Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FBW Presentation

Caricato da

debduttamallik0%(1)Il 0% ha trovato utile questo documento (1 voto)

65 visualizzazioni60 pagineFBW

Titolo originale

Fbw Presentation

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFBW

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0%(1)Il 0% ha trovato utile questo documento (1 voto)

65 visualizzazioni60 pagineFBW Presentation

Caricato da

debduttamallikFBW

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 60

Flash/Butt Welding

Flash Butt Welding

Lesson Objectives

When you finish this lesson you will

understand:

The flash and butt welding process

for plain carbon steel

The weld parameters which must be

controlled to get good welds

Typical flash/butt weld defects

Learning Activities

1. View Slides;

2. Read Notes,

3. Listen to lecture

4. Do on-line

workbook

Keywords

Flash Weld (AC), Butt Weld (DC), Flashing Current, Upset Current,

Upset Force, Upset Velocity, Upset Distance, Forging Temperature,

Linear Platen Motion, Parabolic Platen Motion, Continuous

Acceleration Platen Motion, Flat Spots, Penetrators

Introduction to Flash Welding

[Reference: Welding Process Slides, The Welding Institute]

Basic Steps in Flash Welding

(a) (c)

(b) (d)

Electrodes

[Reference: Welding Handbook, Volume 2, p.583, AWS]

Position and Clamp the Parts

Apply Flashing Voltage

and Start Platen Motion

Flash

Upset and Terminate Current

Equipment Example of Flash Welding

[Reference: Welding Process

Slides, The Welding Institute]

Typical applications:

(1) Butt welding of

matching sections.

(2) Chain links.

(3) Railway lines.

(4) Window frames.

(5) Aero-engine rings.

(6) Car wheel rims.

(7) Metal strip in rolling

mills.

Advantages of Flash Welding

Flexible cross sectioned shapes

Flexible positioning for similar cross section parts

Impurities can be removed during upset acts

Faying surface preparation is not critical except for large

parts

Can weld rings of various cross sections

Narrower heat-affected zones than those of upset welds

Limitations of Flash Welding

Produce unbalance on three-phase primary power

lines

The ejected molten metal particles present a fire

hazard

Require special equipment for removal of flash metal

Difficult alignment for workpieces with small cross

sections

Require almost identical cross section parts

Common Types of Flash Welds

Cross Section After Welding

Transformer

Fixed Platen Movable Platen

Dies

Axially Aligned Weld

[Reference: Welding Handbook, Volume 2, p.589, AWS]

Common Types of Flash Welds

(CONT.)

Cross Section After Welding

Fixed Platen Movable Platen

Transformer

Miter Weld

[Reference: Welding Handbook, Volume 2, p.589, AWS]

Common Types of Flash Welds

(CONT.)

Cross Section After Welding

Fixed Platen Movable Platen

Transformer

Ring Weld

[Reference: Welding Handbook, Volume 2, p.589, AWS]

Shunt

Current

Typical Mill Forms and Products

of Upset Welding

[Reference: Welding Handbook, Volume 2, p.600, AWS]

