Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lecture 2 Cement Contd.

Caricato da

Jappu KumarDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lecture 2 Cement Contd.

Caricato da

Jappu KumarCopyright:

Formati disponibili

Structure III

Lecture 2

Content

Setting time of cement

Tests on cement

Setting time of cement

Cement paste setting time is affected by a number of

items including: cement fineness, water-cement ratio,

chemical content (especially gypsum content) and

admixtures.

Setting tests are used to characterize how a particular

cement paste sets.

For construction purposes, the initial set must not be

too soon and the final set must not be too late.

Additionally, setting times can give some indication of

whether or not a cement is undergoing

normal hydration.

Contd.

Normally, two setting times are defined:-

1. Initial setting time Occurs when the paste begins to

stiffen considerably.

2. Final setting time Occurs when the cement has hardened

to the point at which it can sustain some load.

Note: These particular times are just arbitrary points used

to characterize cement, they do not have any fundamental

chemical significance. They describe the setting of the

cement and are not tied to the setting time of concrete.

Review questions

What do you understand by setting time of

cement ?

What is the difference between initial setting

time and final setting time of cement ?

Tests on cement

The list of main physical tests conducted on

cement are as-

1. Fineness test

2. Soundness test

3. Consistency test

4. Setting time test

5. Compressive strength test

Fineness test

To determine the fineness of cement by dry

sieving as per IS: 4031 (Part 1) 1996. The

principle of this is that we determine the

proportion of cement whose grain size is larger

then specified mesh size.

The apparatus used are 90m IS Sieve, Balance

capable of weighing 10g to the nearest 10mg, A

nylon or pure bristle brush, preferably with 25 to

40mm, bristle, for cleaning the sieve.

IS Standard Sieves

Procedure

Weigh approximately 10g of cement to the nearest 0.01g and place

it on the sieve.

Shake the sieve by linear movements, until no more fine material

passes through it.

Weigh the residue and express its mass as a percentage R1,of the

quantity first placed on the sieve to the nearest 0.1 percent.

Gently brush all the fine material off the base of the sieve.

Repeat the whole procedure using a fresh 10g sample to obtain R2.

Then calculate R as the mean of R1 and R2 as a percentage,

expressed to the nearest 0.1 percent. When the results differ by

more than 1 percent absolute, carry out a third sieving and

calculate the mean of the three values.

Review questions

Why fineness test is carried out ?

Give the standard sieve size used in fineness

test ?

Consistency test

The basic aim is to find out the water content

required to produce a cement paste of standard

consistency as specified by the IS: 4031 (Part 4)

1988. The principle is that standard consistency

of cement is that consistency at which the Vicat

plunger penetrates to a point 5-7mm from the

bottom of Vicat mould.

Apparatus Vicat apparatus conforming to IS:

5513 1976, Balance, whose permissible

variation at a load of 1000g should be +1.0g,

Gauging trowel conforming to IS: 10086 1982.

Procedure

Weigh approximately 400g of cement

and mix it with a weighed quantity of

water. The time of gauging should be

between 3 to 5 minutes.

Fill the Vicat mould with paste and

level it with a trowel.

Lower the plunger gently till it

touches the cement surface.

Release the plunger allowing it to

sink into the paste.

Note the reading on the gauge.

Repeat the above procedure taking

fresh samples of cement and

different quantities of water until the

reading on the gauge is 5 to 7mm.

contd.

Reporting of result-

Express the amount of

water as a percentage

of the weight of dry

cement to the first

place of decimal.

Review questions

What do you understand by consistency of

cement ?

Why consistency test is carried out ?

What is the name of apparatus used in this

test ?

Test for setting time of cement

We need to calculate the initial and final

setting time as per IS: 4031 (Part 5) 1988. To

do so we need Vicat apparatus conforming to

IS: 5513 1976, Balance, whose permissible

variation at a load of 1000g should be +1.0g,

Gauging trowel conforming to IS: 10086

1982.

Procedure

Prepare a cement paste by gauging the cement

with 0.85 times the water required to give a paste

of standard consistency.

Start a stop-watch, the moment water is added to

the cement.

Fill the Vicat mould completely with the cement

paste gauged as above, the mould resting on a

non-porous plate and smooth off the surface of

the paste making it level with the top of the

mould. The cement block thus prepared in the

mould is the test block.

(A) Initial setting time

Place the test block under the rod bearing the needle.

Lower the needle gently in order to make contact with

the surface of the cement paste and release quickly,

allowing it to penetrate the test block.

