Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Metal Alloys

Caricato da

Abie RexoMenCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Metal Alloys

Caricato da

Abie RexoMenCopyright:

Formati disponibili

Metallurgical Engineering 211

(630.211)

Metal Alloys

(Ferrous Alloys)

A.Prof. Yinong Liu

School of Mechanical Engineering The University of Western Australia

ME204 Ferrous Alloys

Todays lecture: Fe-C System Classification of metal alloys

Ferrous alloys Fe-Fe3C phase diagram Austenite, Ferrite, Cementite, Pearlite Peritectic reaction: +L Eutectic reaction: L+Fe3C Eutectoid reaction: a+Fe3C Steels and Cast Irons

ME204 Ferrous Alloys

Most engineering metallic materials are alloys. Metals are alloyed to enhance their properties, such as strength, hardness or corrosion resistance, and to create new properties, such as shape memory effect and magnetic properties. Engineering alloys can be broadly divided into Ferrous Alloys and Nonferrous Alloys Metal Steel Cast irons Stainless steel Aluminium Copper Nickel Titanium Magnesium, Tin, Zinc, 13,000 20,000 3,200 1,100 56 Lead 2,000 2,000 2,500 12,300 35,000 26 40 8 13.5 2 Global demand tonnes, x1000 900,000 Price $/tonne 400 Market $ billion 360

ME204 Ferrous Alloys

Ferrous Alloys

Metal Alloys Ferrous Steels Carbon

Low-C Medium-C High-C Tool

Non-ferrous Cast irons

Low Alloy

High strength low alloy steels Bearing steels Rail steels (<5% alloying elements)

High Alloy

Stainless High-Mn Tool

Grey iron Nodular iron White iron Malleable iron Alloy cast irons

(Mo,V,W,Cr,Ni)

(>5% total alloying elements)

ME204 Ferrous Alloys

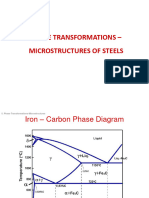

Fe-C system

Polymorphism of Fe: At 1394C: At 912 C: a Five basic solid phases: -phase: solid solution of C in bcc Fe at high T. Austenite (A, ): solid solution of C in fcc Fe. Maximum solubility of C in fcc Fe: 2.11wt% at 1148C. Ferrite (F, a): solid solution of C in bcc Fe. Maximum solubility of C in bcc Fe: 0.022wt% at 727C. Cementite (Fe3C): Fe-C intermetallic compound of complex structure; metastable. Graphite (G): pure C; stable.

ME204 Ferrous Alloys

Fe-C system

Three reactions: Peritectic reaction: +L Eutectic reaction: L+Fe3C Eutectoid reaction: a+Fe3C

The product of eutectoid transformation is a laminar structure of F and Fe3C, known as pearlite.

ME204 Ferrous Alloys

Ferrous

are alloys containing Fe as the main element. The most important ferrous alloy system is the Fe-C system. Alloys of this system can be further divided into steels and cast irons. Steels contain less C (generally <1.4wt%C) than do cast irons Steels (generally 2.4~4.3wt%C). As a result, all steels solidify into a single -Fe structure first and then experience the complex eutectoid reaction. Therefore, Cast irons heat treatment processes, which alter the eutectoid reaction, are vitally important for controlling microstructure and properties of steels. Cast irons, on the other hand, experience complex eutectic reaction during solidification, due to the formation of graphite or cementite. Consequently, solidification control is the most important single factor for properties of cast irons.

Alloys

ME204 Ferrous Alloys

Microstructure of Ferrous Alloys -Fe (Austenite):

solid solution of C in FCC iron, formed by solidification from liquid, large grains and straight grain boundaries, stable at high temperatures, high solubility for C, high ductility and formability

ME204 Ferrous Alloys

a-Fe (ferrite): A solid solution of C in BCC iron, formed from austenite

through solid phase transformation, small grains and irregular grain boundaries, stable at room temperature, very low solubility for carbon, ductile and soft, not so strong

ME204 Ferrous Alloys

10

Pearlite (P): A composite

structure of laminar ferrite and cementite, formed as a product of eutectoid transformation from Austenite, good combined strength and toughness, ideal for structural applications

Cementite plates (Fe3C)

Ferrite matrix

ME204 Ferrous Alloys

11

Hypoeutectoid steels:

Steel of <0.77%C. These account for low and medium carbon steels. Microstructure consists of pearlite and proeutectoid ferrite. The proportion of pearlite increases with increasing C% towards 0.77wt%. Higher portion of P makes the steel stronger but less ductile.

