Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Operations Management: Statistical Process Control Supplement 6

Caricato da

Hafiz UmmarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Operations Management: Statistical Process Control Supplement 6

Caricato da

Hafiz UmmarCopyright:

Formati disponibili

S6-1

Operations

Management

Statistical Process Control

Supplement 6

S6-2

Outline

+Statistical Process Control (SPC).

+ Mean charts or X-Charts.

+ Range chart or R-Charts.

+ Control charts for attributes.

+ Managerial issues and control charts.

+Acceptance Sampling.

S6-3

+Statistical technique to identify when non-

random variation is present in a process.

+All processes are subject to variability.

+ Natural causes: Random variations.

+ Assignable causes: Correctable problems.

+ Machine wear, unskilled workers, poor materials.

+Uses process control charts.

Statistical Process Control (SPC)

S6-4

Produce Good

Provide Service

Stop Process

No

Yes

Is process

in control?

Take Samples

Find Out Why

Create

Control Chart

Start

Statistical Process Control Steps

Take Sample

Inspect Sample

S6-5

Process Control Charts

Plot of Sample Data Over Time

0

20

40

60

80

1 5 9 13 17 21

Time

S

a

m

p

l

e

V

a

l

u

e

Upper control limit

Lower control limit

S6-6

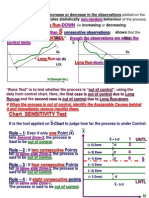

+Process is not in control if:

+ Sample is not between upper and lower control

limits.

+ A non-random pattern is present, even when

between upper and lower control limits.

+Based on sample being normally distributed.

Control Charts

S6-7

Distribution of Sample Means

x means sample of Mean =

n

x

x

o

o = =

Standard deviation of

the sample means

(mean)

x

2 within fall x all of 95.5% o

x

3 within fall x all of 99.7% o

x

3

x

2

x

x

x

1

x

2

x

3 o + o + o 1 + o o o

S6-8

X

As sample size

gets

large

enough,

distribution of mean

values becomes

approximately normal

for any population

distribution.

Central Limit Theorem

X

Central Limit Theorem

S6-9

Control

Charts

R

Chart

Variables

Charts

Attributes

Charts

X

Chart

P

Chart

C

Chart

Continuous

Numerical Data

Categorical or

Discrete Numerical

Data

Control Chart Types

S6-10

+ Characteristics for which

you focus on defects.

+ Categorical or discrete

values.

+ Good or Bad.

+ # of defects.

Attributes Variables

Quality Characteristics

+ Characteristics that you

measure, e.g., weight,

length.

+ Continuous values.

S6-11

+Shows sample means over time.

+Monitors process average.

+Example: Weigh samples of coffee.

+Collect many samples, each of n bags.

+ Sample size = n.

+ Compute mean and range for each sample.

+ Compute upper and lower control limits (UCL, LCL).

+ Plot sample means and control limits.

X Chart

S6-12

X Chart Control Limits -

Std. Dev. of Process Is Known

sample mean

at time i

x x

z x

x

LCL z x

x

UCL = + =

n

i

x

x

n

i

=

=

1

n

x

=

o = known process

standard deviation

S6-13

Each sample is 4 measurements.

Process mean is 5 lbs.

Process standard deviation is 0.1 lbs.

Determine 3o control limits.

X Chart - Example 1

85 . 4

4

1 . 0

3 5

15 . 5

4

1 . 0

3 5

= =

= + =

x

LCL

x

UCL

S6-14

X Chart Control Limits -

Std. Dev. of Process is Not Known

sample range

at time i

A

2

is from Table S6.1

R A x

x

LCL R A x

x

UCL

2 2

= + =

n

i

R

n

i

R

1 =

=

sample mean

at time i

n

i

x

x

n

i

=

=

1

S6-15

Factors for Computing Control

Chart Limits

Sample

Size, n

Mean

Factor, A

2

Upper

Range, D

4

Lower

Range, D

3

2 1.880 3.268 0

3 1.023 2.574 0

4 0.729 2.282 0

5 0.577 2.115 0

6 0.483 2.004 0

7 0.419 1.924 0.076

8 0.373 1.864 0.136

9 0.337 1.816 0.184

10 0.308 1.777 0.223

S6-16

Each sample is 4 measurements.

Determine 3o control limits.

sample mean range.

