Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Coagulation and Flocculation at Water Treatment Plants

Caricato da

Khalid Rehman0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

121 visualizzazioni51 pagineabout Coagulation

Titolo originale

Coagulation

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoabout Coagulation

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

121 visualizzazioni51 pagineCoagulation and Flocculation at Water Treatment Plants

Caricato da

Khalid Rehmanabout Coagulation

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 51

Coagulation and Flocculation

at Water Treatment Plants

WQT 131

Water Works Operation III

Water Treatment

Chapter 4 Coagulation and Flocculation

Lecture 3

Week 3 Objectives

Understand conventional treatment to remove turbidity

Understand turbidity and its primary constituents

Explain coagulation chemistry

Understand mechanism of function involved in coagulant

aggregation

Explain flocculation chemistry

Understand mechanism of function involved in flocculent

aggregation

Understand the role of pH, alkalinity, turbidity,

temperature on coagulation and flocculation application

Reading assignment:

AWWA 2003. Water Treatment, Principles and Practices of Water Supply Operation, Third

Edition, American Waterworks Association, ISBN 1-58321-230-2

Chapter 4 Coagulation and Flocculation

Key Words

Coagulation: adding and rapid mixing of chemicals to

remove particles from water. (flash mixing)

Flocculation: adding and slow mixing of chemicals and

particles to create flocs that settle out of water.

Turbidity: suspended, dissolved, and colloidal particles in

pretreated water that need to be removed to optimize

treatment efficiency.

Suspended Solids: particles held in suspension by the

natural action of flowing waters.

Colloidal Solids: fine silt that does not settle out of water

but remain in suspension.

Dissolved Solids: organic or inorganic molecules that are

dissolved into the aqueous phase.

Which of the following is the

main purpose of the

coagulation/flocculation

process?

a

.

t

o

r

e

m

o

v

e

t

u

r

b

i

d

i

t

y

b

.

t

o

s

o

f

t

e

n

t

h

e

w

a

t

e

r

c

.

t

o

a

d

d

o

x

y

g

e

n

d

.

t

o

d

i

s

i

n

f

e

c

t

.

0% 0% 0% 0%

a. to remove turbidity

b. to soften the water

c. to add oxygen

d. to disinfect.

The most important raw water

constituent for a surface water

plant is:

a

.

t

e

m

p

e

r

a

t

u

r

e

b

.

h

a

r

d

n

e

s

s

c

.

t

u

r

b

i

d

i

t

y

d

.

p

H

0% 0% 0% 0%

a. temperature

b. hardness

c. turbidity

d. pH

WQT 131

Water Works Operation III

Water Treatment

Chapter 4

Coagulation and

Flocculation at Water

Treatment Plants

Ironically, it is easier to clean up dirty water

than to make clean water cleaner. The reason

is because particles must collide before they

can stick together to make larger flocs. More

particles means more collisions.

Water Treatment

Conventional Treatment

Conventional Treatment common treatment steps

used to remove turbidity from the initial source

water.

1. Coagulation

2. Flocculation

3. Sedimentation

4. Filtration

Rapid Mixing

Slow Mixing

Settling

Cleaning

Turbidity

Turbidity particles (sand, silt, clay, bacteria,

viruses) in the initial source water that need to be

removed to improve treatment.

1. Suspended Solids

2. Colloidal Solids (~0.1 to 1 mm)

3. Dissolved Solids (<0.02 mm)

3 1 2

The turbidity of a water

treatment plant effluent cannot

be above?

5

n

t

u

1

n

t

u

.

5

n

t

u

.

3

n

t

u

0% 0% 0% 0%

1. 5 ntu

2. 1 ntu

3. .5 ntu

4. .3 ntu

Turbidity

Turbidity/Colloids negative charged particles

particles (sand, silt, clay, organic matter) in the initial

source water that need to be removed to improve

treatment.

Coagulation

Coagulants tend to be positively charged.

Due to their positive charge, they are attracted to

the negative particles in the water

The combination of positive and negative charge

results in a neutral , or lack, of charge

Van der Waal's forces refer to the tendency of

particles in nature to attract each other weakly if

they have no charge.

Settling Forces

Zeta Potential refers to the electrostatic potential

generated by the accumulation of ions at the surface of the

colloidal particle. It can help you understand and control

colloidal suspensions

van der Waals Force- van der Waals forces are weak

attractive forces that hold non-polar molecules together. They

tends to pull molecules together and forms flocs.

Zeta potential analyzer

van der Waals in action

Settling Forces

Zeta Potential -is the electrical potential that exists at the

"shear plane" of a particle, which is some small distance

from its surface. Keeps particles apart and in suspension

Zeta Potential [mV] Stability behavior of the colloid

from 0 to 5, Rapid coagulation or

flocculation

Water Treatment Coagulants

Particles in water are negative; coagulants

usually positively charged.

