Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boilers

Caricato da

Kuntamukkala Chandrakaladhara RaoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Boilers

Caricato da

Kuntamukkala Chandrakaladhara RaoCopyright:

Formati disponibili

STEAM

GENERATORS

OR BOILERS

A boiler or steam generator is a device used to

create steam by applying heat energy to water.

A steam generator generates steam at the desired rate at the

desired pressure and temperature by burning fuel in its

furnace.

It is mainly of 2 types :

1. Fossil fuel steam generators

2. Nuclear fuel steam generators

AN INDUSTRIAL

BOILER

USUALLY MADE OF ALLOYS OR

SUPER-ALLOYS

TYPES OF STEAM

GENERATORS

BASED ON APPLICATION:

UTILITY

INDUSTRIAL

MARINE

BASED ON RELATIVE FLOWS OF

PRODUCTS OF COMBUSTION

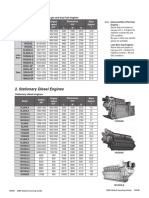

FIRE TUBE BOILERS

Here hot flue gases flow through

tubes surrounded by water in a

shell

WATER TUBE BOILERS

Here water from a drum flows

through the tubes and hot flue

gases flow over them.

WATER TUBE BOILERS

Water tube boilers were developed to permit

increases in boiler pressure and capacity with

reasonable metal stresses.

Different types include :

I. Straight tube boiler

II. Bent tube boiler

STRAIGHT TUBE

BOILER

A FOUR DRUM

BENT TUBE BOILER

HEAT ABSORPTION IN

WATER TUBE BOILERS

FEEDWATER IS HEATED BY THREE KINDS OF

HEAT EXCHANGERS :

ECONOMISER

EVAPORATOR

SUPER-HEATER

HEAT ABSORTION

IN A WATER TUBE

BOILER

HEAT ABSORPTION

IN DIFFERENT HEAT

EXCHANGERS OF

A WATER TUBE

BOILER

ECONOMISERS

AN ECONOMISER IS A HEAT EXCHANGER THAT

RAISES THE TEMPERATURE OF THE FEEDWATER.

THE ECONOMISER IS PLACED BETWEEN

CONVECTIVE SUPER-HEATER AND AIR PRE-

HEATER.

SUPER HEATERS

IT IS A HEAT EXCHANGER IN WHICH HEAT IS

TRANSFERRED TO THE SATURATED STEAM TO

INCREASE ITS TEMPERATURE.

IT INCREASES THE OVERALL EFFICIENCY AND

REDUCES MOISTURE IN THE LAST STAGES.

FLUIDISED BED BOILERS

They produce steam from fossil fuels and waste

fuels by using a technique called fluidised bed

combustion.

They can be of 2 types:

1. Bubbling fluidised bed boilers

2. Circulating fluidised bed boilers

AN ATMOSPHERIC

BUBBLING

FLUIDISED BED

BOILER

CIRCULATING

FLUIDISED BED

BOILER

EVAPORATION

Evaporation of pre-treated water by motive

steam bled from the turbine is often used where

the boiler make-up water treatment is not large.

Both evaporated water and condensed steam

exiting the evaporator are fed back as make-up

into the plant.

SINGLE EFFECT

SUBMERGED

EVAPORATOR

DEAERATOR

It is a feedwater heater that is a contact type

open heater.

It involves heating the water to remove gases like

oxygen and carbon dioxide that make water

corrosive as they react with metal to form iron

oxide.

These are removed by heating to saturation

temperature by the steam extracted from the

turbine.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Turning GearDocumento13 pagineTurning GearKuntamukkala Chandrakaladhara Rao100% (2)

- 220Documento1 pagina220fahmi wibowoNessuna valutazione finora

- Fgmo of Steam TurbinesDocumento39 pagineFgmo of Steam TurbinesKuntamukkala Chandrakaladhara RaoNessuna valutazione finora

- Boiler EfficiencyDocumento28 pagineBoiler Efficiencybzkizo_sbbNessuna valutazione finora

- Boiler EfficiencyDocumento28 pagineBoiler Efficiencybzkizo_sbbNessuna valutazione finora

- of Coal-Fired Thermal Power StationDocumento6 pagineof Coal-Fired Thermal Power Stationshivendupadte0% (1)

- Geothermal Energy PresentationDocumento13 pagineGeothermal Energy Presentationdragonartist100% (1)

- Time TableDocumento1 paginaTime TableAmit SonagraNessuna valutazione finora

- Hindustan Petroleum Corporation LimitedDocumento1 paginaHindustan Petroleum Corporation LimitedKuntamukkala Chandrakaladhara RaoNessuna valutazione finora

- Sbi Notice For NitcDocumento2 pagineSbi Notice For NitcKuntamukkala Chandrakaladhara RaoNessuna valutazione finora

- Fees Structure NitcDocumento1 paginaFees Structure NitcKuntamukkala Chandrakaladhara RaoNessuna valutazione finora

- Rankine CycleDocumento8 pagineRankine CycleKuntamukkala Chandrakaladhara RaoNessuna valutazione finora