1 5.02 .12 4.96, 5.03, 5.01, 5.08

2 4.99 .08.

3 4.97 .13.

4 5.03 .18.

5 4.99 .14.

X Chart - Example 2

905 . 4 13 . 0 729 . 0 5

095 . 5 13 . 0 729 . 0 5

= =

= + =

x

LCL

x

UCL

13 . 0 0 . 5 = = R x

S6-17

X Chart - Example 2

4.9

5.0

5.1

Time

S

a

m

p

l

e

M

e

a

n

Upper control limit

Lower control limit

S6-18

sample values mean range

6 5.05, 5.00, 4.80, 4.95 4.95 0.25

7 5.00, 5.10, 5.10, 5.00 5.05 0.10

8 4.80, 5.20, 5.10, 5.00 5.025 0.40

4.9

5.0

5.1

Time

S

a

m

p

l

e

M

e

a

n

Upper control limit

Lower control limit

Example 2 New Samples

S6-19

+Shows sample ranges over time.

+ Sample range = largest - smallest value in sample.

+Monitors process variability.

+Example: Weigh samples of coffee.

+ Collect many samples, each of n bags.

+ Sample size = n.

+ Compute range for each sample & average range.

+ Compute upper and lower control limits (UCL, LCL).

+ Plot sample ranges and control limits.

R Chart

S6-20

sample range at

time i

From Table S6.1

R Chart Control Limits

n

R

R

R D LCL

R D UCL

i

n

1 i

3 R

4 R

=

=

=

=

S6-21

Each sample is 4 measurements.

Determine 3o control limits.

sample mean range

1 5.02 .12

2 4.99 .08

3 4.97 .13

4 5.03 .18

5 4.99 .14

R Chart - Example 2

0 13 . 0 0

297 . 0 13 . 0 282 . 2

= =

= =

R

R

LCL

UCL

13 . 0 0 . 5 = = R x

4.96, 5.03, 5.01, 5.08

S6-22

R Chart - Example 2

0

0.2

0.3

Time

S

a

m

p

l

e

R

a

n

g

e

Upper control limit

Lower control limit

0.1

S6-23

sample values mean range

6 5.05, 5.00, 4.80, 4.95 4.95 0.25

7 5.00, 5.10, 5.10, 5.00 5.05 0.10

8 4.80, 5.20, 5.10, 5.00 5.025 0.40

Example 2 New Samples

0

0.2

0.3

Time

S

a

m

p

l

e

R

a

n

g

e

Upper control limit

Lower control limit

0.1

S6-24

Control Chart Steps

+Collect 20 to 25 samples of n=4 or n=5 from a

stable process & compute the mean and range.

+Compute the overall mean and average range.

+Calculate upper and lower control limits.

+Collect new samples, and plot the means and

ranges on their respective control charts.

S6-25

Control Chart Steps - Continued

+Investigate points or patterns that indicate the

process is out of control. Assign causes for

the variations.

+Collect additional samples and revalidate the

control limits.

S6-26

Use of Control Charts

S6-27

sample values mean range

1 4.9, 5.0, 5.1 5.0 0.2

2 5.2, 5.3, 5.4 5.3 0.2

3 5.5, 5.6, 5.7 5.6 0.2

4 5.8, 5.9, 6.0 5.9 0.2

Example 3

2454 . 5 2 . 0 023 . 1 45 . 5

6546 . 5 2 . 0 023 . 1 45 . 5

= =

= + =

x

LCL

x

UCL

2 . 0 45 . 5 = = R x

0 2 . 0 0

5148 . 0 2 . 0 574 . 2

= =

= =

R

LCL

R

UCL

S6-28

Example 3 Control Charts

5.0

5.5

6.0

Time

S

a

m

p

l

e

M

e

a

n

Upper control limit = 5.6546

Lower control limit = 5.2454

0.0

0.5

1.0

Time

S

a

m

p

l

e

R

a

n

g

e

Upper control limit = 0.5148

Lower control limit = 0

S6-29

sample values mean range

1 5.0, 5.0, 5.0 5.0 0.0

2 4.5, 5.0, 5.5 5.0 1.0

3 4.0, 5.0, 6.0 5.0 2.0

4 3.0, 5.0, 7.0 5.0 4.0

Example 4

20975 . 3 75 . 1 023 . 1 0 . 5

79025 . 6 75 . 1 023 . 1 0 . 5

= =

= + =

x

LCL

x

UCL

75 . 1 0 . 5 = = R x

0 75 . 1 0

5045 . 4 75 . 1 574 . 2

= =

= =

R

LCL

R

UCL

S6-30

Example 4 Control Charts

3.0

5.0

7.0

Time

S

a

m

p

l

e

M

e

a

n

Upper control limit = 6.79025

Lower control limit = 3.20975

0.0

3.0

6.0

Time

S

a

m

p

l

e

R

a

n

g

e

Upper control limit = 4.5045

Lower control limit = 0

S6-31

+Attributes control chart.

