Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Iso 9001 2008 Standard

Caricato da

Arun KumarDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Iso 9001 2008 Standard

Caricato da

Arun KumarCopyright:

Formati disponibili

5/30/2014 ISO 9001:2008 1

ABACUS

ISO 9001:2008

Quality Management Systems-

Requirements

5/30/2014 ISO 9001:2008 2

ISO 9000: SERIES OF

STANDARDS

ISO 9000:2005 Fundamentals

ISO 9001:2008 The requirements

ISO 9004:2000 Guidance

ISO 19011:2002 Auditing Quality &

Environmental systems

5/30/2014 ISO 9001:2008 3

SCOPE OF THE STANDARD

The standard specifies requirements for a quality management system

where an organization

(a) Needs to Demonstrate its ability to consistently provide product

that meets customer and applicable regulatory requirements, and

(b) Aims to Enhance customer satisfaction through effective

application of the system including processes for continual

improvement of the system and the assurance of conformity to

customer & applicable statutory and regulatory requirements

Note : Product only applies to product intended for the customer /any

intended out put resulting from product realization. Statutory &

regulatory requirements can be expressed as legal requirements.

5/30/2014 ISO 9001:2008 4

ELEMENTS OF ISO

9000:2008

CLAUSE NO. 4 QUALITY MANAGEMENT SYSTEM

CLAUSE NO. 5 MANAGEMENT RESPONSIBILITY

CLAUSE NO. 6 RESOURCE MANAGEMENT

CLAUSE NO. 7 PRODUCT REALIZATION

CLAUSE NO. 8 MEASUREMENT, ANALYSIS AND

IMPROVEMENT

5/30/2014 ISO 9001:2008 5

1.2 Permissible exclusions

Limited to clause 7 Product Realisation

Exclusions do not affect the organizations

ability or responsibility to provide product

that meets customer / statutory & regulatory

requirements

5/30/2014 ISO 9001:2008 6

Process-Based QMS Model

4 quality management system

8 Continual improvement

5 Management

responsibility

7 Product

realization

8 Measurement,

analysis and

improvement

CUSTOMERS

Requirements

CUSTOMERS

Satisfaction

Product

6 Resource

management

OUTPUT

INPUT

Value-adding activities

Information flow

5/30/2014 ISO 9001:2008 7

4 Quality management

system

5/30/2014 ISO 9001:2008 8

4.1 General requirements

The organisation shall

establish,

document,

implement,

maintain and

continually improve effectiveness in accordance with

the International Standard.

To enhance Customer Satisfaction

To ensure that the product meets statutory &

regulatory requirements

5/30/2014 ISO 9001:2008 9

4.1 General requirements

To implement the organisation shall:

identify the processes needed;

determine the sequence and

interaction of these processes;

determine criteria and methods required to

ensure the effective operation and control of

these processes;

5/30/2014 ISO 9001:2008 10

4.1 General requirements

availability of information to support the

operation and monitoring of these processes;

measure, monitor and analyse these processes,

and implement action necessary to achieve

planned results and continual improvement.

The organisation shall manage these processes

in accordance with the requirements of this

International Standard.

5/30/2014 ISO 9001:2008 11

4.2 Documentation Requirements

General

The quality management system documentation shall

include:

documented statements of a quality policy and

quality objectives

a quality manual

documented procedures required by this

International Standard.

documents required by the organisation to

ensure the effective planning operation and

control of its processes.

Records required by this International Standard

5/30/2014 ISO 9001:2008 12

4.2 Documentation Requirements

General

The extent of the quality management system

documentation shall be dependent on the following:

size and type of the organisation;

complexity and interaction of the processes;

competence of personnel.

The documentation can be in any form or type of

medium

5/30/2014 ISO 9001:2008 13

4.2.2 Quality Manual

The organization shall establish and maintain a

quality manual that includes

the scope of the quality management system,

including details of, and justification for, any

exclusions

documented procedures or reference to them;

a description of the interaction between the

processes of the quality management system.

5/30/2014 ISO 9001:2008 14

4.2.3 Control of documents

Documents required for the quality management system

shall be controlled. Records are a special type of

document and shall be controlled according to the

requirements for control of records

A documented procedure shall be established to define

controls needed

to approve documents for adequacy prior to issue;

to review, update as necessary and re-approve

documents;

To ensure that changes and the current revision

status of documents are identified ;

to ensure that relevant versions of applicable

documents are available at points of use;

5/30/2014 ISO 9001:2008 15

4.2.3 Control of documents

to ensure that documents remain legible and

readily identifiable ;

to ensure that documents of external origin are

identified and their distribution controlled; and

to prevent the unintended use of obsolete

documents, and to apply suitable identification

to them if they are retained for any purpose.

5/30/2014 ISO 9001:2008 16

4.2.4 Control of records

Records established to provide evidence of

conformity to requirements and of the effective

operation of the quality management system shall

be controlled .

The organization shall establish a documented

procedure to define controls needed for the

identification, storage, retrieval, retention and

disposition of records.

Records shall remain legible, readily identifiable

and retrievable

5/30/2014 ISO 9001:2008 17

5 Management responsibility

5/30/2014 ISO 9001:2008 18

5.1 Management commitment

Top management shall provide evidence of its

commitment to the development and

implementation of the quality management

system and continually improving its

effectiveness by:

communicating to the organisation the

importance of meeting customer as well as

statutory and regulatory l requirements,

establishing the quality policy and ensuring

that quality objectives are established,

conducting management reviews &

ensuring the availability of resources.