Repeat the procedure till the needle fails to pierce the

test block to a point 5.0 0.5mm measured from the

bottom of the mould.

The time period elapsing between the time, water is

added to the cement and the time, the needle fails to

pierce the test block by 5.0 0.5mm measured from

the bottom of the mould, is the initial setting time.

(B) Final setting time

Replace the above needle by the one with an annular

attachment.

The cement should be considered as finally set when,

upon applying the needle gently to the surface of the

test block, the needle makes an impression therein,

while the attachment fails to do so.

The period elapsing between the time, water is added

to the cement and the time, the needle makes an

impression on the surface of the test block, while the

attachment fails to do so, is the final setting time.

Review questions

What is the main significance of this test ?

How initial and final setting time is

determined from test specimen ?

How much quantity of water is used in this

test ?

Soundness test

This test is performed to determine the

presence of uncombined lime in cement.

If uncombined lime is present in cement,

during the setting action it might slake causing

increase in volume and will cause the

development of cracks.

In structure, cracks are objectionable as they

deteriorate the structure.

Contd.

Soundness of cement is determined by Le-

Chatelier method as per IS: 4031 (Part 3)

1988.

Apparatus The apparatus for conducting the

Le-Chatelier test should conform to IS: 5514

1969, Balance, whose permissible variation at

a load of 1000g should be +1.0g and Water

bath.

Le-Chateliers Apparatus

Procedure

Place the mould on a glass sheet and fill it with the cement paste

formed by gauging cement with 0.78 times the water required to

give a paste of standard consistency.

Cover the mould with another piece of glass sheet, place a small

weight on this covering glass sheet and immediately submerge the

whole assembly in water at a temperature of 27 2

o

C and keep it

there for 24hrs.

Measure the distance separating the indicator points to the nearest

0.5mm (say d

1

).

Submerge the mould again in water at the temperature prescribed

above. Bring the water to boiling point in 25 to 30 minutes and

keep it boiling for 3hrs.

Remove the mould from the water, allow it to cool and measure the

distance between the indicator points (say d

2

).

(d

2

d

1

) represents the expansion of cement.

Review questions

Why this test is carried out ?

Give the practical utility of this test.

Name the apparatus used in this test.

Compressive strength test

The compressive strength of hardened cement is the most

important of all the properties. Therefore, it is not surprising that

the cement is always tested for its compressive strength at the

laboratory before the cement is used in important works.

Apparatus Required-

1. Non porous enamel tray

2. Trowel

3. Cube mould of size 7.06cm

4. Platform vibrator (or) Equipment for hand compaction

5. Compression testing machine

6. Balance to measure weight

Contd.

Strength test are not done on neat cement paste

because of difficulties of excessive shrinkage and

subsequent cracking of neat cement.

Strength of cement is indirectly found on cement

sand mortar in specific proportion.

The cubes are prepared for this purpose.

The cubes are then tested in compression testing

machine at the end on three days and seven days.

Testing of cubes is carried out on their three sides

without packing.

Thus the cubes are tested at each time.

Procedure

Preparation of cement mortar cubes:

1. Take 555 gms of standard sand, 185gms of cement (i.e. ratio of cement to sand

is 1:3) in a non porous enamel tray and mix them with a trowel for one minute.

2. Add water quantity (P/4 + 3.0) % of combined weight of cement and sand and

mix the three ingredients thoroughly until the mixture is of uniform colour. The

time of mixing should not be less than three minutes and not more than four

minutes.

3. Immediately after mixing fill the mortar into a cube mould of sizes 7.06cm.

4. Compact the mortar either by hand compaction in a standard specified manner

or on the vibrating table.

5. Place the moulds in cabin at a temperature of 27 2 C for 24 hours

6. Remove the specimen from the moulds and submerge them in clean water for

curing.

Contd.

Testing of cement mortar cubes:

1. Take the cube out of water at the end of three days with dry cloth.

Measure the dimensions of the surface in which the load is to be

applied. Let be L and B respectively.

2. Place the cube in compressive testing machine and apply the load

uniformly at the rate of 35N/mm

2

.

3. Note the load at which the cube fails. Let it be P.

4. Calculate the compressive strength of the cube by using formula. The

compressive strength at the end of three days should not be less than

16N/mm

2

5. Repeat the same procedure (steps 1 to 4) for other two cubes.

6. Repeat the whole procedure (Step 1 to 5) to find the compressive

strength of the cube at the end of 7 days and it should not be less than

22 N/mm

2

.

