Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Current Approach To Pavement Design

Caricato da

April IngramTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Current Approach To Pavement Design

Caricato da

April IngramCopyright:

Formati disponibili

Current Approach to Pavement Design

CIV2242

Dr Jayantha Kodikara (Kodi)

Pavement Design System

(Austroads, 2001 draft)

Structural Design

1. Flexible Pavements

2. Rigid Pavements

3. Overlays

Design Traffic

Pavement

Materials

Subgrade

Evaluation

Environment

Construction

&

Maintenance

Considerations

Comparison

Of Designs

Implement

and monitor

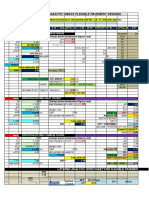

Flexible Pavement Design

Flexible Approach

Distress Modes for Flexible Pavements

(modified from Austroads, 2004)

Distress

Mode

Likely Causes Materials

Affected

Rutting

Deformation of underlying materials,

specially subgrade

Unbound materials,

(bound materials?)

Cracking

Traffic associated

Single or low repetitions of high load

Many repetitions of normal loads

Non-traffic associated

Thermal cycling

Reflection of shrinkage cracks

Swelling/shrinking of subgrade materials

Asphalt, cemented

materials, granular

materials

Roughness

variability of density, swelling/shrinking of

subgrade materials

All materials

Design Chart for Granular

Materials with Thin Bituminous

Surfacing (Austroads, 2004)

| | ) 120 / log( ) (log 58 ) (log 211 219

2

DESA CBR CBR t + =

Example

Example:

A unbound pavement is to be designed over a weak subgrade of CBR

4 to carry design ESAs of 2 x 10

6

. Design a pavement with base

and one subbase layer over the subgrade. The base is to be made

of good quality crushed rock with CBR well over 80. The subbase

layer is to be made of marginal gravel material with a design CBR of

30.

From Figure 2, the thickness of the pavement needed above the

subgrade of CBR 4 is 480 mm.

If we place, gravel above the subgrade, then the pavement

thickness needed above that layer is, by looking up the graph for

CBR 30, is 130 mm.

Therefore, the pavement layer thicknesses are: base (crushed rock)

= 130 mm; subbase (gravel) = (480-130) = 350 mm.

Mechanistic Pavement Design

Mechanistic Pavement Design Model for

Flexible Pavements (Austroads, 2001 draft)

Asphalt

300 300

1800 mm

165

2

3 3

Granular

Material

Cemented

Material

Subgrade

1 Tensile strain at bottom of asphalt

2 Tensile strain at bottom of cemented material

3 Compressive strain at top of subgrade

Critical locations

1

Uniform stress

(equal to tyre

pressure)

Material behaviour and input

parameters

Material Behaviour Properties

Asphalt Isotropic E

flex

, v

Cement treated Isotropic E

flex

, v

Unbound granular Anisotropic Ev, Eh, vv, vh, and

f (shear modulus)

But,

E

h

= 0.5 E

v

v

v

= v

h

= v

f = E

v

/ (1+v)

E

v

is the resilient

modulus.

Determination of pavement life

100

1000

10000

100000

1.E+01 1.E+02 1.E+03 1.E+04 1.E+05 1.E+06 1.E+07

Austroads (2004) Approach for

Subgrade Modelling

Prevent the rutting failure by limiting the vertical strain on

the subgrade.

Basically assume that soil behaves in a resilient manner

under these strains.

7

9300

(

=

c

N

log N

log c

How is c is determined?

Asphalt

Asphalt is a mixture of bituminious binder and

aggregate which is spread and compacted while

hot to form a pavement layer.

The strength/stiffness of asphalt is derived from

friction between the bitumen coated aggregate

particles and the cohesion resulted from bitumen

binder.

Main forms of distress are:

Fatigue failure

Rutting and shoving due to inadequate strength and

stiffness.