Savage, Flash Welding,

Welding Journal March 1962

Systems

Electrical

Force Application

Applications

Wheel Truck Rims

Ball Bearing Raceways

Bar Welding

Strip Welding During Continuous Processing

Pipelines

Schematic of Typical Flash Weld Cycle

Savage, Flash Welding,

Welding Journal March 1962

0 .05 .10 .15

Initial Flashing

Partial Burn-off

Stage 1 - Heat Soaking

Increased Burn-off

Stage 2 - Steady State

Excessive Burn-off

Stage 3 - Heat out

Best Region For

Upset

Nippes, Temp Dist During Flash Welding,

Welding Journal, Dec 1951

In Steady State, the Heat into the HAZ

Equals the Heat Out

Stage 3 Occurs When More Heat Flows

Out than is Flowing In

T

e

m

p

At Upset

Short Time After

Long Time After

Forge Temp

Upset in the Steady State - Stage 2 Region

Nippes, Cooling Rates in Flash Welding,

Welding Journal, July 1959

Time

T

e

m

p

Time

T

e

m

p

Time

T

e

m

p

Time

T

e

m

p

Temperature vs Time As a Function Of Distance

From Interface At Moment of Upset

At Moment Of Upset & Short Time Thereafter

Nippes, Cooling Rates in Flash Welding,

Welding Journal, July 1959

Factors Which Effect Extent

of Stable Stage 2

Material Electrical & Thermal Conductivity

Platen Motion During Flashing

Initial Clamping Distance

Preheat

Material Geometry

Burnoff

Dist from Instantaneous

Interface

T

e

m

p

e

r

a

t

u

r

e

I

n

s

t

a

n

t

a

n

e

o

u

s

T

e

m

p

e

r

a

t

u

r

e

Electrical & Thermal Conductivity

High Resistance = More I

2

R Heating

Low Thermal Conductivity = Less Heat Out

More Rapid Heating

Longer Stage 2

Higher Temperature

Wider HAZ

HAZ

Wide HAZ Narrow HAZ

Oxides Trapped

At Interface

Oxides Forced

To Flashing

Flashing Time

P

l

a

t

e

n

D

i

s

p

l

a

c

e

m

e

n

t

Platen Motion

Linear

Parabolic

Continuous Acceleration

Continuous Acceleration lead to Stub Out

Nippes, Temp Dist During Flash Welding,

Welding Journal, Dec 1951

Burnoff

Dist from Instantaneous

Interface

T

e

m

p

e

r

a

t

u

r

e

I

n

s

t

a

n

t

a

n

e

o

u

s

T

e

m

p

e

r

a

t

u

r

e

Linear Flashing - Effect of Increased Velocity

Higher Velocity

Parabolic Flashing

Nippes, Temp Dist During Flash Welding,

Welding Journal, Dec 1951

Temperature Comparison of Linear and Parabolic Flashing

Nippes, Temp Dist During Flash Welding,

Welding Journal, Dec 1951

Initial Clamping Distance

Burnoff

Dist from Instantaneous

Interface

T

e

m

p

e

r

a

t

u

r

e

I

n

s

t

a

n

t

a

n

e

o

u

s

T

e

m

p

e

r

a

t

u

r

e

Closer Initial Clamping

Shorter Stage 2

More Burnoff to Establish Steady State

Steeper Temperature Gradient

Effect of Preheat

Burnoff

Dist from Instantaneous

Interface

T

e

m

p

e

r

a

t

u

r

e

I

n

s

t

a

n

t

a

n

e

o

u

s

T

e

m

p

e

r

a

t

u

r

e

Beneficial

Larger HAZ

Burnoff

Dist from Instantaneous

Interface

T

e

m

p

e

r

a

t

u

r

e

I

n

s

t

a

n

t

a

n

e

o

u

s

T

e

m

p

e

r

a

t

u

r

e

Thicker Material

Thicker Material is more of a Heat Sink

Turn to the person sitting next to you and discuss (1 min.):

OK, we went back to the faster platen motion and told the

night shift guy to keep his hands off, but the weld still seems

to be too cold. What would you suggest?

DC Butt Welding

Introduction to Upset Welding

Finished Upset Weld

Heated Zone

To Welding Transformer

Clamping Die

Upsetting

Force

Movable Part

Clamping Die

Stationary Part

[Reference: Welding Handbook, Volume 2, p.598, AWS]

Schematic of Typical Butt Weld Cycle

Medar Technical Literature

Turn to the person sitting next to you and discuss (1 min.):

Because the part are first touching as DC current is

applied in butt welding, large current levels occur

immediately. How would welding steels containing large

manganese sulfide inclusions be effected by this?