+Shows % of nonconforming items.

+Example: Count # defective chairs & divide by

total chairs inspected.

+ Chair is either defective or not defective.

p Chart

S6-32

+Attributes control chart.

+Shows number of defects in a unit.

+ Unit may be chair, steel sheet, car, etc.

+ Size of unit must be constant.

+Example: Count # defects (scratches, chips

etc.) in each chair of a sample of 100 chairs.

c Chart

S6-33

+Quality testing for incoming materials or

finished goods.

+Procedure:

+ Take one or more samples at random from a lot

(shipment) of items.

+ Inspect each of the items in the sample.

+ Decide whether to reject the whole lot based on

the inspection results.

Acceptance Sampling

S6-34

+Inspecting all items is too expensive.

+The larger the sample inspected:

+ The greater the cost for inspection.

+ The less likely you are to accept a bad lot or to

reject a good lot.

+Key questions:

+ How many should be inspected in each lot?

+ How confident are you in the accept/reject

decision?

Acceptance Sampling

Potrebbero piacerti anche

- Homework Assignment 2 QUALITY MANAGEMENT YANISDocumento4 pagineHomework Assignment 2 QUALITY MANAGEMENT YANISYanis AlbinetNessuna valutazione finora

- Vogue's New Book For Better SewingDocumento171 pagineVogue's New Book For Better SewingMinh NguyenNessuna valutazione finora

- Statistical Process ControlDocumento43 pagineStatistical Process ControlninaswayNessuna valutazione finora

- SPC Probs Solns s07Documento4 pagineSPC Probs Solns s07Siva Krishna Reddy Nallamilli100% (1)

- Example For Financial Statement AnalysisDocumento2 pagineExample For Financial Statement AnalysisMobile Legends0% (1)

- U-340 Valve BodyDocumento19 pagineU-340 Valve BodyAle100% (4)

- Cisco Wireless LAN Controller - Configuration Guide PDFDocumento696 pagineCisco Wireless LAN Controller - Configuration Guide PDFMiguel MazaNessuna valutazione finora

- SPC: Statistical Process ControlDocumento53 pagineSPC: Statistical Process ControlSaoloan NaiborhuNessuna valutazione finora

- Chap 04Documento9 pagineChap 04gttomcatNessuna valutazione finora

- Chapter 3 - Control Chart For VariablesDocumento66 pagineChapter 3 - Control Chart For VariablesSultan Almassar100% (1)

- Process Capability and SPC : Operations ManagementDocumento43 pagineProcess Capability and SPC : Operations ManagementRahul KhannaNessuna valutazione finora

- Statistical Quality Control (SQC) FinalDocumento47 pagineStatistical Quality Control (SQC) FinalSagar DhageNessuna valutazione finora

- Operations Management: Statistical Process Control Supplement 6Documento34 pagineOperations Management: Statistical Process Control Supplement 6زهديابوانسNessuna valutazione finora

- ASSIGNMENT ON STATISTICAL PROCESS CONTROL ProdDocumento4 pagineASSIGNMENT ON STATISTICAL PROCESS CONTROL ProdsamanthaNessuna valutazione finora

- Chapter 3 Control Chart For VariablesDocumento66 pagineChapter 3 Control Chart For VariablesRitam PalNessuna valutazione finora

- Ken Black QA ch18Documento54 pagineKen Black QA ch18Rushabh VoraNessuna valutazione finora

- 10 SQCDocumento31 pagine10 SQCsingharvindkumarNessuna valutazione finora

- 4 SPCDocumento53 pagine4 SPCShubham AggarwalNessuna valutazione finora

- Statistic ProcessDocumento39 pagineStatistic ProcessxredjokerxNessuna valutazione finora

- 7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationDocumento55 pagine7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationNilesh RathoreNessuna valutazione finora