5/30/2014 ISO 9001:2008 19

5.2 Customer focus

Top management shall ensure that

customer requirements are determined

and are met with the aim of achieving

customer satisfaction.

5/30/2014 ISO 9001:2008 20

5.3 Quality policy

Top management shall ensure that the quality

policy:

is appropriate to the purpose of the

organisation;

includes a commitment to comply with

requirements and to continually improve the

effectiveness of the quality management

system;

provides a framework for establishing and

reviewing quality objectives;

is communicated and understood within the

organisation; and

is reviewed for continuing suitability.

5/30/2014 ISO 9001:2008 21

5.4 Planning

5/30/2014 ISO 9001:2008 22

5.4.1 Quality objectives

Top management shall ensure that quality

objectives,including those needed to meet

requirements for product are established at

relevant functions and levels within the

organization.

5/30/2014 ISO 9001:2008 23

5.4.1 Quality objectives

The quality objectives shall be measurable

and consistent with the quality policy.

5/30/2014 ISO 9001:2008 24

5.4.2 Quality Planning

Top management shall ensure that the

resources needed to achieve the quality

objectives are identified and planned.

5/30/2014 ISO 9001:2008 25

5.4.2 Quality planning

Top management shall ensure that

the planning of the management system is

carried out to meet the requirements in clause

4.1 as well as the quality objectives, and

the integrity of the quality management system

is maintained when changes to the quality

management system are planned and

implemented.

5/30/2014 ISO 9001:2008 26

5.5 Responsibility, authority,

and communication

5/30/2014 ISO 9001:2008 27

5.5.1 Responsibility and

Authority

Top management shall ensure that

responsibilities and authorities are defined

and communicated within the organisation.

5/30/2014 ISO 9001:2008 28

5.5.2 Management representative

Top management shall appoint a member of the

management team who, irrespective of other

responsibilities, shall have responsibility and

authority that includes:

ensuring that processes of the quality

management system are established and

maintained;

reporting to top management on the

performance of the quality management

system, including needs for improvement;

ensuring the promotion of customer

requirements

5/30/2014 ISO 9001:2008 29

5.5.3 Internal communication

The organisation shall ensure that

appropriate communication processes

are established within the organization

regarding the effectiveness of quality

management system.

Department A

Department B

5/30/2014 ISO 9001:2008 30

5.6 Management review

5.6.1 General

Top management shall review the organizations

quality management system, at planned intervals, to

ensure its continuing suitability, adequacy and

effectiveness.

The review shall include assessing opportunities for

improvement and the need for changes to the

organisation's quality management system, including

quality policy and quality objectives.

Records from management reviews shall be

maintained

5/30/2014 ISO 9001:2008 31

5.6.2 Review input

The Input to management review shall include

information on:

results of audits;

customer feedback;

process performance and product conformity;

status of preventive and corrective actions;

follow-up actions from earlier management

reviews;

changes that could affect the quality

management system, and

Recommendations for improvement

5/30/2014 ISO 9001:2008 32

5.6.3 Review output

The output from the management review

shall include any decisions and actions

related to

improvement of the management system

and its processes;

improvement of product related to

customer requirements;

resource needs.

5/30/2014 ISO 9001:2008 33

6 Resource management

5/30/2014 ISO 9001:2008 34

6.1 Provision of resources

The organisation shall determine and provide

the resources needed:

to implement and maintain the quality

management system and continually

improve its effectiveness, and

to enhance customer satisfaction by

meeting customer requirements.

5/30/2014 ISO 9001:2008 35

6.2 Human resources

6.2.1 General

Personnel performing work affecting product

quality shall be competent on the basis of

applicable education, training, skills and

experience.

5/30/2014 ISO 9001:2008 36

6.2.2 Competence ,Training,

and awareness

The organisation shall:

Determine the necessary competence for personnel

performing work affecting product quality;

Where applicable provide training or take other

actions to achieve the necessary competence;

evaluate the effectiveness of the actions taken;

ensure that its personnel are aware of the relevance

and importance of their activities and how they

contribute to the achievement of the quality

objectives;

maintain appropriate records of education,training

,skills and experience.

5/30/2014 ISO 9001:2008 37

6.3 Infrastructure

The organisation shall identify, provide, and maintain

the infrastructure needed to achieve conformity to

product requirements. Infrastructure includes as

applicable:

buildings, workspace and associated utilities;

process equipment (hardware and software);

supporting services (such as transport,

communication or information systems ).

5/30/2014 ISO 9001:2008 38

6.4 Work environment

The organisation shall determine and

manage the work environment needed to

achieve conformity to product requirements.

Note: Work environment relates to those conditions under which

work is performed including physical environment and other

factors ( such as noise , temperature, humidity , lighting or

weather .)

5/30/2014 ISO 9001:2008 39

7 Product realization

5/30/2014 ISO 9001:2008 40

7.1 Planning of Product

Realization

The organization shall plan and develop the

processes needed for product realization.

