Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ISO 14971, 2 Ed., 2007 Medical Devices: Application of Risk Management To Medical Devices

Caricato da

Nausheen Ahmed NobaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ISO 14971, 2 Ed., 2007 Medical Devices: Application of Risk Management To Medical Devices

Caricato da

Nausheen Ahmed NobaCopyright:

Formati disponibili

ISO 14971, 2

nd

Ed., 2007

Medical devices: Application of risk

management to medical devices

By Grant Schmidbauer

Nemko USA, Inc. San Diego, CA

Introduction to ISO 14971

Scope of ISO 14971

Key terms and definitions

General requirements for risk management

Risk analysis

Risk evaluation

Risk control

Evaluation of overall residual risk acceptability

Risk management report

Production and post-production information

Summary

Contents

Introduction to ISO 14971

The requirements contained in this

International Standard provide

manufacturers with a framework

within which experience, insight and

judgment are applied systematically

to manage the risks associated with

the use of medical devices.

Introduction to ISO 14971

This International Standard was

developed specifically for medical

device and medical system

manufacturers using established

principles of risk management.

Introduction to ISO 14971

This International Standard deals

with processes for managing risks,

primarily to the patient, but also to

the operator, other persons, other

equipment and the environment.

Introduction to ISO 14971

It is accepted that the concept of risk

has two components:

a) the probability of occurrence of

harm;

b) the consequences of that harm, that

is, how severe it might be.

Introduction to ISO 14971

This International Standard specifies a

process through which the manufacturer

of a medical device can identify hazards

associated with a medical device,

estimate and evaluate the risks

associated with these hazards, control

these risks, and monitor the effectiveness

of that control.

1. Scope of ISO 14971

The requirements of this International

Standard are applicable to all stages of the

life-cycle of a medical device.

This International Standard does not apply

to clinical decision making.

This International Standard does not

specify acceptable risk levels.

1. Scope of ISO 14971

This International Standard does not

require that the manufacturer have a

quality management system in place.

However, risk management can be an

integral part of a quality management

system.

2. Key Terms and Definitions

2.2 harm

physical injury or damage to the health

of people, or damage to property or the

environment

2.3 hazard

potential source of harm

2.4 hazardous situation

circumstance in which people, property,

or the environment are exposed to one

or more hazard(s)

2. Key Terms and Definitions

2.7 life-cycle

all phases in the life of a medical

device, from the initial conception to

final decommissioning and disposal

2.10 objective evidence

data supporting the existence or verity

of something

2. Key Terms and Definitions

2.11 post-production

part of the life-cycle of the product after

the design has been completed and the

medical device has been manufactured

2.15 residual risk

risk remaining after risk control

measures have been taken

2. Key Terms and Definitions

2.16 risk

combination of the probability of

occurrence of harm and the severity of

that harm

2.17 risk analysis

systematic use of available information

to identify hazards and to estimate the

risk

2. Key Terms and Definitions

2.18 risk assessment

overall process comprising a risk

analysis and a risk evaluation

2.19 risk control

process in which decisions are made

and measures implemented by which

risks are reduced to, or maintained

within, specified levels

2. Key Terms and Definitions

2.20 risk estimation

process used to assign values to the

probability of occurrence of harm and

the severity of that harm

2.21 risk evaluation

process of comparing the estimated risk

against given risk criteria to determine

the acceptability of the risk

2. Key Terms and Definitions

2.22 risk management

systematic application of management

policies, procedures and practices to the

tasks of analyzing, evaluating,

controlling and monitoring risk

2.23 risk management file

set of records and other documents that

are produced by risk management

2. Key Terms and Definitions

2.24 safety

freedom from unacceptable risk

2.25 severity

measure of the possible consequences of a

hazard

2.27 use error

act or omission of an act that results in a

different medical device response than

intended by the manufacturer or expected by

the user

3. General Requirements

3.1 Risk management process

The manufacturer shall establish,

document and maintain throughout the

life-cycle an ongoing process for

identifying hazards associated with a

medical device, estimating and

evaluating the associated risks,

controlling these risks, and monitoring

the effectiveness of the controls.

3. General Requirements

3.1 Risk management process

This process shall include the following

elements:

- risk analysis;

- risk evaluation;

- risk control;

- production and post-production

information.

3. General Requirements

3.1 Risk management process

Where a documented product

realization process exists (such as

described in ISO 13485:2003), it shall

incorporate the appropriate parts of the

risk management process.

