Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Measurement of Viscosity Using Viscometer: Presented by N.Vinayaga Muruga Pandy & S. Santhosh Research Scholar

Caricato da

Santhosh SrinivasanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Measurement of Viscosity Using Viscometer: Presented by N.Vinayaga Muruga Pandy & S. Santhosh Research Scholar

Caricato da

Santhosh SrinivasanCopyright:

Formati disponibili

MEASUREMENT OF VISCOSITY USING VISCOMETER

&

MEASUREMENT OF TAPER ANGLE USING SINE BAR

Presented by

N.Vinayaga Muruga Pandy & S. Santhosh

Research scholar

MEASUREMENT OF VISCOSITY USING

VISCOMETER

To determine the kinematic and dynamic viscosity of given oil sample using Redwood

viscometer.

Aim of the Experiment

Principle used

Newtons law of viscosity

Shear stress is directly proportional to velocity gradient

Viscosity of fluids is inversely proportional to temperature

1. Redwood viscometer apparatus

2. Digital thermometer-2 Nos

3. 50 ml and 500 ml beaker

4. Oil sample

5. Temperature controller Energy Regulator type

Apparatus required

Procedure

1.Pour the oil sample into the cup through a filter. Pour water into the bath.

2. Heat and stir the viscometer water bath to a few degrees above the desired test

temperature.

3. Stir the sample during the preliminary period, e.g. by means of the ball valve

closing the bottom of the jet by suitable means but do not stir the sample during

the actual determination.

4. Control the temperature of the bath such that the oil sample is maintained at the

test temperature.

5. When the temperature of the sample has become quite steady at the desired

value, maintain the oil level up to the indicated level, by allowing the sample to

flow out of the cup.

Procedure

6. Place the oil cup -cover which shall be slightly warmed.

7. Place a clean and dry standard 50ml flask centrally below the jet. Do not

insulate the flask.

8. Lift the bob so that the oil drains through the orifice and simultaneously start

the time recorder. Suspend the bob valve from the clip supporting the oil-

cup thermometer by means of the hook.

9. Stop the time recorder at the instant the sample reaches the graduation mark

of the 50ml flask and note the final readings of the oil cup thermometer.

10. If the temperature of the sample in the oil-cup varies more than 0.5C, then

repeat the experiment.

Calculation

Since the instruments used are of standard dimensions, kinematic viscosity

of the flowing oil in centistokes can be calculated from the time taken by

the oil to flow through the standard orifice of the instrument with the help

of the following equation.

Plots

1. Kinematic viscosity versus Temperature

2. Dynamic viscosity versus Temperature

MEASUREMENT OF TAPER ANGLE USING

SINE BAR

To determine unknown angle using sine bar.

Aim of the Experiment

Principle used

Trigonometry

Sin = Opposite side / Hypotenuse

[A] [B]

1. Sine bar

2. Surface plate

3. Dial indicator,

4. Slip gauges.

5. Vernier height gauge

Apparatus required

Procedure

1) Surface plate is placed on a horizontal surface.

2) Build up slip gauges of a proper height by wringing.

3) Place one of the cylinders of sine bar on surface plate and other

on slip gauges.

4) Dial indicator is set at one end of the component and moved to the

other end.

5) Note the deviation in dial reading.

6) Again slip gauges are so adjusted that dial indicator reads zero

deviation across the work surface if deviation is h over length l1,

change slip gauge height by (h x L / l1)

Where L is standard sine bar length

7) Again take dial indicator reading to assure zero deviation.

8) Read slip gauge height and perform calculation

Calculation

Reading:-

A] h= L=

B] h1= h2= L=

Calculations:-

A] Sin = h/L

= Sin-1 ( h/L )

=

B] Sin = h1-h2 / L

= Sin-1 ( h1-h2 / L)

=

References

1. http://en.wikipedia.org/wiki/Viscosity

2. http://en.wikipedia.org/wiki/sinebar

3. http://en.wikipedia.org/wiki/Temperature_dependence_of_liquid_viscosity

4. 'Numerical Methods for Engineers' by Steven C Chapra and Raymand P

Canale.