- Need To Go Back To CLT - Lecture 4 Hypothesis Testing in The Multiple Regression ModelDocumento23 pagineNeed To Go Back To CLT - Lecture 4 Hypothesis Testing in The Multiple Regression ModelChamika WijerathneNessuna valutazione finora

- Chapter 4 Control Charts For VariablesDocumento44 pagineChapter 4 Control Charts For Variablesgeletaw mitawNessuna valutazione finora

- Variation: The Presence of VariationDocumento17 pagineVariation: The Presence of VariationHarris ChackoNessuna valutazione finora

- 14 Process CapabilityDocumento33 pagine14 Process CapabilitySamNessuna valutazione finora

- Statistical Quality Control (S.Q.C.) Presented By-: Nikhil Garg ROLL NO-0129626Documento38 pagineStatistical Quality Control (S.Q.C.) Presented By-: Nikhil Garg ROLL NO-0129626jolaakNessuna valutazione finora

- 6e ControlchartsforvariablesDocumento39 pagine6e ControlchartsforvariablesdeepikaNessuna valutazione finora

- Heizer Om10 Ism 06SDocumento15 pagineHeizer Om10 Ism 06SNadia NathaniaNessuna valutazione finora

- SQC Notes 2018 AdminDocumento9 pagineSQC Notes 2018 AdminAby MathewNessuna valutazione finora

- (DONE) OPIM - Practice Questions Week 6Documento5 pagine(DONE) OPIM - Practice Questions Week 6Dexter KhooNessuna valutazione finora

- Statistical Process Control: Managing For Quality Dr. Ron LembkeDocumento39 pagineStatistical Process Control: Managing For Quality Dr. Ron Lembkekr_padmavathiNessuna valutazione finora

- Technical Note 8: Process Capability and Statistical Quality ControlDocumento46 pagineTechnical Note 8: Process Capability and Statistical Quality ControlVipin NairNessuna valutazione finora

- 5.2 Process Capability Analysis Rev2ADocumento8 pagine5.2 Process Capability Analysis Rev2APollyNessuna valutazione finora

- Quality and PerformanceDocumento96 pagineQuality and PerformanceHoNestLiArNessuna valutazione finora

- Extra Numericals of Control ChartsDocumento31 pagineExtra Numericals of Control ChartsAnurag Sharma100% (2)

- Process Capab SixsigmaDocumento3 pagineProcess Capab SixsigmaHemantNessuna valutazione finora

- CH 06Documento55 pagineCH 06Swapnil BondeNessuna valutazione finora

- Statistical Process Control: Operations Management - 5 EditionDocumento49 pagineStatistical Process Control: Operations Management - 5 EditionGunasekaran ChinnusamyNessuna valutazione finora

- SPCDocumento59 pagineSPCadibhai06100% (2)

- Quality ManagementDocumento10 pagineQuality ManagementTifarie Luesas33% (3)

- EafdvcdfvcDocumento34 pagineEafdvcdfvcAmara UiNessuna valutazione finora

- Statistical Quality Control: By: Vilas PathakDocumento45 pagineStatistical Quality Control: By: Vilas Pathakgazala100% (2)

- Statistics For Business and Economics: Bab 20Documento43 pagineStatistics For Business and Economics: Bab 20balo100% (1)

- Hypothesis Testing in The Multiple Regression PDFDocumento23 pagineHypothesis Testing in The Multiple Regression PDFShabbir WahabNessuna valutazione finora

- Hypothesis Testing in The Multiple Regression ModelDocumento23 pagineHypothesis Testing in The Multiple Regression ModelMartinNessuna valutazione finora

- Statistical Quality ControlDocumento36 pagineStatistical Quality ControlDr Rushen SinghNessuna valutazione finora

- Statistical Quality ControlDocumento13 pagineStatistical Quality ControlsekelanilunguNessuna valutazione finora

- 14 SolutionsDocumento14 pagine14 Solutionsdiego_cáceres_30Nessuna valutazione finora

- Statistical Quality Control 2Documento34 pagineStatistical Quality Control 2Tech_MXNessuna valutazione finora

- Statistical Process Control: Quality Engineering Laboratory 540:434 Section 1 Lab 6 11/30/2009Documento13 pagineStatistical Process Control: Quality Engineering Laboratory 540:434 Section 1 Lab 6 11/30/2009fvijayanNessuna valutazione finora

