Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Compressed Air Validation

Caricato da

bpharmbaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Compressed Air Validation

Caricato da

bpharmbaCopyright:

Formati disponibili

COMPRESSED AIR

VALIDATION

Md.Aftab Siddiqui.

Dept. Of QA & RA

Torrent Pharmaceuticals ltd

To generate oil free compressed air with dew point

(-) 20 C for process & instrumentation application.

Compressed Air System comprises of -

Air Compressor - Chicago Pneumatic India Ltd.

Capacity : - 600 cfm each @ 8 Kg / cm2

Inter cooler, Moisture Separator , Auto/Manual/Sample

Valve

Air Dryer - Delair India Pvt. Ltd

Capacity : - 2400 cfm , 120 0C

Air Receiver - Delair India Pvt. Ltd

Capacity : - 10 m3 , Operating Pressure- 7 to 8 Kg / cm2(g)

Control Air System upto all user points - Godrej-Boyce

2400 cfm (max.)

P&IDs, circuit and wiring diagrams etc.).

backflow preventor

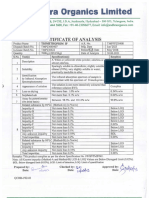

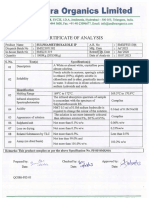

Certificate of Filter

Pressure Gauge, Temp sensor, Dew point Apparatus

SYSTEM DESCRIPTION

AIR COMPRESSOR

Compressor comprises of low pressure (LP) &

High pressure (HP) cylinders that are spaced

and arranged to permit access to all the

openings and components without removing

cylinder, cylinder head, water or air piping. The

compressor is equipped with shell & tube type

inter-cooler and Surge vessel to store

compressed air and to reduce dampening from

the respective air compressor.

Total Air Compressors - ____Nos.

AIR DRIER

After air compressor, the air is finally passed

through heat of Compression type air dryer for

removal of moisture. Air dryer consists of two

drying towers. The dryers remove moisture

from compressed air by adsorption. Activated

Alumina is used as a desiccant in the two drying

towers and is capable of delivering air at dew

point of (-) 20 C, while one tower adsorbs

moisture, the other is getting regenerated.

DRY AIR RECEIVER

Dry air from air dryer goes to dry air

receiver which acts as a short time

hold up for the compressed air before

going for distribution.

CONTROL AIR SYSTEM

A control air system is provided to

minimize energy wastage during

loading unloading operations.

Where air is coming in contact with

product, air is filtered through 1

micron filter and followed by 0.2

micron filter.

TEST AND FREQUENCY

TEST LIMIT FREQUENCY

DEW POINT - 20C Monthly

MICROBIAL LIMIT NMT 3 cfu/m3 Monthly

HYDROCARBON Less than 5 ppm Six Monthly

FILTER INTEGRITY _____________ Six Monthly

SAMPLING POINTS

TEST SAMPLING POINTS

DEW POINT OUTPUT OF AIR DRYER

MICROBIAL LIMIT 12 Sampling points as per drawings

Total air outlets ; -

HYDROCARBON OUTPUT OF AIR DRYER & user points as

per alternative basis

FILTER INTEGRITY All 12 locations where air comes in

contact of product

Services for Air Compressor

Services

Specified

Cooling water to Air

Compressor X 401

A/B/C

Inlet Temperature: 32

o

C

Outlet Temperature: 37

o

C

Pressure:.3 Kg /cm

2

Pipe Diameter: 80 mm

(for each)

Electricity

Voltage: 415 10 % V

Phases: 3

Frequency: 50 Hz 3 %

Services for Air Dryer

Services

Specified

Cooling water to

AIR Dryer

Inlet Temperature: 32

o

C

Outlet Temperature:

Pressure:.3 Kg /cm

2

Electricity

Voltage: 415 10 % V

Phases: 3

Frequency: 50 Hz 3 %

Services for Control Air System

Services

Specified

Electricity

Voltage: 220 V

Phases: 1

Frequency: 50Hz 3%

PLC Application

Lubricants List

5 micron Filter

The Principle Reference is the following

Master Validation Plan for Torrent Pharmaceuticals

Limited, Baddi, Himachal Pradesh (India) Tablets,

Capsules and Liquid Orals Manufacturing Facility,

VMP/00, Revision 00.

Schedule M Good Manufacturing Practices and

Requirements of Premises, Plant and Equipment for

Pharmaceutical Products.