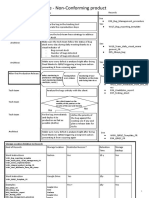

A schematic representation of the risk

management process is shown next.

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

3. General Requirements

3. General Requirements

3.2 Management responsibilities

Top management shall provide

evidence of its commitment to the risk

management process by:

- ensuring the provision of adequate

resources, and

- ensuring the assignment of qualified

personnel for risk management.

3. General Requirements

3.2 Management responsibilities

Top management shall:

- define and document the policy for

determining criteria for risk acceptability; this

policy shall ensure that criteria are based

upon applicable national or regional

regulations and relevant International

Standards, and take into account available

information such as the generally accepted

state of the art and known stakeholder

concerns;

3. General Requirements

3.2 Management responsibilities

Top management shall:

- review the suitability of the risk

management process at planned intervals to

ensure continuing effectiveness of the risk

management process and document any

decisions and actions taken; if the

manufacturer has a quality management

system in place, this review may be part of

the quality management system review.

3. General Requirements

3.3 Qualification of personnel

Persons performing risk management tasks

shall have the knowledge and experience

appropriate to the tasks assigned to them.

These shall include, where appropriate,

knowledge and experience of the particular

medical device (or similar medical devices)

and its use, the technologies involved or risk

management techniques. Appropriate

qualification records shall be maintained.

3. General Requirements

3.4 Risk management plan

Risk management activities shall be

planned. Therefore, for the particular

medical device being considered, the

manufacturer shall establish and

document a risk management plan in

accordance with the risk management

process. The risk management plan

shall be part of the risk management

file.

3. General Requirements

3.4 Risk management plan

This plan shall include at least the

following:

a) the scope of the planned risk

management activities, identifying and

describing the medical device and the

life-cycle phases for which each

element of the plan is applicable;

b) assignment of responsibilities and

authorities;

3. General Requirements

3.4 Risk management plan

This plan shall include at least the

following:

c) requirements for review of risk

management activities;

d) criteria for risk acceptability, based on

the manufacturers policy for determining

acceptable risk, including criteria for

accepting risks when the probability of

occurrence of harm cannot be estimated;

3. General Requirements

3.4 Risk management plan

This plan shall include at least the following:

e) verification activities;

f) activities related to collection and review of

relevant production and post-production

information.

If the plan changes during the life-cycle of the

medical device, a record of the changes shall be

maintained in the risk management file.

3. General Requirements

3.5 Risk management file

For the particular medical device being

considered, the manufacturer shall

establish and maintain a risk management

file.

3. General Requirements

3.5 Risk management file

The risk management file shall provide

traceability for each identified hazard to:

- the risk analysis;

- the risk evaluation;

- the implementation and verification of

the risk control measures;

- the assessment of the acceptability of any

residual risk(s).

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

4. Risk Analysis

4. Risk Analysis

4.1 Risk analysis process

Risk analysis shall be performed for the

particular medical device.

The implementation of the planned risk

analysis activities and the results of the

risk analysis shall be recorded in the risk

management file.

4. Risk Analysis

4.1 Risk analysis process

The documentation of the conduct and

results of the risk analysis shall include at

least the following:

a) a description and identification of the

medical device that was analysed;

b) identification of the person(s) and

organization who carried out the risk

analysis;

c) scope and date of the risk analysis.

4. Risk Analysis

4.2 Intended use and identification of

characteristics related to the safety of the medical

device

For the particular medical device being

considered, the manufacturer shall document the

intended use and reasonably foreseeable misuse.

The manufacturer shall identify and document

those qualitative and quantitative characteristics

that could affect the safety of the medical device

and, where appropriate, their defined limits.

This documentation shall be maintained in the

risk management file.

4. Risk Analysis

4.3 Identification of hazards

The manufacturer shall compile

documentation on known and foreseeable

hazards associated with the medical device

in both normal and fault conditions.

This documentation shall be maintained in

the risk management file.

4. Risk Analysis

4.4 Estimation of the risk(s) for each

hazardous situation

Reasonably foreseeable sequences or

combinations of events that can result in a

hazardous situation shall be considered and

the resulting hazardous situation(s) shall be

recorded.

4. Risk Analysis

4.4 Estimation of the risk(s) for each hazardous

situation

For each identified hazardous situation, the

associated risk(s) shall be estimated using

available information or data.