Pearlite (dark regions) Ferrite (white regions)

ME204 Ferrous Alloys

12

Hypereutectoid steels: Steels

of >0.77%C. These accounts for high-C steels. Microstructure consists of pearlite matrix and cementite network along grain boundaries; cementite network reduces toughness and ductility significantly. Proportion of cementite increases with increasing C content away from 0.77wt%.

Pearlite matrix Cementite

ME204 Ferrous Alloys

13

Todays lecture: Steels and their applications Low-C Steels Medium-C steels and HSLA steels High-C steels and tool steels Stainless steels Alloy designation of steels Steel products

ME204 Ferrous Alloys

(0.15% carbon steel)

14

Plain Carbon Steels

Low carbon steels (mild steels): 0.1-0.25%C proeutectoid F + small amount of P high formability, high ductility: ~30%EL relatively low strength: y= 250~400MPa excellent weldability cannot be strengthened by heat treatment usually strengthened by cold working typical applications: pipes, panels, sheets, wires, I-beams etc.

ME204 Ferrous Alloys

15

(0.4% carbon steel)

Medium-carbon steels (structural steels)

0.25-0.55%C

Good combination of strength and ductility Yield strength: 300~600MPa Tensile strength: 400~800MPa Elongation: ~25% Strengthenable by heat treatment Weldable; weldability deteriorates with increasing C% Used for load-bearing applications, crankshaft, bolts, gears, Heavy-duty machinery, mining equipment, cranes

ME204 Ferrous Alloys

16

High strength low alloy steels (HSLA) Medium carbon steels have desired mechanical properties for structural applications, but suffer from welding-induced embrittlement due to the formation of martensite. To overcome this problem, C content in these steels is reduced (<0.3%) and the loss of strength is compensated by increasing Mn content (>1%) and by microalloying with Nb, V, Ti, Cr and Cu. This leads to the development of HSLA steels. These steels are widely used for manufacturing large welded structures, such as Sydney harbor bridge, ocean liners and cargo ships, oil drilling rigs and platforms, large mining and earth moving equipment, and pressure vessels and storage tanks.

ME204 Ferrous Alloys

17

High carbon steels Spring steels: 0.6~0.8%C predominately eutectoid pearlite at room temperature often strengthened and hardened by heat treatment high strength and moderate toughness

Tool steels: 0.8~1.2%C proeutectoid cementite + pearlite very high hardness, low toughness, very difficult to machine used for chisels, hammers, knives, saw blades, drills, dies, punches, cutlery, chine tools and wear resistant applications High carbon steels have poor weldability and poor machinability

spring

Extrusion dies

Cutting blades

ME204 Ferrous Alloys

18

Alloy Designation

(carbon and low-alloy steels)

AISI: American Iron and Steel Institute SAE: Society of Automotive Engineers ASTM: American Society for Testing and Materials UNS: Uniform Numbering System AISI/SAE

carbon steels

UNS

1040 1xYY

low alloy steels

G10400 G1xYY0

G2xxx0

plain carbon steel containing 0.4wt%C modified carbon steel (S, P, Mn)

alloy steels

2xxx

ME204 Ferrous Alloys

19

Tool Steels High alloy tool steels are often alloyed with Mo, V, W, Cr and/or Ni. UNS: Txxxxx Normally specified by hardness and impact toughness.