FLASH/BUTT WELD DISCONTINUITIES

MECHNICAL

Misalignment

Poor Scarfing

Die Burns

HEAT AFFECTED ZONE

Turned Up Fibers (Hook Cracks)

HAZ Softening

CENTERLINE

Cold Weld

Flat Spots / Penetrators

Pinholes

Porosity

Cracking

Misalignment

Notch: Stress Riser

Notch

Thin Section

Poor Scarfing

Arcing

Die Burns

Martensite

Crack

Turned Up Fibers - Hook Cracks

Hook Cracks

Hardness Loss

Cold Weld

Cold Weld

Flat Spots & Penetrators in Flash Welds

Factors During Upset Which Reduce Defects

Upset Velocity

Upset Current

Upset Force

Upset Distance

Material Hot Strength/Chemistry

Upset Velocity

Higher Velocity Helps extrude Centerline Oxides Out

1. Oxides Are Present Because Melting

Points are high

2. Oxides Tend to Solidify or Harden and

Get entrapped at the Interface

3. Rapid Velocity Helps Get Them Moving

Upset Current

Advantages

Keeps Heat at Center Line During Upset

Keeps Oxides Fluid

Aids In Forcing Oxides Out

Disadvantages

Excess Heating Can Produce Excess Upset

More HAZ Fiber Turn Up

Upset Force

Generally Use Maximum Available

(Too Light a Force May Entrap Oxides)

Upset Distance

Need Enough Upset to Squeeze all Oxides Out

(Rule of Thumb: 1/2 to 1.25 times the thickness)

Material Hot Strength/Chemistry

Materials with higher hot strength require

higher force during upset

Materials producing refractory oxides or nitrides

require higher upset distance to squeeze them out

Feedback Control on Platen Motion During Flashing

TIME

P

l

a

t

e

n

T

r

a

v

e

l

Flashing Current Also Monitored; In Case of Short Circuit

Motion is Reversed

Acceptable Pre-

Programmed

Range

Torstensson, Electro-hydraulic Control of Flash Welding..

Svetsaren, Feb 1975

Monitor pre-programmed motion

Voltage

Current

Observation

Action

High

Low

Wide gap

Speed up

Low

High

Gap too

small

Slow down

Very low

Very high

Short circuit

Reverse

Current

Voltage

Feedback Control on Platen Motion

During Flashing

Medar Technical Literature, Medar Flashweld Control

with Programmable Adaptive Cam

Measure

Voltage

and

Current

Monitored During

Flashing

Upset Current Until

Proportional Amount of

Power Attained

Dickinson Adapting HSLA Steel to Welded Wheel Rims,

Welding Design & Fab, May 1979

Flash Welding

Potrebbero piacerti anche

- Flash Butt Welding Process OverviewDocumento60 pagineFlash Butt Welding Process OverviewHarisbarthi0% (1)

- 2c1 Seam WeldingDocumento57 pagine2c1 Seam WeldingSathish KumarNessuna valutazione finora

- Welding Power Source CharacteristicsDocumento5 pagineWelding Power Source CharacteristicsEmad A.AhmadNessuna valutazione finora

- Resistance Welding ProcessesDocumento47 pagineResistance Welding ProcessesJohan ZraghozNessuna valutazione finora

- Welding Lectures 9-11Documento60 pagineWelding Lectures 9-11khudhayerNessuna valutazione finora

- Definition of Resistance WeldingDocumento16 pagineDefinition of Resistance WeldingMitul patelNessuna valutazione finora

- Heat Removal: NPTEL Online Course On Analysis and Modelling of WeldingDocumento20 pagineHeat Removal: NPTEL Online Course On Analysis and Modelling of Weldinganish tNessuna valutazione finora

- 1-3 Cold Welding, EtcDocumento50 pagine1-3 Cold Welding, EtcUndertheroadNessuna valutazione finora

- Resistance AWSDocumento82 pagineResistance AWSaravindan100% (1)

- 2-3 Diffusion WeldingDocumento40 pagine2-3 Diffusion WeldingvaidyanathanNessuna valutazione finora

- PHWT PPT En24Documento25 paginePHWT PPT En248207 ASCETNessuna valutazione finora

- Welding Course NPTELDocumento39 pagineWelding Course NPTELAbhijeetSethi0% (1)

- Welding Lecture - 8: Welding Processes-Resistance WeldingDocumento22 pagineWelding Lecture - 8: Welding Processes-Resistance WeldingganeshNessuna valutazione finora

- Resistance Welding ExplainedDocumento25 pagineResistance Welding ExplainedameerakeemNessuna valutazione finora

- 1)Fundamentals of WeldingDocumento33 pagine1)Fundamentals of WeldingDivyang MistryNessuna valutazione finora

