When pressure rises above 2000

mm WC, then it throws out the

water from the over flow outlet.

2000

Mm

WC

P

Safety in

cable cellars

Cable galleries at P&BS2

1. below 33kV GIS room which handles 33kV

cable, 6.6kV cable, 415V cable and 220V

DC cable

2. Second below Main LT Switchgear which

handles 415V cable and 220V DC cable

Cable trenches in P&BS2

1. Near Boiler Area

2. Near DM Plant

3. Near Cooling Tower

4. Near Cooling water Pumphouse

Use CO gas sensor to measure any presence

of CO gas near cable trench before entering.

Incase of detection of CO gas, go away from

the source of CO gas; preferably to an open

area and inform control room in-charge and

plant in-charge.

Ensure no steam is coming into the

gallery/trench.

Keep someone outside the cable trench.

Keep walkie-talkie tied with you if possible.

Use 24V Lamp/Torches inside the trench.

Safety in cabale galleries & trenches

Ensure running earthing in the cable trench and the

connectivity with the earth grid. Use local earth in

the cable tray.

Use mask, gum boot, hand gloves, helmet, and

goggles.

Ensure no insects/snakes inside.

Do not use metallic material for cleaning. Use

wooden stick or bamboos.

Do not take flammable material.

Ensure both side entry of cable trenches are packed

with fire retardant boards and packing material.

Do not touch open cables if found inside and

immediately inform to the EIC.

Safety in cabale galleries & trenches

ADDITIONAL MEASURES TO BE TAKEN

THROUGH SOPS & SMPS

Always ensure overflow in the Drain-pot

and

Always ensure overflow in U-seal when U-

seal has been done for gas isolation.

Whenever the overflow is not found in a U-

seal or Drain-pot, same to be attended only

after ensuring by a gas detector that there

is no CO gas in the vicinity of U-seal or

Drain-pot.

.

ADDITIONAL MEASURES TO BE TAKEN

THROUGH SOPS & SMPS

Whenever a gas line is

isolated by U-seal for a

maintenance job, in addition

to ensuring overflow, ensure

that drain valve is closed

with tag DONT OPERATE or

preferably keep the drain

valve locked.

ADDITIONAL MEASURES TO BE TAKEN

THROUGH SOPS & SMPS

Whenever there is a total shutdown of

all ACW pumps, it is to be ensured

through a gas detector that there is no

CO gas in the CW pump house before

starting any job.

Never keep any gas vent open during

Thunderstorm.

ADDITIONAL MEASURES TO BE TAKEN

THROUGH SOPS & SMPS

Whenever a job is to be

taken inside furnace ensure

with gas detector that no CO

gas is present inside, also

ensure O2 content is 21%.

Keep a gas detector at

working place throughout the

job duration to be alert for

any seeping CO gas during

the job.

ADDITIONAL MEASURES TO BE TAKEN

THROUGH SOPS & SMPS

Whenever a job is to be

taken in a confined place like

Boiler Drum, Main Oil Tank,

LDO Storage Tank, Condenser

etc, ensure that O2% inside

is 21% before starting the

job.

ADDITIONAL MEASURES TO BE TAKEN

THROUGH SOPS & SMPS

Dont charge COG/BFG/BOF Gas

in an empty pipeline without

purging with N2 or steam.

Always ensure that Oxygen

content in the purged line is less

than 2% before admitting Gas.

ADDITIONAL MEASURES TO BE TAKEN

THROUGH SOPS & SMPS

Never allow Boiler area, cable cellars to

be used as resting place.

Never allow use of any tapping in the

water network of boiler area for

washing or drinking.

Cable cellars, Boiler area are to be

treated as restricted places with no un-

authorized entry

Summary

We have total 5 drain-pots and 3 U-seals in COG

network

Drain-pot & U-seal overflow to be ensured always

During gas isolation by a U-seal it is to be ensured

nobody opens the drain valves inadvertently.