Potrebbero piacerti anche

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- NAME 178 - ThermodynamicsLab SheetDocumento48 pagineNAME 178 - ThermodynamicsLab SheetMahadi HasanNessuna valutazione finora

- Lab Summary NewDocumento5 pagineLab Summary NewmijasofoNessuna valutazione finora

- Thermal Lab1st CycleDocumento26 pagineThermal Lab1st CyclesreyajerryNessuna valutazione finora

- ViscometerDocumento4 pagineViscometerArie Emmanuel ListonNessuna valutazione finora

- Petroleum Testing Lab ManualDocumento59 paginePetroleum Testing Lab ManualHari_Kumar_143494% (33)

- ViscosityDocumento17 pagineViscosityLau Neal AplandNessuna valutazione finora

- LAB MANUAL Mechanical LabDocumento30 pagineLAB MANUAL Mechanical LabLeela PrasadNessuna valutazione finora

- CS6431-Thermal Engineering Lab - I: Laboratory ManualDocumento21 pagineCS6431-Thermal Engineering Lab - I: Laboratory ManualVivek AnandanNessuna valutazione finora

- Viscosity Lab 1Documento2 pagineViscosity Lab 1JhiGz Llausas de GuzmanNessuna valutazione finora

- Fluid Mechanics Lab Report 1 AliDocumento10 pagineFluid Mechanics Lab Report 1 AliAli ArshadNessuna valutazione finora

- Lab Report 2Documento7 pagineLab Report 2SadiaNessuna valutazione finora

- Viscometer: Prepared by M.B. VanaraDocumento21 pagineViscometer: Prepared by M.B. Vanaraurvish_soniNessuna valutazione finora

- Fuel Testing Laboratory OverviewDocumento12 pagineFuel Testing Laboratory Overviewjohn powerNessuna valutazione finora

- Lab Report 2Documento7 pagineLab Report 2Minhaj UllahNessuna valutazione finora

- Redwood ViscometerDocumento7 pagineRedwood ViscometerCaro Kan LopezNessuna valutazione finora

- Kinematic ViscosityDocumento4 pagineKinematic ViscosityAloka KarunarathneNessuna valutazione finora

- ICS Lab Manual Final 2018-19Documento34 pagineICS Lab Manual Final 2018-19Shyam KumarNessuna valutazione finora

- Performance Qualification of Autoclave Cum Bung ProcessorDocumento17 paginePerformance Qualification of Autoclave Cum Bung ProcessorĐức LinhNessuna valutazione finora

- MFE LabDocumento12 pagineMFE Lab076bch031.ritishaNessuna valutazione finora

- Calibration Procedures Virginia PDFDocumento81 pagineCalibration Procedures Virginia PDFraja qammarNessuna valutazione finora

- Pour Point Test ASTM D5853Documento6 paginePour Point Test ASTM D5853Michael Medina100% (1)

- AF Lab ManualDocumento40 pagineAF Lab ManualArun PrasathNessuna valutazione finora

- EC Lab Manualprint123Documento38 pagineEC Lab Manualprint123Logic ManjuNessuna valutazione finora

- Redwood I UpdatedDocumento7 pagineRedwood I UpdatedVitalram RayankulaNessuna valutazione finora

- Redwood ViscometerDocumento3 pagineRedwood Viscometerghambira85% (34)

- Saybolt Viscometer CheckedDocumento6 pagineSaybolt Viscometer CheckedbjmarsoniaNessuna valutazione finora

- Fuel Engineering ManualDocumento42 pagineFuel Engineering Manualmaz zlsNessuna valutazione finora

- Study of Redwood Viscometer To Determine Kinematic ViscosityDocumento4 pagineStudy of Redwood Viscometer To Determine Kinematic ViscosityAyon SenguptaNessuna valutazione finora

- EEDocumento15 pagineEEWasif MalikNessuna valutazione finora

- ME6412 Thermal Engineering Lab I 2013 RegulationDocumento21 pagineME6412 Thermal Engineering Lab I 2013 RegulationSumit Chandra VermaNessuna valutazione finora