WHO Essential Drugs and Medicines Policy, QA of

Pharmaceuticals, Vol 2 Good Manufacturing Practices

and Inspection.

The following references are used to give addition guidance

FDA/ISPE Baseline Pharmaceutical Engineering Guide-Volume 5:-

Commissioning and Qualification Guide, First Edition / March 2001.

Code of Federal Regulations (CFR), Title 21, Part 210, Current Good

Manufacturing Practice (cGMP) in Manufacturing, Processing, Packing,

or Holding of Drugs, General. April 1, 1998.

Code of Federal Regulations (CFR), Title 21, Part 211, Current Good

Manufacturing Practice (cGMP) for Finished Pharmaceuticals, April 1,

1998.

EU Guide to Good Manufacturing Practice, Part 4, 1997.

European Commissions working party on control of medicines and

inspections document, Validation Master Plan, Design Qualification,

Installation & Operational Qualification, Non Sterile Process Validation,

Cleaning Validation, October 1999.

GAMP Guide, Validation of Automated Systems in Pharmaceutical

Manufacture, Version 4.0, December 2001.

Potrebbero piacerti anche

- Urs HvacDocumento11 pagineUrs Hvacanon-17046494% (18)

- Validation of Water SystemDocumento25 pagineValidation of Water Systemsukanya100% (2)

- Pharma Water SystemDocumento75 paginePharma Water SystemSangram KendreNessuna valutazione finora

- Facility and AHU ValidationDocumento63 pagineFacility and AHU ValidationShankar kumar roy100% (3)

- HVAC SYSTEM Validation Approach and QualificationDocumento4 pagineHVAC SYSTEM Validation Approach and QualificationPrecious GaffudNessuna valutazione finora

- Principles of Cleanroom ValidationDocumento8 paginePrinciples of Cleanroom ValidationNiranjan Lak100% (1)

- HVAC SYSTEM RE-QUALIFICATION PROTOCOL - Pharmaceutical Guidance PDFDocumento22 pagineHVAC SYSTEM RE-QUALIFICATION PROTOCOL - Pharmaceutical Guidance PDFShubam SharmaNessuna valutazione finora

- Qualification Compressed Air SystemHPDocumento21 pagineQualification Compressed Air SystemHPboedy175% (4)

- Qualification of Purified Water Systems PDFDocumento12 pagineQualification of Purified Water Systems PDFMario Vazquez B100% (1)

- Ispe Temperaturemappingpower Point Kevinloomis 140827013750 Phpapp01Documento18 pagineIspe Temperaturemappingpower Point Kevinloomis 140827013750 Phpapp01meong100% (2)

- AHU Val ProtocolDocumento53 pagineAHU Val ProtocolPalani Arumugam100% (1)

- G 52 Pure Steam System Commissioning and Qualification - Sampling PlansDocumento5 pagineG 52 Pure Steam System Commissioning and Qualification - Sampling PlansDoan Chi ThienNessuna valutazione finora

- Technical and Qualification Issues: Alain KupfermanDocumento65 pagineTechnical and Qualification Issues: Alain Kupfermanjonh366100% (1)

- OPQ For Compressed Air SystemDocumento33 pagineOPQ For Compressed Air SystemOanh Nguyen100% (4)

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemDocumento20 pagineStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (3)

- PQ Sterile TunnelDocumento10 paginePQ Sterile TunnelReza JafariNessuna valutazione finora

- Compressed Air in Pharmaceutical IndustryDocumento26 pagineCompressed Air in Pharmaceutical IndustryPaulus Gunawan94% (17)

- HVAC QualificationDocumento36 pagineHVAC QualificationMuhammadAteeq100% (3)

- Cross Contamination Prevention in HVACDocumento8 pagineCross Contamination Prevention in HVAChuynhhaichauchauNessuna valutazione finora

- Cross Contamination Control Facility DesignDocumento22 pagineCross Contamination Control Facility DesignAlok Kumar SharmaNessuna valutazione finora

- Purified Water Installation QualificationDocumento112 paginePurified Water Installation Qualificationankur_haldarNessuna valutazione finora

- Qualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesDocumento1 paginaQualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesAli Goutas50% (2)

- HVAC System ValidationDocumento4 pagineHVAC System ValidationemonwreNessuna valutazione finora

- URS-1808 - Rev - 01 - Final - 06.07.2020 SignedDocumento41 pagineURS-1808 - Rev - 01 - Final - 06.07.2020 Signedmohammed MOHAMMEDMNessuna valutazione finora

