Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eccentric Shear Welded Connection Design

Caricato da

vladyflores529100%(1)Il 100% ha trovato utile questo documento (1 voto)

367 visualizzazioni7 pagine1) Eccentric shear welded connections are commonly used to support crane and mezzanine loads. These connections subject the weld to both shear and torsion forces.

2) The eccentric load is transferred to the centroid of the weld group, producing both a shear load (P) and a bending moment (M=P*e) where e is the eccentricity.

3) Stresses are evaluated at critical points on the weld from the shear load, bending moment, and polar moment of inertia. These stresses are combined vectorially to determine the required weld size.

Descrizione originale:

Titolo originale

4 2(Welded Connection)

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento1) Eccentric shear welded connections are commonly used to support crane and mezzanine loads. These connections subject the weld to both shear and torsion forces.

2) The eccentric load is transferred to the centroid of the weld group, producing both a shear load (P) and a bending moment (M=P*e) where e is the eccentricity.

3) Stresses are evaluated at critical points on the weld from the shear load, bending moment, and polar moment of inertia. These stresses are combined vectorially to determine the required weld size.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

367 visualizzazioni7 pagineEccentric Shear Welded Connection Design

Caricato da

vladyflores5291) Eccentric shear welded connections are commonly used to support crane and mezzanine loads. These connections subject the weld to both shear and torsion forces.

2) The eccentric load is transferred to the centroid of the weld group, producing both a shear load (P) and a bending moment (M=P*e) where e is the eccentricity.

3) Stresses are evaluated at critical points on the weld from the shear load, bending moment, and polar moment of inertia. These stresses are combined vectorially to determine the required weld size.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

W-29

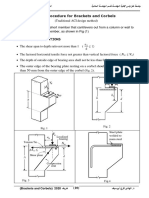

Eccentric shear welded connection are popular for column

brackets supporting gantry crane loadings or mezzanine floors. The

connection below produces (shear + torsion) on the weld. The LRFD

method for (shear + torsion) is both difficult and lengthy, A more

conservative elastic vector analysis method is allowed by AISC:

W-30

The eccentric load is

transferred to the centroid of the weld

group. The transferred load shall

consist of a load

plus a moment (M

z

= Pe), where:

e = eccentrity.

The actual weld thickness

resisting shear and torsion forces is

(0.707w), but for simplicity, we

consider effective throat

thickness = 1.0 inch.

From direct shear only (due to P):-

( )

y x

P P P

~ ~ ~

+ =

L

P

f

L

P

f

L

P

f

y

1y

x

1x

1

=

=

=

1 inch

P

y

P

x

P

M=Pe

W-31

J

d M

f

.

2

=

The transferred moment (M) causes additional shear stresses

depending on the critical locations of the weld (far edges of the weld).

where:

M = moment due to eccentricity = (P.e)

d = distance to far this weld point

J = Polar moment of inertia.

( )

yy xx

A A

A

A

I I

dA y dA x

dA y x

dA r J

+ =

+ =

+ =

=

} }

}

}

2 2

2 2

2

where:

This can be vector analyzed to:

J

Mx

f

J

My

f

2y

2x

=

=

W-32

Once these four stress components are evaluated for an

extreme point of the weld. They can be added vectorially:

2 2

2 1

2 1

) ( ) (

y x v

y y y

x x x

f f f

f f f

f f f

+ =

+ =

+ =

Then the strength of 1 inch wide weld is evaluated as:

) F (0.6 0.707

w required

EXX

|

v

f

>

F

v

= | 0.707 w x 1 x (0.6 F

EXX

)

W-33

Example W-6

Determine the size of the weld required

for the bracket shown. A-36 steel is

used, SMAW process?

Solution:

. in 915 195 720 I I J

in 195.0 (1.714) 8 1

12

1x(8)

2 86) (1x12)(2.2 I

in 720 288 288 144

8x(6) 8x(6)

12

x(12) 1

I

in. k 942.8 5.714) (10 x 60 . M

inch 2.286

8 8 12

4 x 8 x 2

x

4

yy xx

4 2

3

2

yy

4

2 2

3

xx

= + = + =

=

(

+ + =

= + + =

+ + =

= + = =

=

+ +

=

e P

W-34

Example (W-6) - Continued

ksi 2.143

28

60

12) 8 1x(8

60

f

forces). horizontal (no 0 f

1y

1x

= =

+ +

=

=

By inspection points (A $ B) are more critical than points (B & C);

Take point (A):

ksi 10.131

5.886) (2.143 (6.181)

) f (f ) (f f

ksi 5.886

915

5.714 942.8

J

x M

) (f

ksi 6.181

915

6 942.8

J

y M

) (f

2 2

2

A 2y 1y

2

A 2x v

A 2y

A 2x

=

+ + =

+ + =

=

=

=

=

W-35

EXX

v

req.