ME204 Ferrous Alloys

20

Stainless Steels Three basic classes, specified by microstructure: Ferritics: Fe-Cr alloys (12~25%Cr), can be cheap Martensitics: Fe-Cr alloys, low Cr, hard, cutting tools Austenitics: Fe-Cr-Ni alloys (18Cr-8Ni), corrosion resistance Precipitation hardened, high strength and hardness Duplex (18Cr-5Ni) Alloys designation type AISI 2xx 3xx 4xx UNS S2xx00 S3xx00 S4xx00

304, 316, 316L (austenitics) 410 (martensitic), 446 (ferritic)

ME204 Ferrous Alloys

21

Stainless Steels - Typical Mechanical Properties Yield strength: 200MPa ~ 1600MPa Tensile strength: 300 MPa ~ 1800 MPa Ductility: EL% 40 ~ 2 Youngs modulus: ~ 170 GPa

ME204 Ferrous Alloys

22

Steel Products Nearly all carbon and alloy steels can be produced either as cast products or wrought products. Castings: Casting is used to produce near-finish components. Wrought products are produced more as semi-processed raw materials for further fabrication into components. Wrought products are usually produced by any or combination of rolling, extrusion, drawing and forging. Common forms available are bars, tubes, sheets, coils, wires, I-beams, angles. Most structural and mild steels, stainless steels are found in these forms. Tool steels: usually produced by casting and forging and are available as bars, rods and forged shapes.

ME204 Ferrous Alloys

23

Todays lecture: Cast irons Grey irons Nodular irons White irons Malleable irons Alloy cast irons Alloy designation for cast irons

ME204 Ferrous Alloys

24

Cast Irons - Microstructures

From a microstructural view point, cast irons can regarded as steels embedded with a carbonrich phase, which can be either graphite or cementite (Fe3C). Graphite offers no strength nor toughness and acts like voids in the iron; cementite is very hard and brittle.

Grey iron: graphite flakes embedded in ferrite matrix, cutting the continuity of the matrix and rendering the metal high brittleness. Nodular iron: graphite nodules in ferrite matrix, significantly improving toughness and ductility of the metal

White iron: cementite plates embedded in pearlite matrix, renders the metal high hardness and brittleness. Malleable iron: graphite clusters converted by decomposing cementite in white iron, significantly improving toughness and ductility

ME204 Ferrous Alloys

25

Grey Irons SAE G1800 G2500 G3000 G6000 UNS F10004 F10005 F10006 F10012 Tensile Strength 18 (ksi) (140MPa) yield ductility -

60 (ksi) (400MPa)

Cheap to produce, excellent castability, high damping capacity, good metal-metal wear resistance when lubricated, strength much higher in compression than in tension, brittle in tension.

ME204 Ferrous Alloys

26

Grey Irons - Application Grey irons are by far the most produced among all cast irons. Grey irons are used primarily for their low cost and excellent castability. Typical applications include:

engine cylinders, pistons, gear box casing, transmission casing, machine tool bases, balance weight of large cranes, large diameter underground pipework.

They are used always under compressive loading conditions. They are unsuitable for taking tensile loads or bending loads.

Stress

Mild steel Grey iron

Strain Tensile stress-strain behaviour of grey cast iron

ME204 Ferrous Alloys

27

Typical grey iron components

ME204 Ferrous Alloys

28

Nodular Irons (ductile irons) ASTM 60-40-18 120-90-02 UNS F32800 F36200 Tensile 60 (ksi) 120 Yield 40 90 Ductility 18 2

Produced by inoculating (addition of RE or Mg to molten metal just before casting) grey iron. This treatment converts graphite flakes into granules. These irons are much stronger and tougher than grey irons. They are produced and used for high specification applications. They are more expensive than grey irons. Typical applications include: gears, crankshafts, pump bodies, pressure valves, rollers.

ME204 Ferrous Alloys

29

Typical nodular iron components

ME204 Ferrous Alloys

30

Malleable Irons ASTM 32510 35018 UNS F32510 F36200 Yield strength 32.5 (ksi) 35 Ductility 10 18

Produced by heat treating white iron at elevated temperatures for long times. Such treatment decomposes cementite into ferrite and graphite. Consequently, these cast irons are stronger, tougher and much more ductile than grey irons, compatible to nodular irons. They have certain capacity to take shock loading, bending and tension. They are suitable for castings of thin thickness. They are expensive to produce, largely due to the heat treatment. Typical applications include gear box casing, transmission casing, differential casing.