For hazardous situations for which the probability

of the occurrence of harm cannot be estimated,

the possible consequences shall be listed for use

in risk evaluation and risk control.

The results of these activities shall be recorded in

the risk management file.

4. Risk Analysis

4.4 Estimation of the risk(s) for each

hazardous situation

Any system used for qualitative or

quantitative categorization of probability of

occurrence of harm or severity of harm

shall be recorded in the risk management

file.

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

5. Risk Evaluation

5. Risk Evaluation

For each identified hazardous situation, the

manufacturer shall decide, using the criteria

defined in the risk management plan, if risk

reduction is required.

If risk reduction is not required,

completeness of risk control applies.

The results of this risk evaluation shall be

recorded in the risk management file.

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

6. Risk Control

6. Risk Control

6.1 Risk reduction

When risk reduction is required, risk

control activities shall be performed.

6.2 Risk control option analysis

The manufacturer shall identify risk control

measure(s) that are appropriate for reducing

the risk(s) to an acceptable level.

6. Risk Control

6.2 Risk control option analysis

The manufacturer shall use one or more of

the following risk control options in the

priority order listed:

a) inherent safety by design;

b) protective measures in the medical

device itself or in the manufacturing

process;

c) information for safety.

6. Risk Control

6.2 Risk control option analysis

The risk control measures selected shall be

recorded in the risk management file.

If, during risk control option analysis, the

manufacturer determines that required risk

reduction is not practicable, the

manufacturer shall conduct a risk/benefit

analysis of the residual risk.

6. Risk Control

6.3 Implementation of risk control measures

Implementation of each risk control

measure shall be verified.

This verification shall be recorded in the

risk management file.

The effectiveness of the risk control

measures shall be verified and the results

shall be recorded in the risk management

file.

6. Risk Control

6.4 Residual risk evaluation

After the risk control measures are applied,

any residual risk shall be evaluated using

the criteria defined in the risk management

plan.

The results of this evaluation shall be

recorded in the risk management file.

6. Risk Control

6.4 Residual risk evaluation

If the residual risk is not judged acceptable

using these criteria, further risk control

measures shall be applied.

For residual risks that are judged

acceptable, the manufacturer shall decide

which residual risks to disclose and what

information is necessary to include in the

accompanying documents in order to

disclose those residual risks.

6. Risk Control

6.5 Risk/benefit analysis

If the residual risk is not judged acceptable

using the criteria established in the risk

management plan and further risk control is

not practicable, the manufacturer may

gather and review data and literature to

determine if the medical benefits of the

intended use outweigh the residual risk.

6. Risk Control

6.5 Risk/benefit analysis

If this evidence does not support the

conclusion that the medical benefits

outweigh the residual risk, then the risk

remains unacceptable.

If the medical benefits outweigh the

residual risk, then the risk can be accepted.

6. Risk Control

6.5 Risk/benefit analysis

For risks that are demonstrated to be

outweighed by the benefits, the

manufacturer shall decide which

information for safety is necessary to

disclose the residual risk.

The results of this evaluation shall be

recorded in the risk management file.

6. Risk Control

6.6 Risks arising from risk control

measures

The effects of the risk control measures

shall be reviewed with regard to:

a) the introduction of new hazards or

hazardous situations; and

b) whether the estimated risks for

previously identified hazardous situations

are affected by the introduction of the risk

control measures.

6. Risk Control

6.6 Risks arising from risk control

measures

Any new or increased risks shall be

managed.

The results of this review shall be

recorded in the risk management file.

6. Risk Control

6.7 Completeness of risk control

The manufacturer shall ensure that the

risk(s) from all identified hazardous

situations have been considered.

The results of this activity shall be

recorded in the risk management file.

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

7. Evaluation of Residual Risk

7. Evaluation of Residual Risk

After all risk control measures have been

implemented and verified, the manufacturer

shall decide if the overall residual risk

posed by the medical device is acceptable

using the criteria defined in the risk

management plan.

7. Evaluation of Residual Risk

If the overall residual risk is not judged

acceptable using the criteria established in the risk

management plan, the manufacturer may gather

and review data and literature to determine if the

medical benefits of the intended use outweigh the

overall residual risk.

If this evidence supports the conclusion that the

medical benefits outweigh the overall residual

risk, then the overall residual risk can be judged

acceptable.