Planning of product realization shall be

consistent with the requirements of other

processes of the quality management system

(see 4.1)

5/30/2014 ISO 9001:2008 41

7.1 Planning of realization

processes

In planning product realization the organisation shall

determine the following as appropriate:

quality objectives and requirements for the product

need to establish processes, documents, and provide

resources specific to the product

Required Verification, validation, monitoring, inspection

and testing activities specific to the product and criteria

for product acceptance

records to provide evidence that the realisation

processes and the resulting product meet requirements

output of this planning shall be in a form suitable for the

organisations methods of operation

5/30/2014 ISO 9001:2008 42

7.2 Customer - related

processes

5/30/2014 ISO 9001:2008 43

7.2.1 Determination of requirements

related to the product

The organisation shall determine

customer requirements including requirements for

delivery and post-delivery activities

requirements not stated by the customer but

necessary for intended or specified use, where

known,

statutory and regulatory requirements applicable

to the product, and

any additional requirements considered

necessary & determined by the organisation

5/30/2014 ISO 9001:2008 44

7.2.2 Review of product requirements

The organisation shall review the requirements

related to the product

The review shall be conducted prior to the

commitment to supply a product to the customer

(e.g. submission of a tender, acceptance of a

contract or order, acceptance of changes to

contracts or orders) to ensure that:

product requirements are defined

contract or order requirements differing from

those previously expressed are resolved

the organisation has the ability to meet the

defined requirements

5/30/2014 ISO 9001:2008 45

7.2.2 Review of product requirements

Records of the review shall be maintained

Where the customer provides no documented

statement of requirement, the customer

requirements shall be confirmed by the

organization before acceptance

Where product requirements are changed,

the organization shall ensure that

the relevant documents are amended

relevant personnel are made aware of the

changed requirements

5/30/2014 ISO 9001:2008 46

7.2.3 Customer communication

The organisation shall determine and

implement effective arrangements for

communicating with customers in relation to

product information;

enquiries, contracts or order handling,

including amendments; and

customer feedback, including customer

complaints.

5/30/2014 ISO 9001:2008 47

7.3 Design and development

5/30/2014 ISO 9001:2008 48

7.3.1 Design and

development planning

The organization shall plan and control the design

and development of product.

During the design and development planning, the

organization shall determine:

the design and development stages

the review, verification and validation that are

appropriate to each design and development

stage, and

The responsibilities and authorities for the design

and development.

5/30/2014 ISO 9001:2008 49

7.3.1 Design and development

planning

The organization shall manage the interfaces

between different groups involved in design and

development to ensure effective communication

and clarity of responsibilities.

Planning output shall be updated, as appropriate,

as the design and development progresses.

5/30/2014 ISO 9001:2008 50

7.3.2 Design and development

inputs

Inputs relating to product requirements shall be

determined and records maintained ( See 4.2.4 ). These

shall include:

functional and performance requirements;

applicable statutory and regulatory requirements;

where applicable information derived from previous

similar designs, and

other requirements essential for design and

development.

Inputs shall be reviewed for adequacy. Requirements

shall be complete, unambiguous and not in conflict

with each other

5/30/2014 ISO 9001:2008 51

7.3.3 Design and development

outputs

The output of design and development shall be

provided in a form that enables verification against

the design and development inputs and shall be

approved prior to release.

Design and development output shall:

meet the input requirements for design &

development

provide appropriate information for purchasing,

production, and service provision

contain or reference product acceptance criteria

specify the characteristics that are essential for

safe and proper use. ( can include details of

preservation of the product )

5/30/2014 ISO 9001:2008 52

7.3.4 Design and development

review

At suitable stages, systematic reviews of design and

development shall be conducted in accordance with

the planned arrangements

to evaluate the ability of the results of the design

process to meet requirements; and

to identify problems and propose necessary

actions.

Participants in such reviews shall include

representatives of functions concerned with the

design and development stage(s) being reviewed.

Records of the results of the reviews and any

necessary actions shall be maintained.

5/30/2014 ISO 9001:2008 53

7.3.5 Design and development

verification

Verification shall be performed in accordance with

planned arrangements (see 7.3.1) to ensure that the

design and development outputs have met the

design and development input requirements.

Records of the results of the verification and any

necessary actions shall be maintained. (see 4.2.4)

5/30/2014 ISO 9001:2008 54

7.3.6 Design and / or development

validation

Design and development validation shall be

performed in accordance with planned

arrangements to ensure that resulting product is

capable of meeting the requirements for the

specified application or intended use, where

known.

Wherever practicable, validation shall be

completed prior to the delivery or implementation

of the product.

Records of the results of validation and any

necessary actions shall be maintained.

(see 4.2.4)

5/30/2014 ISO 9001:2008 55

7.3.7 Control of design and

development changes

Design and development changes shall be identified

and records maintained.

The changes shall be reviewed, verified and

validated,as appropriate and approved before

implementation.

The review of design and development changes shall

include evaluation of the effect of the changes on

Constituent parts and Products already delivered

Records of the results of the review of changes and

any necessary actions shall be maintained

( see 4.2.4 )

5/30/2014 ISO 9001:2008 56

7.4 Purchasing

5/30/2014 ISO 9001:2008 57

7.4.1 Purchasing process

The organization shall ensure that purchased product

conforms to specified purchase requirements.

The type and extent of control shall be dependent

upon the effect of the purchased product on

- subsequent product realisation or the final product.

The organisation shall evaluate and select suppliers

based on their ability to supply product as per the

requirements.

5/30/2014 ISO 9001:2008 58

7.4.1 Purchasing process

Criteria for supplier selection, evaluation and

re-evaluation shall be established.

Records of the results of evaluations and any

necessary actions arising shall be

maintained.