ME204 Ferrous Alloys

31

White Irons White irons contain relatively less C and Si. As a result cementite (Fe3C) is formed instead of graphite. This makes the alloy very hard and brittle, practically useless as structural materials. The high hardness, however, renders them high resistance to abrasive wear. White irons are produced mainly for two purposes: Intermediate product for producing malleable irons As abrasive wear resistant components, such as ball mill lining tiles, slurry pipe elbows, slurry pump bodies

Potrebbero piacerti anche

- Classification of Materials NotesDocumento9 pagineClassification of Materials NotesJohn K KikwaiNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Ch13 Materials ApplicationsDocumento63 pagineCh13 Materials ApplicationsThefairman UnkownNessuna valutazione finora

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Da EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Valutazione: 5 su 5 stelle5/5 (1)

- METAL AND ITS ALLOYS - Steel1451580149Documento30 pagineMETAL AND ITS ALLOYS - Steel1451580149OnEd NepalNessuna valutazione finora

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Da EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Nessuna valutazione finora

- Brazing Filler Metal Selector Chart: NicrobrazDocumento2 pagineBrazing Filler Metal Selector Chart: NicrobrazathulpcucekNessuna valutazione finora

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965Da EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNessuna valutazione finora

- AISI SteelsDocumento5 pagineAISI Steelsanirudh_indana100% (1)

- The Iron Puddler My life in the rolling mills and what came of itDa EverandThe Iron Puddler My life in the rolling mills and what came of itNessuna valutazione finora

- Evaluation of Aluminum-Lithium Alloys 8090 and Weldalite-049Documento39 pagineEvaluation of Aluminum-Lithium Alloys 8090 and Weldalite-049skylancer-3441Nessuna valutazione finora

- Limit and Fit - ISO Hole Chart - ToleranceDocumento2 pagineLimit and Fit - ISO Hole Chart - Toleranceagniva datta100% (2)

- NS-1-70. Hardness TestingDocumento2 pagineNS-1-70. Hardness TestingWHWENNessuna valutazione finora

- Adore Electrode BookletDocumento207 pagineAdore Electrode BookletKrisna SinghNessuna valutazione finora

- TTT DiagramDocumento31 pagineTTT DiagramEducated SmugglerNessuna valutazione finora

- Inconel 718 Alloy 718 Uns n07718 Din 2.4668Documento3 pagineInconel 718 Alloy 718 Uns n07718 Din 2.4668SamkitNessuna valutazione finora

- AnodizingDocumento9 pagineAnodizingalphadingNessuna valutazione finora

- Study of Wear Characteristics of Hardfaced Layers Made by E430 and E410 Electrodes Using SMAW ProcessDocumento8 pagineStudy of Wear Characteristics of Hardfaced Layers Made by E430 and E410 Electrodes Using SMAW ProcessIJRASETPublicationsNessuna valutazione finora

- Lista Spec Mss SPDocumento4 pagineLista Spec Mss SPginursamadNessuna valutazione finora

- SEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding RodDocumento2 pagineSEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding Rodsoft4gsmNessuna valutazione finora

- Failure Analysis of Friction Weld (FRW) in Truck Axle ApplicationDocumento4 pagineFailure Analysis of Friction Weld (FRW) in Truck Axle ApplicationVivekintenseCmNessuna valutazione finora

- Technical Service Manual: Model Number ChartDocumento19 pagineTechnical Service Manual: Model Number ChartIván NavarroNessuna valutazione finora

- Forgingforging ProcessDocumento13 pagineForgingforging Processpatel ketanNessuna valutazione finora

- Bossard Taptite Self Tapping Screw CatalogueDocumento10 pagineBossard Taptite Self Tapping Screw CataloguepmlmkpNessuna valutazione finora

- Welding AISI 4130 PDFDocumento5 pagineWelding AISI 4130 PDFDarioNessuna valutazione finora

- Stress Relieving Heat Treatments For Austenitic Stainless SteelsDocumento1 paginaStress Relieving Heat Treatments For Austenitic Stainless SteelsVijay BedakihaleNessuna valutazione finora

- WCC Colmonoy 200 Series - TDSDocumento3 pagineWCC Colmonoy 200 Series - TDSedipson100% (2)