- GATE2014 Qual MarksDocumento1 paginaGATE2014 Qual Marksatharvasaxena93Nessuna valutazione finora

- GATE2014 Qual MarksDocumento1 paginaGATE2014 Qual Marksatharvasaxena93Nessuna valutazione finora

- Monsoon CalenserDocumento1 paginaMonsoon CalenserKuntamukkala Chandrakaladhara RaoNessuna valutazione finora

- Engg Services Exam 2013 KeyDocumento36 pagineEngg Services Exam 2013 KeyrvrsantoshNessuna valutazione finora

- Gree DehumiDocumento1 paginaGree DehumiAnkhi BaroiNessuna valutazione finora

- Sustainable Charcoal Briquettes Production Executive SummaryDocumento1 paginaSustainable Charcoal Briquettes Production Executive SummaryEMMANUEL SENINessuna valutazione finora

- Google Corporate Social Responsibility (CSR) : Energy Consumption by GoogleDocumento2 pagineGoogle Corporate Social Responsibility (CSR) : Energy Consumption by GoogleVikash MauryaNessuna valutazione finora

- Thermal and Refregeration Based Projects PDFDocumento3 pagineThermal and Refregeration Based Projects PDFShankar GNessuna valutazione finora

- Complex Engineering Assignemt Power Plant Session 2017Documento2 pagineComplex Engineering Assignemt Power Plant Session 2017vj kumar100% (2)

- A Novel Design For PV Integrated Buck Converter Using MPPT and Sub MPPTDocumento1 paginaA Novel Design For PV Integrated Buck Converter Using MPPT and Sub MPPTGlan DevadhasNessuna valutazione finora

- Transparent Solar PanelDocumento18 pagineTransparent Solar PanelAMAYE GATALAWARNessuna valutazione finora

- SunWize Tech Notes IEEE 1562 2007Documento1 paginaSunWize Tech Notes IEEE 1562 2007Mostafa El SayedNessuna valutazione finora

- Thermal Recoveries Methods.Documento11 pagineThermal Recoveries Methods.Florian Ananias ByarugabaNessuna valutazione finora

- Electric Cars and The PrepperDocumento5 pagineElectric Cars and The PrepperVincentNessuna valutazione finora

- Pressure Vessel Training - May June 2012Documento1 paginaPressure Vessel Training - May June 2012Kantharaj ChinnappaNessuna valutazione finora

- Mr. Hariprasad - Presentation SGEPLDocumento34 pagineMr. Hariprasad - Presentation SGEPLSHANMUGAPRIYANNessuna valutazione finora

- PV SystemDocumento21 paginePV SystemAhmed SalemNessuna valutazione finora

- ITS-90 Table For Type J Thermocouple (Ref Junction 0°C) °C 0 - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 Thermoelectric Voltage in MVDocumento4 pagineITS-90 Table For Type J Thermocouple (Ref Junction 0°C) °C 0 - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 Thermoelectric Voltage in MVsyeadtalhaaliNessuna valutazione finora

- Vermicomposting Production, Packaging & Marketing Business Plan in PakistanDocumento23 pagineVermicomposting Production, Packaging & Marketing Business Plan in PakistanExotics FarmsNessuna valutazione finora

- Wikipedia - ASME Section III TOCDocumento2 pagineWikipedia - ASME Section III TOCroblin88xNessuna valutazione finora

- Green City PlanningDocumento16 pagineGreen City PlanningSujeet Kumar0% (1)

- SR Bio-Naphtha Missing LinkDocumento2 pagineSR Bio-Naphtha Missing LinkVictoria Sahaya RaniNessuna valutazione finora

- Vehicle To Grid Technology:A Review: (Ym - Zhou, Xy - Li) @siat - Ac.cnDocumento6 pagineVehicle To Grid Technology:A Review: (Ym - Zhou, Xy - Li) @siat - Ac.cnEhtisham ZiaNessuna valutazione finora

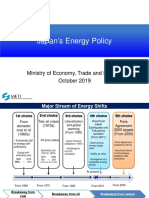

- J-0 - METI - KANEKO - Energy PolicyDocumento14 pagineJ-0 - METI - KANEKO - Energy PolicyrahmanNessuna valutazione finora

- Doe Organizational ChartDocumento1 paginaDoe Organizational ChartAnonymous HIBt2h6z7Nessuna valutazione finora

- Solar Based Cold StorageDocumento5 pagineSolar Based Cold StorageSudhendra Soni100% (1)

- Enerwaste Green HubDocumento20 pagineEnerwaste Green Hubgaby.hernandez485703Nessuna valutazione finora

- Emergency +fire Agents+Fire FightingDocumento28 pagineEmergency +fire Agents+Fire FightingBava LovaNessuna valutazione finora

- G C Datta RoyDocumento30 pagineG C Datta RoyAmit B NagaonkarNessuna valutazione finora

- Solar Power Engineer-Ahmed KamalDocumento2 pagineSolar Power Engineer-Ahmed KamalahmedNessuna valutazione finora

- Assignment 2Documento3 pagineAssignment 2muhammad.shahrukhNessuna valutazione finora