Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Programmable Logic Controller

Caricato da

Mukhlizar IsmailDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Programmable Logic Controller

Caricato da

Mukhlizar IsmailCopyright:

Formati disponibili

PROGRAMMABLE LOGIC CONTROLLER

Mukhlizar 20213048

ELEKTRONIKA INDUSTRI copy right 2013

Overview of Programmable Controllers

The programmable controllers has become the most powerful change to occur in the electronics world for factory automation. The programmable controller (P/C) is also called the programmable logic controller (PLC). Since the personal computer is called a PC, the programmable controller is referred to as a PLC to prevent confusion. As an electronics technician, you will run into the PLC in a number of places such as on the factory floor, in a repair facility, or you might work for a company that manufactures components and boards that are used to interface with PLCs.

In this chapter you are going to study PLCs from two different perspectives. First, you will see how the PLCs can be programmed to perform the same logic functions that the IC logic chips and relay in Chapter 1 and 2 performed. Second, you will see the large amount of electronics involved in the input and output modules that the controller uses for interfacing a variety of industrial voltages.

ELEKTRONIKA INDUSTRI copy right 2013

Overview of Programmable Controllers

The programmable logic controller (PLC) is a computer that is designed to solve logic (AND, OR, NOT) that specifically controls industrial devices such as motors and switches and allow oher control devices of varied voltages to be easily interfaced to provide simple or complex machine control. The computer part of the PLC, which is called a central processing unit (CPU), allows a program to be entered into its memory that will represent the logic functions. The program in the PLC is not a normal computer programming language like BASIC, Fortran, or C. Instead the PLC program uses contact and coil symbols to indicate which switches should control which output. These symbols look similar to a typical relay ladder diagram shown in chapter 1.

ELEKTRONIKA INDUSTRI copy right 2013

Figure 1.1 Example of a typical programmable controller program called ladder logic. This program uses to generic addresses of input 1, input 2, output 1, and so on.

ELEKTRONIKA INDUSTRI copy right 2013

Basic Parts of Simple Programmable Controller

All PLCs have four basic major parts: power supply, processor, input modules, and output modules. A fifth part, a pogramming device, is not considered a basic part since some PLCs will not have one if its program is loaded from an EPROM (erasable programmable read-only memory) chip.

Figur 1.2 Block diagram showing the four major parts of a programmable controller. The programming panel is the fifth part of the system, but it is not considered a basic part of the PLC since it can be disconnected when it is not needed.

ELEKTRONIKA INDUSTRI copy right 2013

The Programming Panel

At the bottom of the diagram in figure 1.2 you can also see a programming panel. Today the programming panel is a computer and is necessary to program the PLCs, but it is not considered to be one of the parts of a PLC because the programming panel or device can be disconnected after the program is loaded and the PLC will run by itself. The programming device is used so humans can make changes to the program, troubleshoot the inputs and outputs by viewing the status of contacts and coils to see if they are energized or deenergized, and for saving programs to disk, or loading programs from disk. The programming panel can be a dedicated device or it can be a personal or portable computer with PLC programming software loaded on it. The ladder logic program is able to be displayed on the programming device where it can become animated. This feature is unique to the PLC and it helps the technician troubleshoot very large logic circuits that control complex equipment. Another feature that makes a PLC so desirable is the fact that it has most of the logic functions found in the machine language program of any miroprocessor chip. This means that functions such as timing and counting can be executed by the PLC rather than using electromechanical or electronic timers and counters.

ELEKTRONIKA INDUSTRI copy right 2013

An Example Programmable Controller Application

Figure 1.3 Input and output diagram that shows all switches that are connected to the PLC input module and motor starters that are connected to the PLC output modules. The input and output numbering is generic and does not represent any brand-name programmable controller

ELEKTRONIKA INDUSTRI copy right 2013

Scanning a PLC program When It is The Run Mode

The PLC processor examines its program line by line, which is the way it solves its logic. The processor in the PLC actually performs several additional functions when it is in the run mode. These functions include reading the status of all inputs, solving logic, and writing the results of the logic to the output. When the processor is performing all of these functions, it said to be scanning its program. Image Register The Run Mode and the Program Mode On-line and Off-line Programming

ELEKTRONIKA INDUSTRI copy right 2013

Equating the PLC with Traditional Solid-State Logic

Figure 1.4 Solid-state logic gates used to provide the same logic as the PLC box-sorting program

It may be easier to equate the operation of a PLC-controlled program with the same program using solidstate logic (AND, OR, and NOT) functions.