- How To Validate An AutoclaveDocumento3 pagineHow To Validate An AutoclaveqhpuongNessuna valutazione finora

- HVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesDocumento18 pagineHVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesFabiola Olivares100% (2)

- Form URS FPP Vial Washing Machine 050307.odtDocumento10 pagineForm URS FPP Vial Washing Machine 050307.odtNur ChamidahNessuna valutazione finora

- Texwipe PDA Cleaning and Cleaning Validation Chapter19Documento26 pagineTexwipe PDA Cleaning and Cleaning Validation Chapter19davincicode888100% (1)

- New Zealand Healthcare Pharmacists' Association Compounding Nutrition & Oncology SIGDocumento31 pagineNew Zealand Healthcare Pharmacists' Association Compounding Nutrition & Oncology SIGcleanroom100% (1)

- Wfi UrsDocumento43 pagineWfi UrsMohsinShaikh100% (1)

- Disinfectant ValidationDocumento7 pagineDisinfectant Validationrose itaNessuna valutazione finora

- DQ - WfiDocumento50 pagineDQ - WfiAtul Sharma100% (2)

- DI IQ OQ ReportDocumento11 pagineDI IQ OQ ReportVemulapalli SaibabuNessuna valutazione finora

- User Requirement Specification: User Requirement SpecificationDocumento10 pagineUser Requirement Specification: User Requirement SpecificationsakshiNessuna valutazione finora

- HVAC, Water, and Other Critical Utility QualificationsDocumento51 pagineHVAC, Water, and Other Critical Utility Qualificationsvijaysirsat2007100% (1)

- Particle Monitoring in Pharmaceutical CleanroomsDocumento8 pagineParticle Monitoring in Pharmaceutical CleanroomsAbd Al-Rahmman Al-qatananiNessuna valutazione finora

- ISPE CTU Evaluation PresentationDocumento25 pagineISPE CTU Evaluation PresentationOscar HoyosNessuna valutazione finora

- Validation of Compressed AirDocumento33 pagineValidation of Compressed AirRaihan Uchiha86% (7)

- PQ WfiDocumento9 paginePQ Wfisami2210Nessuna valutazione finora

- HVAC ValidationDocumento15 pagineHVAC Validationpiyusharora1964100% (3)

- Validation Protocol FOR Compressed Air: Alembic LimitedDocumento7 pagineValidation Protocol FOR Compressed Air: Alembic LimitedAtul Sharma100% (1)

- Compressed AirDocumento7 pagineCompressed Airpradeep281001Nessuna valutazione finora

- HVAC ProtocolDocumento45 pagineHVAC ProtocolUjwal C KambleNessuna valutazione finora

- Checklist of Validation of Dy Heat SterilizerDocumento8 pagineChecklist of Validation of Dy Heat Sterilizersami2210Nessuna valutazione finora

- Commissioning and Qualification Mapping DocumentDocumento4 pagineCommissioning and Qualification Mapping DocumentrobertprincewrightNessuna valutazione finora

- PQ of AutoclaveDocumento23 paginePQ of Autoclavedinesh000786100% (7)

- Operational Qualification of Air CompressorDocumento5 pagineOperational Qualification of Air CompressorPhan Chaugiang100% (1)

- Cleanroom Technology: Fundamentals of Design, Testing and OperationDa EverandCleanroom Technology: Fundamentals of Design, Testing and OperationNessuna valutazione finora

- Pharmaceutical Facilities: Design, Layouts and ValidationDa EverandPharmaceutical Facilities: Design, Layouts and ValidationValutazione: 4 su 5 stelle4/5 (6)

- Production of Plasma Proteins for Therapeutic UseDa EverandProduction of Plasma Proteins for Therapeutic UseValutazione: 3 su 5 stelle3/5 (5)

- Biocontamination Control for Pharmaceuticals and HealthcareDa EverandBiocontamination Control for Pharmaceuticals and HealthcareValutazione: 5 su 5 stelle5/5 (1)

- Principles and Practices of Contamination Control and CleanroomsDa EverandPrinciples and Practices of Contamination Control and CleanroomsNessuna valutazione finora

- Process Validation A Complete Guide - 2020 EditionDa EverandProcess Validation A Complete Guide - 2020 EditionNessuna valutazione finora