- Segregation and Banding in SteelDocumento2 pagineSegregation and Banding in SteelskluxNessuna valutazione finora

- Annealing of Wire TechDocumento4 pagineAnnealing of Wire TechJayabharath KrishnanNessuna valutazione finora

- Plasma Nitriding of Stainless Steels at Low TemperaturesDocumento7 paginePlasma Nitriding of Stainless Steels at Low TemperaturesmwasicNessuna valutazione finora

- Welding of Tool SteelDocumento15 pagineWelding of Tool SteelRonaldo JuniorNessuna valutazione finora

- Advances in Wear Resistant Alloys and ApplicationsDocumento56 pagineAdvances in Wear Resistant Alloys and ApplicationsMilanWaNessuna valutazione finora

- AISI 12L14 Steel Analysis and PropertiesDocumento2 pagineAISI 12L14 Steel Analysis and PropertiessyuepiNessuna valutazione finora

- Wear Analysis of Hard Faced Agricultural Equipment - Doc FFDocumento15 pagineWear Analysis of Hard Faced Agricultural Equipment - Doc FFSunil BasavarajuNessuna valutazione finora

- Martensite and The Control of Retained AusteniteDocumento6 pagineMartensite and The Control of Retained AusteniteMarcoTulioFonsecaNessuna valutazione finora

- Tankguard Storage: Technical Data SheetDocumento5 pagineTankguard Storage: Technical Data SheetEngTamerNessuna valutazione finora

- PCD Wire Edm Technology PDFDocumento6 paginePCD Wire Edm Technology PDFyorf1989Nessuna valutazione finora

- Sensitivity and Reliability of Commercial Drill-String Inspection ServicesDocumento8 pagineSensitivity and Reliability of Commercial Drill-String Inspection ServicesFélix Gallo CruzNessuna valutazione finora

- Threads - NPTF Taper Thread GagingDocumento5 pagineThreads - NPTF Taper Thread GagingTrushantNessuna valutazione finora

- Gray IronDocumento9 pagineGray Ironiamraghu2309Nessuna valutazione finora

- ERIKS20 20Oring20Technical20ManualDocumento219 pagineERIKS20 20Oring20Technical20ManualEfrain SaldañaNessuna valutazione finora

- Great Minds of Carbon Equivalent - 1 PDFDocumento3 pagineGreat Minds of Carbon Equivalent - 1 PDFSiva SubramaniNessuna valutazione finora

- Ni-Resist Alloy Properties and Applications GuideDocumento40 pagineNi-Resist Alloy Properties and Applications GuidePrasad Aher100% (1)

- Metco105TechnicalBulletin PDFDocumento8 pagineMetco105TechnicalBulletin PDF張政雄100% (1)

- Pipe Brochure (Spiral Welded Pipe)Documento20 paginePipe Brochure (Spiral Welded Pipe)AmalsyahNessuna valutazione finora

- API 5CT P110 7Documento2 pagineAPI 5CT P110 7rageshmv100% (1)

- Casting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesDocumento11 pagineCasting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesIOSRjournalNessuna valutazione finora

- 10 37 00 1110 NS 1 A4 WatermarkedDocumento7 pagine10 37 00 1110 NS 1 A4 Watermarkedislam atif100% (1)

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Documento2 pagine55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNessuna valutazione finora

- Data Sheet AluminaDocumento10 pagineData Sheet AluminaXin EnNessuna valutazione finora

- ASME ASTM Difference PDFDocumento5 pagineASME ASTM Difference PDFSiddharth PawarNessuna valutazione finora

- AbrasivesDocumento49 pagineAbrasivesfockewulNessuna valutazione finora

- Alloys DensityDocumento4 pagineAlloys DensityArnold Melissa CollettNessuna valutazione finora

- Durehete 950Documento5 pagineDurehete 950ellisforheroes100% (1)

- Steel Data ChartDocumento2 pagineSteel Data Chartsmartcad60Nessuna valutazione finora

- KL UHP Catalog 2011-02 PDFDocumento30 pagineKL UHP Catalog 2011-02 PDFaconibet9040Nessuna valutazione finora

- Understanding DecarburizationDocumento6 pagineUnderstanding Decarburizationoquintero990% (1)