Review questions

Give the significance of this test.

What is the size of cubes prepares for the test

?

What is the minimum compressive strength

recommended for the cubes after 3 days and

7 days ?

Potrebbero piacerti anche

- Unit 5 CementDocumento34 pagineUnit 5 CementJeewan KunwarNessuna valutazione finora

- Engineering Bulletin No 1: Boiler and Furnace TestingDa EverandEngineering Bulletin No 1: Boiler and Furnace TestingValutazione: 4.5 su 5 stelle4.5/5 (2)

- Test On Cement PDFDocumento6 pagineTest On Cement PDFIrfan NazirNessuna valutazione finora

- Welcome To To Concrete Technology LaboratoryDocumento8 pagineWelcome To To Concrete Technology LaboratoryRaviteja GirijalaNessuna valutazione finora

- Test For Properties of Cement: Physical & ChemicalDocumento4 pagineTest For Properties of Cement: Physical & ChemicalmuqeetNessuna valutazione finora

- Cemetn TestingDocumento20 pagineCemetn TestingKrishnan SubramaniamNessuna valutazione finora

- Muddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsDocumento15 pagineMuddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsAafaq Ur RehmanNessuna valutazione finora

- Concrete TestsDocumento111 pagineConcrete Testschaitanyatripathi4321Nessuna valutazione finora

- Material Testing ManualDocumento56 pagineMaterial Testing ManualJithin Benny JithinNessuna valutazione finora

- Testing Procedures Adopted For Cement and SteelDocumento6 pagineTesting Procedures Adopted For Cement and Steelp.v.n. lakshmanNessuna valutazione finora

- Consistency of Standard Cement PasteDocumento53 pagineConsistency of Standard Cement PasteLakshay SinghalNessuna valutazione finora

- CT Lab ManualDocumento26 pagineCT Lab ManualJagathChandraNessuna valutazione finora

- Experiment No. 1 Fineness of Cement by Hand SievingDocumento22 pagineExperiment No. 1 Fineness of Cement by Hand SievingUmed Abd-alsatarNessuna valutazione finora

- Concrete &highway Lab New ManualDocumento40 pagineConcrete &highway Lab New Manualshruthicivil100% (4)

- Chapter 3 MethodologyDocumento22 pagineChapter 3 MethodologySiva KrishnaNessuna valutazione finora

- Tests On CementDocumento138 pagineTests On CementKalasekar M Swamy50% (2)

- Concrete Technology LABDocumento52 pagineConcrete Technology LABBanoth Manjula SonuNessuna valutazione finora

- 05) CE 304 Lec 3 (Compatibility Mode)Documento21 pagine05) CE 304 Lec 3 (Compatibility Mode)priyadarshanNessuna valutazione finora

- Cement PPT ArunDocumento10 pagineCement PPT ArunAbhishek SharmaNessuna valutazione finora

- Concrete Technology - LabDocumento3 pagineConcrete Technology - LabSasi ShashNessuna valutazione finora

- Batch No 8Documento18 pagineBatch No 8LokeshNessuna valutazione finora

- Testing of CementDocumento17 pagineTesting of CementbinoNessuna valutazione finora

- Testing of CEMENT - 1Documento3 pagineTesting of CEMENT - 1সন্দীপ চন্দ্রNessuna valutazione finora

- Various Lab Test On CementDocumento4 pagineVarious Lab Test On Cementhncc ghazniNessuna valutazione finora

- Lju CT Lab Manual Dku FinalDocumento52 pagineLju CT Lab Manual Dku FinalAryan RathodNessuna valutazione finora

- Cycle 2 Som LabDocumento10 pagineCycle 2 Som LabAnonymous SEDun6PWNessuna valutazione finora

- Concrete Technology Notes 2Documento10 pagineConcrete Technology Notes 2Munir HalimzaiNessuna valutazione finora

- Concrete Technology (Lab Manual)Documento23 pagineConcrete Technology (Lab Manual)VipulShukla100% (3)

- Lab ManualDocumento23 pagineLab ManualSuraj AgrawalNessuna valutazione finora

- Determination of Consistency of Cement: ObjectiveDocumento26 pagineDetermination of Consistency of Cement: ObjectiveSruthiNessuna valutazione finora

- Unit 1 Handout # 3Documento6 pagineUnit 1 Handout # 3Oumar CoulibalyNessuna valutazione finora

- Bulking of SandDocumento12 pagineBulking of SandTauseefNessuna valutazione finora