Asphalt modulus (x1000, MPa)

Typical Australian Dense-Graded Asphalt at 25

o

C (Austroads, 2004)

Binder Mix Size (maximum particle size, mm)

10 14 20

Range Typical Range Typical Range Typical

Class

170

2-6 3.5 2.5-3.5 3.7 2-4.5 4

Class

320

3-6 4.5 2-7 5 3-7.5 5.5

Class

600

3-6 6 4-9 6.5 4-9.5 7

Multigra

de

3.3-5 4.5 3-7 5 4-7 5.5

SBS 1.5-4 2.2 2-4.5 2.5 3-7 3

EVA 3-6.5 5.6

Asphalt Fatigue Failure

(Austraods, 2004 using Shell (1978) relationship)

500

1000

800

400

300

200

100

1.0E+03

600

900

700

1100

1.0E+04 1.0E+07 1.0E+08 1.0E+05 1.0E+06

E=2000 MPa

Vb=10%

E=2000 MPa

Vb=12%

E=4000 MPa

Vb=10%

E=4000 MPa

Vb=12%

M

i

c

r

o

s

t

r

a

i

n

ESA Repetitions

V

b

=bitumen percentage by volume; E=asphalt resilient modulus

5

36 . 0

) 08 . 1 856 . 0 ( 6918

(

(

+

=

c

flex

b

E

V

RF N

RF=0.95

Behaviour of Cemented Materials

Cemented materials may be described as a

mixture of a cementitious binder, granular

material and water, compacted and cured.

The material has strength/stiffness more than

the granular material (host material) but less

than those of concrete.

Typical binder contents used are 2 to 6% by

weight.

In contrast to granular materials, these materials

develop some tensile strength.

Cemented Materials

Approximated to be linear elastic (under normal

operating conditions) and isotropic.

Elastic modulus and Poissons ratio are needed

to characterise the material.

Because the bending tensile fatigue failure is

considered to be main distress mode under

traffic loading, flexural modulus is preferred.

Parameters for Cemented Materials

Flexural modulus at 28 days curing in the road-

bed is required.

This may be obtained by:

Laboratory flexural beam tests, E

flex

Correlations of E

flex

with other laboratory tests (UCS)

E

flex

=1500 UCS ; UCS of lab specimens at 28 days curing.

Presumptive values.

Span/depth >3

P

A

P

A

Presumptive Parameters for

Cemented Materials

Material

Category

Cemented Materials

Property

(E in MPa)

Lean Mix

Concrete

Base

4 to 5%

Cement

Crushed Rock

2 to 4%

Cement

Subbase

quality natural

gravel 4 to 5%

cement

Range of E 5000 15000 3000-8000 2000 to 5000 1500 - 3000

Typical E 7000 (Rolled)

10000 (Screed)

5000 3500 2000

Degree of

anisotrophy

1 1 1 1

Range of

Poissons ratio

0.1 - 0.3 0.1 - 0.3

0.1 - 0.3

0.1 - 0.3

Typical u 0.2 0.2

0.2

0.2

Failure of Cemented Materials

Austroads (2004)

12

804 . 0

) 191

113000

(

(

(

(

(

+

=

c

E

RF N

RF=0.95

Granular materials

No failure criteria is used.

It is assumed that the material property requirements

have been met (discussed under Pavement Materials).

The material is considered as anisotropic elastic material

for mechanistic analyses.

The granular layer can be divided into sublayers to

account for the variation of modulus due to different

stress levels.

Need E

v

and Poissons ratio u. For mechanistic

designs, the soil is assumed to be anisotropic with

E

v

/E

H

=2 and u

v

= u

H

. Another parameter (shear modulus)

f=E/(1+ u

v

).