1. Alum- aluminum sulfate

2. Ferric chloride or ferrous sulfate

3. Polymers

What determines the optimum

and most cost-effective amount

of a coagulant to use?:

B

e

y

o

n

d

t

h

a

t

d

o

s

e

,

i

t

.

.

.

B

e

l

o

w

t

h

a

t

d

o

s

e

t

h

e

.

.

.

T

h

e

t

r

e

a

t

m

e

n

t

p

l

a

n

t

.

.

.

D

i

v

i

d

e

t

h

e

n

u

m

b

e

r

o

f

.

.

.

0% 0% 0% 0%

1. Beyond that dose, it takes a

very large increase in the

amount of chemical to

produce a small increase in

turbidity removal

2. Below that dose the

coagulant results in poor

settling

3. The treatment plant budget

4. Divide the number of

gallons of water in the

coagulation tank by the

nephelometric turbidity unit

reading to determine the

dosage in mg/L.

Which is NOT a common method

for determining optimum

coagulant effectiveness?:

J

a

r

t

e

s

t

Z

e

t

a

p

o

t

e

n

t

i

a

l

d

e

t

e

c

t

o

r

S

t

r

e

a

m

i

n

g

c

u

r

r

e

n

t

d

e

.

.

.

C

o

l

o

r

i

m

e

t

r

i

c

m

e

t

h

o

d

0% 0% 0% 0%

1. Jar test

2. Zeta potential detector

3. Streaming current

detector

4. Colorimetric method

Water Treatment Coagulant Alum

Alum- (aluminum sulfate)- particles suspended in

natural, untreated water normally carry a negative electrical

charge. These particles are attracted to the positive charges

created by aluminum hydroxides. Dosage is generally around

25 mg/L.

1. Trivalent Al

+3

charge attracts neg particles

2. Forms flocs of aluminum hydroxide (AlOH

3

).

3. Impacted by mixing, alkalinity, turbidity

and temp.

4. Ideal pH range 5.8-8.5

Alum CHEMISTRY

Alum- (aluminum sulfate)- made by dissolving

aluminum hydroxide (bauxite or clay) in sulfuric acid

2Al(OH)

3

+ 3H

2

SO

4

+ 10H

2

O Al

2

(SO

4

)

3

16H

2

O

When ALUM is dissolved in alkaline water, it

undergoes hydrolysis (reacts with water) to produce

a high surface area gelatinous precipitate of

aluminum hydroxide, Al(OH)

3

(gibbsite)

(Al(OH)

3

sticks the negatives.

When ALUM is reacted with water it hydrolyzes to

form aluminum hydroxide and dilute sulfuric

acid (lowers pH). -----Need alkalinity adjustment

Alum CHEMISTRY

Alum- (aluminum sulfate)-

Al

2

(SO

4

)

3

14H

2

O 2Al

+3

+3SO

4

-2

+14H

2

O

2Al

+3

+ negatively charged colloids neutral surface charge

WHY IS ALKALINITY SO IMPORTANT??

2Al

+3

+ 6 HCO

3

-

2(Al(OH

3

)

(S)

+ 6CO

2

No bicarbonate (low alkalinity, low pH sulfuric acid!):

Al

2

(SO

4

)

3

14H

2

O 2(Al(OH3)

(S)

+3H

2

SO

4

-2

+14H

2

O

Optimum pH: 5.5 to 6.5

Operating pH: 5 to8

Alum MSDS Safety and Handling

Alum- (aluminum sulfate)-

Health Rating: 2 - Moderate

Flammability Rating: 0 - None

Reactivity Rating: 1 - Slight

Contact Rating: 2 - Moderate

Lab Protective Equip: GOGGLES; LAB COAT; VENT HOOD;

PROPER GLOVES

Storage Color Code: Green (General Storage)

Inhalation: Causes irritation to the respiratory tract.

Ingestion: Causes nausea, vomiting and diarrhea. There have

been two cases of fatal human poisonings from ingestion of

30 grams of alum.

Skin Contact: Causes redness, itching, and pain.

Eye Contact: Causes irritation, redness, and pain.

When alum is added to water, a

floc is formed from the

combination of alum and

a

.

a

l

k

a

l

i

n

i

t

y

b

.

a

c

i

d

c

.

c

h

l

o

r

i

n

e

d

.

l

i

m

e

0% 0% 0% 0%

a. alkalinity

b. acid

c. chlorine

d. lime

The precipitate formed by

coagulation with alum is

aluminum ________.

B

i

c

a

r

b

o

n

a

t

e

C

a

r

b

o

n

a

t

e

H

y

d

r

o

x

i

d

e

S

u

l

f

a

t

e

0% 0% 0% 0%

1. Bicarbonate

2. Carbonate

3. Hydroxide

4. Sulfate

Adding Alum to water will cause

the pH of the water to increase.