5/30/2014 ISO 9001:2008 59

7.4.2 Purchasing information

Purchasing information shall describe the product to

be purchased, including where appropriate:

requirements for approval of product, procedures,

processes, equipment

requirements for qualification of personnel &

quality management system requirements.

The organization shall ensure the adequacy of

specified purchase requirements prior to their

communication to the supplier.

5/30/2014 ISO 9001:2008 60

7.4.3 Verification of purchased

products

The organization shall establish and implement the

inspection or other activities necessary for ensuring

that the purchased product meets specified purchase

requirements.

Where the organisation or its customer intends to

perform verification at the supplier's premises, the

organisation shall state the intended verification

arrangements and method of product release in the

purchasing information.

5/30/2014 ISO 9001:2008 61

7.5 Production and service

provision

5/30/2014 ISO 9001:2008 62

7.5.1 Control of production and

service provision

The organisation shall plan & carry out production and

service provision under controlled conditions. Controlled

conditions shall include as applicable

the availability of information that describes the

characteristics of the product;

the availability of work instructions, as necessary,

the use of suitable equipment

the availability and use of measuring and monitoring

equipments ,

the implementation of monitoring and measurement,

the implementation of release, delivery and post-

delivery activities.

5/30/2014 ISO 9001:2008 63

7.5.2 Validation of processes

The organization shall validate any processes

for production and service provision where

the resulting output cannot be verified by

subsequent measurement or monitoring & as

a consequence , deficiencies become

apparent only after the product is in use or

the service has been delivered.

5/30/2014 ISO 9001:2008 64

7.5.2 Validation of processes

Validation shall demonstrate the ability of the

processes to achieve planned results.

The organization shall establish arrangements for

these processes including, as applicable

defined criteria for review and approval of the

processes

approval of equipment and qualification of

personnel

use of specific methods and procedures

requirements for records

revalidation

5/30/2014 ISO 9001:2008 65

7.5.3 Identification and traceability

Where appropriate, the organization shall identify,

where appropriate, the product by suitable means

throughout product realization.

The organization shall identify the product status with

respect to measurement and monitoring

requirements throughout product realization .

Where traceability is a requirement, the organization

shall control and record the unique identification of

the product and maintain records .

5/30/2014 ISO 9001:2008 66

7.5.4 Customer property

The organization shall exercise care with customer

property while it is under the organizations control or

being used by the organization

The organization shall identify, verify, protect and

safeguard customer property provided for use or

incorporation into the product.

If any customer property is lost, damaged or otherwise

found to be unsuitable for use, the organization shall

be report this to the customer and maintain records.

NOTE: Customer property can include intellectual

property & personal data.

5/30/2014 ISO 9001:2008 67

7.5.5 Preservation of product

The organization shall preserve conformity of

product during internal processing and delivery

to the intended destination in order to maintain

conformity to the requirements .

As applicable this preservation shall include

identification, handling, packaging, storage and

protection.

Preservation shall also apply to the constituent

parts of a product.

5/30/2014 ISO 9001:2008 68

7.6 Control of monitoring and

measuring devices

The organization shall determine the monitoring

and measurement to be undertaken and the

monitoring and measuring devices needed to

provide evidence of conformity of product to

determined requirements.

The organization shall establish processes to

ensure that d monitoring and measurement can

be carried out and are carried out in a manner

that is consistent with the monitoring and

measuring requirements.

5/30/2014 ISO 9001:2008 69

7.6 Control of monitoring and

measuring devices

Where necessary to ensure valid results, measuring equipment

shall:

be calibrated or verified at specified intervals or prior to use,

against measurement standards traceable to international or

national measurement standards; where no such standards

exist, the basis used for calibration or verification shall be

recorded;

Be adjusted or readjusted as necessary;

Have identification to enable the calibration status to be

determined

be safeguarded from adjustments that would invalidate the

measurement results

Be protected from damage and deterioration during handling,

maintenance, & storage

5/30/2014 ISO 9001:2008 70

7.6 Control of measuring and

monitoring devices

The organization shall assess and record the validity

of the previous measuring results when the

equipment is found not to conform to requirements

The organization shall take appropriate action on the

equipment and any product affected

Records of the results of calibration and verification

shall be maintained

When used in monitoring and measurement, the

ability of computer software to satisfy the intended

application shall be confirmed prior to initial use and

reconfirmed as necessary.

( Confirmation of the ability of the computer software to satisfy the intended

application would typically include its verification and configuration

management to maintain its suitability for use .)

5/30/2014 ISO 9001:2008 71

8 Measurement, analysis

and improvement

5/30/2014 ISO 9001:2008 72

8.1 General

The organization shall plan and implement the

measurement, monitoring, analysis and improvement

processes needed :

- to demonstrate conformity to the product requirements

to ensure conformity of the management system

to continually improve the effectiveness of the

management system

This shall include the determination of applicable methods,

including statistical techniques & the extent of their use.

5/30/2014 ISO 9001:2008 73

8.2 Measurement and

monitoring

5/30/2014 ISO 9001:2008 74

8.2.1 Customer satisfaction

As on of the measurements of the performance of the

Quality management System , the organization shall

monitor information to customer perception as to weather

the organization has met the customer requirements.