Presumptive Values for Granular Unbound

Materials (Austroads, 2004)

Material

Category

Unbound Granular

High Quality Crushed

Rock

Base Quality Gravel Subbase Gravel

Property

E in MPa

Over

Granular

Material

Over Stiff

Cemented

Material

Over

Granular

Material

Over Stiff

Cemented

Material

Over

Granular

Material

Over Stiff

Cemented

Material

Range E

v

150-700 200-700 150-500 200-500 150-400 150-450

Typical E

v

500 500 400 400 300 300

Degree of

Anisotropy

2 2 2 2 2 2

Range of u

u

v

= u

H

0.25-0.4 0.25-0.4 0.25-0.4 0.25-0.4 0.25-0.4 0.25-0.4

Typical u 0.35 0.35 0.35 0.35 0.35 0.35

Project Reliability and Reliability

Factor (RF)

Road classes Project reliability (%)

Freeway 95-97.5

Highway: lane AADT >2000 95-97.5

Highway: lane AADT s2000 85-95

Main Road: lane AADT >500 85-95

Other Roads: lane AADT s500 80-90

Desired

project

reliability

Reliability Factor (RF)

Asphalt Cemented

materials

80% 4.7 2.5

85% 3.3 2.0

90% 2.0 1.5

95% 1.0 1.0

97.5% 0.5 0.67

Summary of pavment design strategy

Construction &

Maintenance

Influences

Environment

Subgrade

Evaluation

Traffic

Select Trial

Pavement

Accept?

& Collect Feedback

Comparsion of

Yes

Criteria

Performance

Implement Design

Designs

Materials

Pavement

Analysis

Pavement

No

References

1. Austroads Pavement Design Guide (2004)

2. Brown, S.F. (1996). Soil mechanics in pavement engineering, Geotechnique

46, No. 3, pp. 383-426.

3. Lay, M.G. 1998). Handbook of road technology, Volume 1, Third Edition,

Transportation Studies volume 8, Gorden and Beach Science Publishers

4. Shell (1978). Pavement Design Manual.

END

Potrebbero piacerti anche

- Lesson 2-1 Structural Responses in Flexible PavementsDocumento32 pagineLesson 2-1 Structural Responses in Flexible PavementsTiffany NeubigNessuna valutazione finora

- Asphalt Concrete Ingredient, Design, Production and LayingDocumento17 pagineAsphalt Concrete Ingredient, Design, Production and LayingKali Bahadur ShahiNessuna valutazione finora

- CEB 705 - Week 11 - Lecture 1 - Road Construction MethodsDocumento37 pagineCEB 705 - Week 11 - Lecture 1 - Road Construction MethodsCharles Taloboe100% (1)

- Composite Pavements-A Technical and Economic Analysis During The Pavement Type Selection ProcessDocumento162 pagineComposite Pavements-A Technical and Economic Analysis During The Pavement Type Selection ProcessAjir Still HereNessuna valutazione finora

- ASD Specification (Volumn 1 Corrigendum)Documento0 pagineASD Specification (Volumn 1 Corrigendum)Agnon FungNessuna valutazione finora

- Flexible Pavement DesignDocumento33 pagineFlexible Pavement DesignLalith Koushik GanganapalliNessuna valutazione finora

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Da EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Nessuna valutazione finora

- 04 - Traffic Characteristics - Relationship Speed Volume DensityDocumento25 pagine04 - Traffic Characteristics - Relationship Speed Volume DensityQueen BrilliantNessuna valutazione finora

- A Guide To Good Quality Control Practices OnAsphalt Production and ConstructionDocumento59 pagineA Guide To Good Quality Control Practices OnAsphalt Production and ConstructionAmirrudin Johari100% (1)

- Road Note 8 (Sub Soil Drainage)Documento25 pagineRoad Note 8 (Sub Soil Drainage)Someshwar Rao ThakkallapallyNessuna valutazione finora

- Comparative Study of Flexible and Rigid Pavements For Different Soil and Traffic ConditionsDocumento10 pagineComparative Study of Flexible and Rigid Pavements For Different Soil and Traffic ConditionsMano DragonNessuna valutazione finora

- Compaction and Water Content Ratio of Compacted Soil Using Hilf Rapid MethodDocumento7 pagineCompaction and Water Content Ratio of Compacted Soil Using Hilf Rapid MethodErdrick PérezNessuna valutazione finora

- Malaysia Road Safety Situation - Ir Nordin (KKR) PDFDocumento24 pagineMalaysia Road Safety Situation - Ir Nordin (KKR) PDFAk Kun Full100% (1)