7. Evaluation of Residual Risk

Otherwise, the overall residual risk remains

unacceptable.

For an overall residual risk that is judged

acceptable, the manufacturer shall decide

which information is necessary to include

in the accompanying documents in order to

disclose the overall residual risk.

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

8. Risk Management Report

8. Risk Management Report

Prior to release for commercial distribution of the

medical device, the manufacturer shall carry out a

review of the risk management process.

This review shall at least ensure that:

- the risk management plan has been appropriately

implemented;

- the overall residual risk is acceptable;

- appropriate methods are in place to obtain

relevant production and post-production

information.

8. Risk Management Report

The results of this review shall be recorded

as the risk management report and included

in the risk management file.

The responsibility for review should be

assigned in the risk management plan to

persons having the appropriate authority.

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

9. Production and Post-

Production Information

The manufacturer shall establish, document

and maintain a system to collect and review

information about the medical device or

similar devices in the production and the

post-production phases.

When establishing a system to collect and

review information about the medical

device, the manufacturer should consider

among other things:

9. Production and Post-

Production Information

a) the mechanisms by which information

generated by the operator, the user, or those

accountable for the installation, use and

maintenance of the medical device is

collected and processed; or

b) new or revised standards.

9. Production and Post-

Production Information

The system should also collect and review

publicly available information about similar

medical devices on the market.

This information shall be evaluated for possible

relevance to safety, especially the following:

- if previously unrecognized hazards or

hazardous situations are present or

- if the estimated risks arising from a hazardous

situation is/are no longer acceptable.

9. Production and Post-

Production Information

If any of the above conditions occur:

1) the impact on previously implemented

risk management activities shall be

evaluated and shall be fed back as an input

to the risk management process, and

9. Production and Post-

Production Information

If any of the above conditions occur:

2) a review of the risk management file for

the medical device shall be conducted; if

there is a potential that the residual risk(s)

or its acceptability has changed, the impact

on previously implemented risk control

measures shall be evaluated.

The results of this evaluation shall be

recorded in the risk management file.

9. Production and Post-

Production Information

Risk Analysis

Risk Evaluation

Risk control

Risk control option analysis

Implementation of risk control measures

Residual risk evaluation

Risk / benefit analysis

Risk arising from risk control measures

Completeness of risk control

Risk management report

Intended use and identification of characteristics

related to the safety of the medical device

Identification of hazards

Estimation of the risk for each hazardous situation

Production and post-production information

Evaluation of overall residual risk acceptability

Summary

Summary

ISO 14971 provides manufacturers with a

framework to manage the risks associated

with the use of medical devices.

ISO 14971 specifies a process for a

manufacturer to identify the hazards

associated with medical devices, to

estimate and evaluate the associated risks,

to control these risks, and to monitor the

effectiveness of the controls.

Grant Schmidbauer

General Manager

Nemko USA, Inc.

11696 Sorrento Valley Road

San Diego, CA 92121 USA

Tel: 858-755-5525 Ex. 208

Fax: 858-452-1810

Email: grant.schmidbauer@nemko.com

Website: www.nemko.com

Contact Information

Potrebbero piacerti anche

- QP-007 Risk Management ProcessDocumento12 pagineQP-007 Risk Management Processesraa asemNessuna valutazione finora

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19Da EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19Nessuna valutazione finora

- New EN ISO Risk Management StandardDocumento24 pagineNew EN ISO Risk Management Standardmaran.suguNessuna valutazione finora

- Risk Management ISO 14971 - 2019 r10v1.0 (01-08-20)Documento84 pagineRisk Management ISO 14971 - 2019 r10v1.0 (01-08-20)AelindahNessuna valutazione finora

- Analyzing The Changes To Risk Management Standard ISO 149712019 PDFDocumento5 pagineAnalyzing The Changes To Risk Management Standard ISO 149712019 PDFrakesh marwahNessuna valutazione finora

- ISO 13485 Operational Procedure QOP-73-02 (A) Design Risk ManagementDocumento4 pagineISO 13485 Operational Procedure QOP-73-02 (A) Design Risk Managementtahir_rizvi1569Nessuna valutazione finora

- ISO 14971 ChangedDocumento1 paginaISO 14971 ChangedSen MingNessuna valutazione finora

