Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Conversion & Reactor Sizing

Caricato da

Reyhan97Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Conversion & Reactor Sizing

Caricato da

Reyhan97Copyright:

Formati disponibili

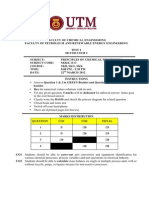

Chemical Engineering

Department

CCB3043 KINETICS AND REACTOR

DESIGN

CHAPTER 2: CONVERSION AND

REACTOR SIZING

(part 1)

1

Basic

knowledge

Application

1. Define conversion

2. Develop design equation for batch reactor

3. Develop design equation for flow reactor

4. Applying design equation to solve reactor problems

5. Applying design equation to reactors in series

6. Differentiate between space time and space velocity

3

OBJECTIVES OF CHAPTER 2

4

Overview on Objective of Chapter 2

Re-write

reactor sizing

in terms of

conversion

Reactor sizing

in terms of

mole balance

Relating mole

balance to

conversion

CHAPTER 1

CHAPTER 2

APPLYING

DESIGN

EQUATION TO

SOLVE

PROBLEMS

RELATED TO

FLOW REACTOR

AND REACTOR

IN SERIES

What is conversion?

Consider the general equation (irreversible eqn)

aA + bB cC + dD

We will choose A as our basis of calculation

D

a

d

C

a

c

B

a

b

A + +

How do we define

conversion?

Conversion

Conversion is define as:

feed A of moles

reacted A of moles

=

A

X

MAXIMUM CONVERSION?

Irreversible Reaction

X = 1

Reversible Reaction

X = X

e

7

Conversion

How do we

relate

conversion with

flow rate or

moles of

reactant?

8

Relating conversion with moles of reactant

Batch reactor

( ) ( )

( )( )

X N

X N

A

A

0

0

.

reacted A of Mole

onversion C fed A of Moles reacted A of Mole

=

=

=

reacted A of Mole - fed A of Mole time any at A of Mole = t

X N N N

A A A 0 0

- =

0

0

-

A

A A

N

N N

X =

9

Relating conversion with molar flow rate

Flow reactor (CSTR and PFR/PBR)

( ) ( )

( )( )

X F

X F

A

A

0

0

.

reacted A of flowrate Molar

onversion C fed A of flowrate Molar reacted A of flowrate Molar

=

=

=

t = Molar flowrate A at any time

Molar flowrate A fed - Molar flowrate A reacted

X F F F

A A A 0 0

- =

0

0

-

A

A A

F

F F

X =

Now, recap back our design equation:

10

Relating V to X

dt

dN

V r

A

A

=

HOW TO RE-

WRITE

V = f(X)

WHAT WE HAVE JUST

DISCOVERED:

0

0

-

A

A A

N

N N

X =

0

0

-

A

A A

F

F F

X =

Develop Design Equation for batch reactor

Batch reactor

}

=

=

X

A

A

A

A

V r

dX

N t

V r

dt

dN

0

0

PFR

0

A

A

A

A

A

dF

r

dV

dX

V F

r

=

=

}

CSTR

A

A

A A A

r

X F

V

V r F F

=

= +

0

0

0

Develop Design Equation for flow reactor

Design Equation

(Summary)

Reactor Differential Algebraic Integral

Batch

CSTR

PFR

PBR

Example:

E. 2-1: Using ideal gas law to calculate C

AO

and F

A0

A gas of pure A at 830 kPa (8.2 atm) enters a reactor with a

volumetric flow rate, v

0

of 2 dm

3

/s at 500K. Calculate the

entering concentration of A and its molar flow rate.

15

For FLOW REACTOR, we can estimate the reactor

size using a LEVENSPI EL PLOT.

What is LEVENSPIEL plot?

From a given data of and X, and a know value of F

A0

:

16

Reactor Sizing for flow reactor

r

A

X F

A0

/-r

A

F

A0

/-r

A

X

Reactor Sizing for flow reactor

Knowing r

A

= f(X

A

), reactor size can be determine

using Levenspiel plot

Consider the design equation for CSTR

A

0 A

r

X F

V

=

Consider the design equation of a PFR

Reactor Sizing for flow reactor

A 0 A

r

dV

dX

F =

Example 2-2 / 2-3: Sizing a CSTR / PFR

The gas phase reaction A B is carried out

in a CSTR and the entering molar flow rate

of A is 0.4 mol/s. Using data in Table 2-1:

1. Calculate the volume required to

achieve 80% conversion. Shade the

area on the Levenspiel plot that

corresponds to this conversion.