- SDRC TR1Documento44 pagineSDRC TR1syafiqfat100% (1)

- Design of Flexible Pavement Using British Road NoteDocumento17 pagineDesign of Flexible Pavement Using British Road NoteObinna ObiefuleNessuna valutazione finora

- Thickness Design On Flexible Pavement - AASHTO 1993 MethodDocumento35 pagineThickness Design On Flexible Pavement - AASHTO 1993 MethodBenedictus YosiaNessuna valutazione finora

- Highway Engineering: ReferencesDocumento6 pagineHighway Engineering: ReferencesZain GxNessuna valutazione finora

- D4254 - Maximum Index Density and Unit Weight of Soils and Calculation of Relative DensityDocumento8 pagineD4254 - Maximum Index Density and Unit Weight of Soils and Calculation of Relative DensityJhon Hilario AquinoNessuna valutazione finora

- School of Civil Engineering: A Project Report On Traffic Volume CountDocumento20 pagineSchool of Civil Engineering: A Project Report On Traffic Volume Countsai vandan100% (1)

- Handout 3 Earthwork OperationsDocumento25 pagineHandout 3 Earthwork OperationsthuraiyaNessuna valutazione finora

- Plate Bearing Load TestDocumento1 paginaPlate Bearing Load TestTk Kendrick Lau100% (1)

- Flexible Pavement DistressesDocumento4 pagineFlexible Pavement DistressesSivakumar M100% (1)

- To Transportation Engineering: Prof. Dr. Padma Bahadur ShahiDocumento58 pagineTo Transportation Engineering: Prof. Dr. Padma Bahadur ShahiPadma ShahiNessuna valutazione finora

- Geogrids in Walls and SlopesDocumento6 pagineGeogrids in Walls and SlopesYong Cheng Hung100% (1)

- Exercise: Lucy Consulting EngineersDocumento8 pagineExercise: Lucy Consulting EngineersAXMEDNessuna valutazione finora

- TERRAZYMEDocumento36 pagineTERRAZYMEJean MbuNessuna valutazione finora

- Pavement Design AASHTO SOAL QUEZ 05 DES 2016 Hal 7 14 08 12 2016 Conto 4 6 Hal 186 RevisiiiDocumento4 paginePavement Design AASHTO SOAL QUEZ 05 DES 2016 Hal 7 14 08 12 2016 Conto 4 6 Hal 186 RevisiiiHanafiahHamzahNessuna valutazione finora

- Comparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionDocumento5 pagineComparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionIAEME PublicationNessuna valutazione finora

- Design of Flexible PavementDocumento43 pagineDesign of Flexible Pavementtarakeswara rao kantubhukta100% (1)

- CBR MDD Index Correlation Study-Addis Ababa University - 2013Documento172 pagineCBR MDD Index Correlation Study-Addis Ababa University - 2013nimm1962Nessuna valutazione finora

- Chapter 6-Structural Design of PavementsDocumento36 pagineChapter 6-Structural Design of Pavementsabebe nanoNessuna valutazione finora

- Design Thickness For Flexible PavementDocumento6 pagineDesign Thickness For Flexible PavementMarc MathieuNessuna valutazione finora

- 002 - Preliminary SectionsDocumento17 pagine002 - Preliminary SectionssamNessuna valutazione finora

- Green BuildingDocumento23 pagineGreen BuildingSatyabrata MishraNessuna valutazione finora

- Falling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsDocumento18 pagineFalling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsEdisson Eduardo Valencia Gomez100% (1)

- OCW Marshall Mix Design MethodDocumento25 pagineOCW Marshall Mix Design MethodPacifique NicholasNessuna valutazione finora

- Standard Penetration TestDocumento6 pagineStandard Penetration TestDanica Alejo100% (1)

- To Design The Flexible Pavement Using Group Index Method: Experiment 1Documento13 pagineTo Design The Flexible Pavement Using Group Index Method: Experiment 1Muhammad Nouman KhanNessuna valutazione finora