- Concrete-Technology-Lab MINIMAL EDITEDDocumento20 pagineConcrete-Technology-Lab MINIMAL EDITEDsidNessuna valutazione finora

- Normal Consistancy and Settling Lab ManualDocumento4 pagineNormal Consistancy and Settling Lab ManualAnonymous gQzqEs3Nessuna valutazione finora

- WI 15 Cement TestingDocumento6 pagineWI 15 Cement TestingRaja Varshney100% (1)

- Report 1 Testing On Cement: Engineering MaterialsDocumento9 pagineReport 1 Testing On Cement: Engineering MaterialsEman SalahNessuna valutazione finora

- ASTM C 1157: Performance Specification For Portland CementDocumento13 pagineASTM C 1157: Performance Specification For Portland CementKenneth Malubay AndayaNessuna valutazione finora

- Taller MaterialesDocumento11 pagineTaller MaterialesJulian Rolando Sierra RodriguezNessuna valutazione finora

- Experiment No. 1 Consistency Test On CementDocumento8 pagineExperiment No. 1 Consistency Test On CementAjinkya Shendarkar0% (1)

- Lab Manual.1pdfDocumento31 pagineLab Manual.1pdfAshish KumarNessuna valutazione finora

- 04a Physical PropertiesDocumento13 pagine04a Physical PropertiesGanesh.RajanNessuna valutazione finora

- Laboratory Manual: CIV206 Unified Lab-IDocumento35 pagineLaboratory Manual: CIV206 Unified Lab-IItinderjot SinghNessuna valutazione finora

- CTM 1Documento7 pagineCTM 1Sajil KrishnaNessuna valutazione finora

- Durgesh CementDocumento43 pagineDurgesh Cementpandeydurgesh996Nessuna valutazione finora

- TESTSDocumento19 pagineTESTSarun chavanNessuna valutazione finora

- Experiment No. 01: S.A-I Laboratory Manual 1 Prepared By: Nishant SharmaDocumento13 pagineExperiment No. 01: S.A-I Laboratory Manual 1 Prepared By: Nishant Sharmasaket01nemaNessuna valutazione finora

- NORMAL CONSISTENCY TEST ON CEMENT A4 SheetDocumento3 pagineNORMAL CONSISTENCY TEST ON CEMENT A4 Sheetasishraj2003Nessuna valutazione finora

- Cement Physical TestingDocumento6 pagineCement Physical TestingPradeep SinghNessuna valutazione finora

- Rohini 56951549584Documento10 pagineRohini 56951549584Oumar CoulibalyNessuna valutazione finora

- Tests of Cement - SOPDocumento13 pagineTests of Cement - SOPElegant PrinceNessuna valutazione finora

- Standard Consistency, Setting Time,, and Fineness of CementDocumento6 pagineStandard Consistency, Setting Time,, and Fineness of CementNur Syahira0% (1)

- Tests On CementDocumento24 pagineTests On CementIan BondocNessuna valutazione finora

- Presentation 1Documento22 paginePresentation 1MEHALANessuna valutazione finora

- Practical No19Documento6 paginePractical No19Sam GamerNessuna valutazione finora

- ConcreteDocumento131 pagineConcreteHimanshu BhardwajNessuna valutazione finora

- Cement: Tests: Waim Akshay RavindraDocumento13 pagineCement: Tests: Waim Akshay RavindraAkshay WaimNessuna valutazione finora

- Cement Fineness Test (ASTM C 184 - 94)Documento4 pagineCement Fineness Test (ASTM C 184 - 94)Hazem Diab33% (3)

- Produced by An Autodesk Educational ProductDocumento1 paginaProduced by An Autodesk Educational ProductJappu KumarNessuna valutazione finora

- Essroc Masonry Tech 15 - Bulking of SandDocumento1 paginaEssroc Masonry Tech 15 - Bulking of SandJappu KumarNessuna valutazione finora

- Primary School: Submitted By:-Harshit Kochar Piyush NagiDocumento10 paginePrimary School: Submitted By:-Harshit Kochar Piyush NagiJappu KumarNessuna valutazione finora

- Lecture 4 Concrete PropertiesDocumento33 pagineLecture 4 Concrete PropertiesJappu KumarNessuna valutazione finora

- Lecture 1 CementDocumento23 pagineLecture 1 CementJappu KumarNessuna valutazione finora

- Sathya Consultants: For Thermal ComfortDocumento10 pagineSathya Consultants: For Thermal ComfortJappu KumarNessuna valutazione finora