2. Re-do the problem if the reaction is

carried out in a PFR.

3. Any comment on the reactor size?

19

Reactor Sizing for flow reactor

X

A

-r

A

(mol/m

3

.s)

0.0 0.45

0.1 0.37

0.2 0.30

0.4 0.195

0.6 0.113

0.7 0.079

0.8 0.05

TABLE 2.1

Solution Ex 2-2: Sizing for CSTR

TABLE 2.1

X

A

-r

A

(mol/m

3

.s) 1/-r

A

(m

3.

.s/mol) F

A0

/-r

A

(m

3.

.s/mol)

0.0 0.45 2.22 0.89

0.1 0.37 2.70 1.08

0.2 0.30 3.33 1.33

0.4 0.195 5.13 2.05

0.6 0.113 8.85 3.54

0.7 0.079 12.70 5.06

0.8 0.05 20.00 8.00

( ) X F

r

V

A

A

0

1

|

|

.

|

\

|

=

DESIGN EQUATION OF CSTR!!

Solution Ex 2-2: Sizing for PFR

TABLE 2.1

X

A

-r

A

(mol/m

3

.s)

F

A0

/-r

A

(m

3.

.s/mol)

0.0 0.45 0.89

0.2 0.30 1.33

0.4 0.195 2.05

0.6 0.113 3.54

0.8 0.05 8.00

0.8

0

0

A

A

F

V dX

r

=

}

DESIGN EQUATION OF PFR!!

Use 5-point quadrature formula:

( ) ( )

4

0

0 1 2 3 4

4 2 4

3

X

X

h

f X dX f f f f f = + + + +

}

4 0

4

X X

h

=

Summary what we have learned:

Important things to remember

Volume

CSTR

Volume PFR

General mole balance

Mole balance equations for

each reactor

Design equations for each

reactor

Conversion

Reactor sizing

Reactors in Series

Knowing r

A

= f(X

A

), we can design any sequence of

reactors

Provided theres no side reactors, conversion at any

reactor outlet is define as:

reactor first to fed A of mole

i point to up reacted A of moles total

=

i

X

Reactors in series

Try and develop these design

equations..

2 CSTR in series

1 2

0

2

4

6

8

10

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Conversion, X

F

A

0

/

-

r

A

F

A2

X

2

=0.8

F

A0

F

A1

X

1

=0.4

2 PFR in series

0

2

4

6

8

10

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Conversion, X

F

A

0

/

-

r

A

1

2

F

A0

F

A1

X

1

=0.4

F

A2

X

2

=0.8

CSTR in series = 1 PFR

5 4 3 2 1

1 2 3 4 5

Equals to

As no. of CSTR in series increases, the total volume required for a given

conversion is similar to the volume of one PFR

0

2

4

6

8

10

0 0.2 0.4 0.6 0.8 1

Conversion, X

F

A

0

/

-

r

A

CSTR in series = 1 PFR

CSTR 1

CSTR 2

CSTR 3

CSTR 4

CSTR 5

PFR

Reactors in series

Example 2-5: Comparing volumes for CSTR in

series

From data below, calculate the volume of CSTR if 2 CSTR in series

is use for the reaction. Given that the intermediate conversion is

40% and the final conversion is 80%. Then, use the Levenspiel

plot to help you explain on the difference of the reactor volume for

single CSTR and CSTR in series.

Will there be any difference in volume if the reaction is carried out

in 2 PFR in series? Use the Levenspiel plot to explain your answer.

X 0.0 0.1 0.2 0.4 0.6 0.7 0.8

FA0/-rA 0.89 1.09 1.33 2.05 3.54 5.06 8.0

0

2

4

6

8

10

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Conversion, X

F

A

0

/

-

r

A

( )( )

3

1

3

1

3

4 . 0

0

8 . 0

4 . 0 0 . 2

0 . 2

m V

m V

m

r

F

X

A

A

=

=

=

|

|

.

|

\

|

=

( )

( )( )

3 3

2

1 2

2

0

2

3

8 . 0

0

2 . 3 4 . 0 8 . 0 0 . 8

0 . 8

m m V

X X

r

F

V

m

r

F

A

A

X

A

A

= =

|

|

.

|

\

|

=

=

|

|

.

|

\

|

=

V

T

= V

1

+V

2

= 0.82 + 3.2 = 4.02 m

3

Answer Example 2-5

Reactors in series

Example 2-6: Sizing plug flow reactors in series

Redo Example 2-5 but using 2 PFR in series. The

intermediate and final conversion remains the same. The

flow rate, F

A0

, also remains the same.