- Atmospheric Corrosion of Copper and The Colour Structure and Composition of Natural Patinas On Copper 2006 Corrosion ScienceDocumento30 pagineAtmospheric Corrosion of Copper and The Colour Structure and Composition of Natural Patinas On Copper 2006 Corrosion ScienceEmanuela Leite FragosoNessuna valutazione finora

- Chapter 1. Materials For EngineeringDocumento30 pagineChapter 1. Materials For EngineeringAbie RexoMenNessuna valutazione finora

- Lecture 1Documento39 pagineLecture 1Abie RexoMenNessuna valutazione finora

- Specific Surface AreaDocumento3 pagineSpecific Surface AreaantoniojaviermaciasNessuna valutazione finora

- Introduction To Welding: Welding Principles and ApplicationsDocumento14 pagineIntroduction To Welding: Welding Principles and ApplicationsAbie RexoMenNessuna valutazione finora

- Corrosive Damage in Metals and Its PreventionDocumento36 pagineCorrosive Damage in Metals and Its Preventionsamurai7_7783% (6)

- Chapter 2 Arc WeldingDocumento39 pagineChapter 2 Arc WeldingAbie RexoMenNessuna valutazione finora

- YoderDocumento13 pagineYoderAbie RexoMen0% (1)

- Fusion Welding Process, Chapter 27Documento24 pagineFusion Welding Process, Chapter 27Abie RexoMen100% (1)

- Automated Welding TechnologiesDocumento26 pagineAutomated Welding TechnologiesAbie RexoMenNessuna valutazione finora

- Joining MetalsDocumento22 pagineJoining MetalsAbie RexoMenNessuna valutazione finora

- Brazing and Oxy-Fuel Cutting Processes ExplainedDocumento18 pagineBrazing and Oxy-Fuel Cutting Processes ExplainedAbie RexoMenNessuna valutazione finora

- Saddle AnalysisDocumento17 pagineSaddle AnalysisAntonio Perez ZornozaNessuna valutazione finora

- Fesi TranstitionDocumento5 pagineFesi TranstitionAbie RexoMenNessuna valutazione finora

- Galvanizing For Corrosion Protection (AGA)Documento18 pagineGalvanizing For Corrosion Protection (AGA)Abrianto AkuanNessuna valutazione finora

- Corrosion and Environmental Degradation of MaterialDocumento9 pagineCorrosion and Environmental Degradation of MaterialAbie RexoMenNessuna valutazione finora

- SRB Test InstructionsDocumento1 paginaSRB Test InstructionsAbie RexoMenNessuna valutazione finora

- Soil PH Testing ProceduresDocumento6 pagineSoil PH Testing ProceduresAbie RexoMenNessuna valutazione finora

- Condenser Tube Fouling and FailureDocumento11 pagineCondenser Tube Fouling and FailureAbie RexoMenNessuna valutazione finora

- Liquid Coatings For Girthwelds and Joints Proven Corrosion Protection Protection For PipelinesDocumento15 pagineLiquid Coatings For Girthwelds and Joints Proven Corrosion Protection Protection For PipelinesAbie RexoMenNessuna valutazione finora

- Vacuum Requirements For Steel DegassingDocumento6 pagineVacuum Requirements For Steel DegassingAbie RexoMenNessuna valutazione finora

- Storage Tank DetailDocumento22 pagineStorage Tank DetailRamu NallathambiNessuna valutazione finora

- All DataDocumento121 pagineAll DataShashank SaxenaNessuna valutazione finora

- 2-BMCG2312 Manufaturing MaterialsDocumento80 pagine2-BMCG2312 Manufaturing MaterialsMuhd IzzNessuna valutazione finora

- METAL FORMING AND HEAT TREATING GUIDEDocumento10 pagineMETAL FORMING AND HEAT TREATING GUIDEGibran JuniansyahNessuna valutazione finora

- ASTM A192 Boiler Tubes SpecificationDocumento3 pagineASTM A192 Boiler Tubes SpecificationSon-Tuan PhamNessuna valutazione finora