Though we have U-seal in the water filling line we

should check the CO gas with detector at the place

of work if ACW system shutdown is taken.

We should take requisite precaution as said while

working in confined places, cable cellers etc.

We should never allow PBS2 Boiler area to be used

as resting place.

Any tapping of the water network in Boiler area

should never be used for washing or drinking

Never Always

Never fail to

anticipate

emergencies. Do not

wait until something

happens to start the

thinking process

Always study every

conceivable

emergency and plan

exactly what moves

to make.

SAFETY RULES DURING AN

EMERGENCY

Never Always

Never start to

manage

emergency without

understanding

what exactly has

happened

Always proceed to proper

valves or switches rapidly

but without confusion in

time of emergency. You

can better walking than

running.

SAFETY RULES DURING AN

EMERGENCY

Potrebbero piacerti anche

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Gas SafetyDocumento28 pagineGas SafetySyed Safiur RahmanNessuna valutazione finora

- BFG Safety How To PreventDocumento25 pagineBFG Safety How To PreventPower PowerNessuna valutazione finora

- Handout - CO2 SystemDocumento46 pagineHandout - CO2 SystemKunal BhatiaNessuna valutazione finora

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocumento14 pagineInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickNessuna valutazione finora

- Furnace Internal PressureDocumento3 pagineFurnace Internal PressureskluxNessuna valutazione finora

- MFL67584519Documento56 pagineMFL67584519Power PowerNessuna valutazione finora

- 45Kg Cylinder & Valve Assembly PN.81-100067-002Documento4 pagine45Kg Cylinder & Valve Assembly PN.81-100067-002max_powerNessuna valutazione finora

- Vacuum Techniques For Organic ChemistryDocumento30 pagineVacuum Techniques For Organic ChemistryJoe Vito Morabito100% (1)

- CFBC Refractory Dryout Along With Atmospheric Boilout FinalDocumento7 pagineCFBC Refractory Dryout Along With Atmospheric Boilout FinalpurvgargNessuna valutazione finora

- S T K SQ1: Set Up and User GuideDocumento16 pagineS T K SQ1: Set Up and User GuideschumonNessuna valutazione finora

- Internal Furnace Pressure PDFDocumento2 pagineInternal Furnace Pressure PDFfawmer61Nessuna valutazione finora

- Gas Tightness TestDocumento3 pagineGas Tightness TestRod Kenneth LubongNessuna valutazione finora

- 11 Preservation: Rabab Harweel Power PlantDocumento10 pagine11 Preservation: Rabab Harweel Power PlantPazhamalairajan KaliyaperumalNessuna valutazione finora

- KGL ManualDocumento47 pagineKGL ManualAaron Shane IrvinNessuna valutazione finora

- 1956 - Colinese - Boiler Efficiencies in SugarDocumento7 pagine1956 - Colinese - Boiler Efficiencies in SugarPaul DurkinNessuna valutazione finora

- ACME AHX Water-Cooled Condenser - 06.10 PDFDocumento3 pagineACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002Nessuna valutazione finora

- 189 010 - en 15.710057 V3.0Documento12 pagine189 010 - en 15.710057 V3.0balzac191Nessuna valutazione finora

- Boiler MountingsDocumento302 pagineBoiler MountingsJames AmirNessuna valutazione finora

- Thermax BoilerDocumento10 pagineThermax Boileramitrawal0100% (1)

- Biogas SystemsDocumento8 pagineBiogas SystemsvedpathakNessuna valutazione finora

- Knowledge Management Series-Low Vacuum in Steam Turbine PDFDocumento4 pagineKnowledge Management Series-Low Vacuum in Steam Turbine PDFMadhusudhan Pasumarty100% (1)

- Low Pressure CO2 SystemsDocumento4 pagineLow Pressure CO2 SystemsNarineNessuna valutazione finora