Answer Example 2-6

Use Simpsons three-point rule

( ) | |

3 3

1

0 0 0

1

4 . 0

0

0 1

551 . 0 05 . 2 33 . 1 4 89 . 0

3

2 . 0

) 4 . 0 ( ) 2 . 0 (

4

) 0 ( 3

m m V

r

F

r

F

r

F X

V

r

dX

F V

A

A

A

A

A

A

A

A

= + + =

(

A

=

=

}

( ) | |

3 3

1

0 0 0

2

8 . 0

4 . 0

0 2

614 . 1 0 . 8 54 . 3 4 05 . 2

3

2 . 0

) 8 . 0 ( ) 6 . 0 (

4

) 4 . 0 ( 3

m m V

r

F

r

F

r

F X

V

r

dX

F V

A

A

A

A

A

A

A

A

= + + =

(

A

=

=

}

( ) ( ) ( ) | |

2 1 0

4

3

) (

2

0

X f X f X f

X

dX x f

X

X

+ +

A

=

}

( )

3 3

2 1

165 . 2 614 . 1 551 . 0 m m V V V

T

= + = + =

This is the same volume if we were to calculate for a single PFR to achieve the same

conversion.

Example 2.7 An adiabatic liquid phase isomerisation

The isomerisation of butane was carried out adiabatically in

the liquid phase and the data in Table 2-7 was obtained. The

entering molar flow rate of n-butane of 50 kmol/hr.

Given the reactor scheme in Figure E 2-7.1, use Levenspiel

plot to show how to calculate the reactor volume

Reactors in series

25 38 59 53 39 -r

A

(kmol/m

3

.hr)

0.65 0.6 0.4 0.2 0 X

Table 2-7

Reactors in series

V

1

X

1

=0.2

X

2

=0.6

X

3

=0.65

Figure E2-7.1

35

Levenspiel plot for adiabatic reactors in series

0.00

0.50

1.00

1.50

2.00

2.50

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70

Conversion, X

F

A

0

/

-

r

A

1

st

CSTR 2

nd

CSTR PFR

CSTR PFR

Some further definitions

Relative rate of reaction

Obtained from stoichiometric ratio

Example:

d

r

c

r

b

r

a

r

D C B A

= =

Space time

Reactor Fluid

Also know as Mean Residence Time or Holding Time

Defined as the time necessary to process one reactor volume of fluid based on

entrance condition (volumetric flow rate)

0

u

t

V

=

Volume of reactor

Volumetric flowrate

Space time = time it for the fluid to enter the reactor completely

Space velocity (SV)

2 common measures of space velocity

Liquid hourly space velocity (LHSV)

Liquid flowrate measured at 60 - 70

o

F

Gas hourly space velocity (GHSV)

Gas flow rate measured at STP

Given by:

Some further definitions

V

v

SV

o

= =

t

1

END OF LECTURE

39

Potrebbero piacerti anche

- Chbe 6300 Graduate Kinetics and Reactor Design: Carsten Sievers 8/18/2020Documento18 pagineChbe 6300 Graduate Kinetics and Reactor Design: Carsten Sievers 8/18/2020AnnNessuna valutazione finora

- Aircraft Gas Turbine Tecnology by IRWINE TREAGER PDFDocumento684 pagineAircraft Gas Turbine Tecnology by IRWINE TREAGER PDFJai Deep87% (67)

- 1.multiple ReactionsDocumento58 pagine1.multiple ReactionsDianah NajeebNessuna valutazione finora

- Pharma Pathway SopDocumento350 paginePharma Pathway SopDinesh Senathipathi100% (1)

- PLJ-8LED Manual Translation enDocumento13 paginePLJ-8LED Manual Translation enandrey100% (2)

- Required Reading For Piano Technicians PDFDocumento28 pagineRequired Reading For Piano Technicians PDFNinaNessuna valutazione finora

- Maximizing Product Selectivity in Multiple Parallel ReactionsDocumento21 pagineMaximizing Product Selectivity in Multiple Parallel ReactionsMark Antony LevineNessuna valutazione finora

- 021SAACK Burner Operating Instructions PDFDocumento136 pagine021SAACK Burner Operating Instructions PDFmekidmu tadesse100% (1)