( Monitoring customer perception can include obtaining input from source

such as customer satisfaction surveys, customer data, and delivered product

quality ,user surveys, lost business analysis, compliments, warranty claims &

dealer reports )

5/30/2014 ISO 9001:2008 75

8.2.2 Internal audit

The organization shall conduct internal audits at planned

intervals to determine whether the quality management

system

Conforms to the planned arrangements to the requirements

of this international standard & to the Quality management

system requirements established by the organization

Is effectively implemented & maintained.

An audit programme shall be planned taking into

consideration the status and importance of the processes

and areas to be audited as well as the results of previous

audits.

The audit criteria, scope, frequency and methods shall be

defined.

5/30/2014 ISO 9001:2008 76

8.2.2 Internal audit

The selection of auditors & conduct of audits shall ensure

objectivity and impartiality of the audit process . Auditors

shall not audit their own work.

Documented procedure shall be established to define the

responsibilities and requirements for planning &

conducting audits, establishing records and reporting

results.

Records of the audits and their results shall be maintained

5/30/2014 ISO 9001:2008 77

8.2.2 Internal audit

The management responsible for the area being audited

shall ensure that any necessary corrections and corrective

actions are taken without any delay to eliminate detected

non conformities and their causes.

Follow-up actions shall include the verification of the

actions taken & reporting of verification results.

5/30/2014 ISO 9001:2008 78

8.2.3 Monitoring and

measurement of processes

The organization shall apply suitable methods for

monitoring & where applicable, measurement of the

Quality management system processes.

These methods shall demonstrate the ability of the

processes to achieve the planned results. When results are

not achieved, correction & corrective actions shall be

taken, as appropriate . ( It is advisable that the type and extent of monitoring

or measurement appropriate to each process in relation to their impact of the conformity

with the product requirements & on effectiveness of the Quality management System.)

5/30/2014 ISO 9001:2008 79

8.2.4 Monitoring and

measurement of product

The organization shall monitor & Measure the

characteristics of the product to verify that product

requirements have been met.

This shall be carried out at appropriate stages of the

product realization process in accordance with the planned

arrangements..

Evidence of conformity with the acceptance criteria shall

be maintained.

Records shall indicate the person/s authorizing release of

the product for delivery to the customer.

5/30/2014 ISO 9001:2008 80

8.2.4 Measurement and

monitoring

The release of the Product & to the customer shall not

proceed until the planned arrangements have been

satisfactorily completed , unless otherwise approved by

a relevant authority and, where applicable, by the

customer.

5/30/2014 ISO 9001:2008 81

8.3 Control of Non-conformances

5/30/2014 ISO 9001:2008 82

8.3 Control of nonconforming

product

The organization shall ensure that product which does not

conform to product requirements is identified & controlled

to prevent its unintended use or delivery.

A documented procedure shall be established to define the

controls and related responsibilities and authorities for

dealing with nonconforming product.

5/30/2014 ISO 9001:2008 83

8.3 Control of nonconformity

Where applicable the organization shall deal with

nonconforming product by one or more of the following ways:

By taking action to eliminate the detected nonconformity

By authorizing its use , release or acceptance under concession

by a relevant authority and where applicable by the customer

By taking action to preclude its original intended use or

application

By taking action appropriate to the effects or potential effects, of

the nonconformity product is detected after delivery or use has

started.

When nonconforming product is corrected it shall be subjected

to revivification to demonstrate conformity to requirements.

Record of the nature of nonconformities and any subsequent

actions taken, including concessions obtained, shall be

maintained.

5/30/2014 ISO 9001:2008 84

8.4 Analysis of data

The organization shall determine, collect &

analyse appropriate data to demonstrate the

suitability and effectiveness of the Quality

Management System and to evaluate where

continual improvements of the effectiveness of the

Quality management System can be made .

This shall include data generated as a result of

monitoring and measuring activities from other

relevant sources.

5/30/2014 ISO 9001:2008 85

8.4 Analysis of data

The analysis of data shall provide information

relating to :

customer satisfaction

Conformity to product requirements

characteristics of processes, products and

opportunities for preventive action

suppliers.

5/30/2014 ISO 9001:2008 86

8.5 Improvement

5/30/2014 ISO 9001:2008 87

8.5.1 Continual improvement

The organisation shall continually improve the

effectiveness of the management system through the

use of:

the quality policy

quality objectives

audit results

analysis of data

corrective and preventive actions

management review.

5/30/2014 ISO 9001:2008 88

8.5.2 Corrective action

The organisation shall take action to eliminate the cause of

nonconformities in order to prevent recurrence. Corrective

action shall be appropriate to the effect of the non-

conformities encountered.

A documented procedure shall be established to define

requirements for:

Reviewing nonconformities (including customer complains)

Determining the causes of the nonconformities

Evaluating the need for action to ensure that nonconformities do not

reoccur.

Determining and implementing actions needed.

Record the actions taken

Reviewing the effectiveness of the corrective action taken .

5/30/2014 ISO 9001:2008 89

8.5.3 Preventive action

The organization shall determine action to eliminate the

causes of potential nonconformities to prevent occurrence

Preventive actions shall be appropriate to the effects of the

potential problems.