- Carbon Dioxide: All About CO2 Systems: Requirements, System and Procedures!Documento8 pagineCarbon Dioxide: All About CO2 Systems: Requirements, System and Procedures!IntuitionNessuna valutazione finora

- Boiler CommissioningDocumento7 pagineBoiler CommissioningDevanshu SinghNessuna valutazione finora

- The Boiler HouseDocumento9 pagineThe Boiler Housemeijon pelayerNessuna valutazione finora

- Isolation, Gas Freeing & Reinstate Procedures (PTP-8) Training Package PTP 8.2 Equipment IsolationDocumento20 pagineIsolation, Gas Freeing & Reinstate Procedures (PTP-8) Training Package PTP 8.2 Equipment IsolationJayNessuna valutazione finora

- Lessons Learned-FINAL-NEW PDFDocumento8 pagineLessons Learned-FINAL-NEW PDFImtinan MohsinNessuna valutazione finora

- 45Kg Cylinder & Valve AssemblyDocumento4 pagine45Kg Cylinder & Valve AssemblyRaju Saha100% (1)

- Iso 14224 2016 EspanolDocumento21 pagineIso 14224 2016 EspanolpicottoNessuna valutazione finora

- Steam Blowing BHELDocumento9 pagineSteam Blowing BHELdnageshm4n244100% (1)

- Boiler Q&A FurtherDocumento7 pagineBoiler Q&A FurtherRachitNessuna valutazione finora

- S. P. Thermal Systems Inc.: 4504 Green Meadow Blvd. Beamsville, Ontario L0R 1B5, CanadaDocumento8 pagineS. P. Thermal Systems Inc.: 4504 Green Meadow Blvd. Beamsville, Ontario L0R 1B5, CanadaShankar JhaNessuna valutazione finora

- Copper Pipes InstallationDocumento6 pagineCopper Pipes InstallationrkssNessuna valutazione finora

- Therm 23 Tca AnglDocumento13 pagineTherm 23 Tca AnglLIVIUBRATUNessuna valutazione finora

- BSEE Test ProcedureDocumento35 pagineBSEE Test ProcedureNatraji100% (2)

- Boiler Hydro TestDocumento26 pagineBoiler Hydro TestKuntal Satpathi83% (6)

- Utility ManualDocumento95 pagineUtility ManualMuhammad Haris HamayunNessuna valutazione finora

- BoilerDocumento22 pagineBoilerAngel Silva VicenteNessuna valutazione finora

- Inertgas SystemDocumento67 pagineInertgas SystemBerbik Mukorobin100% (1)

- Risk AssesmentDocumento6 pagineRisk AssesmentHuynh LamNessuna valutazione finora

- GoogleDocumento15 pagineGoogleWin AlcaideNessuna valutazione finora

- Rogers Water Utilities Water System Rogers, ArkansasDocumento4 pagineRogers Water Utilities Water System Rogers, ArkansasrohalestatNessuna valutazione finora

- Operating Experience With Steam Generator S: InconelDocumento26 pagineOperating Experience With Steam Generator S: InconelDonatas BertasiusNessuna valutazione finora

- C-18.a-Intro To Natural Gas WellsDocumento6 pagineC-18.a-Intro To Natural Gas Wellsteddy132Nessuna valutazione finora

- B. Prestart Checks of Boiler LightupDocumento14 pagineB. Prestart Checks of Boiler LightupPrudhvi RajNessuna valutazione finora

- KORALLIN Kalkreaktor Check List: Incl. Lid, Tubing, White Pad, Sieve, Screws, Integrated O-Ring, EtcDocumento5 pagineKORALLIN Kalkreaktor Check List: Incl. Lid, Tubing, White Pad, Sieve, Screws, Integrated O-Ring, EtcHumberto DTNessuna valutazione finora

- Pressure Testing in Main PipelineDocumento7 paginePressure Testing in Main PipelineChintamani KuralkarNessuna valutazione finora

- Service Manual Ariston T2Documento52 pagineService Manual Ariston T2cris_43100% (1)