- Tutorial 4Documento3 pagineTutorial 4EreenNessuna valutazione finora

- Pathways-Childrens Ministry LeaderDocumento16 paginePathways-Childrens Ministry LeaderNeil AtwoodNessuna valutazione finora

- Cs On RH IncompatibilityDocumento17 pagineCs On RH IncompatibilityRupali Arora100% (2)

- CHE3044F, 2013: Reactor Design 1: TUTORIAL 3Documento3 pagineCHE3044F, 2013: Reactor Design 1: TUTORIAL 3nmhatityeNessuna valutazione finora

- L9 Reactor Design For Multiple RxnsDocumento21 pagineL9 Reactor Design For Multiple RxnsKarrar AlhsnawyNessuna valutazione finora

- L10 Nonelementary RxnsDocumento34 pagineL10 Nonelementary RxnsRama KrishnaNessuna valutazione finora

- Tutorial 2Documento2 pagineTutorial 2EreenNessuna valutazione finora

- Chapter 2 - Conversion Reactor SizingDocumento26 pagineChapter 2 - Conversion Reactor SizingKai Faha LukumNessuna valutazione finora

- Chapter 2 Conversion and Reactor SizingDocumento37 pagineChapter 2 Conversion and Reactor SizingAmir NasrinNessuna valutazione finora

- Steady State Non-Isothermal Reactor DesignDocumento34 pagineSteady State Non-Isothermal Reactor DesignFaisal MumtazNessuna valutazione finora

- Kinetics of Homogeneous ReactionDocumento56 pagineKinetics of Homogeneous ReactionSahel SahraeeNessuna valutazione finora

- TRK1 2013 Chapt 2Documento14 pagineTRK1 2013 Chapt 2Putri JulietaNessuna valutazione finora

- Tutorial For Chapter 23Documento9 pagineTutorial For Chapter 23Thurgah VshinyNessuna valutazione finora

- Kinetic Reactor Design Chapter 3 Lecture 4Documento21 pagineKinetic Reactor Design Chapter 3 Lecture 4Khairul Imran AzmanNessuna valutazione finora

- 3 - Prob PFR 11-12 23-35 English-1Documento4 pagine3 - Prob PFR 11-12 23-35 English-1Biniyam haileNessuna valutazione finora

- Gazi University Chemical Reaction Engineering ProblemsDocumento4 pagineGazi University Chemical Reaction Engineering ProblemsJerson Mendoza CNessuna valutazione finora

- Tute 1 PDFDocumento1 paginaTute 1 PDFRBNessuna valutazione finora

- Tutorial 4Documento1 paginaTutorial 4Aisyah ShaariNessuna valutazione finora

- Tutorial 3Documento2 pagineTutorial 3Aisyah ShaariNessuna valutazione finora

- Rate Law Determination and Kinetic Analysis TechniquesDocumento17 pagineRate Law Determination and Kinetic Analysis TechniquesAmroKashtNessuna valutazione finora

- Kinetics and Reactor Design Assignment 1Documento2 pagineKinetics and Reactor Design Assignment 1Muhd HafetzNessuna valutazione finora

- CEB2043 - Reaction Engineering I - Ch03 Rate Laws PDFDocumento25 pagineCEB2043 - Reaction Engineering I - Ch03 Rate Laws PDFScorpion RoyalNessuna valutazione finora

- Assignment 2 DR Azizul PDFDocumento4 pagineAssignment 2 DR Azizul PDFjinNessuna valutazione finora

- Lecture 2 - Chapter 1-Mole Balance PDFDocumento40 pagineLecture 2 - Chapter 1-Mole Balance PDFNizam JumadiNessuna valutazione finora

- Assignment 1 CHE594 April 2013Documento1 paginaAssignment 1 CHE594 April 2013riniz92Nessuna valutazione finora

- Reaction Kinetics Sample ProblemsDocumento1 paginaReaction Kinetics Sample ProblemsBenedict MarzanNessuna valutazione finora

- ChE 404 Final 2nd Semester 1428-1429Documento12 pagineChE 404 Final 2nd Semester 1428-1429JassimMohamed0% (1)

- Chapter 3 - Rate Laws and StoichiometryDocumento32 pagineChapter 3 - Rate Laws and StoichiometryKai Faha LukumNessuna valutazione finora

- 1 Chapter 1-Mole BalancesDocumento21 pagine1 Chapter 1-Mole BalancesKai Faha LukumNessuna valutazione finora