- Constructability Concepts Significance and ImplemeDocumento11 pagineConstructability Concepts Significance and ImplemeHari Dwi KisbiyantoroNessuna valutazione finora

- Visual Inspection of Seamless PipesDocumento20 pagineVisual Inspection of Seamless PipesFasil Paruvanath100% (2)

- Fire Tube Boilers PDFDocumento16 pagineFire Tube Boilers PDFG.SWAMI67% (3)

- CellrodDocumento2 pagineCellrodjude tallyNessuna valutazione finora

- 23Cr Infrastructure TNPADocumento15 pagine23Cr Infrastructure TNPAHarul Ganesh S BNessuna valutazione finora

- Clean Room Wall FinishDocumento6 pagineClean Room Wall FinishjoannakahlNessuna valutazione finora

- Ice-502-Ce-502 - FinalDocumento2 pagineIce-502-Ce-502 - Finalarjunv_14Nessuna valutazione finora

- Large Submersible Pump Station Design GuideDocumento12 pagineLarge Submersible Pump Station Design Guide陈伟麟100% (1)

- FloSet BrochureDocumento6 pagineFloSet BrochureHector TosarNessuna valutazione finora

- RA Bill FormatDocumento66 pagineRA Bill Formatdebajyoti dasNessuna valutazione finora

- 2012 - 03 - Online Doka Formwork Engineering DesignDocumento148 pagine2012 - 03 - Online Doka Formwork Engineering Designmma87Nessuna valutazione finora

- 1562-2 Design and Installation of Sheet Roof and Wall CladdingDocumento25 pagine1562-2 Design and Installation of Sheet Roof and Wall CladdingVasko DrogriskiNessuna valutazione finora

- Hot MixesDocumento14 pagineHot MixesNM2104TE06 PRATHURI SUMANTHNessuna valutazione finora

- Brooklyn Grade Crossing Elimination CommissionDocumento138 pagineBrooklyn Grade Crossing Elimination CommissionBob DiamondNessuna valutazione finora

- Gabions: Product Installation GuideDocumento2 pagineGabions: Product Installation Guidesgm6911Nessuna valutazione finora

- HS PU Elastoseal PrimerDocumento2 pagineHS PU Elastoseal PrimergopipcuddaloreNessuna valutazione finora

- Verification 001Documento6 pagineVerification 001Med El Hadi AbidiNessuna valutazione finora

- Workover Program KE23B2Documento14 pagineWorkover Program KE23B2Malau Arief100% (1)

- SP-008 Doors and WindowsDocumento100 pagineSP-008 Doors and WindowsmcbluedNessuna valutazione finora

- Analysis of Roller BearingDocumento15 pagineAnalysis of Roller Bearingusama666Nessuna valutazione finora

- Conceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Documento16 pagineConceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Dawit SolomonNessuna valutazione finora

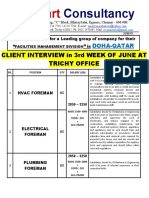

- MBA Qatar Company InterviewDocumento2 pagineMBA Qatar Company InterviewTradiyo ForexNessuna valutazione finora

- Ajiya 2018 CATALOGUE-B2 Rev10-1Documento4 pagineAjiya 2018 CATALOGUE-B2 Rev10-1manova enterpriseNessuna valutazione finora

- KuwaitDocumento16 pagineKuwaitGualberto AlarconNessuna valutazione finora

- Aitc Tn8 March 2010Documento3 pagineAitc Tn8 March 2010seagull70Nessuna valutazione finora

- 27 Jul 2018 Tenders Bids of Pakistan by Maven PKDocumento162 pagine27 Jul 2018 Tenders Bids of Pakistan by Maven PKMaven PKNessuna valutazione finora

- 34.51.01.33 P6000CFP 000 PV - A DEP Tanks VariationDocumento22 pagine34.51.01.33 P6000CFP 000 PV - A DEP Tanks VariationNaser Alshraim100% (1)

- Pipe Flow CalculatorDocumento2 paginePipe Flow CalculatordavideristixNessuna valutazione finora

- Free Download Here: RCC Design of Structures A K Jain PDFDocumento2 pagineFree Download Here: RCC Design of Structures A K Jain PDFMustafa MalikyNessuna valutazione finora

- James M Apple K R Govindan S.C.Sharma-R.B.Choudary & G.R.N.Tagore - D.R.SuleDocumento73 pagineJames M Apple K R Govindan S.C.Sharma-R.B.Choudary & G.R.N.Tagore - D.R.SuleWeecky HunterNessuna valutazione finora