A documented procedure shall be established to define

requirements for :

Determining potential nonconformities and their

causes

evaluating the need for action to prevent occurrence of

non-conformities

determining and implementing the actions needed

recording results of action taken

reviewing preventive action taken

5/30/2014 ISO 9001:2008 90

Thank you

ANY QUESTIONS

Potrebbero piacerti anche

- Process Approach A Complete Guide - 2019 EditionDa EverandProcess Approach A Complete Guide - 2019 EditionNessuna valutazione finora

- 6 Draft HandS Training Policy and ProcedureDocumento9 pagine6 Draft HandS Training Policy and ProcedurerajaNessuna valutazione finora

- CAT 2010 Criteria For Shortlisting PDFDocumento3 pagineCAT 2010 Criteria For Shortlisting PDFmahabharat007Nessuna valutazione finora

- HRRL Shortlisting Criteria WebsiteDocumento2 pagineHRRL Shortlisting Criteria WebsiteManeesh DwivediNessuna valutazione finora

- Board Meeting Through TeleconferencingDocumento2 pagineBoard Meeting Through TeleconferencingbrownboomerangNessuna valutazione finora

- Informal Reports TAHIRDocumento6 pagineInformal Reports TAHIRyasir23Nessuna valutazione finora

- ISO 9001 QMS Internal AuditDocumento2 pagineISO 9001 QMS Internal AuditNurul AfizaNessuna valutazione finora

- ToR - Workshop Facilitator Staff RetreatDocumento5 pagineToR - Workshop Facilitator Staff Retreatمتعلم لغة أنجليزيةNessuna valutazione finora

- Pef131 PDFDocumento320 paginePef131 PDFdarl1Nessuna valutazione finora

- IELTS Writing Actual Tests 2008Documento4 pagineIELTS Writing Actual Tests 2008FLed NguyenNessuna valutazione finora

- Job Announcement For HR AssistantDocumento2 pagineJob Announcement For HR AssistantLeang KirirathNessuna valutazione finora

- Strategic Management: Unit 1Documento22 pagineStrategic Management: Unit 1Shabira MoushinaNessuna valutazione finora

- Leadership TemplateDocumento24 pagineLeadership TemplateJonas Miranda CabusbusanNessuna valutazione finora

- Natural HR Administrators GuideDocumento124 pagineNatural HR Administrators GuideShuhan Mohammad Ariful HoqueNessuna valutazione finora

- MHI AuthorisationDocumento21 pagineMHI Authorisationnainesh959Nessuna valutazione finora

- Iso 9001Documento2 pagineIso 9001JawaNessuna valutazione finora

- Competency Are Your Staff Adequately TrainedDocumento22 pagineCompetency Are Your Staff Adequately TrainedirdinamarchsyaNessuna valutazione finora

- Performance Management System at HBLDocumento36 paginePerformance Management System at HBLArslan Ali80% (5)

- Chapter 3 Quality System StandardsDocumento129 pagineChapter 3 Quality System StandardsSanjay AdhikariNessuna valutazione finora

- Rencana Tindakan Perbaikan Untuk Eksternal Audit ReportDocumento1 paginaRencana Tindakan Perbaikan Untuk Eksternal Audit ReportAde Haris MustafaNessuna valutazione finora

- ISO 9000 - Quality ManagementDocumento9 pagineISO 9000 - Quality ManagementVictor DharNessuna valutazione finora

- LQMS-SIP Checklist Final v1 - Jan 12 2016 PDFDocumento48 pagineLQMS-SIP Checklist Final v1 - Jan 12 2016 PDFrasimc9475Nessuna valutazione finora

- Barkat Recruitment From India Pakistan NepalDocumento5 pagineBarkat Recruitment From India Pakistan NepalFiroz RahmanNessuna valutazione finora

- Ems Manual Environmental Policy & Objectives Doc: NSC/ em Issue No 02 Page 1 of 2 Page Rev. No 00Documento1 paginaEms Manual Environmental Policy & Objectives Doc: NSC/ em Issue No 02 Page 1 of 2 Page Rev. No 00BAlaNessuna valutazione finora

- Rules 3rdDocumento47 pagineRules 3rdviet579100% (1)

- 1.1. Management Review InputDocumento3 pagine1.1. Management Review InputCok Mayun WidyatmikaNessuna valutazione finora

- HR Audit TorsDocumento3 pagineHR Audit TorsShumyla Kanval0% (1)

- Application For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012Documento13 pagineApplication For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012arvindNessuna valutazione finora

- FSSAI Presentation 1 PDFDocumento12 pagineFSSAI Presentation 1 PDFR C MathewNessuna valutazione finora

- 069 Audit Report RSUD Sekayu 9K St2 To ClientsDocumento11 pagine069 Audit Report RSUD Sekayu 9K St2 To ClientstutiarlyNessuna valutazione finora

- Software Quality Assurance W15L30 Instructor: Saliha ZahoorDocumento55 pagineSoftware Quality Assurance W15L30 Instructor: Saliha ZahoorygfdsgdgsdhdjkghkgjNessuna valutazione finora

- IMTE RegisterDocumento1 paginaIMTE RegisterMomo Itachi100% (1)

- Quality ManualDocumento8 pagineQuality ManualAnonymous B7pghhNessuna valutazione finora

- Quality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1Documento55 pagineQuality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1faroakNessuna valutazione finora

- Checklist KenyaDocumento45 pagineChecklist Kenyaketsela12Nessuna valutazione finora

- Control of Monitoring and Measuring EquipmentDocumento18 pagineControl of Monitoring and Measuring EquipmentFranklyn OnyeneNessuna valutazione finora

- Quality Management System ModuleDocumento181 pagineQuality Management System ModuleJhonrick MagtibayNessuna valutazione finora