T

r

u

e

F

a

l

s

e

0% 0%

1. True

2. False

Alum comes in dry grade as a

minimum of 17.5% pure product,

in liquid form it is 49% pure or

8.23% by weight Al

2

O

3

?

1. True

2. False

The coagulation process will

most likely improve when:

T

h

e

h

a

r

d

n

e

s

s

o

f

t

h

e

i

.

.

.

T

h

e

t

e

m

p

e

r

a

t

u

r

e

o

f

t

h

.

.

.

T

h

e

t

e

m

p

e

r

a

t

u

r

e

o

f

t

h

.

.

.

T

h

e

a

l

k

a

l

i

n

i

t

y

o

f

t

h

e

i

n

.

.

.

11%

0%

89%

0%

1. The hardness of the

influent increases

2. The temperature of the

influent decreases

3. The temperature of the

influent increases

4. The alkalinity of the

influent decreases

Water Treatment Coagulant Iron Salt

Iron salt- (Iron chloride or sulfate)- particles

suspended in natural, untreated water normally carry a

negative electrical charge. These particles are attracted to the

positive charges created by Fe(III) salts.

1. Trivalent Fe

+3

charge attracts neg particles

2. Work over a larger pH range than alum

3. Lower costs than alum

4. Better removal of natural organics

5. Corrosive

6. Special handling necessary

7. Leave a residue of Fe in water (taste, stains)

Which one of the following

chemicals would you most likely

use as a coagulant?:

C

a

t

i

o

n

i

c

p

o

l

y

m

e

r

S

u

l

f

u

r

i

c

a

c

i

d

H

y

d

r

o

c

h

l

o

r

i

c

a

c

i

d

S

o

d

i

u

m

h

y

d

r

o

x

i

d

e

100%

0% 0% 0%

1. Cationic polymer

2. Sulfuric acid

3. Hydrochloric acid

4. Sodium hydroxide

A coagulant aid is a chemical added

during coagulation to improve

coagulation; to build stronger, more

settleable floc; to overcome the effects of

temperature drops; to reduce the amount

of coagulant needed, and/or to reduce

the amount of sludge produced. Which

of the following is not a type of

coagulant aid:

A

c

t

i

v

a

t

e

d

s

il

ic

a

G

r

e

e

n

s

a

n

d

P

o

ly

e

l

e

c

t

r

o

ly

t

e

s

o

r

p

...

W

e

i

g

h

t

in

g

a

g

e

n

t

s

0% 0% 0%

100%

1. Activated silica

2. Green sand

3. Polyelectrolytes or

polymers

4. Weighting agents

A microfloc is a colloid that has

reacted with a chemical

coagulant?

T

r

u

e

F

a

l

s

e

11%

89%

1. True

2. False

In determining the proper

dosage of alum, the most useful

test is the _______ test:

a

.

m

a

r

b

l

e

b

.

j

a

r

c

.

c

a

r

b

o

n

a

t

e

d

.

p

H

9%

0% 0%

91%

a. marble

b. jar

c. carbonate

d. pH

Alum added to turbid water

containing alkalinity forms

_________, which increase in

size and settle

out.

a

.

f

l

o

c

p

a

r

t

i

c

l

e

s

b

.

c

o

a

g

u

l

a

n

t

s

c

.

c

o

a

g

u

l

a

n

t

a

i

d

s

d

.

a

l

u

m

i

n

u

m

s

u

l

f

a

t

e

89%

0% 0%

11%

a. floc particles

b. coagulants

c. coagulant aids

d. aluminum sulfate

Overcoming problems of cold-

water floc can be corrected by

operating the process at the best

pH for that water temperature,

increasing the coagulant dosage,

or:

A

d

d

i

n

g

w

e

i

g

h

t

i

n

g

a

g

.

.

.

P

e

r

f

o

r

m

i

n

g

t

h

e

j

a

r

t

e

s

t

I

n

c

r

e

a

s

i

n

g

t

h

e

n

u

m

b

.

.

I

n

c

r

e

a

s

i

n

g

t

h

e

d

e

t

e

n

t

i

.

.

50%

40%

10%

0%

1. Adding weighting

agents

2. Performing the jar test

3. Increasing the number

and strength of floc

particles

4. Increasing the

detention time for floc

formation

Which of the following

conditions most affect

coagulation performance?

a

.

v

e

l

o

c

i

t

y

,

c

h

l

o

r

i

n

e

.

.

.

b

.

v

e

l

o

c

i

t

y

,

w

a

t

e

r

t

e

.

.

.

c

.

w

a

t

e

r

t

e

m

p

e

r

a

t

u

r

e

,

.

.

.

d

.

d

e

t

e

n

t

i

o

n

t

i

m

e

,

v

e

l

.

.