- Welding DistortionDocumento51 pagineWelding DistortionRaj singhNessuna valutazione finora

- Synopsis PPT 1Documento41 pagineSynopsis PPT 1api-423757765Nessuna valutazione finora

- Welding Processes (Compatibility Mode)Documento36 pagineWelding Processes (Compatibility Mode)Bharat KhandekarNessuna valutazione finora

- Top 7 Welding and Metal Joining ProcessesDocumento20 pagineTop 7 Welding and Metal Joining Processesvikasbhadoria9894Nessuna valutazione finora

- Aluminum Spot Welding: General ConsiderationsDocumento74 pagineAluminum Spot Welding: General ConsiderationshaikalNessuna valutazione finora

- Welding Fundamentals GuideDocumento68 pagineWelding Fundamentals GuideSaiprasad Thakar100% (1)

- 12 TIG WeldingDocumento27 pagine12 TIG WeldingPraviBeetlesNessuna valutazione finora

- 2a1 Physics Spot WeldDocumento25 pagine2a1 Physics Spot WeldNitish RanjanNessuna valutazione finora

- Welding Problems and Defects - Causes and Remedies: Deformation Arc Blow SpatterDocumento3 pagineWelding Problems and Defects - Causes and Remedies: Deformation Arc Blow Spatterdselvakuu50% (2)

- WELDING PROCESSES GUIDEDocumento52 pagineWELDING PROCESSES GUIDEAnil Kumar TNessuna valutazione finora

- Friction Welding: By, Ramu RajendranDocumento25 pagineFriction Welding: By, Ramu RajendranAmal XuvNessuna valutazione finora

- Proy Sold ResDocumento3 pagineProy Sold Resvitor17050137Nessuna valutazione finora

- Motivation:-: WWW - Parhladsharma.inDocumento4 pagineMotivation:-: WWW - Parhladsharma.inDeekshith DileepNessuna valutazione finora

- WINSEM2018-19 - MEE6004 - ETH - GDN128 - VL2018195001506 - Reference Material I - MJ - 1.1-1.2 - RM PDFDocumento25 pagineWINSEM2018-19 - MEE6004 - ETH - GDN128 - VL2018195001506 - Reference Material I - MJ - 1.1-1.2 - RM PDFAbinash PurushothamanNessuna valutazione finora

- Welding SlidesDocumento23 pagineWelding SlidesVi PowderNessuna valutazione finora

- 7.0 Failure of Materials 4 - Creep and Creep FractureDocumento26 pagine7.0 Failure of Materials 4 - Creep and Creep FractureTest TryNessuna valutazione finora

- PRES TIG Hot Wire Narrow Gap Welding enDocumento25 paginePRES TIG Hot Wire Narrow Gap Welding enRavishankarNessuna valutazione finora

- Thermal Effects Caused by Arc WeldingDocumento6 pagineThermal Effects Caused by Arc WeldingErma Ramos EstilloreNessuna valutazione finora

- Welding Types and DefectsDocumento30 pagineWelding Types and DefectsHarisagar ThulasiramanNessuna valutazione finora

- 2e1a Capacitive Discharge WeldingDocumento30 pagine2e1a Capacitive Discharge WeldingGurjinder SinghNessuna valutazione finora

- Stud Welding Capacitive Discharge WeldingDocumento30 pagineStud Welding Capacitive Discharge WeldingwenigmaNessuna valutazione finora

- l10 c2tc2 Cts 302 Dynamics of Laser Material InteractionDocumento27 paginel10 c2tc2 Cts 302 Dynamics of Laser Material InteractionHemanthKumarNessuna valutazione finora

- Lecture Slides - AMPDocumento28 pagineLecture Slides - AMPRoodrapratap Singh PariharNessuna valutazione finora

- Promanu II WeldingDocumento68 paginePromanu II WeldingRyan FilbertNessuna valutazione finora

- ShajuDocumento49 pagineShajuArunprasad MurugesanNessuna valutazione finora

- Arc Welding ProcessesDocumento153 pagineArc Welding Processespratap biswasNessuna valutazione finora