- Shallow Foundation: Terzaghi's Ultimate Bearing CapacityDocumento20 pagineShallow Foundation: Terzaghi's Ultimate Bearing CapacityKevin Clinton CamamaNessuna valutazione finora

- Bituminous Material and Pavement DesignDocumento35 pagineBituminous Material and Pavement Designmannie edetNessuna valutazione finora

- Miro's Solutions For Road SafetyDocumento2 pagineMiro's Solutions For Road Safetyazcomp100% (1)

- Horizontal AlignmentDocumento84 pagineHorizontal AlignmentDennis Kurniawan100% (1)

- Geosynthetic in OverlaysDocumento8 pagineGeosynthetic in OverlaysSivakumar MNessuna valutazione finora

- Reconnaissance Survey Methods For Highway Route SelectionDocumento5 pagineReconnaissance Survey Methods For Highway Route SelectionOladunni Afolabi100% (1)

- Flexible Pavement ConstructionDocumento18 pagineFlexible Pavement ConstructionThopuri Maruthi Chowdary100% (1)

- Typical Unit Weights and Densities of SoilDocumento7 pagineTypical Unit Weights and Densities of SoilkayshephNessuna valutazione finora

- A Laboratory Investigation Into Effect of Water Content On The CBR of A Subgrade SoilDocumento8 pagineA Laboratory Investigation Into Effect of Water Content On The CBR of A Subgrade SoilAlberto AmparánNessuna valutazione finora

- Types of PavementsDocumento17 pagineTypes of PavementsPereira KastroNessuna valutazione finora

- High-Type Bituminous Pavements: Dr. Taleb M. Al-RousanDocumento67 pagineHigh-Type Bituminous Pavements: Dr. Taleb M. Al-RousanSaurav BhattacharjeeNessuna valutazione finora

- DEsign, Cons and Maintenance RP) PDFDocumento215 pagineDEsign, Cons and Maintenance RP) PDFShiba Shankar Satapathy100% (1)

- Pavement Design Kiran BiradarDocumento18 paginePavement Design Kiran BiradarSudipto PaulNessuna valutazione finora

- (10 Marks) : Faculty of EngineeringDocumento4 pagine(10 Marks) : Faculty of EngineeringChamin SubhawickramaNessuna valutazione finora

- Determination of Flakiness and Elongation Index For The Given Aggregate Sample.Documento4 pagineDetermination of Flakiness and Elongation Index For The Given Aggregate Sample.Huma AliNessuna valutazione finora

- Flexible PavementsDocumento13 pagineFlexible PavementsAhmad NajiNessuna valutazione finora

- Rebound Hammer Test - MOSDocumento6 pagineRebound Hammer Test - MOSFaizah Sophi100% (1)

- Lecture 3 (CE-860)Documento33 pagineLecture 3 (CE-860)MUHAMMAD AHMAD JAMILNessuna valutazione finora

- Comparative Evaluation of The Performance of DiffeDocumento8 pagineComparative Evaluation of The Performance of Diffepranayayare74Nessuna valutazione finora

- AASHTO93 Flexible 2018Documento61 pagineAASHTO93 Flexible 2018sultonNessuna valutazione finora

- Chapter Seven Structural Design of PavementDocumento61 pagineChapter Seven Structural Design of PavementRobeam SolomonNessuna valutazione finora

- Numerical Investigation On The Performance of Stone Columns Under Raft Foundation in Soft Clayey SoilsDocumento9 pagineNumerical Investigation On The Performance of Stone Columns Under Raft Foundation in Soft Clayey Soilstekla gom-lua groupNessuna valutazione finora

- Course Details - Master of Infrastructure Engineering and Management (Online Study)Documento7 pagineCourse Details - Master of Infrastructure Engineering and Management (Online Study)April IngramNessuna valutazione finora

- About Civil Engg. DeptDocumento17 pagineAbout Civil Engg. DeptMitaNessuna valutazione finora

- Calculus Self Taught Well Summarized Lecture Notes With Relevant Examples For BetterDocumento31 pagineCalculus Self Taught Well Summarized Lecture Notes With Relevant Examples For BetterApril IngramNessuna valutazione finora