- Soil&Concrete LabDocumento10 pagineSoil&Concrete Labutachi93Nessuna valutazione finora

- Practical Workbook Ach-612 Petroleum and PetrochemicalsDocumento17 paginePractical Workbook Ach-612 Petroleum and PetrochemicalsMuhammad sherazNessuna valutazione finora

- Sgsa ProceduresDocumento5 pagineSgsa ProceduresemiljuchiacNessuna valutazione finora

- Aniline Point Test Aparatus (By U-Tube Method)Documento48 pagineAniline Point Test Aparatus (By U-Tube Method)Violett ParrNessuna valutazione finora

- Fuel Technology 2 Lab ManualDocumento17 pagineFuel Technology 2 Lab Manualjohn powerNessuna valutazione finora

- Practica 4 Tecnicas de Medición ExperimentalDocumento6 paginePractica 4 Tecnicas de Medición ExperimentalFidel E. Castro FloresNessuna valutazione finora

- HK-3535 User Manual (New Type)Documento14 pagineHK-3535 User Manual (New Type)aacostajNessuna valutazione finora

- Virginia Calibration MethodsDocumento81 pagineVirginia Calibration MethodsWillard ApengNessuna valutazione finora

- The Viscosity Sheet Exp 2Documento4 pagineThe Viscosity Sheet Exp 2Helin HassanNessuna valutazione finora

- Thermometer Liquid in Glass Calibrationvvs102Documento10 pagineThermometer Liquid in Glass Calibrationvvs102juncar25100% (1)

- Karl Fischer ApparatusDocumento54 pagineKarl Fischer ApparatusREDDYGAARI ABBAYINessuna valutazione finora

- اسفلتDocumento6 pagineاسفلتalialwasity1914Nessuna valutazione finora

- ViscosityDocumento10 pagineViscosityTenzin KesangNessuna valutazione finora

- Exp 2Documento3 pagineExp 2Titus RNessuna valutazione finora

- Experiment 02: ObjectiveDocumento3 pagineExperiment 02: Objectivevj kumarNessuna valutazione finora

- Liquid Meter Proving TechniquesDocumento3 pagineLiquid Meter Proving TechniquesIkhsan ArifNessuna valutazione finora

- Pharmacognosy SopDocumento20 paginePharmacognosy Sopbandameedi.ramu281950% (2)

- Online Lab - Me Lab1 Expt 4 Measurement of DensityDocumento6 pagineOnline Lab - Me Lab1 Expt 4 Measurement of DensityDessa GuditoNessuna valutazione finora

- Say Bolt ViscometerDocumento3 pagineSay Bolt Viscometerghambira75% (4)

- Thermo ManualDocumento24 pagineThermo ManualRajakhalidNessuna valutazione finora

- The University of Hong Kong: Department of Mechanical EngineeringDocumento20 pagineThe University of Hong Kong: Department of Mechanical EngineeringChristal ChukNessuna valutazione finora

- Chem - Lab ManualDocumento53 pagineChem - Lab ManualHarshit JainNessuna valutazione finora

- Determining The Viscosity of Fuel Oil Using An Engler Viscometer - KHDocumento8 pagineDetermining The Viscosity of Fuel Oil Using An Engler Viscometer - KHshock06knightNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Handbook of Mechanical and Materials EngineeringDa EverandHandbook of Mechanical and Materials EngineeringValutazione: 5 su 5 stelle5/5 (4)

- Instrument Technology: Measurement of Pressure, Level, Flow and TemperatureDa EverandInstrument Technology: Measurement of Pressure, Level, Flow and TemperatureValutazione: 4 su 5 stelle4/5 (1)

- AP Biology Lab 1Documento10 pagineAP Biology Lab 1Abby Loneker0% (1)

- Iso 2063 2 2017 en PDFDocumento11 pagineIso 2063 2 2017 en PDFMichael Hii0% (1)

- API-521 Flare KOD Design and Even More - Part 1Documento6 pagineAPI-521 Flare KOD Design and Even More - Part 1Said Ahmed Salem100% (1)

- Automotive Painting ProcessesDocumento21 pagineAutomotive Painting ProcessesAham Gty0% (1)