- Welding Processes ExplainedDocumento20 pagineWelding Processes ExplainedNawaz RafiqueNessuna valutazione finora

- Lecture 20 - Laser Materials ProcessingDocumento29 pagineLecture 20 - Laser Materials ProcessingGaurav GodseNessuna valutazione finora

- Welding Quality & In-Service ConcernsDocumento37 pagineWelding Quality & In-Service Concerns江宸宸Nessuna valutazione finora

- Gas Tungsten Arc Welding GuideDocumento41 pagineGas Tungsten Arc Welding GuideJayaraman KamarajNessuna valutazione finora

- Modes of Heat Transfer PresentationDocumento12 pagineModes of Heat Transfer PresentationYashvir SinghNessuna valutazione finora

- SMAW Guide: Shielded Metal Arc Welding Process ExplainedDocumento45 pagineSMAW Guide: Shielded Metal Arc Welding Process ExplainedEugenio Jr. MatesNessuna valutazione finora

- Low Energy Arc Joining Process For Materials Sensitive To HeatDocumento5 pagineLow Energy Arc Joining Process For Materials Sensitive To Heatg4okk8809Nessuna valutazione finora

- 1E and 1F - Diffusion Bonding and FSWDocumento15 pagine1E and 1F - Diffusion Bonding and FSWDeepakNessuna valutazione finora

- Welding 3Documento1 paginaWelding 3Edon MorinaNessuna valutazione finora

- Welding 171002150527Documento40 pagineWelding 171002150527Sk SajedulNessuna valutazione finora

- 11 Mma Welding-5Documento1 pagina11 Mma Welding-5Dipesh PatelNessuna valutazione finora

- Spot WeldingDocumento14 pagineSpot WeldingMuhammad Bin RiazNessuna valutazione finora

- Week No 3Documento6 pagineWeek No 3surajit biswasNessuna valutazione finora

- Gas Tungsten Arc Welding: by L D PoyyaraDocumento38 pagineGas Tungsten Arc Welding: by L D PoyyaraAayush PandeyNessuna valutazione finora

- Welcome YOU: Institute of Welding & Testing TechnologyDocumento66 pagineWelcome YOU: Institute of Welding & Testing TechnologyHimanshu MishraNessuna valutazione finora

- Electrical Characterization of Organic Electronic Materials and DevicesDa EverandElectrical Characterization of Organic Electronic Materials and DevicesNessuna valutazione finora

- The Execution FactorDocumento6 pagineThe Execution FactorSamanthaPereraNessuna valutazione finora

- Wheel AlignmentDocumento9 pagineWheel AlignmentSamanthaPereraNessuna valutazione finora

- Ceramic Backing: Reduce Costs Using One-Sided WeldingDocumento16 pagineCeramic Backing: Reduce Costs Using One-Sided WeldingSamanthaPereraNessuna valutazione finora

- The Definitive Guide To Cryogenic EngineeringDocumento21 pagineThe Definitive Guide To Cryogenic EngineeringSamanthaPereraNessuna valutazione finora

- Xa00044820 EngDocumento28 pagineXa00044820 EngDanem HalasNessuna valutazione finora

- General Details For WPS As Per EN PDFDocumento12 pagineGeneral Details For WPS As Per EN PDFAnilNessuna valutazione finora

- The Leadership KillerDocumento6 pagineThe Leadership KillerSamanthaPereraNessuna valutazione finora

- Acethylene Solubility in AcetoneDocumento12 pagineAcethylene Solubility in AcetoneBamrung SungnoenNessuna valutazione finora

- Acid Mixtures GuideDocumento40 pagineAcid Mixtures GuideSamanthaPereraNessuna valutazione finora

- Wps Follow Chart PDFDocumento2 pagineWps Follow Chart PDFmail_younes6592100% (1)

- Extreme Ownership PDFDocumento14 pagineExtreme Ownership PDFNilesh ShobhaneNessuna valutazione finora

- W Frec27Documento41 pagineW Frec27e_gerlaNessuna valutazione finora

- List of Helpful Windows Alt CodesDocumento7 pagineList of Helpful Windows Alt CodesSamanthaPerera100% (1)