- ISO 14000 Quality StandardsDocumento4 pagineISO 14000 Quality Standardsmastercontroldotcom100% (1)

- Q M S (QMS) : Uality Anagement YstemDocumento37 pagineQ M S (QMS) : Uality Anagement YstemDaud AliNessuna valutazione finora

- Vendor Assessment Questionnaire: Pt. Bakrie Pipe IndustriesDocumento7 pagineVendor Assessment Questionnaire: Pt. Bakrie Pipe IndustriesBang UcuppNessuna valutazione finora

- CalendarDocumento3 pagineCalendarWhitney LouisNessuna valutazione finora

- Chapter Three Purchasing and Materials ManagementDocumento15 pagineChapter Three Purchasing and Materials ManagementHorlick~IceNessuna valutazione finora

- ISQC 1 Implementation Guide PDFDocumento107 pagineISQC 1 Implementation Guide PDFKashif KamranNessuna valutazione finora

- About The Presenter : Avinash M BhardwajDocumento41 pagineAbout The Presenter : Avinash M BhardwajManoj RanaNessuna valutazione finora

- QMS, EMS ChecklistDocumento9 pagineQMS, EMS Checklistgayathrisrk001Nessuna valutazione finora

- Integrated Management System " All in One": Action PlanDocumento9 pagineIntegrated Management System " All in One": Action PlanAshraf S. YoussefNessuna valutazione finora

- SOP SampleDocumento4 pagineSOP SampleMuzaffar Zahoor FataniNessuna valutazione finora

- Basic Management Principles PDFDocumento88 pagineBasic Management Principles PDFDaveP.100% (1)

- The Marketing Audit Comes of AgeDocumento14 pagineThe Marketing Audit Comes of AgeRaluca NistorNessuna valutazione finora

- IRCA Code of ConductDocumento1 paginaIRCA Code of ConductRonaldo CostaNessuna valutazione finora

- Internal Quality Management System Audit Checklist (ISO9001:2015)Documento24 pagineInternal Quality Management System Audit Checklist (ISO9001:2015)Fatimaezzahraa BouaalamNessuna valutazione finora

- Qhse Policy: Applicable Legislative, Regulatory and Customer-Based RequirementsDocumento2 pagineQhse Policy: Applicable Legislative, Regulatory and Customer-Based RequirementsBenito TadeoNessuna valutazione finora

- Neville Clarke Training Calendar MalaysiaDocumento3 pagineNeville Clarke Training Calendar MalaysiaAswad AzizNessuna valutazione finora

- L03-Project Quality ManagementDocumento42 pagineL03-Project Quality ManagementMUHAMMAD AZEEM Khan100% (1)

- SM Finalnew Vol2 Cp7 CHAPTER 7Documento51 pagineSM Finalnew Vol2 Cp7 CHAPTER 7Prin PrinksNessuna valutazione finora

- ISO 9001 Evidence ChecklistDocumento40 pagineISO 9001 Evidence ChecklistsanrexiNessuna valutazione finora

- ISO 9001 Requirements ExplainedDocumento18 pagineISO 9001 Requirements ExplaineddesurkarbNessuna valutazione finora

- Introduction To ISO 9001:2008: Clause 1: ScopeDocumento58 pagineIntroduction To ISO 9001:2008: Clause 1: ScopeMula SrikantNessuna valutazione finora

- ISO 9001 Quality Manual TemplateDocumento43 pagineISO 9001 Quality Manual TemplateNC Rigor Luis92% (13)

- Veg DishesDocumento45 pagineVeg DishesArun KumarNessuna valutazione finora

- Non Veg DishesDocumento99 pagineNon Veg DishesArun KumarNessuna valutazione finora

- Ehandbook Process Safety 1309 PDFDocumento15 pagineEhandbook Process Safety 1309 PDFArun KumarNessuna valutazione finora

- Seko Dosing DiaDocumento12 pagineSeko Dosing DiaSeptriani LaoliNessuna valutazione finora

- Pug Mills / Paddle Mixers: Design & Principles of OperationDocumento1 paginaPug Mills / Paddle Mixers: Design & Principles of OperationArun KumarNessuna valutazione finora

- Melting Points of MetalsDocumento1 paginaMelting Points of MetalsArun KumarNessuna valutazione finora

- Industrial Pipe Marking GuideDocumento2 pagineIndustrial Pipe Marking GuideArun KumarNessuna valutazione finora

- Safety Management SystemDocumento17 pagineSafety Management SystemPradeep NegiNessuna valutazione finora

- Safety Is Money in The BankDocumento3 pagineSafety Is Money in The BankArun KumarNessuna valutazione finora

- Ims Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageDocumento9 pagineIms Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageArun KumarNessuna valutazione finora

- Safety Management SystemDocumento17 pagineSafety Management SystemPradeep NegiNessuna valutazione finora

- Glass GlossaryDocumento3 pagineGlass GlossaryArun Kumar100% (1)

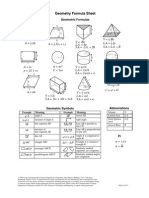

- Geometry Formula SheetDocumento1 paginaGeometry Formula SheetArun KumarNessuna valutazione finora

- Bearing Shaft Fits and Tolerances 1Documento9 pagineBearing Shaft Fits and Tolerances 1Arun KumarNessuna valutazione finora