- MTech SMFE Rev12032019Documento78 pagineMTech SMFE Rev12032019Mr.Bhaskar WabhitkarNessuna valutazione finora

- Lecture 11Documento6 pagineLecture 11April IngramNessuna valutazione finora

- CE GATE 2021 Postal ChecklistDocumento3 pagineCE GATE 2021 Postal ChecklistApril IngramNessuna valutazione finora

- Opencut ExampleDocumento2 pagineOpencut ExampleApril IngramNessuna valutazione finora

- Check List 2019Documento1 paginaCheck List 2019April IngramNessuna valutazione finora

- Amity M.tech. - Structural EngineeringDocumento2 pagineAmity M.tech. - Structural EngineeringApril Ingram100% (1)

- 1904Documento24 pagine1904Palani KumarNessuna valutazione finora

- Btech Syll Civil r2013-14 PDFDocumento256 pagineBtech Syll Civil r2013-14 PDFdhiliban1989Nessuna valutazione finora

- BH ECN CurrentDocumento2 pagineBH ECN CurrentApril IngramNessuna valutazione finora

- Advanced Concrete Technology MSC (Eng) - PGDip - Advanced Concrete Technology MSC (Eng) - PGDip - School of Civil Engineering - University of LeedsDocumento2 pagineAdvanced Concrete Technology MSC (Eng) - PGDip - Advanced Concrete Technology MSC (Eng) - PGDip - School of Civil Engineering - University of LeedsApril IngramNessuna valutazione finora

- Indian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (Documento20 pagineIndian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (api-19754583100% (1)

- M.E.ft Construction Engg. Managment 2015Documento29 pagineM.E.ft Construction Engg. Managment 2015April IngramNessuna valutazione finora

- 189ufrep prelims-GS PDFDocumento45 pagine189ufrep prelims-GS PDFRavi SNessuna valutazione finora

- 1904Documento24 pagine1904Palani KumarNessuna valutazione finora

- Indian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (Documento20 pagineIndian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (api-19754583100% (1)

- Infrastructure 2011+Documento5 pagineInfrastructure 2011+April IngramNessuna valutazione finora

- School of Civil and Environmental Engineering: Project CVEN04Documento3 pagineSchool of Civil and Environmental Engineering: Project CVEN04April IngramNessuna valutazione finora

- Class Routine (19 & 21 Jan 2015) : AdviceDocumento1 paginaClass Routine (19 & 21 Jan 2015) : AdviceApril IngramNessuna valutazione finora

- 189ufrep prelims-GS PDFDocumento45 pagine189ufrep prelims-GS PDFRavi SNessuna valutazione finora

- Btech Are 2010Documento73 pagineBtech Are 2010April IngramNessuna valutazione finora

- Class Routine (22 & 23 Nov 2014) : AdviceDocumento1 paginaClass Routine (22 & 23 Nov 2014) : AdviceApril IngramNessuna valutazione finora

- Class Routine (13 & 14 Dec 2014) : All Classes Are Suspended Due To Semester ExamDocumento1 paginaClass Routine (13 & 14 Dec 2014) : All Classes Are Suspended Due To Semester ExamApril IngramNessuna valutazione finora

- Struc Constr IllustrationsDocumento1 paginaStruc Constr IllustrationsApril IngramNessuna valutazione finora

- Class Routine (17 & 18 Jan 2015) : AdviceDocumento1 paginaClass Routine (17 & 18 Jan 2015) : AdviceApril IngramNessuna valutazione finora

- Syllabuses CivE 14 15 4YDocumento19 pagineSyllabuses CivE 14 15 4YApril IngramNessuna valutazione finora

- Spying From Space - Constructing America's Satellite Command and Control Systems (PDFDrive)Documento230 pagineSpying From Space - Constructing America's Satellite Command and Control Systems (PDFDrive)MohammadNessuna valutazione finora

- PCBDocumento5 paginePCBarampandey100% (4)

- Mech Syllabus R-2017 - 1Documento110 pagineMech Syllabus R-2017 - 1goujjNessuna valutazione finora