F 0.6 1 0.707

w

>

|

f

Select E70XX as given by matching table.

inch 0.455

70 0.6 1 0.707 0.75

10.131

w

req

=

=

Use inch weld size

inch) / (t inch

8

3

size weld minimum

inch /

16

1

16

9

size weld maximum Since

16

1.9

f

2

1

= =

= =

Example (W-6) - Continued

Potrebbero piacerti anche

- (QUIZ) NEMATODES (2nd Year BS Medical Technology)Documento2 pagine(QUIZ) NEMATODES (2nd Year BS Medical Technology)avery aerNessuna valutazione finora

- Manual: Installation, Operation & MaintenanceDocumento86 pagineManual: Installation, Operation & MaintenanceNhân NgọcNessuna valutazione finora

- Mechanical Columns Buckling FailureDocumento19 pagineMechanical Columns Buckling FailurePraful Patil100% (1)

- Wall Footing DesignDocumento102 pagineWall Footing DesignAUNGPSNessuna valutazione finora

- Aircraft MaintenanceDocumento207 pagineAircraft MaintenanceSenthil Kumar100% (1)

- Research Proposal On Antimicrobial and Antioxidant Properties of Kiwi FruitDocumento25 pagineResearch Proposal On Antimicrobial and Antioxidant Properties of Kiwi FruitCatherine100% (1)

- Sand Heap AnalogyDocumento23 pagineSand Heap AnalogyTatyGendadeReynosoNessuna valutazione finora

- Review of Related Literature of Jackfruit SeedDocumento4 pagineReview of Related Literature of Jackfruit SeedPrince Martin John Villamor80% (5)

- Design of Slender Reinforced Concrete ColumnsDocumento35 pagineDesign of Slender Reinforced Concrete ColumnsWindi AstutiNessuna valutazione finora

- Chapter 5 Flexural MembersDocumento40 pagineChapter 5 Flexural MembersAriel Dela CruzNessuna valutazione finora

- Module 5 Structural Steel Design 1Documento19 pagineModule 5 Structural Steel Design 1Rich Lenard L. MagbooNessuna valutazione finora

- Export Sap2000 To DWG - Sap2000 - CsiDocumento7 pagineExport Sap2000 To DWG - Sap2000 - Csivladyflores529Nessuna valutazione finora

- Surge Arrester Function and Working PrinciplesDocumento25 pagineSurge Arrester Function and Working PrinciplesMidhun Varghese100% (1)

- Approved Pre Stressed Concrete Formula Sheet 2Documento12 pagineApproved Pre Stressed Concrete Formula Sheet 2Adil ImtiazNessuna valutazione finora

- Design of Combined FootingsDocumento45 pagineDesign of Combined FootingsAnkit AgrawalNessuna valutazione finora

- MSCE 509-103 - Yield Line Analysis ExamplesDocumento18 pagineMSCE 509-103 - Yield Line Analysis ExamplesAmari Laurie100% (1)

- Design An Interior Rib of A Concrete Joist Floor System With TheDocumento4 pagineDesign An Interior Rib of A Concrete Joist Floor System With TheChea VannaiNessuna valutazione finora

- 343 400Documento58 pagine343 400MakaraSoyNessuna valutazione finora

- Single RC Staircase DesignDocumento4 pagineSingle RC Staircase Designezarul fitri100% (4)

- Prestressed Beam Analysis ExampleDocumento7 paginePrestressed Beam Analysis ExampleHaymanAHMEDNessuna valutazione finora

- How To Use PathlossDocumento32 pagineHow To Use Pathlosspathlossanwar100% (9)

- Cont Beam DesignDocumento76 pagineCont Beam Designsiti HawaNessuna valutazione finora

- Beam ExampleProblemsDocumento10 pagineBeam ExampleProblemsApril IngramNessuna valutazione finora