- Hersill - KAV-1 - CO2 Absorber - UserManualDocumento12 pagineHersill - KAV-1 - CO2 Absorber - UserManualAnniel Mendez Broche100% (1)

- Water Seald and Drain Seal Pots Maintenance On Gas LinesDocumento28 pagineWater Seald and Drain Seal Pots Maintenance On Gas LinesAliya James100% (3)

- Manual Do orDocumento16 pagineManual Do orRosa Maria PaisNessuna valutazione finora

- Sime RX Range Installation ManualDocumento12 pagineSime RX Range Installation ManualToni ChirilaNessuna valutazione finora

- Low Pressure Engineering ManualDocumento140 pagineLow Pressure Engineering Manualzfrl100% (1)

- Boiler Hydro TestDocumento35 pagineBoiler Hydro TestMoez HamoudiNessuna valutazione finora

- HPCO2 Engineering ManualDocumento84 pagineHPCO2 Engineering ManualRicky LimNessuna valutazione finora

- Control de FlujoDocumento40 pagineControl de FlujojnpaisNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingDa EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNessuna valutazione finora

- Chlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionDocumento17 pagineChlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionSyed Safiur RahmanNessuna valutazione finora

- How To Improve The Vacuum of STG-2Documento6 pagineHow To Improve The Vacuum of STG-2Syed Safiur RahmanNessuna valutazione finora

- Question Paper BoilerDocumento12 pagineQuestion Paper BoilerSyed Safiur RahmanNessuna valutazione finora

- Chlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionDocumento17 pagineChlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionSyed Safiur RahmanNessuna valutazione finora

- Information Regarding Present Indian Power ScenarioDocumento3 pagineInformation Regarding Present Indian Power ScenarioSyed Safiur RahmanNessuna valutazione finora

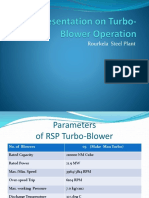

- Turbo-Blower Operation - PPSXDocumento12 pagineTurbo-Blower Operation - PPSXSyed Safiur Rahman100% (1)

- SSS Clutch PrincipleDocumento2 pagineSSS Clutch PrincipleSyed Safiur RahmanNessuna valutazione finora

- Productivity For Global CompetitivenessDocumento47 pagineProductivity For Global CompetitivenessSyed Safiur RahmanNessuna valutazione finora

- Project 1Documento7 pagineProject 1Syed Safiur RahmanNessuna valutazione finora

- How To Improve The Vacuum of STG-2: Power & Blowing Station - 2Documento6 pagineHow To Improve The Vacuum of STG-2: Power & Blowing Station - 2Syed Safiur RahmanNessuna valutazione finora

- Low Intensity Flame Scanner in Boiler1Documento10 pagineLow Intensity Flame Scanner in Boiler1Syed Safiur RahmanNessuna valutazione finora

- Turbo Blower OperationDocumento12 pagineTurbo Blower OperationSyed Safiur RahmanNessuna valutazione finora

- Water ChemistryDocumento17 pagineWater ChemistrySyed Safiur RahmanNessuna valutazione finora

- Deminerlise PlantDocumento34 pagineDeminerlise PlantSyed Safiur Rahman100% (1)

- WPT PresentationDocumento23 pagineWPT PresentationSyed Safiur RahmanNessuna valutazione finora

- How To Improve The Vacuum of STG-2Documento6 pagineHow To Improve The Vacuum of STG-2Syed Safiur RahmanNessuna valutazione finora

- Deminerlise PlantDocumento34 pagineDeminerlise PlantSyed Safiur Rahman100% (1)

- Sinusifdv GB V301 R13-A5Documento149 pagineSinusifdv GB V301 R13-A5Mr.K chNessuna valutazione finora

- BMW - Us X1 - 2015Documento66 pagineBMW - Us X1 - 2015Alex PaunaNessuna valutazione finora