- Q1 Practical Research 2 - Module 1bDocumento15 pagineQ1 Practical Research 2 - Module 1bRhea Mae MacabodbodNessuna valutazione finora

- Advanced Office Add-In DevelopmentDocumento40 pagineAdvanced Office Add-In DevelopmentReadoneNessuna valutazione finora

- Module 1 Inclusive Education Lecture 1 & Introduction - OnlineDocumento32 pagineModule 1 Inclusive Education Lecture 1 & Introduction - OnlineSharon ShenNessuna valutazione finora

- Propositional LogicDocumento41 paginePropositional LogicMuneeb Javaid100% (1)

- PUP 200 Quizzes 6Documento47 paginePUP 200 Quizzes 6Nam TranNessuna valutazione finora

- The Magical Number 5: Towards A Theory of Everything?Documento27 pagineThe Magical Number 5: Towards A Theory of Everything?cesarfrancaNessuna valutazione finora

- Generic StructureDocumento6 pagineGeneric StructureAndre AlvarezNessuna valutazione finora

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Documento27 pagineChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNessuna valutazione finora

- Chapter 01 Fundamental and Derived QuantitiesDocumento7 pagineChapter 01 Fundamental and Derived QuantitiesAlicia WilliamsNessuna valutazione finora

- An Introduction To EFTDocumento24 pagineAn Introduction To EFTkunjammuNessuna valutazione finora

- ENGLISH TOEFL Structure (3rd Exercise)Documento5 pagineENGLISH TOEFL Structure (3rd Exercise)susannnnnnNessuna valutazione finora

- Steam TableDocumento3 pagineSteam TableMUHAMAD SAUKINessuna valutazione finora

- Silenat Berhanu SimaDocumento6 pagineSilenat Berhanu SimaSilenat BerhanuNessuna valutazione finora

- Analytical Chemistry (CHM111) Laboratory ManualDocumento73 pagineAnalytical Chemistry (CHM111) Laboratory ManualKatrina BucudNessuna valutazione finora

- Fire Alarm SymbolsDocumento6 pagineFire Alarm Symbolscarlos vasquezNessuna valutazione finora

- Ultimate Electronics - Book - CircuitLabDocumento3 pagineUltimate Electronics - Book - CircuitLabEldon50% (2)

- Sem06 Gca InsoDocumento2 pagineSem06 Gca InsoBogdan PistolNessuna valutazione finora

- 20160323110112-Sae 1215Documento1 pagina20160323110112-Sae 1215awesome_600Nessuna valutazione finora

- St. Louis College of Bulanao: Title/Topic Technical English I Introduction To Police Report WritingDocumento41 pagineSt. Louis College of Bulanao: Title/Topic Technical English I Introduction To Police Report WritingNovelyn LumboyNessuna valutazione finora

- ASME Geometric Dimension Ing and Tolerance Professional CertificationDocumento20 pagineASME Geometric Dimension Ing and Tolerance Professional CertificationPaul Anthony Red60% (5)

- Ideal Vs Real OttoDocumento5 pagineIdeal Vs Real Ottoa7med SoulimanNessuna valutazione finora

- Engine Torque Settings and Spec's 3.0L V6 SCDocumento4 pagineEngine Torque Settings and Spec's 3.0L V6 SCMario MaravillaNessuna valutazione finora

- Assignment 4Documento2 pagineAssignment 4Komal SinghNessuna valutazione finora

- WideScreen Code For PS2 GamesDocumento78 pagineWideScreen Code For PS2 Gamesmarcus viniciusNessuna valutazione finora

- Basic Program Structure in C++: Study Guide For Module No. 2Documento9 pagineBasic Program Structure in C++: Study Guide For Module No. 2Ji YoungNessuna valutazione finora

- 6000 Most Common Korean Words - For All TOPIK Levels PDFDocumento232 pagine6000 Most Common Korean Words - For All TOPIK Levels PDFZac67% (3)

- Effect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaDocumento6 pagineEffect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaEditor IJTSRDNessuna valutazione finora