- Chapter 4 Flexural Design - (Part 5)Documento35 pagineChapter 4 Flexural Design - (Part 5)Raja AliNessuna valutazione finora

- TR 334 Tutorial-1Documento5 pagineTR 334 Tutorial-1Adaminovic MrishoNessuna valutazione finora

- Beam Bearing PlatesDocumento23 pagineBeam Bearing PlatesShah Jehan HanifNessuna valutazione finora

- Torsion Design of Prestressed ConcreteDocumento20 pagineTorsion Design of Prestressed ConcreteDr. M.V.Krishna RaoNessuna valutazione finora

- RC Practice Set 2 2016 SolutionsDocumento5 pagineRC Practice Set 2 2016 SolutionsSayed YusufNessuna valutazione finora

- Design of Plate GirderDocumento9 pagineDesign of Plate GirdermunnaiitrNessuna valutazione finora

- Method of Design - SLAB & BEAMDocumento19 pagineMethod of Design - SLAB & BEAMসামিউলইসলামNessuna valutazione finora

- Chapter One in Elastic Moment RedistributionDocumento8 pagineChapter One in Elastic Moment RedistributionHaftom GebreegziabiherNessuna valutazione finora

- Equations of Motion for Two-Story Shear BuildingDocumento27 pagineEquations of Motion for Two-Story Shear BuildingbourneremembersNessuna valutazione finora

- Slender-Concrete-Columns-Non-Sway-Frame-Moment-Magnification-ACI 318-19Documento21 pagineSlender-Concrete-Columns-Non-Sway-Frame-Moment-Magnification-ACI 318-19Thadarth NaNessuna valutazione finora

- Problem LossesDocumento5 pagineProblem LossesArvee GavinoNessuna valutazione finora

- Sagging: Compression Compres SionDocumento45 pagineSagging: Compression Compres SionramsundarNessuna valutazione finora

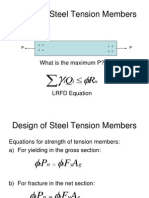

- Design and Analysis of Tension MemberDocumento29 pagineDesign and Analysis of Tension MemberJhianne Dulpina RoqueNessuna valutazione finora

- 02 - Design of Steel Tension MembersDocumento15 pagine02 - Design of Steel Tension MembersMayur PatelNessuna valutazione finora

- Lesson 9 Influence LinesDocumento16 pagineLesson 9 Influence LinesKlai Arriola100% (1)

- Deflection of BeamsDocumento28 pagineDeflection of BeamsishwaryaNessuna valutazione finora

- Design of Doubly Reinforced BeamDocumento7 pagineDesign of Doubly Reinforced BeamAmrutha SivaramanNessuna valutazione finora

- Design of Tension MembersDocumento10 pagineDesign of Tension MembersSandgrouse RajNessuna valutazione finora

- Designing Trapezoidal Footings for Unequal Column LoadsDocumento11 pagineDesigning Trapezoidal Footings for Unequal Column LoadsJosh EdilreyNessuna valutazione finora

- RCD Lesson 1b Flexural Analysis of Beams (Cracking Moment) PDFDocumento14 pagineRCD Lesson 1b Flexural Analysis of Beams (Cracking Moment) PDFEduard Joseph Dela CruzNessuna valutazione finora

- Chapter 3 Lateral Earth PressureDocumento47 pagineChapter 3 Lateral Earth PressureJiregna Tesfaye100% (2)

- RC Beam and Slab Design PrinciplesDocumento21 pagineRC Beam and Slab Design PrinciplesKrishna DhageNessuna valutazione finora

- Pre Stressed Concrete 18Cv641: Topic: Magnels MethodDocumento14 paginePre Stressed Concrete 18Cv641: Topic: Magnels MethodShobhaNessuna valutazione finora

- Soil Mechanics Formula p1 To p3Documento5 pagineSoil Mechanics Formula p1 To p3Arjie RecarialNessuna valutazione finora

- Shear Lag Factor Explained in 40 CharactersDocumento12 pagineShear Lag Factor Explained in 40 CharactersLarissa RiveraNessuna valutazione finora

- Design of Compression Members-3Documento62 pagineDesign of Compression Members-3eseem0% (1)