- Advances in Welding and Joining TechnologiesDocumento31 pagineAdvances in Welding and Joining TechnologiesSamanthaPereraNessuna valutazione finora

- 30 Design of Welded JointsDocumento8 pagine30 Design of Welded JointsPRASAD326Nessuna valutazione finora

- CWS Exam PackageDocumento10 pagineCWS Exam PackageSamanthaPereraNessuna valutazione finora

- Calculus Volume 1Documento871 pagineCalculus Volume 1Chancy Nordick100% (6)

- Lecture 17: Design and Static Strength of Welded JointsDocumento36 pagineLecture 17: Design and Static Strength of Welded Jointssprashant5Nessuna valutazione finora

- Technical Mathematics 1611787947Documento257 pagineTechnical Mathematics 1611787947om prakash patelNessuna valutazione finora

- CalculusVolume1 OPDocumento829 pagineCalculusVolume1 OPMOHAMMED IRFANUDDIN100% (1)

- LeadershipDocumento44 pagineLeadershipSamanthaPereraNessuna valutazione finora

- 10 Elements of Business Killer Sales People UnderstandDocumento47 pagine10 Elements of Business Killer Sales People UnderstandJad SoaiNessuna valutazione finora

- IntermediateAlgebra2e-WEB PDFDocumento1.395 pagineIntermediateAlgebra2e-WEB PDFAshwin Hulikunte Mattadha100% (2)

- Beyond Lean - Simulation in Practice Second EditionDocumento323 pagineBeyond Lean - Simulation in Practice Second EditionJeampierr JIMENEZ MARQUEZNessuna valutazione finora

- Physical Sciences Gr12 PDFDocumento541 paginePhysical Sciences Gr12 PDFYanga MbetaneNessuna valutazione finora

- Full Math in Society PDF With Optional Sections 11-20-20Documento406 pagineFull Math in Society PDF With Optional Sections 11-20-20SamanthaPereraNessuna valutazione finora

- Mathematics Extension 2 HSC LevelDocumento250 pagineMathematics Extension 2 HSC LevelkalstarNessuna valutazione finora

- Weld Profile ShapesDocumento10 pagineWeld Profile ShapesSamanthaPereraNessuna valutazione finora

- Math 105 Odd Answers 1-3-21Documento67 pagineMath 105 Odd Answers 1-3-21SamanthaPereraNessuna valutazione finora

- CH4 2 Welding Joint PreparationDocumento46 pagineCH4 2 Welding Joint PreparationMatija BušićNessuna valutazione finora

- Heat Transfer: Conservation of EnergyDocumento28 pagineHeat Transfer: Conservation of EnergyAhmadJaffarGulfarazNessuna valutazione finora

- Ageing Phenomena of CelluloseDocumento9 pagineAgeing Phenomena of CellulosedchyNessuna valutazione finora

- IKEA United States (English) - IKEA Kitchen Brochure 2023-5Documento12 pagineIKEA United States (English) - IKEA Kitchen Brochure 2023-5lololNessuna valutazione finora

- DOWSIL™ 795 Structural Glazing Sealant Technical Data SheetDocumento5 pagineDOWSIL™ 795 Structural Glazing Sealant Technical Data SheetTrung Nguyễn NgọcNessuna valutazione finora

- (CHEM 108) M1C1 - Introduction To Chemistry-Matter and MeasurementDocumento29 pagine(CHEM 108) M1C1 - Introduction To Chemistry-Matter and MeasurementVladimir TimbrezaNessuna valutazione finora

- Ceilcote 180 Flakeline+ds+engDocumento4 pagineCeilcote 180 Flakeline+ds+englivefreakNessuna valutazione finora

- Matter of Long-Term Deflection Control in TCVNDocumento21 pagineMatter of Long-Term Deflection Control in TCVNHoang Duc LocNessuna valutazione finora

- Environmental Engineering QuizDocumento4 pagineEnvironmental Engineering QuizmikeengineeringNessuna valutazione finora

- Literature Review of Glass FiberDocumento7 pagineLiterature Review of Glass Fiberaflsjizaf100% (1)