.

0% 0% 0%

100%

a. velocity, chlorine dosage,

detention time, and air

temperature

b. velocity, water temperature,

detention time and

coagulant dosage

c. water temperature, detention

time, air temperature, and

chlorine dosage

d. detention time, velocity, air

temperature, and chlorine

dosage

With the coming of winter, the

water temperature drops. A

likely operational problem at a

filtration plant with coagulation

is:

F

l

o

c

c

a

r

r

y

o

v

e

r

f

r

o

m

t

.

.

H

i

g

h

c

h

l

o

r

i

n

e

r

e

s

i

d

u

a

l

H

i

g

h

a

l

k

a

l

i

n

i

t

y

O

d

o

r

100%

0% 0% 0%

1. Floc carryover from the

sedimentation system

2. High chlorine residual

3. High alkalinity

4. Odor

Water Treatment Coagulant Aids

Activated silica (sodium silicate)- helps improve

coagulation, decreases volume of coagulant necessary.

Typically is sodium silicate.

1. secondary coagulant

2. reduces primary coagulants needed

3. Sodium silicate are alkaline

4. widens pH range for coagulation

5. used at 7-11% of alum

6. Heavier denser floc that settles faster

7. Can be formed on site

8. Corrosion inhibitor (forms a surface coating)

The three most commonly used

coagulants in water treatment

are:

A

l

u

m

i

n

u

m

h

y

d

r

o

x

i

d

e

,

.

.

.

A

l

u

m

i

n

u

m

s

u

l

f

a

t

e

,

f

e

r

r

.

.

L

i

m

e

,

s

o

d

i

u

m

h

y

d

r

o

x

i

.

.

.

S

o

d

a

,

l

i

m

e

a

n

d

c

h

l

o

r

i

n

e

33%

0% 0%

67%

1. Aluminum hydroxide,

lime and sodium

hydroxide

2. Aluminum sulfate,

ferric chloride, and

ferrous sulfate

3. Lime, sodium

hydroxide, and chlorine

4. Soda, lime and chlorine

Water Treatment Coagulant Aids

Bentonite (clay)- helps improve coagulation, decreases

volume of coagulant necessary.

1. high in color, low turbidity, low mineral content

water

2. 10-50 mg/L dosage

3. Heavier denser floc that settles faster

Which of the following would

most likely improve the

coagulation/flocculation

process?

a

.

i

n

c

r

e

a

s

e

i

n

r

a

w

w

a

t

.

.

b

.

d

e

c

r

e

a

s

e

i

n

w

a

t

e

r

.

.

.

c

.

i

n

c

r

e

a

s

e

i

n

w

a

t

e

r

.

.

.

d

.

d

e

c

r

e

a

s

e

i

n

r

a

w

w

a

.

.

.

0% 0%

100%

0%

a. increase in raw water

hardness

b. decrease in water

temperature

c. increase in water

temperature

d. decrease in raw water

alkalinity

Water Treatment Coagulant Aids

Polyelectrolytes- are water-soluble organic polymers

that are used as both primary coagulants and

coagulant aids. Act as "bridges" between the already

formed particles :

Anionicionize in solution to form negative sites

along the polymer molecule.

Cationicionize to form positive sites.

Non-ionicvery slight ionization.

effectiveness: particles type, turbidity present, and

the turbulence (mixing) available during coagulation.

Which one of the following

chemicals would be most

suitable as a filter aid?

a

.

a

l

u

m

b

.

s

o

d

a

a

s

h

c

.

s

o

d

i

u

m

h

y

d

r

o

x

i

d

e

d

.

a

n

i

o

n

i

c

p

o

l

y

m

e

r

0%

100%

0% 0%

a. alum

b. soda ash

c. sodium hydroxide

d. anionic polymer

A high molecular weight

substance that is formed by

either a natural or synthetic

process. Can have either

positive or negative charge.

P

o

l

y

m

e

r

P

r

o

t

e

i

n

C

a

r

b

o

h

y

d

r

a

t

e

E

n

z

y

m

e

D

e

o

x

y

r

i

b

o

n

u

c

l

e

i

c

a

c

i

d

100%

0% 0% 0% 0%

1. Polymer

2. Protein

3. Carbohydrate

4. Enzyme

5. Deoxyribonucleic acid

Water Treatment Coagulant/pH

Alkalinity- Alkalinity is a measure of the buffering

capacity of water. These buffering materials are

primarily the bases bicarbonate (HCO

3

-

), and

carbonate (CO

3

2-

), and occasionally hydroxide (OH

-

), borates, silicates, phosphates, ammonium,

sulfides, and organic ligands.