- Equipment Qualification in the Pharmaceutical IndustryDa EverandEquipment Qualification in the Pharmaceutical IndustryValutazione: 3.5 su 5 stelle3.5/5 (3)

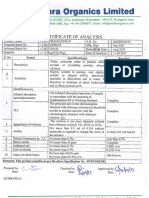

- Sulphadiazine CoaDocumento1 paginaSulphadiazine CoabpharmbaNessuna valutazione finora

- Coa Mometsone FuroateDocumento1 paginaCoa Mometsone FuroatebpharmbaNessuna valutazione finora

- Linagliptin COADocumento2 pagineLinagliptin COAbpharmbaNessuna valutazione finora

- TMP23060407Documento1 paginaTMP23060407bpharmbaNessuna valutazione finora

- ICB-5 Procurement of Inj - DMPA - FINAL PDFDocumento110 pagineICB-5 Procurement of Inj - DMPA - FINAL PDFbpharmbaNessuna valutazione finora

- Wintech Eco Solutions PVT LTD: CIN: U28998UR2017PTC007839Documento6 pagineWintech Eco Solutions PVT LTD: CIN: U28998UR2017PTC007839bpharmbaNessuna valutazione finora

- SMX23071382Documento1 paginaSMX23071382bpharmbaNessuna valutazione finora

- The Indian Pharmaceutical Industry The Way Forward - Report-17-06Documento34 pagineThe Indian Pharmaceutical Industry The Way Forward - Report-17-06Chandan ShahNessuna valutazione finora

- New Hire Checklist Download 20170907 PDFDocumento1 paginaNew Hire Checklist Download 20170907 PDFSanjeev NalurNessuna valutazione finora

- OOS FormatDocumento4 pagineOOS Formatbpharmba100% (1)

- Biomedical CVDocumento4 pagineBiomedical CVbpharmbaNessuna valutazione finora

- Bid Document of ICB-7Documento110 pagineBid Document of ICB-7bpharmbaNessuna valutazione finora

- ICB-57 - Bid Document - RIG - FINALDocumento100 pagineICB-57 - Bid Document - RIG - FINALbpharmbaNessuna valutazione finora

- HRDocumento1 paginaHRbpharmbaNessuna valutazione finora

- Nepal Pharmceutical IndustryDocumento35 pagineNepal Pharmceutical IndustrybpharmbaNessuna valutazione finora

- India Pharma 2020 Proindia Pharma 2020pelling Access and Acceptance Realising True PotentialDocumento29 pagineIndia Pharma 2020 Proindia Pharma 2020pelling Access and Acceptance Realising True PotentialDeepa DevanathanNessuna valutazione finora

- The Indian Pharmaceutical Industry The Way Forward - Report-17-06Documento34 pagineThe Indian Pharmaceutical Industry The Way Forward - Report-17-06Chandan ShahNessuna valutazione finora

- OMS HR Policy & PracticeDocumento25 pagineOMS HR Policy & PracticebpharmbaNessuna valutazione finora

- Administrative Staff Job DescriptionDocumento8 pagineAdministrative Staff Job DescriptionbpharmbaNessuna valutazione finora

- Agent FormDocumento1 paginaAgent FormbpharmbaNessuna valutazione finora

- OMS Employee Information FormDocumento1 paginaOMS Employee Information FormbpharmbaNessuna valutazione finora

- HRDocumento1 paginaHRbpharmbaNessuna valutazione finora

- Project ManagerDocumento2 pagineProject ManagerbpharmbaNessuna valutazione finora

- Om Megashree Pharmaceutical Pvt. LTD: Jugedi, ChitwanDocumento16 pagineOm Megashree Pharmaceutical Pvt. LTD: Jugedi, ChitwanbpharmbaNessuna valutazione finora

- Nepal Pharmceutical IndustryDocumento35 pagineNepal Pharmceutical IndustrybpharmbaNessuna valutazione finora

- PharmxelDocumento22 paginePharmxelbpharmbaNessuna valutazione finora

- LC Application FormDocumento4 pagineLC Application FormbpharmbaNessuna valutazione finora

- Internal Audit GMPDocumento4 pagineInternal Audit GMPbpharmbaNessuna valutazione finora

- PresentatiDITYA PTADocumento1 paginaPresentatiDITYA PTAbpharmbaNessuna valutazione finora

- Title: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesDocumento21 pagineTitle: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesbpharmbaNessuna valutazione finora