- Flare Gas Recovery RGBDocumento4 pagineFlare Gas Recovery RGBAdriana_TorresNessuna valutazione finora

- Module3 PDFDocumento174 pagineModule3 PDFAhallya JaladeepNessuna valutazione finora

- PV Cell CharaDocumento40 paginePV Cell CharaBlessy JoyNessuna valutazione finora

- Cho Loss Model Radial TurbineDocumento13 pagineCho Loss Model Radial TurbineNicolasNessuna valutazione finora

- Chart Summary Analysis - Brandon LeeDocumento18 pagineChart Summary Analysis - Brandon LeeEyeOfLunaNessuna valutazione finora

- Introduction To Capillary PressureDocumento15 pagineIntroduction To Capillary PressureMuhammad MirNessuna valutazione finora

- Project On Global WarmingDocumento22 pagineProject On Global WarmingHilda DsouzaNessuna valutazione finora

- 1SDC210058L0201 Sace Tmax XTDocumento8 pagine1SDC210058L0201 Sace Tmax XTGrzegorz Greg KrukNessuna valutazione finora

- ATPL Notes - ElectricsDocumento23 pagineATPL Notes - ElectricsMoslem Grimaldi100% (3)

- Generic Requirements Specification of Design For EnvironmentDocumento6 pagineGeneric Requirements Specification of Design For EnvironmentAxel CornaloNessuna valutazione finora

- Lab3E8 - Series and Parallel PumpDocumento8 pagineLab3E8 - Series and Parallel PumpRaied Basam0% (1)

- Microturbine Developments PDFDocumento26 pagineMicroturbine Developments PDFsfsagfegfdbfdNessuna valutazione finora

- Arc Mercer 2011 Fall NewsletterDocumento12 pagineArc Mercer 2011 Fall NewsletterarcmercerNessuna valutazione finora

- KJLC Ed09 Sec09 Web200910Documento54 pagineKJLC Ed09 Sec09 Web200910NickMoloNessuna valutazione finora

- 10 Themes For 2024Documento38 pagine10 Themes For 2024eskender93Nessuna valutazione finora

- Effects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamDocumento11 pagineEffects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamPiterNessuna valutazione finora

- Generator Relay Protection Setting Calculation REV 1.0Documento18 pagineGenerator Relay Protection Setting Calculation REV 1.0SreekanthMylavarapuNessuna valutazione finora

- PWM Control IC: BM1P107FJDocumento30 paginePWM Control IC: BM1P107FJArokiaraj RajNessuna valutazione finora

- Learning Module No. 4 - Aircraft Air Conditioning and Pressurization SystemDocumento36 pagineLearning Module No. 4 - Aircraft Air Conditioning and Pressurization SystemDavidSamsonNessuna valutazione finora

- SG Series 41-751NDocumento8 pagineSG Series 41-751NRick JordanNessuna valutazione finora

- Acetanilide Structure andDocumento5 pagineAcetanilide Structure andjdNessuna valutazione finora

- Chapter 9 Energy SourcesDocumento28 pagineChapter 9 Energy SourcesJung HoonNessuna valutazione finora

- Biology FolioDocumento2 pagineBiology Folio黃將賓Nessuna valutazione finora

- Testing of Frost Free Ref. CompontntsDocumento4 pagineTesting of Frost Free Ref. Compontntssantosh Indulkar100% (2)

- Deshidratador PhillipsDocumento4 pagineDeshidratador Phillipssandra fiorelaNessuna valutazione finora

- 6.012 Microelectronic Devices and Circuits Spring 2005Documento10 pagine6.012 Microelectronic Devices and Circuits Spring 2005dan gNessuna valutazione finora

- It's Gettin' Hot in Here!Documento28 pagineIt's Gettin' Hot in Here!Dipanjan DasNessuna valutazione finora

- Rammed EarthDocumento10 pagineRammed EarthAnugraha KrishnanNessuna valutazione finora