- BAHBAH BOUKHTIRA ELHABCHI - Sécurité AlimentaireDocumento11 pagineBAHBAH BOUKHTIRA ELHABCHI - Sécurité AlimentaireOuiam OuiamNessuna valutazione finora

- 3 JEE Chemistry Solutions Methods of Expressing Concentration of SolutionDocumento6 pagine3 JEE Chemistry Solutions Methods of Expressing Concentration of Solutionmalboys555Nessuna valutazione finora

- LI-PO SizesDocumento17 pagineLI-PO SizesmariorossiNessuna valutazione finora

- Physical Progress Weightage Rev 03Documento1 paginaPhysical Progress Weightage Rev 03burereyNessuna valutazione finora

- JessintaDocumento19 pagineJessintaAgbara RichardNessuna valutazione finora

- Rosin Based Chemicals and PolymersDocumento44 pagineRosin Based Chemicals and PolymersHimanshu PanchalNessuna valutazione finora

- Kohl Surma Galena CollyriumDocumento5 pagineKohl Surma Galena CollyriumjivasumanaNessuna valutazione finora

- Touch Up Painting Repair ProcedureDocumento28 pagineTouch Up Painting Repair ProcedureSuman Ghosh67% (3)

- A-En MoviPol-5 IMDocumento58 pagineA-En MoviPol-5 IMFabien CazesNessuna valutazione finora

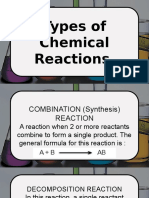

- Types of Chemical ReactionsDocumento36 pagineTypes of Chemical ReactionsAira Villarin100% (3)

- Plastic Product Page NP.00942 EN 11-2011 PDFDocumento12 paginePlastic Product Page NP.00942 EN 11-2011 PDFsanitermNessuna valutazione finora

- An Analytical Solution For Time-Dependent Displacements in A Circular TunnelDocumento10 pagineAn Analytical Solution For Time-Dependent Displacements in A Circular TunnelEugenio DoglioneNessuna valutazione finora

- Molykote Food Grade Lubricants BROCH - EN (80-3189-01)Documento6 pagineMolykote Food Grade Lubricants BROCH - EN (80-3189-01)DiogoNessuna valutazione finora

- Dental Materials Lecture 9 DADocumento18 pagineDental Materials Lecture 9 DAMuthiaraPrazianditeNessuna valutazione finora

- Textile PrintingDocumento32 pagineTextile PrintingParthasarathi Jena100% (5)

- Trumpf Whitepaper Laser Welding BatteryboxDocumento14 pagineTrumpf Whitepaper Laser Welding Batteryboxxafat53862Nessuna valutazione finora

- Homemade FoundryDocumento9 pagineHomemade FoundryHerman HeseNessuna valutazione finora

- Ger 3751a Understanding Diagnosing Repairing Leaks h20 Gen Stator WindingsDocumento28 pagineGer 3751a Understanding Diagnosing Repairing Leaks h20 Gen Stator Windingsnareshvkkd100% (1)

- 5070 s11 QP 22 PDFDocumento20 pagine5070 s11 QP 22 PDFNeural Spark Physics CieNessuna valutazione finora

- Proceedings ICoMP Vol1Documento377 pagineProceedings ICoMP Vol1Anisa SafutriNessuna valutazione finora

- Alchemical TalesDocumento15 pagineAlchemical TalesVic LoveNessuna valutazione finora

- End Term Exam Chemistry Year 13Documento13 pagineEnd Term Exam Chemistry Year 13Barminga KamurenNessuna valutazione finora

- Me - Question Paper PDFDocumento12 pagineMe - Question Paper PDFSubradip debnathNessuna valutazione finora

- Carbohydrates StainsDocumento25 pagineCarbohydrates StainsIceMarie AgabasNessuna valutazione finora

- Preparatory Problems SolutionsDocumento38 paginePreparatory Problems SolutionsĐạt Trần VănNessuna valutazione finora

- 1.8 Gas Well Testing PDFDocumento3 pagine1.8 Gas Well Testing PDFHATEMNessuna valutazione finora