- CM Heavy-Duty Crane Hooks BrochureDocumento12 pagineCM Heavy-Duty Crane Hooks Brochuretvmehta01Nessuna valutazione finora

- Case Study of Vessel As Per BS 4994Documento4 pagineCase Study of Vessel As Per BS 4994nagarathinam82100% (1)

- FDA Checklist: Emergency Ventilation EquipmentDocumento2 pagineFDA Checklist: Emergency Ventilation EquipmentRyan DosetarehNessuna valutazione finora

- NCTF PresentationDocumento22 pagineNCTF PresentationfaridaNessuna valutazione finora

- Chemistry of Kupipakwa RasayanasDocumento7 pagineChemistry of Kupipakwa RasayanasSrinivas Naik0% (1)

- Variation of Soil Microbial Population in Different Soil HorizonsDocumento4 pagineVariation of Soil Microbial Population in Different Soil HorizonsprabhatNessuna valutazione finora

- Numericals of ChemistryDocumento4 pagineNumericals of ChemistryAakash AkronosNessuna valutazione finora

- Discussion Saponification of SoapDocumento3 pagineDiscussion Saponification of Soappijechad0% (1)

- OGP Hydrocarbon Level Measurement - Report 547 PDFDocumento96 pagineOGP Hydrocarbon Level Measurement - Report 547 PDFmgkvprNessuna valutazione finora

- CHEM 160 Module 3 Resource 1Documento9 pagineCHEM 160 Module 3 Resource 1meyaNessuna valutazione finora

- Us 6796382 United States Patent 6,796,382 B2Documento11 pagineUs 6796382 United States Patent 6,796,382 B2Daniel SullivanNessuna valutazione finora

- Mark Scheme (Results) : Summer 2018Documento17 pagineMark Scheme (Results) : Summer 2018Atiqur RahmanNessuna valutazione finora

- 20EN 20001 K12 PartsCatalogue QuicklubDocumento112 pagine20EN 20001 K12 PartsCatalogue QuicklubPakoNessuna valutazione finora

- Concrete Society - Concrete Advice No 26 - RC Bund StructuresDocumento3 pagineConcrete Society - Concrete Advice No 26 - RC Bund StructuresKarishma JuttunNessuna valutazione finora

- Sikaflex - 428 PrecastDocumento4 pagineSikaflex - 428 PrecastrasasiNessuna valutazione finora

- TS TVS TFS ProtocolsDocumento16 pagineTS TVS TFS ProtocolsTaulehia Pulefou SemisiNessuna valutazione finora

- Chemical Resistance GuideDocumento20 pagineChemical Resistance GuideDarien EdwardsNessuna valutazione finora

- Handbook of Petroleum Refining Processes 9.4 PDFDocumento12 pagineHandbook of Petroleum Refining Processes 9.4 PDFMelgi159Nessuna valutazione finora

- 3 NsaidsDocumento23 pagine3 NsaidsHagai MagaiNessuna valutazione finora

- Cadweld MS UsDocumento12 pagineCadweld MS UsEfrain Melgarejo PinedaNessuna valutazione finora

- Cleaning Validation MACO Swab Rinse Ovais PDFDocumento5 pagineCleaning Validation MACO Swab Rinse Ovais PDFAnonymous yBhOAi5UHNessuna valutazione finora

- Process Safety - Recommended Practice On KPIsDocumento36 pagineProcess Safety - Recommended Practice On KPIsKB100% (2)

- Common Tea Pest and Pesticide Use in NepalDocumento13 pagineCommon Tea Pest and Pesticide Use in Nepalkhadka80% (5)

- Vocabulary PortfolioDocumento4 pagineVocabulary Portfolioapi-533343759Nessuna valutazione finora

- Material Pressure Regulator - enDocumento32 pagineMaterial Pressure Regulator - enMohamed ElbahyNessuna valutazione finora

- Safety CatalogDocumento107 pagineSafety CatalogMiguel G V PNessuna valutazione finora

- Il Mod Astm C 1107Documento2 pagineIl Mod Astm C 1107Nitesh AroraNessuna valutazione finora

- Structure Test 2Documento3 pagineStructure Test 2Seda Aydin100% (1)

- ASTM D7393-07 (2012) Standard Practice For Indicating Oil in AbrasivesDocumento2 pagineASTM D7393-07 (2012) Standard Practice For Indicating Oil in Abrasivesalexander zuritaNessuna valutazione finora

- Main Project Part IDocumento7 pagineMain Project Part IBigNessuna valutazione finora