- Calculation of Long-Term Cracked Deflection and Deflection Due To Live LoadDocumento1 paginaCalculation of Long-Term Cracked Deflection and Deflection Due To Live LoadJohn STC0% (1)

- Moment Distribution Method: Presented by Fuad Bin NazrulDocumento20 pagineMoment Distribution Method: Presented by Fuad Bin NazrulMOZAHER UL KABIR MAHADINessuna valutazione finora

- DRB & Ar 331Documento314 pagineDRB & Ar 331Abdul Hamid BhattiNessuna valutazione finora

- Concrete Lectures Slab.2 Direct Design Method - PPT ExamplesDocumento58 pagineConcrete Lectures Slab.2 Direct Design Method - PPT ExamplesUmer WaheedNessuna valutazione finora

- Brackets and Corbels ACI 318 L # 1Documento7 pagineBrackets and Corbels ACI 318 L # 1soran azizNessuna valutazione finora

- RC 3Documento4 pagineRC 3Jade David FranciscoNessuna valutazione finora

- 5) Design of Beams Using WSDDocumento6 pagine5) Design of Beams Using WSDVanessa Rosal PalerNessuna valutazione finora

- Tall Buildings Chap 3 ADocumento7 pagineTall Buildings Chap 3 ATharangi MunaweeraNessuna valutazione finora

- Determinacy and IndeterminacyDocumento12 pagineDeterminacy and IndeterminacyMode NaseerNessuna valutazione finora

- Ultimate Strength Design (Doubly)Documento17 pagineUltimate Strength Design (Doubly)C.j. CaparasNessuna valutazione finora

- CM Qssss33Documento11 pagineCM Qssss33ayat hussienNessuna valutazione finora

- Lecture 3 - Influence LinesDocumento87 pagineLecture 3 - Influence LinesMary Dominique OnateNessuna valutazione finora

- Analysis and Design of One Way SlabsDocumento9 pagineAnalysis and Design of One Way Slabsسيف جمال مدين عبداللهNessuna valutazione finora

- Concurrent Force Systems LectureDocumento45 pagineConcurrent Force Systems LecturetolgaenesNessuna valutazione finora

- Calculation of column reinforcement area according to EN 1992Documento6 pagineCalculation of column reinforcement area according to EN 1992Florian EsnaultNessuna valutazione finora

- Torsion of Non Circular BeamsDocumento24 pagineTorsion of Non Circular BeamsXavier WallerNessuna valutazione finora

- Mechanics of Solids BestDocumento39 pagineMechanics of Solids Bestzahid_497Nessuna valutazione finora

- Twisting by Axial LoadsDocumento15 pagineTwisting by Axial LoadsVignesh KumarNessuna valutazione finora

- O-H. Kim, Y.C. Kim: 2. TheoryDocumento4 pagineO-H. Kim, Y.C. Kim: 2. Theoryjainrakeshj4987Nessuna valutazione finora

- Be First Year Engineering Semester 1 2019 December Engineering Mechanics Emrev 2019'c' SchemeDocumento43 pagineBe First Year Engineering Semester 1 2019 December Engineering Mechanics Emrev 2019'c' Schemesinghsitturaj78Nessuna valutazione finora

- Readme PCLDocumento5 pagineReadme PCLHutdi Nur CahyonoNessuna valutazione finora

- Texto TradDocumento20 pagineTexto Tradvladyflores529Nessuna valutazione finora

- Ce408 Chap.cDocumento21 pagineCe408 Chap.cmadafaca13100% (1)

- Chapter - (C) New 4 PagesDocumento4 pagineChapter - (C) New 4 Pagesmadafaca13100% (1)

- Story load case analysis and structural responseDocumento10 pagineStory load case analysis and structural responsevladyflores529Nessuna valutazione finora

- FlorDocumento1 paginaFlorvladyflores529Nessuna valutazione finora

- LLDF 1Documento20 pagineLLDF 1UnknownNessuna valutazione finora

- Batman DescriptionDocumento1 paginaBatman Descriptionvladyflores529Nessuna valutazione finora

- File1 MartinDocumento10 pagineFile1 Martinvladyflores529Nessuna valutazione finora

- FCC Declaration of ConformityDocumento1 paginaFCC Declaration of ConformityTiago GomesNessuna valutazione finora

- Beam Design LoadsDocumento2 pagineBeam Design LoadsZayyan RomjonNessuna valutazione finora