- Lec 1 - Fundamental Concepts, Force VectorsDocumento66 pagineLec 1 - Fundamental Concepts, Force VectorsMarian Galvez-LuisNessuna valutazione finora

- Statics of Particles Chapter SummaryDocumento21 pagineStatics of Particles Chapter SummaryhidayatullahNessuna valutazione finora

- Lesson Plan Reaction Engineering 1Documento4 pagineLesson Plan Reaction Engineering 1EreenNessuna valutazione finora

- Tutorial 4Documento5 pagineTutorial 4Aakash R RajwaniNessuna valutazione finora

- CH 1. Kinematics of Particles 2016 - Part A (Rectilinear Motion) PDFDocumento36 pagineCH 1. Kinematics of Particles 2016 - Part A (Rectilinear Motion) PDFOstaz SasaNessuna valutazione finora

- Tutorial 2 - Questions PDFDocumento2 pagineTutorial 2 - Questions PDFRaymond KakalaNessuna valutazione finora

- For Student Test1 Version 3 SKKK1113 1112-1 PDFDocumento3 pagineFor Student Test1 Version 3 SKKK1113 1112-1 PDFDon Jer Bear FirdausNessuna valutazione finora

- Assignment 1 CHE502/594 Reaction Engineering 1 Due Date: Monday (14 OF MAY 2018)Documento1 paginaAssignment 1 CHE502/594 Reaction Engineering 1 Due Date: Monday (14 OF MAY 2018)nazirulNessuna valutazione finora

- Tutorial 1Documento1 paginaTutorial 1Aisyah ShaariNessuna valutazione finora

- L16 Unsteady State and Reaction EngrDocumento25 pagineL16 Unsteady State and Reaction EngrDaniel TemoltzinNessuna valutazione finora

- CHM 152 Final Exam Review 1 Spring 2012 NEW KEYDocumento4 pagineCHM 152 Final Exam Review 1 Spring 2012 NEW KEYCaguioa Mark Anthony G.Nessuna valutazione finora

- Chemical Reaction Engineering (CHE 331A) Assignment-2 (2017-18-II)Documento2 pagineChemical Reaction Engineering (CHE 331A) Assignment-2 (2017-18-II)Anonymous rkAeZVSKNessuna valutazione finora

- Lecture 1 - Introduction of CREDocumento6 pagineLecture 1 - Introduction of CRENizam JumadiNessuna valutazione finora

- Chemical Reaction Engineering Mole Balances: ContentDocumento29 pagineChemical Reaction Engineering Mole Balances: ContentMhmad E. HerzallahNessuna valutazione finora

- Chapter 3 Rev1 Rate Laws & StoichiometryDocumento35 pagineChapter 3 Rev1 Rate Laws & StoichiometryHakashiMirudoNessuna valutazione finora

- 4.collection and Analysis of Rate Data - CHAPTER 5Documento37 pagine4.collection and Analysis of Rate Data - CHAPTER 5Marsya FarahNessuna valutazione finora

- Topic 1: Siti Wahidah Binti Puasa PHONE NO: 03-55436327 011-32338927 Reference: Fogler 4 Edition, Levenspeil 3 EditionDocumento35 pagineTopic 1: Siti Wahidah Binti Puasa PHONE NO: 03-55436327 011-32338927 Reference: Fogler 4 Edition, Levenspeil 3 EditionJohnNessuna valutazione finora

- Engineering Mechanic - Chapter 1Documento22 pagineEngineering Mechanic - Chapter 1NurzanM.JefryNessuna valutazione finora

- L12 Nonisothermal Reaction EngineeringDocumento24 pagineL12 Nonisothermal Reaction EngineeringShixia Xu100% (1)

- CRE I Assignment - 250919Documento11 pagineCRE I Assignment - 250919UpanyaaNessuna valutazione finora

- Assignment Reaction EngineeringDocumento6 pagineAssignment Reaction Engineeringnur hidayatiNessuna valutazione finora

- Sample Exams Problems CHE 402Documento3 pagineSample Exams Problems CHE 402Ricardo VelozNessuna valutazione finora

- Lec 4 - Isothermal Reactor Design PDFDocumento39 pagineLec 4 - Isothermal Reactor Design PDFMhmad E. HerzallahNessuna valutazione finora