- ISO 31000 Risk Management Best Practice A Complete Guide - 2020 EditionDa EverandISO 31000 Risk Management Best Practice A Complete Guide - 2020 EditionNessuna valutazione finora

- Risk Management Plan TemplateDocumento8 pagineRisk Management Plan TemplateRysta Yulandari100% (1)

- Quality Manual Policy ObjectivesDocumento5 pagineQuality Manual Policy ObjectivesImane AaNessuna valutazione finora

- 1Documento11 pagine1Jonathan McloughlinNessuna valutazione finora

- Od-2044 Ed.2.2Documento54 pagineOd-2044 Ed.2.2Adalnei GomideNessuna valutazione finora

- List of Documents ISO 13485 Documentation ToolkitDocumento4 pagineList of Documents ISO 13485 Documentation ToolkitGreeshma Certvalue100% (3)

- Risk Management SOP For ISO14971Documento21 pagineRisk Management SOP For ISO14971Daniel Francis Yap88% (8)

- Risk Management of Medical DevicesDocumento16 pagineRisk Management of Medical DevicesDr. Johanny Pestalozzi100% (1)

- Risk Management ReportDocumento18 pagineRisk Management ReportVictor AlarcónNessuna valutazione finora

- Post Marketing Surveillance Plan NMRA NewDocumento9 paginePost Marketing Surveillance Plan NMRA NewDeshal RanasingheNessuna valutazione finora

- Risk Manangement For Medical DevicesDocumento73 pagineRisk Manangement For Medical Deviceshamed IranpourNessuna valutazione finora

- QP19-Vigilance Report - CE MarkDocumento18 pagineQP19-Vigilance Report - CE Markanusha shankarNessuna valutazione finora

- As ISO 10993.12-2004 Biological Evaluation of Medical Devices Sample Preparation and Reference MaterialsDocumento8 pagineAs ISO 10993.12-2004 Biological Evaluation of Medical Devices Sample Preparation and Reference MaterialsSAI Global - APACNessuna valutazione finora

- Bsi MD Risk Management For Medical Devices Webinar 131119 Uk enDocumento29 pagineBsi MD Risk Management For Medical Devices Webinar 131119 Uk enrakesh marwahNessuna valutazione finora

- Risk Management Plan TemplateDocumento2 pagineRisk Management Plan TemplateDimitris PapadopoulosNessuna valutazione finora

- Medical Device Risk Management - IsO 14971Documento86 pagineMedical Device Risk Management - IsO 14971novdic71% (7)

- Medical Devices Benefit Risk ManagementDocumento7 pagineMedical Devices Benefit Risk ManagementSteven KingNessuna valutazione finora

- Risk Management ManualDocumento20 pagineRisk Management ManualTom@GGC100% (2)

- 1 4d - Qualiy Risk ManagementDocumento22 pagine1 4d - Qualiy Risk Managementelektron2010Nessuna valutazione finora

- 2 5 Obl 1 309 0607 B16 enDocumento8 pagine2 5 Obl 1 309 0607 B16 enZoli0984Nessuna valutazione finora

- 1.1.1. Quality Risk Assessment. 1.1.1.1. Introduction & ScopeDocumento6 pagine1.1.1. Quality Risk Assessment. 1.1.1.1. Introduction & ScopeKannan MurugesanNessuna valutazione finora

- EMERGO ISO 14971 Webinar Sept 2017Documento40 pagineEMERGO ISO 14971 Webinar Sept 2017CeangoNessuna valutazione finora

- Software Non Conforming Product ISO 13485 For IEC 62304Documento2 pagineSoftware Non Conforming Product ISO 13485 For IEC 62304BealNessuna valutazione finora

- Bsi MD Risk Management For Medical Devices QaDocumento10 pagineBsi MD Risk Management For Medical Devices Qadhir.ankurNessuna valutazione finora

- Awareness of Application of Risk Managment Based On ISO 14971-2019 Standard - HandoutDocumento84 pagineAwareness of Application of Risk Managment Based On ISO 14971-2019 Standard - HandoutVidyashree PujariNessuna valutazione finora

- Iso 14971 8-B2017065Documento6 pagineIso 14971 8-B2017065Mircod SenseNessuna valutazione finora

- EU MDR - Pinnacle Software Technologies LimitedDocumento6 pagineEU MDR - Pinnacle Software Technologies LimitedPinnacle Software Technologies Limited100% (1)