- List of Youtube Video Clips For Kataline Infraproducts PVT Ltd-IndiaDocumento4 pagineList of Youtube Video Clips For Kataline Infraproducts PVT Ltd-IndiaArun KumarNessuna valutazione finora

- Corrective and Preventive Actions: "A Five Step Approach"Documento41 pagineCorrective and Preventive Actions: "A Five Step Approach"Arun KumarNessuna valutazione finora

- The Explosives Rules, 1983: Preliminary 1. Short Title and CommencementDocumento2 pagineThe Explosives Rules, 1983: Preliminary 1. Short Title and CommencementArun KumarNessuna valutazione finora

- Double Paddle MixerDocumento118 pagineDouble Paddle MixerArun Kumar80% (5)

- CapaDocumento24 pagineCapaArun KumarNessuna valutazione finora

- Dust Control in TunnelsDocumento27 pagineDust Control in TunnelsrockyminNessuna valutazione finora

- OISD Standard 244 DraftDocumento94 pagineOISD Standard 244 DraftSuresh GanesanNessuna valutazione finora

- Chemical Process Plant SafetyDocumento37 pagineChemical Process Plant Safetyvenky437Nessuna valutazione finora

- MUDPRO Plus Advanced Mud ReportingDocumento2 pagineMUDPRO Plus Advanced Mud ReportinglarasNessuna valutazione finora

- Micronta 12VDC Power Adapter 273-1653A InstructionsDocumento2 pagineMicronta 12VDC Power Adapter 273-1653A Instructions240GL guyNessuna valutazione finora

- Operator'S Manual: E-Series Ultraviolet Hand LampsDocumento9 pagineOperator'S Manual: E-Series Ultraviolet Hand LampsGuiss LemaNessuna valutazione finora

- BOB SO Information HandoutDocumento5 pagineBOB SO Information HandoutKabya SrivastavaNessuna valutazione finora

- Zeal High Precision Wet Test Gas Flow Meters 2022Documento5 pagineZeal High Precision Wet Test Gas Flow Meters 2022Hiran ChathurangaNessuna valutazione finora

- Air Filters PDFDocumento2 pagineAir Filters PDFTan Jai0% (1)

- 09931374A Clarus 690 User's GuideDocumento244 pagine09931374A Clarus 690 User's GuideLuz Idalia Ibarra Rodriguez0% (1)

- 15mm K115 GW-S CUP STD (SH005 1014 B)Documento2 pagine15mm K115 GW-S CUP STD (SH005 1014 B)Ionut BucurNessuna valutazione finora

- DH Xvr4b16Documento3 pagineDH Xvr4b16Jumar JumadiaoNessuna valutazione finora

- 00 EET3196 Lecture - Tutorial Ouline Plan1Documento6 pagine00 EET3196 Lecture - Tutorial Ouline Plan1mikeNessuna valutazione finora

- Service Pack 2Documento149 pagineService Pack 2billwong169Nessuna valutazione finora

- Presentation On Market Potential of Tag TasteDocumento10 paginePresentation On Market Potential of Tag TasteRajaNessuna valutazione finora

- 5 CombiflameDocumento8 pagine5 CombiflamenitantharaniNessuna valutazione finora

- p20 PDFDocumento12 paginep20 PDFpraphul gamangoNessuna valutazione finora

- Resistive Capacitive Inductive and Magnetic Sensor Technologies by Winncy Y Du PDFDocumento400 pagineResistive Capacitive Inductive and Magnetic Sensor Technologies by Winncy Y Du PDFlocthaiquoc83% (6)

- DELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Documento4 pagineDELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Ronnie Ayala SandovalNessuna valutazione finora

- Johannes Gensfleisch Zur Laden Zum GutenbergDocumento2 pagineJohannes Gensfleisch Zur Laden Zum GutenbergNathan SidabutarNessuna valutazione finora

- JeeleDocumento9 pagineJeeleAnonymous SZDGk7SvGNessuna valutazione finora

- 晴天木塑目录册Documento18 pagine晴天木塑目录册contaeduNessuna valutazione finora

- Phase ShifterDocumento7 paginePhase ShifterNumanAbdullahNessuna valutazione finora

- Assessment of Reinforcement CorrosionDocumento5 pagineAssessment of Reinforcement CorrosionClethHirenNessuna valutazione finora

- Water FountainDocumento13 pagineWater Fountaingarych72Nessuna valutazione finora

- Getting Started With ATV310: DangerDocumento4 pagineGetting Started With ATV310: DangerAdnan Naeem MalikNessuna valutazione finora

- SWIFT Case Study Accord EADS 200808Documento3 pagineSWIFT Case Study Accord EADS 200808maheshbendigeri5945Nessuna valutazione finora

- Omni III User's Manual Va.1.0-20140124Documento130 pagineOmni III User's Manual Va.1.0-20140124Reuel TacayNessuna valutazione finora

- MCSL-045 Solved Assignments 2014-15Documento6 pagineMCSL-045 Solved Assignments 2014-15manishNessuna valutazione finora

- Mouse 200Documento2 pagineMouse 200Amjad AliNessuna valutazione finora

- Syllabus 330C SystemsDocumento1 paginaSyllabus 330C SystemsDANIEL VARGAS RODRIGUEZNessuna valutazione finora

- Project Proposal CarolingDocumento7 pagineProject Proposal CarolingAmparo Daniel Einstein D.Nessuna valutazione finora