- StarCraft II Fansite LicenseDocumento1 paginaStarCraft II Fansite Licensevladyflores529Nessuna valutazione finora

- StarCraft II Fansite Kit - Concept Art, Avatars, Logos & MoreDocumento2 pagineStarCraft II Fansite Kit - Concept Art, Avatars, Logos & Morevladyflores529Nessuna valutazione finora

- The Pussycat Dolls - Perhaps Perhaps PerhapsDocumento1 paginaThe Pussycat Dolls - Perhaps Perhaps Perhapsvladyflores529Nessuna valutazione finora

- 0 AutoCAD Structural CompletoDocumento1 pagina0 AutoCAD Structural Completovladyflores529Nessuna valutazione finora

- Air Preparation Products: Parker Pneumatic Section EDocumento11 pagineAir Preparation Products: Parker Pneumatic Section EPartsGopher.comNessuna valutazione finora

- A Study On Financial Analysis of Tri Van Drum AirportDocumento81 pagineA Study On Financial Analysis of Tri Van Drum AirportN.MUTHUKUMARAN100% (1)

- 842e In001 - en PDocumento4 pagine842e In001 - en PNilson Eduardo TorresNessuna valutazione finora

- 2 13 Ionisation EnergiesDocumento6 pagine2 13 Ionisation EnergiesRobertLiu100% (2)

- G9_Q4_W2_MODDocumento4 pagineG9_Q4_W2_MODKkkkkNessuna valutazione finora

- trs5 Key Cho Cac BanDocumento35 paginetrs5 Key Cho Cac BanNguyệt NgôNessuna valutazione finora

- Chapte4 ZamznDocumento24 pagineChapte4 ZamznAHMED DARAJNessuna valutazione finora

- Mitsubishi: Technical Service BulletinDocumento11 pagineMitsubishi: Technical Service BulletinKonstantinNessuna valutazione finora

- Operation and Analysis of The Three Phase Fully Controlled Bridge ConverterDocumento24 pagineOperation and Analysis of The Three Phase Fully Controlled Bridge Convertermohammed aliNessuna valutazione finora

- Ashrae Handbook 2000 CHDocumento32 pagineAshrae Handbook 2000 CHKazuto NakazatoNessuna valutazione finora

- Workshop Practices Lab Course DescriptorDocumento8 pagineWorkshop Practices Lab Course DescriptorWossenu MekonnenNessuna valutazione finora

- Specification SG 15CDocumento3 pagineSpecification SG 15CJohan AlvarezNessuna valutazione finora

- Report of Mechanics of Machines 1Documento12 pagineReport of Mechanics of Machines 1muhammaduzairNessuna valutazione finora

- UntreatedDocumento29 pagineUntreatedhahahaNessuna valutazione finora

- Columbus United Methodist Church: in This IssueDocumento11 pagineColumbus United Methodist Church: in This IssueColumbusUMCNessuna valutazione finora

- Gross Examination LabmedDocumento2 pagineGross Examination Labmediishayati100% (1)

- PDF If I Break 15 Portia Moore CompressDocumento61 paginePDF If I Break 15 Portia Moore CompressAlbenis RodríguezNessuna valutazione finora

- Experiment No.8Documento5 pagineExperiment No.8Osama RashaydaNessuna valutazione finora

- Jacques-Émile Blanche - Cahiers D'un Artiste 1916Documento247 pagineJacques-Émile Blanche - Cahiers D'un Artiste 1916matwashereNessuna valutazione finora

- Trapezoidal Rule for Numerical IntegrationDocumento8 pagineTrapezoidal Rule for Numerical IntegrationGian SanchezNessuna valutazione finora

- Chevrolet 2005 Uplander Electrical Wiring DiagramDocumento62 pagineChevrolet 2005 Uplander Electrical Wiring Diagramromain.richertNessuna valutazione finora

- EHV SERIES 2-WAY HIGH PRESSURE CARBON STEEL BALL VALVEDocumento2 pagineEHV SERIES 2-WAY HIGH PRESSURE CARBON STEEL BALL VALVESHANENessuna valutazione finora

- AC 91-56 Amdt. 0 - Continuing Structural Integrity Program For Transport Category AirplaneDocumento18 pagineAC 91-56 Amdt. 0 - Continuing Structural Integrity Program For Transport Category Airplaneyogaga100% (1)