- CHFEN 3553 Chemical Reaction Engineering: April 28, 2003 1:00 PM - 3:00 PM Answer All QuestionsDocumento4 pagineCHFEN 3553 Chemical Reaction Engineering: April 28, 2003 1:00 PM - 3:00 PM Answer All QuestionsIzzati KamalNessuna valutazione finora

- Lec 6 - Multiple ReactionsDocumento37 pagineLec 6 - Multiple ReactionskaurNessuna valutazione finora

- Tutorial 1Documento3 pagineTutorial 1Aakash R RajwaniNessuna valutazione finora

- CKB 20104 - Reaction EngineeringDocumento9 pagineCKB 20104 - Reaction EngineeringNoor FatihahNessuna valutazione finora

- Chemical Reaction Engineering (CRE) Reactor DesignDocumento37 pagineChemical Reaction Engineering (CRE) Reactor DesignHAJEYYNessuna valutazione finora

- Reaction Engineering Reactor SizingDocumento54 pagineReaction Engineering Reactor SizingRicardo VelozNessuna valutazione finora

- Data Validation and Verification - BBC BitsizeDocumento56 pagineData Validation and Verification - BBC BitsizeluciferothegoatNessuna valutazione finora

- Löwenstein Medical: Intensive Care VentilationDocumento16 pagineLöwenstein Medical: Intensive Care VentilationAlina Pedraza100% (1)

- Bosch Committed to Outsourcing to Boost CompetitivenessDocumento4 pagineBosch Committed to Outsourcing to Boost CompetitivenessPriya DubeyNessuna valutazione finora

- Fabm1 q3 Mod4 Typesofmajoraccounts FinalDocumento25 pagineFabm1 q3 Mod4 Typesofmajoraccounts FinalClifford FloresNessuna valutazione finora

- Case 1 1 Starbucks Going Global FastDocumento2 pagineCase 1 1 Starbucks Going Global FastBoycie TarcaNessuna valutazione finora

- 7 Equity Futures and Delta OneDocumento65 pagine7 Equity Futures and Delta OneBarry HeNessuna valutazione finora

- 114 ArDocumento254 pagine114 ArJothishNessuna valutazione finora

- Biotechnology Eligibility Test (BET) For DBT-JRF Award (2010-11)Documento20 pagineBiotechnology Eligibility Test (BET) For DBT-JRF Award (2010-11)Nandakumar HaorongbamNessuna valutazione finora

- Batool2019 Article ANanocompositePreparedFromMagn PDFDocumento10 pagineBatool2019 Article ANanocompositePreparedFromMagn PDFmazharNessuna valutazione finora

- MMH Dan StoringDocumento13 pagineMMH Dan Storingfilza100% (1)

- Module 7 - Assessment of Learning 1 CoursepackDocumento7 pagineModule 7 - Assessment of Learning 1 CoursepackZel FerrelNessuna valutazione finora

- Geometric Dilution of Precision ComputationDocumento25 pagineGeometric Dilution of Precision ComputationAntonius NiusNessuna valutazione finora

- CM Template For Flora and FaunaDocumento3 pagineCM Template For Flora and FaunaJonathan Renier Verzosa0% (1)

- Amniotic Membrane in Oral and Maxillofacial SurgeryDocumento13 pagineAmniotic Membrane in Oral and Maxillofacial SurgerySooraj SNessuna valutazione finora

- Assessment (L4) : Case Analysis: Managerial EconomicsDocumento4 pagineAssessment (L4) : Case Analysis: Managerial EconomicsRocel DomingoNessuna valutazione finora

- ABRAMS M H The Fourth Dimension of A PoemDocumento17 pagineABRAMS M H The Fourth Dimension of A PoemFrancyne FrançaNessuna valutazione finora

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THDocumento18 pagineTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonNessuna valutazione finora

- Past Paper Booklet - QPDocumento506 paginePast Paper Booklet - QPMukeshNessuna valutazione finora

- VFD ManualDocumento187 pagineVFD ManualgpradiptaNessuna valutazione finora

- Contract To Sell LansanganDocumento2 pagineContract To Sell LansanganTet BuanNessuna valutazione finora

- Teacher Commitment and Dedication to Student LearningDocumento8 pagineTeacher Commitment and Dedication to Student LearningElma Grace Sales-DalidaNessuna valutazione finora

- Mercury QCDocumento23 pagineMercury QCMarcus MeyerNessuna valutazione finora

- Describing An Object - PPTDocumento17 pagineDescribing An Object - PPThanzqanif azqaNessuna valutazione finora