- 227 20 Unique Device Indentifier UDI For Medical Devices Used in The Gas IndustryDocumento16 pagine227 20 Unique Device Indentifier UDI For Medical Devices Used in The Gas IndustryMauro CostaNessuna valutazione finora

- AbstractDocumento11 pagineAbstractMaurizio FieraNessuna valutazione finora

- PresH - ISO 14971Documento20 paginePresH - ISO 14971William Salgado0% (1)

- How Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementDocumento3 pagineHow Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementPavan MujawdiyaNessuna valutazione finora

- ISO 14971 Risk Management Guidance Document Rev 1 (2016!06!27)Documento7 pagineISO 14971 Risk Management Guidance Document Rev 1 (2016!06!27)bhatnagar29Nessuna valutazione finora

- Sop VigilanceDocumento7 pagineSop VigilanceJane BrownNessuna valutazione finora

- List of Documents ISO 13485 ISO 14971 Premium Documentation Toolkit enDocumento4 pagineList of Documents ISO 13485 ISO 14971 Premium Documentation Toolkit enMichal KrawczynskiNessuna valutazione finora

- Risk Management Report: Mapping of Standard Requirements To Document SectionsDocumento3 pagineRisk Management Report: Mapping of Standard Requirements To Document SectionsSIS AuditorNessuna valutazione finora

- Europe Medical Device Harmonised Standards (MDD, AIMDD, IVDD), 2012-08-30Documento33 pagineEurope Medical Device Harmonised Standards (MDD, AIMDD, IVDD), 2012-08-30yagnaashi9092Nessuna valutazione finora

- A Practical Guide To ISO 10993-5 - Cytotoxicity - MDDI Medical Device and Diagnostic Industry News Products and SuppliersDocumento4 pagineA Practical Guide To ISO 10993-5 - Cytotoxicity - MDDI Medical Device and Diagnostic Industry News Products and SuppliersVanessa DuzNessuna valutazione finora

- MDSAP PresentationDocumento31 pagineMDSAP PresentationAditya C KNessuna valutazione finora

- PGC.7.1-01-Risk Management ENG # 2021 05 12 # V8.1Documento34 paginePGC.7.1-01-Risk Management ENG # 2021 05 12 # V8.1MarcBenetPozo100% (1)

- Quality Manual Policy ObjectivesDocumento4 pagineQuality Manual Policy ObjectivesMemories & Moments Payel & SwastikNessuna valutazione finora

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocumento2 pagineNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNessuna valutazione finora

- Template PMS Report TL01 V01Documento9 pagineTemplate PMS Report TL01 V01Sandra SilvaNessuna valutazione finora

- 400 Day 1 - Swanson - Pres PDFDocumento32 pagine400 Day 1 - Swanson - Pres PDFmuthu. kumarNessuna valutazione finora

- LS QA ManualDocumento55 pagineLS QA ManualjtwaniNessuna valutazione finora

- Iso 13485Documento9 pagineIso 13485Narendra GosaviNessuna valutazione finora

- Medical Device Risk Management ISO 14971: Dan O'Leary President Ombu Enterprises, LLCDocumento86 pagineMedical Device Risk Management ISO 14971: Dan O'Leary President Ombu Enterprises, LLC7lightbourn5893Nessuna valutazione finora

- Sample SoP For Vigilance System PDFDocumento4 pagineSample SoP For Vigilance System PDFhitham shehataNessuna valutazione finora

- Design Dossier Technical Documentation EU R2 5 1-5 Rev4Documento24 pagineDesign Dossier Technical Documentation EU R2 5 1-5 Rev4Andreas WeinfurterNessuna valutazione finora

- Iso13485 QOP4101 RiskMng PDFDocumento4 pagineIso13485 QOP4101 RiskMng PDFQuality and Safety Consultants Co.Nessuna valutazione finora

- ISO 13485 UpdateDocumento43 pagineISO 13485 Updatehitham shehata100% (1)

- Guide Psur Apr 2021Documento55 pagineGuide Psur Apr 2021ifrahNessuna valutazione finora

- Control Transition PolicyDocumento3 pagineControl Transition PolicyNausheen Ahmed NobaNessuna valutazione finora

- IFRS and U.S. GAAP Convergence Projects UpdateDocumento3 pagineIFRS and U.S. GAAP Convergence Projects UpdateNausheen Ahmed Noba0% (1)