- Sliprings and Carbon Brushes For Turbo AlternatorsDocumento24 pagineSliprings and Carbon Brushes For Turbo Alternatorsfaisal100% (1)

- Improved Metallographic Etching Techniques For Stainless Steel and For Stainless Steel To Carbon Steel WeldmentsDocumento17 pagineImproved Metallographic Etching Techniques For Stainless Steel and For Stainless Steel To Carbon Steel WeldmentsSaiful ShokriNessuna valutazione finora

- Unit 4 MSE Heat Treatment of MetalsDocumento85 pagineUnit 4 MSE Heat Treatment of MetalsRushikesh KaleNessuna valutazione finora

- Choose WPSDocumento175 pagineChoose WPSmohamedNessuna valutazione finora

- AISI Designation: Stainless Tool Steels Killed Carbon SteelsDocumento14 pagineAISI Designation: Stainless Tool Steels Killed Carbon SteelsShankar JhaNessuna valutazione finora

- Flame HardeningDocumento2 pagineFlame Hardenings_manikandanNessuna valutazione finora

- Glossary of Metalworking TermsDocumento73 pagineGlossary of Metalworking Termsowox91Nessuna valutazione finora

- ASTM A575-96 Steel Bar, Carbon, Merchant QDocumento2 pagineASTM A575-96 Steel Bar, Carbon, Merchant Qneno2405Nessuna valutazione finora

- Press Hardened Steels - AHSS GuidelinesDocumento28 paginePress Hardened Steels - AHSS GuidelinesRamon Traver TomasaNessuna valutazione finora

- CCT Phase Diagram AssignmentDocumento4 pagineCCT Phase Diagram AssignmentAyu Sekar TunjungNessuna valutazione finora

- PFI Standard ES-22 (Reaffirmed 1999) RECOMMENDED PRATICE FOR COLOR CODING OF PIPING MATERIALSDocumento4 paginePFI Standard ES-22 (Reaffirmed 1999) RECOMMENDED PRATICE FOR COLOR CODING OF PIPING MATERIALSManuel Antonio Santos Vargas100% (1)

- Information TehnDocumento90 pagineInformation TehnAbdullah AnsariNessuna valutazione finora

- Pop A Plug MaterialDocumento2 paginePop A Plug MaterialHijau Auliya Keramat Al-qadiryNessuna valutazione finora

- 05 - MetE 414-Phase Transformations-Microstructures of Steels-Fall 2023Documento70 pagine05 - MetE 414-Phase Transformations-Microstructures of Steels-Fall 2023egesenturk2000Nessuna valutazione finora

- LECTURE ON MATERIALS FOR UREA PLANTSDocumento19 pagineLECTURE ON MATERIALS FOR UREA PLANTSdeepankar kumarNessuna valutazione finora

- Juan Fariq Marcopolo - IVC 2021 Final AssignmentDocumento6 pagineJuan Fariq Marcopolo - IVC 2021 Final AssignmentJuan F MarcoNessuna valutazione finora

- Machine DesignDocumento128 pagineMachine Designshivani joshi100% (1)

- Heat Treatment Effects on Material PropertiesDocumento5 pagineHeat Treatment Effects on Material PropertiesArgha DasNessuna valutazione finora

- Heat Treatment Types for Improving Metal PropertiesDocumento29 pagineHeat Treatment Types for Improving Metal PropertiesPratheep AddrinNessuna valutazione finora

- Properties Value: Ug-23 Maximum Allowable Stress ValuesDocumento2 pagineProperties Value: Ug-23 Maximum Allowable Stress ValuesMohamad Faiz ZulkipliNessuna valutazione finora

- MetallurgyDocumento25 pagineMetallurgyPandu Damay PutraNessuna valutazione finora

- HARDFACING ALLOYS in Sugar IndustryDocumento28 pagineHARDFACING ALLOYS in Sugar IndustryfendynovapamelaNessuna valutazione finora

- Nitin 3Documento16 pagineNitin 3Gaurav SinghNessuna valutazione finora

- The Use of Heheat Straightening To Repair Damaged Steel StructuresDocumento38 pagineThe Use of Heheat Straightening To Repair Damaged Steel Structuresjeanpaul CAYTANNessuna valutazione finora