Chemicals applied to raise alkalinity

LimeCaOH

2

accompanies alum or iron salt

Sodium bicarbonate- NaHCO

3

- raise alkalinity

Soda AshNa

2

CO

3

-raise alkalinity

Caustic SodaNaOH -raise alkalinity

Water Treatment WHO Coagulants

Name Advantages Disadvantages

Aluminum

Sulfate

(Alum)

Al2(SO

4

)

3

.18H

2

O

Easy to handle and apply; most

commonly used; produces less

sludge than lime; most effective

between pH 6.5 and 7.5

Adds dissolved solids (salts) to wa-ter;

effective over a limited pH range.

Sodium

Aluminate

Na

2

Al

2

O

4

Effective in hard waters; small

dos-ages usually needed

Often used with alum; high cost;

ineffective in soft waters

Polyaluminum Chloride

(PAC)

Al

13

(OH)

20

(SO

4

)

2

.Cl

15

In some applications, floc

formed is more dense and faster

settling than alum

Not commonly used; little full scale

data compared to other aluminum

derivatives

Ferric Sulfate

Fe

2

(SO

4

)

3

Effective between pH 46 and

8.89.2

Adds dissolved solids (salts) to wa-ter;

usually need to add alkalinity

Ferric Chloride

FeCl

3

.6H

2

O

Effective between pH 4 and 11 Adds dissolved solids (salts) to wa-ter;

consumes twice as much alka-linity as

alum

Ferrous

Sulfate

(Copperas)

FeSO

4

.7H

2

O

Not as pH sensitive as lime Adds dissolved solids (salts) to wa-ter;

usually need to add alkalinity

Lime

Ca(OH)

2

Commonly used; very effective;

may not add salts to effluent

Very pH dependent; produces large

quantities of sludge; overdose can

result in poor effluent quality

Optimum flocculation requires:

a

.

v

i

o

l

e

n

t

a

g

i

t

a

t

i

o

n

b

.

g

e

n

t

l

e

a

g

i

t

a

t

i

o

n

c

.

h

i

g

h

p

H

d

.

l

o

w

p

H

0% 0% 0%

100%

a. violent agitation

b. gentle agitation

c. high pH

d. low pH

Agglomeration of colloidal and

finely divided suspended matter

after coagulation by gentle

mixing is called what?

F

l

o

c

c

u

l

a

t

i

o

n

S

e

d

i

m

e

n

t

a

t

i

o

n

P

o

l

y

m

e

r

a

c

c

r

e

t

i

o

n

B

a

l

l

a

s

t

i

n

g

100%

0% 0% 0%

1. Flocculation

2. Sedimentation

3. Polymer accretion

4. Ballasting

Which laboratory test is

concerned with indicator

changes at pH 8.3 and about pH

4.5?

a

.

t

o

t

a

l

h

a

r

d

n

e

s

s

b

.

p

H

c

.

a

l

k

a

l

i

n

i

t

y

d

.

t

o

t

a

l

c

h

l

o

r

i

n

e

r

e

s

i

d

u

a

l

0% 0%

100%

0%

a. total hardness

b. pH

c. alkalinity

d. total chlorine residual

_________ is the measure of

how much acid can be added to

a liquid, without causing a great

change in pH.

A

l

k

a

l

i

n

i

t

y

H

a

r

d

n

e

s

s

p

H

A

c

i

d

i

t

y

80%

20%

0% 0%

1. Alkalinity

2. Hardness

3. pH

4. Acidity

When operating a surface water

plant, which laboratory tests are

most significant for establishing

dosages for coagulation?

a

.

p

H

a

n

d

a

l

k

a

l

i

n

i

t

y

b

.

s

u

l

f

a

t

e

s

c

.

c

a

l

c

i

u

m

a

n

d

m

a

g

.

.

.

d

.

t

o

t

a

l

h

a

r

d

n

e

s

s

100%

0% 0% 0%

a. pH and alkalinity

b. sulfates

c. calcium and magnesium

d. total hardness

A test that is commonly

performed to monitor the

treatment process is :

p

H

A

l

k

a

l

i

n

i

t

y

T

u

r

b

i

d

i

t

y

A

l

l

o

f

t

h

e

a

b

o

v

e

0%

100%

0% 0%

1. pH

2. Alkalinity

3. Turbidity

4. All of the above

Tonight's Lecture Objectives: To

understand coagulation

processes has been met?