- Monday 20 May 2019: ChemistryDocumento24 pagineMonday 20 May 2019: Chemistrymostafa barakat75% (4)

- Carbon Steel Ball Valve: Code # 50 (Aksctk)Documento1 paginaCarbon Steel Ball Valve: Code # 50 (Aksctk)thilina lakhithaNessuna valutazione finora

- Astm c1557Documento10 pagineAstm c1557Roxana Elizabeth Valencia Navarrte100% (4)

- X. S. Ling Et Al - Superheating and Supercooling of Vortex Matter in A NB Single Crystal: Direct Evidence For A Phase Transition at The Peak Effect From Neutron DiffractionDocumento4 pagineX. S. Ling Et Al - Superheating and Supercooling of Vortex Matter in A NB Single Crystal: Direct Evidence For A Phase Transition at The Peak Effect From Neutron DiffractionKolddeNessuna valutazione finora

- Science7 - Q3 - M6 - Electrical-Charging Processes - v5Documento29 pagineScience7 - Q3 - M6 - Electrical-Charging Processes - v5CharielyTamparongNessuna valutazione finora

- 1 s2.0 S2215098622001562 MainDocumento9 pagine1 s2.0 S2215098622001562 MainJUAN DAVID PRADO CORTESNessuna valutazione finora

- Series 83 DelMonitor Limit Switch BoxDocumento2 pagineSeries 83 DelMonitor Limit Switch BoxProcess Controls & ServicesNessuna valutazione finora

- Polymer Additives and PlasticizersDocumento25 paginePolymer Additives and PlasticizersDeva Raj100% (1)

- Caesar II Static TrainingDocumento312 pagineCaesar II Static TrainingMed Rjeb100% (1)

- The Analysis and Prevention of Failure in Railway AxlesDocumento10 pagineThe Analysis and Prevention of Failure in Railway AxlesAnonymous PufNjgNessuna valutazione finora

- Eng Chem Lecture NotesDocumento2 pagineEng Chem Lecture NotesJunell TadinaNessuna valutazione finora

- Quarter 2: Week 11 Lo 3. Handle Materials and Equipment TLE-AFAC10CW-11a-e-3Documento16 pagineQuarter 2: Week 11 Lo 3. Handle Materials and Equipment TLE-AFAC10CW-11a-e-3Romeo Jr Vicente Ramirez100% (5)

- Sdre14-2 Dra 1-8-Rev17Documento9 pagineSdre14-2 Dra 1-8-Rev17xuongrong_xdNessuna valutazione finora

- Design For Hot Dip GalvanisingDocumento9 pagineDesign For Hot Dip GalvanisingSreedhar Patnaik.MNessuna valutazione finora

- Corrosion and Protection For Steel Pile: Yoshikazu Akira, Dr. EngDocumento45 pagineCorrosion and Protection For Steel Pile: Yoshikazu Akira, Dr. EngAnand JadoenathmisierNessuna valutazione finora

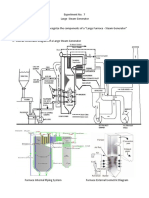

- Internship SeminarDocumento28 pagineInternship Seminarkavya kruthiNessuna valutazione finora

- Large Steam GeneratorDocumento12 pagineLarge Steam GeneratorChe AguilarNessuna valutazione finora

- Water Pitcher Filter EN: MODELS: Time, Agate, Amethyst, Orion, Jasper, Compact, Onyx Operating ManualDocumento2 pagineWater Pitcher Filter EN: MODELS: Time, Agate, Amethyst, Orion, Jasper, Compact, Onyx Operating ManualMstefNessuna valutazione finora

- Flame PhotometryDocumento8 pagineFlame PhotometryNimra MalikNessuna valutazione finora

- Petron Plustm Formula 7 Diesel Engine ConditionerDocumento2 paginePetron Plustm Formula 7 Diesel Engine ConditionerwellblablablaNessuna valutazione finora

- Rihayat 2018 IOP Conf. Ser. Mater. Sci. Eng. 334 012054Documento8 pagineRihayat 2018 IOP Conf. Ser. Mater. Sci. Eng. 334 012054Arina SaukiNessuna valutazione finora