- Statistical Process ControlDocumento42 pagineStatistical Process ControlErick Bok Cang YeongNessuna valutazione finora

- QualityDocumento36 pagineQualityShobitha UchilNessuna valutazione finora

- 08 Process CapabilityDocumento36 pagine08 Process CapabilityMugni SrinoviaNessuna valutazione finora

- Six Sigma Vs TaguchiDocumento14 pagineSix Sigma Vs TaguchiemykosmNessuna valutazione finora

- SPC 10001Documento16 pagineSPC 10001Deepa DhilipNessuna valutazione finora

- Poisson Regression - Stata Data Analysis ExamplesDocumento12 paginePoisson Regression - Stata Data Analysis ExamplesAngger Wiji RahayuNessuna valutazione finora

- JPM TQM Course Mat-5 T-3 Imba 2013Documento14 pagineJPM TQM Course Mat-5 T-3 Imba 2013Vishnu PrasadNessuna valutazione finora

- Dr. Akhilesh Das Gupta Institute of Technology and ManagementDocumento10 pagineDr. Akhilesh Das Gupta Institute of Technology and ManagementAshish KumarNessuna valutazione finora

- Statistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaDocumento40 pagineStatistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaInderpreet SinghNessuna valutazione finora

- Quality 1Documento22 pagineQuality 1pankajdharmadhikariNessuna valutazione finora

- SQCR Practical File - Yash Verma 40515611117 F13 MEDocumento21 pagineSQCR Practical File - Yash Verma 40515611117 F13 MEIsh ShilpNessuna valutazione finora

- Operations Management: Supplement 6 - Statistical Process ControlDocumento73 pagineOperations Management: Supplement 6 - Statistical Process ControlShubham SharmaNessuna valutazione finora

- Six Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneDa EverandSix Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneNessuna valutazione finora

- Consumer 123Documento56 pagineConsumer 123Hafiz UmmarNessuna valutazione finora

- Penn State: The Dickinson School of LawDocumento88 paginePenn State: The Dickinson School of LawHafiz UmmarNessuna valutazione finora

- By Gracie Lee (B94705011), Jennifer Huang (B94705035), Charles Virgile (A97749219), Nicolas Valaize (A97749221), Vincent Montmoreau, Fabien PalmeroDocumento3 pagineBy Gracie Lee (B94705011), Jennifer Huang (B94705035), Charles Virgile (A97749219), Nicolas Valaize (A97749221), Vincent Montmoreau, Fabien PalmeroHafiz UmmarNessuna valutazione finora

- PV Factor FV Factor (1+r) N R RateDocumento1 paginaPV Factor FV Factor (1+r) N R RateHafiz UmmarNessuna valutazione finora

- Kdselfjdskskfih/qafiefkasjnbfcife8y Safsdgfdbhfdbh SDSGFDHFDNH SFDFGFDHN Asfgfh AsdfdghthDocumento1 paginaKdselfjdskskfih/qafiefkasjnbfcife8y Safsdgfdbhfdbh SDSGFDHFDNH SFDFGFDHN Asfgfh AsdfdghthHafiz UmmarNessuna valutazione finora

- Self Perception TheoryDocumento40 pagineSelf Perception TheoryHafiz UmmarNessuna valutazione finora

- The Low Cost Airline: Airasia A Study of Opportunities, Challenges and Critical Success FactorsDocumento13 pagineThe Low Cost Airline: Airasia A Study of Opportunities, Challenges and Critical Success FactorsSam All YmnNessuna valutazione finora

- Running Head: Understanding Employee'S Motivation (Carefully Designed Reward System Is A Key To Success)Documento14 pagineRunning Head: Understanding Employee'S Motivation (Carefully Designed Reward System Is A Key To Success)Hafiz UmmarNessuna valutazione finora

- Fundamentals of Group DynamicsDocumento17 pagineFundamentals of Group DynamicsHafiz Ummar0% (1)

- Ejss 5 3Documento143 pagineEjss 5 3Hafiz UmmarNessuna valutazione finora

- MainPaper 4309 5Documento1 paginaMainPaper 4309 5Hafiz UmmarNessuna valutazione finora

- Culture - Handy: Handy - Gods of ManagementDocumento4 pagineCulture - Handy: Handy - Gods of ManagementHafiz UmmarNessuna valutazione finora