S

t

r

o

n

g

l

y

A

g

r

e

e

A

g

r

e

e

N

e

u

t

r

a

l

D

i

s

a

g

r

e

e

S

t

r

o

n

g

l

y

D

i

s

a

g

r

e

e

78%

22%

0% 0% 0%

1. Strongly Agree

2. Agree

3. Neutral

4. Disagree

5. Strongly Disagree

Potrebbero piacerti anche

- Training Manual For Water TreatmentDocumento181 pagineTraining Manual For Water Treatmentmuhammad abdulrehmanNessuna valutazione finora

- Water Treatment Lecture 4 EENVDocumento35 pagineWater Treatment Lecture 4 EENVEllina TehNessuna valutazione finora

- 1 Sludge Treatment and Disposal-1Documento27 pagine1 Sludge Treatment and Disposal-1Liyana RaisNessuna valutazione finora

- Environmental Engineering Assignment 2Documento1 paginaEnvironmental Engineering Assignment 2Anonymous Vx9KTkM8nNessuna valutazione finora

- 9004.1202EEII Chapter1 3Documento76 pagine9004.1202EEII Chapter1 3पाँशुल जम्वाल राजपूतNessuna valutazione finora

- Water & Wastewater Engineering Head LossDocumento105 pagineWater & Wastewater Engineering Head LossMA. MATEA MARTINEZ100% (3)

- Water Demand and Supply IntroDocumento26 pagineWater Demand and Supply Intromm507Nessuna valutazione finora

- Water Treatment Lecture 5 PDFDocumento40 pagineWater Treatment Lecture 5 PDFSuci DwiNessuna valutazione finora

- WATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9e - DisinfectionDocumento17 pagineWATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9e - Disinfectionmamat88Nessuna valutazione finora

- Sanitary Engineer II: Passbooks Study GuideDa EverandSanitary Engineer II: Passbooks Study GuideNessuna valutazione finora

- Water TreatmentDocumento2 pagineWater TreatmentJumasonicNessuna valutazione finora

- D399DDocumento5 pagineD399DHilarie Jonathan100% (1)

- Lesson Plan: How Do We Clean Polluted Water?Documento15 pagineLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyNessuna valutazione finora

- WATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 5 - Water Quality ParametersDocumento29 pagineWATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 5 - Water Quality Parametersmamat88Nessuna valutazione finora

- Chlorination Guide Presentation PDFDocumento168 pagineChlorination Guide Presentation PDFAmit nayakNessuna valutazione finora

- Chapter 4Documento13 pagineChapter 4selambante shiferawNessuna valutazione finora

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsDocumento34 pagineWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanNessuna valutazione finora

- Lesson 17 - Activated SludgeDocumento8 pagineLesson 17 - Activated SludgeShane RodriguezNessuna valutazione finora

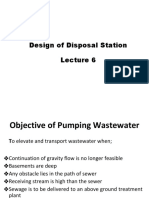

- Design of Disposal StationDocumento16 pagineDesign of Disposal Stationali akmal100% (1)

- 16B - Water and Waste ManagementDocumento37 pagine16B - Water and Waste ManagementHossein HejaziNessuna valutazione finora

- Unit II Primary TreatmentDocumento48 pagineUnit II Primary TreatmentAmit AryanNessuna valutazione finora

- Theory of Practice WaterDocumento5 pagineTheory of Practice WaterTemimi Feras0% (1)

- Water TreatmentDocumento19 pagineWater TreatmentAnonymous 8ooQmMoNs1Nessuna valutazione finora

- Module 2 - Water TreatmentDocumento56 pagineModule 2 - Water TreatmentGorgeous boiNessuna valutazione finora

- Report TreatmentPond PDFDocumento10 pagineReport TreatmentPond PDFSérgio Dos SantosNessuna valutazione finora

- TC Owtu 502 PDFDocumento288 pagineTC Owtu 502 PDFRon100% (1)

- Testing Water and Wastewater Treatment ChemicalsDocumento307 pagineTesting Water and Wastewater Treatment ChemicalsprideNessuna valutazione finora

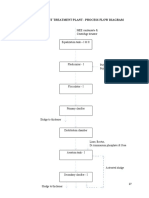

- Effluent Treatment Plant - Process Flow DiagramDocumento45 pagineEffluent Treatment Plant - Process Flow DiagramAmarnath PNessuna valutazione finora

- Cive3223 5 2015 2Documento4 pagineCive3223 5 2015 2Yannick HowNessuna valutazione finora

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityDa EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityNessuna valutazione finora

- Unit 1 Calculations and Chemical ReactionsDocumento7 pagineUnit 1 Calculations and Chemical ReactionsVeraNessuna valutazione finora

- Water and Waste Water Lecture 10Documento44 pagineWater and Waste Water Lecture 10David AquinoNessuna valutazione finora

- Water Treatment CoagulationDocumento6 pagineWater Treatment CoagulationibruNessuna valutazione finora

- 3510 Prob - Set 4 (2017)Documento3 pagine3510 Prob - Set 4 (2017)ShorOuq Mohammed MalkawiNessuna valutazione finora

- Waste Water Treatment Plant Design For Small and Midsized CommunitiesDocumento33 pagineWaste Water Treatment Plant Design For Small and Midsized CommunitieskassyNessuna valutazione finora

- CE405 Environmental Engineering - IDocumento2 pagineCE405 Environmental Engineering - IChithraNessuna valutazione finora

- Treatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityDocumento25 pagineTreatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityAbsharinaNessuna valutazione finora

- Mohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesDocumento104 pagineMohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesAnish Ghimire100% (1)

- High-rate Wastewater Treatment Using Shaft ReactorDocumento6 pagineHigh-rate Wastewater Treatment Using Shaft ReactorFabio NascimentoNessuna valutazione finora

- Activated Sludge DesignDocumento37 pagineActivated Sludge DesignSweety0901Nessuna valutazione finora

- Silica Removal During Lime Softening in Water Treatment PlantDocumento10 pagineSilica Removal During Lime Softening in Water Treatment PlantLouay MansourNessuna valutazione finora

- Chapter 16 Lime SofteningDocumento10 pagineChapter 16 Lime Softeningkpranjal15Nessuna valutazione finora

- Closed Conduit Water SupplyDocumento12 pagineClosed Conduit Water Supplyanil_ajinkya100% (4)

- Coagulacion FloculacionDocumento538 pagineCoagulacion FloculacionGUido JUarezNessuna valutazione finora

- Classified - Internal UseDocumento18 pagineClassified - Internal UseNandha KumarNessuna valutazione finora

- Tutorial 5Documento4 pagineTutorial 5Pratik Babu GhimireNessuna valutazione finora

- Design of Sand FilterDocumento5 pagineDesign of Sand FilterAbhay ThakurNessuna valutazione finora

- CH 9 - Attached Growth ProcessDocumento30 pagineCH 9 - Attached Growth Processxuantra92100% (1)

- Slow Sand Filtration Fact SheetDocumento4 pagineSlow Sand Filtration Fact Sheetjose03Nessuna valutazione finora

- Jar TestDocumento4 pagineJar TestNorhazerahYussopNessuna valutazione finora

- Softening: Water TreatmentDocumento20 pagineSoftening: Water Treatmentpkgarg_iitkgpNessuna valutazione finora

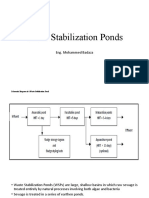

- 4 Waste Stabilization PondsDocumento44 pagine4 Waste Stabilization PondsEgana Isaac100% (1)

- Coagulation and FloculationDocumento42 pagineCoagulation and FloculationAngelJuniorVialetNessuna valutazione finora

- C08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFDocumento123 pagineC08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFAbdelilah KadriNessuna valutazione finora

- Water Treatment Process: Malla Reddy Institute of Technology & ScienceDocumento12 pagineWater Treatment Process: Malla Reddy Institute of Technology & ScienceGopi KrishnaNessuna valutazione finora

- Coagulation & FlocculationDocumento35 pagineCoagulation & FlocculationAbdu BiruNessuna valutazione finora

- Advanced Wastewater Treatment and Sludge ManagementDocumento52 pagineAdvanced Wastewater Treatment and Sludge ManagementFrancis TiehNessuna valutazione finora

- 2015 CVL300 Tutorial 4 SolutionDocumento7 pagine2015 CVL300 Tutorial 4 SolutionAhmed Abuzour100% (2)

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsDa EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNessuna valutazione finora

- Ismail Khan Experience CertificateDocumento1 paginaIsmail Khan Experience CertificateKhalid RehmanNessuna valutazione finora

- Wecccc LoanDocumento11 pagineWecccc LoanKhalid RehmanNessuna valutazione finora

- WAPDA NTS Test Questions for Junior EngineerDocumento10 pagineWAPDA NTS Test Questions for Junior EngineerKhalid RehmanNessuna valutazione finora

- General Knowledge - WORLDDocumento17 pagineGeneral Knowledge - WORLDSadeeq Ullah IhsanNessuna valutazione finora

- Sample Paper PGTP 2013Documento13 pagineSample Paper PGTP 2013bak_0090% (1)

- Ismail Khan Experience CertificateDocumento1 paginaIsmail Khan Experience CertificateKhalid RehmanNessuna valutazione finora

- Soil Test For Road ConstructionDocumento3 pagineSoil Test For Road ConstructionKhalid Rehman100% (5)

- Concept of God in Major World Religions - Dr. Zakir NaikDocumento29 pagineConcept of God in Major World Religions - Dr. Zakir NaikArshad Farooqui100% (5)

- Study Visit Report 2014Documento37 pagineStudy Visit Report 2014Khalid RehmanNessuna valutazione finora

- GPA Calculator - WECDocumento8 pagineGPA Calculator - WECKhalid RehmanNessuna valutazione finora

- Join Pakistan Army As Captain Through Short Service CommissionDocumento4 pagineJoin Pakistan Army As Captain Through Short Service CommissionRazaNessuna valutazione finora