- F5-Examreport-D13 (Deleted)Documento3 pagineF5-Examreport-D13 (Deleted)Nausheen Ahmed NobaNessuna valutazione finora

- F5-Examreport-D15 (Deleted)Documento4 pagineF5-Examreport-D15 (Deleted)Nausheen Ahmed NobaNessuna valutazione finora

- F5-Examreport-D14 (Deleted)Documento5 pagineF5-Examreport-D14 (Deleted)Nausheen Ahmed NobaNessuna valutazione finora

- LSBF - Acca - f9 Study Notes June 2015Documento216 pagineLSBF - Acca - f9 Study Notes June 2015Nausheen Ahmed Noba100% (1)

- Corporate CultureDocumento9 pagineCorporate CultureNausheen Ahmed NobaNessuna valutazione finora

- CIA QuestionsDocumento1 paginaCIA QuestionsNausheen Ahmed NobaNessuna valutazione finora

- IBA MBA CircularDocumento1 paginaIBA MBA CircularMohiuddin JewelNessuna valutazione finora

- The Keys To Expediting Audit Report Delivery-1Documento3 pagineThe Keys To Expediting Audit Report Delivery-1Nausheen Ahmed NobaNessuna valutazione finora

- Cost and Management Accounting Practice in A CompanyDocumento24 pagineCost and Management Accounting Practice in A CompanyNausheen Ahmed NobaNessuna valutazione finora

- Self Adhesive Tape Slitting MachineDocumento2 pagineSelf Adhesive Tape Slitting MachineNausheen Ahmed NobaNessuna valutazione finora

- About Bangladesh IT IndustryDocumento6 pagineAbout Bangladesh IT IndustryNausheen Ahmed NobaNessuna valutazione finora

- Power Loom IndustryDocumento10 paginePower Loom IndustryNausheen Ahmed NobaNessuna valutazione finora

- Commercial History of DhakaDocumento664 pagineCommercial History of DhakaNausheen Ahmed Noba100% (1)

- Performance Management and Appraisal4329Documento48 paginePerformance Management and Appraisal4329Raza SamiNessuna valutazione finora

- All Exchange HouseDocumento2 pagineAll Exchange HouseNausheen Ahmed NobaNessuna valutazione finora

- Centre For Policy Dialogue IRBD FY14 Third Reading Full StudyDocumento70 pagineCentre For Policy Dialogue IRBD FY14 Third Reading Full StudyNausheen Ahmed NobaNessuna valutazione finora

- WF 2013 34Documento12 pagineWF 2013 34Nausheen Ahmed NobaNessuna valutazione finora

- CP Fish FeedDocumento1 paginaCP Fish FeedNausheen Ahmed NobaNessuna valutazione finora

- Power Loom IndustryDocumento10 paginePower Loom IndustryNausheen Ahmed NobaNessuna valutazione finora

- Financial Projections TemplateDocumento66 pagineFinancial Projections TemplateVigneshwari VeeNessuna valutazione finora

- 3500 Calorie Meal PlanDocumento1 pagina3500 Calorie Meal PlananadinathNessuna valutazione finora

- An Overview of The Textile Chemical Sector in BangladeshDocumento8 pagineAn Overview of The Textile Chemical Sector in BangladeshNausheen Ahmed NobaNessuna valutazione finora

- Green Economy BoonorbaneDocumento9 pagineGreen Economy BoonorbaneNausheen Ahmed NobaNessuna valutazione finora

- 212201410841Documento4 pagine212201410841Nausheen Ahmed NobaNessuna valutazione finora

- Bangladesh Out of BasketDocumento11 pagineBangladesh Out of BasketNausheen Ahmed NobaNessuna valutazione finora

- BangladeshDocumento11 pagineBangladeshNausheen Ahmed NobaNessuna valutazione finora

- Banks Credit RatingDocumento63 pagineBanks Credit RatingNausheen Ahmed NobaNessuna valutazione finora

- Bangladesh Economy in FY2014Documento22 pagineBangladesh Economy in FY2014Nausheen Ahmed NobaNessuna valutazione finora

- Maintenence in Cement Industry ProjectDocumento25 pagineMaintenence in Cement Industry ProjectSUMIT SHARMA95% (19)

- Upholding Malay Language Strengthening Command English LanguageDocumento12 pagineUpholding Malay Language Strengthening Command English LanguagemucheliaNessuna valutazione finora