- Assignment 1Documento2 pagineAssignment 1Nayyar AbbasiNessuna valutazione finora

- 10 Must Read Books For Stock Market Investors in India - Trade BrainsDocumento35 pagine10 Must Read Books For Stock Market Investors in India - Trade BrainsCHANDRAKISHORE SINGHNessuna valutazione finora

- Gallipoli Diary, Volume 2 by Hamilton, Ian, 1853-1947Documento191 pagineGallipoli Diary, Volume 2 by Hamilton, Ian, 1853-1947Gutenberg.orgNessuna valutazione finora

- Conducting Effective Meetings WorkBookDocumento36 pagineConducting Effective Meetings WorkBookCheri HoNessuna valutazione finora

- 曼昆《经济学原理第三版》宏观分册原版中英文双语PPT课件Chap 25Documento76 pagine曼昆《经济学原理第三版》宏观分册原版中英文双语PPT课件Chap 25Jia Wei MiaoNessuna valutazione finora

- Lenovo A516 Maintenance ManualDocumento40 pagineLenovo A516 Maintenance Manualpradipto87Nessuna valutazione finora

- 3 - Cellular Respiration NotesDocumento22 pagine3 - Cellular Respiration Notesapi-375285021Nessuna valutazione finora

- 15.guitar ElectronicsDocumento48 pagine15.guitar Electronics王斌Nessuna valutazione finora

- Human Resource Management in Banking Sector in STATE BANK OF INDIA by PrinceDocumento83 pagineHuman Resource Management in Banking Sector in STATE BANK OF INDIA by Princemayur pawarNessuna valutazione finora

- Op QuesDocumento7 pagineOp QuessreelakshmiNessuna valutazione finora

- Methods of Determining Thermal Efficiency in Spray Drying ProcessDocumento3 pagineMethods of Determining Thermal Efficiency in Spray Drying ProcessDfunz WilphenNessuna valutazione finora

- Esp32-Wroom-32se Datasheet enDocumento26 pagineEsp32-Wroom-32se Datasheet enWesllen Dias SouzaNessuna valutazione finora

- Asgkit Coding STDDocumento10 pagineAsgkit Coding STDDavid ZamudioNessuna valutazione finora

- En Firearms Evaluation ReportDocumento168 pagineEn Firearms Evaluation Reportandrew_davidson100% (2)

- CV - Akhil AgarwalDocumento2 pagineCV - Akhil AgarwalIshan SaxenaNessuna valutazione finora

- Negative Effects of Social Media AddictionDocumento2 pagineNegative Effects of Social Media AddictionTubagus Fikih AriansyahNessuna valutazione finora

- Impact of Phragmanthera Capitata (Sprenge.) Balle On Pod and Beans Production of Two Cocoa Clones in Nkoemvone Seed Fields (South Cameroun) - JBES @scribdDocumento9 pagineImpact of Phragmanthera Capitata (Sprenge.) Balle On Pod and Beans Production of Two Cocoa Clones in Nkoemvone Seed Fields (South Cameroun) - JBES @scribdInternational Network For Natural SciencesNessuna valutazione finora

- Gun TypesDocumento125 pagineGun Typesdewaaaaa-76100% (2)

- The Urban Footprint: Trece Martires City, CaviteDocumento1 paginaThe Urban Footprint: Trece Martires City, CaviteJubileo Paul Lara LiganNessuna valutazione finora

- Architecture Firm Business Plan by SlidesgoDocumento20 pagineArchitecture Firm Business Plan by SlidesgoWenna Dale PasquinNessuna valutazione finora

- Z370 AORUS Gaming 3: User's ManualDocumento48 pagineZ370 AORUS Gaming 3: User's ManualAtrocitus RedNessuna valutazione finora

- Workshop On Previewing - CECARDocumento12 pagineWorkshop On Previewing - CECARestefaany tejada100% (2)

- 5 Energy ManagementDocumento1 pagina5 Energy ManagementDibyo SetiawanNessuna valutazione finora

- Course Outline BRM AbasynDocumento4 pagineCourse Outline BRM Abasynsadeeq sahilNessuna valutazione finora

- Grounding-101 IEEE IAS PDFDocumento81 pagineGrounding-101 IEEE IAS PDFRoySnk100% (2)

- Healthcare Mobility SecuirtyDocumento23 pagineHealthcare Mobility SecuirtyDavid AntelizNessuna valutazione finora