- PPT 01Documento60 paginePPT 01Dickson LeongNessuna valutazione finora

- WEC Student Loan ApplicationDocumento3 pagineWEC Student Loan ApplicationKhalid RehmanNessuna valutazione finora

- SedimentationDocumento76 pagineSedimentationKhalid Rehman100% (2)

- Application For EventsDocumento2 pagineApplication For EventsKhalid RehmanNessuna valutazione finora

- Essentials of The Living World 4th Edition by Johnson ISBN Test BankDocumento22 pagineEssentials of The Living World 4th Edition by Johnson ISBN Test Bankpaul100% (20)

- ASTM StandardsDocumento948 pagineASTM StandardsSARVANA39% (33)

- Experiment 8 Acid-Base Titration: Pre - Lab QuestionsDocumento14 pagineExperiment 8 Acid-Base Titration: Pre - Lab QuestionsLeneNessuna valutazione finora

- (Trans) Chem 33 1 NomenclatureDocumento63 pagine(Trans) Chem 33 1 NomenclatureALongNessuna valutazione finora

- Spectrochemical Series For Cobalt (III)Documento8 pagineSpectrochemical Series For Cobalt (III)hectorhernandomsNessuna valutazione finora

- Chemistry June 06 Mark SchemeDocumento3 pagineChemistry June 06 Mark SchemePhooleeNessuna valutazione finora

- Chapter Four: Information Given by Chemical EquationsDocumento82 pagineChapter Four: Information Given by Chemical EquationsalelignNessuna valutazione finora

- Crown EthersDocumento4 pagineCrown EthersAdeeb MirzaNessuna valutazione finora

- SKT1013 Experiment 4Documento4 pagineSKT1013 Experiment 4AbdulRahim059100% (2)

- Chapter 5 Practice Exercises SolutionsDocumento30 pagineChapter 5 Practice Exercises SolutionsAriq Rama NurvirgianNessuna valutazione finora

- 5 (II) - Ionic Equilibria-Acid BesDocumento142 pagine5 (II) - Ionic Equilibria-Acid Besnur hashimahNessuna valutazione finora

- Lab Report 2 Water of HydrationDocumento4 pagineLab Report 2 Water of HydrationsayaanaNessuna valutazione finora

- Mt Mayon volcano types and propertiesDocumento2 pagineMt Mayon volcano types and propertiesRochelle Joy CruzNessuna valutazione finora

- SPM Form 4 Chemistry Chap 7 & 8 ExercisesDocumento20 pagineSPM Form 4 Chemistry Chap 7 & 8 ExercisesJames Wong100% (1)

- WS5-5-4A Everything About EquationsDocumento2 pagineWS5-5-4A Everything About EquationsJim Teston0% (2)

- 11 Chemistry Solved Questions Chapter 8 PDFDocumento6 pagine11 Chemistry Solved Questions Chapter 8 PDFMohd UvaisNessuna valutazione finora

- Chemistry 10 - 12 PDFDocumento283 pagineChemistry 10 - 12 PDFRon ShamendeNessuna valutazione finora

- Diprotic and Triprotic Acids and BasesDocumento1 paginaDiprotic and Triprotic Acids and Baseslimpat nulandayaNessuna valutazione finora

- Reactivity SeriesDocumento14 pagineReactivity SeriesDKFBNessuna valutazione finora

- Periodic Table Elements GuideDocumento22 paginePeriodic Table Elements GuideZennith Orions100% (1)

- Properties of CompoundsDocumento15 pagineProperties of CompoundsPrasad YarraNessuna valutazione finora

- Sap 5Documento22 pagineSap 5reza noviyantiNessuna valutazione finora

- Technical Data Sheet Spectek 787 Bright Nickel Process: Salient FeaturesDocumento8 pagineTechnical Data Sheet Spectek 787 Bright Nickel Process: Salient Featuresshanmukha MechanicalNessuna valutazione finora

- Redox MSDocumento4 pagineRedox MSYounes AlahmadNessuna valutazione finora

- Bonding AP Level Bonding SheetDocumento6 pagineBonding AP Level Bonding Sheetwoojin LeeNessuna valutazione finora

- University of Sargodha, Sargodha - . Assignment TopicDocumento18 pagineUniversity of Sargodha, Sargodha - . Assignment TopicMuhammadNessuna valutazione finora

- Heavy - Metal - METALSORB - by SNFDocumento4 pagineHeavy - Metal - METALSORB - by SNFNikhil MalhotraNessuna valutazione finora

- Steel Coding SystemDocumento5 pagineSteel Coding SystemWell LojuminNessuna valutazione finora

- Stoich PDFDocumento13 pagineStoich PDFJesza Mei GanironNessuna valutazione finora

- 2.5.11. Complexometric TitrationsDocumento1 pagina2.5.11. Complexometric TitrationsMulayam Singh YadavNessuna valutazione finora