- What Is The Delphi Method?Documento2 pagineWhat Is The Delphi Method?Dunia Miqdad100% (1)

- DP Biology - Speciation Lesson PlanDocumento2 pagineDP Biology - Speciation Lesson Planapi-257190713100% (1)

- Jean Faber and Gilson A. Giraldi - Quantum Models For Artifcial Neural NetworkDocumento8 pagineJean Faber and Gilson A. Giraldi - Quantum Models For Artifcial Neural Networkdcsi3Nessuna valutazione finora

- Behavioral Pattern - FinalDocumento6 pagineBehavioral Pattern - FinalSaileneGuemoDellosaNessuna valutazione finora

- Zambian Open University: School of Social Science and HumanitiesDocumento9 pagineZambian Open University: School of Social Science and HumanitiesEvangelist Kabaso SydneyNessuna valutazione finora

- An Appraisal of The Impact of Holy Spirit in The Life of BelieversDocumento8 pagineAn Appraisal of The Impact of Holy Spirit in The Life of BelieversAnonymous ftifJFgbNessuna valutazione finora

- National Social Protection Strategy GhanaDocumento95 pagineNational Social Protection Strategy GhanaSisiraPinnawalaNessuna valutazione finora

- Chapter 3-PIC IO Port ProgrammingDocumento36 pagineChapter 3-PIC IO Port Programmingouterrace67% (3)

- The Right MindDocumento8 pagineThe Right Mindwaltor makuvireNessuna valutazione finora

- Section 3 Solutions PDFDocumento5 pagineSection 3 Solutions PDFSam javaNessuna valutazione finora

- Tony Robbins ResultDocumento11 pagineTony Robbins ResultSalee BuiserNessuna valutazione finora

- Asug PPT FinalDocumento65 pagineAsug PPT FinalcooldvrskNessuna valutazione finora

- 2018 - 14 Sept - Matlit Hymns - Exaltation Holy CrossDocumento16 pagine2018 - 14 Sept - Matlit Hymns - Exaltation Holy CrossMarguerite PaizisNessuna valutazione finora

- Fabrication and Characterization of Polysilane PCBM Bulk Heterojunction Solar CellsDocumento5 pagineFabrication and Characterization of Polysilane PCBM Bulk Heterojunction Solar CellsHERNANDEZ1010Nessuna valutazione finora

- Dental MneumonicDocumento30 pagineDental Mneumonictmle44% (9)

- Metabarons Univers GuideDocumento155 pagineMetabarons Univers Guidebilou hertNessuna valutazione finora

- Aja052550590 786Documento13 pagineAja052550590 786EugeneSeasoleNessuna valutazione finora

- Jaw Crusher Kinematics Simulation and AnalysisDocumento5 pagineJaw Crusher Kinematics Simulation and AnalysisInternational Journal of Research in Engineering and ScienceNessuna valutazione finora

- An Automated Machine Vision Based System For Fruit Sorting and GradingDocumento6 pagineAn Automated Machine Vision Based System For Fruit Sorting and GradingMekaTronNessuna valutazione finora

- Position PaperDocumento19 paginePosition PaperShara BasilioNessuna valutazione finora

- Currencies A PrimerDocumento15 pagineCurrencies A PrimerNicolae VutcariovNessuna valutazione finora

- J.C Tongue & Malocclusion - Copy (Recovered)Documento81 pagineJ.C Tongue & Malocclusion - Copy (Recovered)meghaNessuna valutazione finora

- The Billionaire Brain WaveDocumento3 pagineThe Billionaire Brain WavelittlebirdshomeeducationNessuna valutazione finora

- Socscipi PPT2Documento9 pagineSocscipi PPT2DKY SYSNessuna valutazione finora

- GRADE 8 3rd Quarter ReviewerDocumento9 pagineGRADE 8 3rd Quarter ReviewerGracella BurladoNessuna valutazione finora

- RizalDocumento6 pagineRizalKin BarklyNessuna valutazione finora

- Don Mariano Marcos Memorial State University Mid La Union CampusDocumento5 pagineDon Mariano Marcos Memorial State University Mid La Union CampusSam Bernardo100% (2)

- Oracle Database Performance Tuning Advanced Features and Best Practices For DbasDocumento303 pagineOracle Database Performance Tuning Advanced Features and Best Practices For Dbassss pppNessuna valutazione finora