ELEKTRONIKA INDUSTRI copy right 2013

Features of the Programmable Controller

ELEKTRONIKA INDUSTRI copy right 2013

Operation of Programmable Controller

ELEKTRONIKA INDUSTRI copy right 2013

Operation of the Heat-Treating Part of the System

ELEKTRONIKA INDUSTRI copy right 2013

Using Timers to Stage the Electric Heat

ELEKTRONIKA INDUSTRI copy right 2013

Counter Operation in a PLC

ELEKTRONIKA INDUSTRI copy right 2013

Timing and Counting Large Values

ELEKTRONIKA INDUSTRI copy right 2013

Circuits for Input and output Modules

ELEKTRONIKA INDUSTRI copy right 2013

Wiring Input Switches and Output Devices to the PLC

ELEKTRONIKA INDUSTRI copy right 2013

Analog Input Modules

ELEKTRONIKA INDUSTRI copy right 2013

Master Control Reset and Zone Control Last State

ELEKTRONIKA INDUSTRI copy right 2013

Using a Hand-Held Programmer

ELEKTRONIKA INDUSTRI copy right 2013

Advanced Instructions Found in Larger PLCs

ELEKTRONIKA INDUSTRI copy right 2013

Addressing Other Allen Bradley PLCs

ELEKTRONIKA INDUSTRI copy right 2013

Documenting a PLC Program with Software

ELEKTRONIKA INDUSTRI copy right 2013

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Phison ManualDocumento32 paginePhison Manualmaxo1100% (1)

- ZCPR3 The Manual (Richard Conn - OCR)Documento358 pagineZCPR3 The Manual (Richard Conn - OCR)Jose Luis ColladoNessuna valutazione finora

- Course Guide Book:: Electrical & Electronics Technology Department Addis AbabaDocumento5 pagineCourse Guide Book:: Electrical & Electronics Technology Department Addis AbabaAlemayehu AsmareNessuna valutazione finora

- C & Ds Notes 2022-2023 r22 SyllabusDocumento210 pagineC & Ds Notes 2022-2023 r22 Syllabusbabaforever786Nessuna valutazione finora

- TOSHIBA Qosmio F50-10K: Key FeaturesDocumento3 pagineTOSHIBA Qosmio F50-10K: Key FeaturesacongasoyNessuna valutazione finora

- Grupo7 - Memory and Storage - 25 - 01Documento7 pagineGrupo7 - Memory and Storage - 25 - 01Davis EdwardNessuna valutazione finora

- Possible Questions of Nc2 ExamDocumento10 paginePossible Questions of Nc2 Examlrac_adazolNessuna valutazione finora

- D3E80482474-VAS 6150 Laptops - System Recovery InstructionsDocumento9 pagineD3E80482474-VAS 6150 Laptops - System Recovery InstructionsFrancisco Sancho PujadoNessuna valutazione finora

- Class 3 Comp Worksheet No3Documento3 pagineClass 3 Comp Worksheet No3vmhsphysics100% (3)

- CuSB22R UserManualDocumento7 pagineCuSB22R UserManualjaimeherzNessuna valutazione finora

- CPE Challenge QuestionsDocumento8 pagineCPE Challenge QuestionsSeraphine RiegoNessuna valutazione finora

- Introduction To Computer SoftwareDocumento13 pagineIntroduction To Computer SoftwareShahnawaz MustafaNessuna valutazione finora

- Datasheet mcf5253 Coldfire MicroprocesorDocumento34 pagineDatasheet mcf5253 Coldfire MicroprocesorCamilaNessuna valutazione finora

- B450M Pro-Vdh Max B450M Pro-Vdh Max: FeatureDocumento1 paginaB450M Pro-Vdh Max B450M Pro-Vdh Max: FeaturealungsuharNessuna valutazione finora

- Lecture 1 - Computer Abstractions and TechnologyDocumento34 pagineLecture 1 - Computer Abstractions and TechnologyXrsamixNessuna valutazione finora

- HARGADocumento15 pagineHARGAgalihrahman51Nessuna valutazione finora

- Dma 8257Documento22 pagineDma 8257Kavitha SubramaniamNessuna valutazione finora

- Cea 201 On ThiDocumento9 pagineCea 201 On ThiMai Tien Thanh (K16HL)Nessuna valutazione finora

- LogDocumento26 pagineLogNuru MohammedNessuna valutazione finora

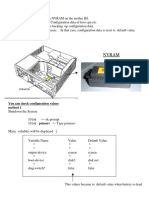

- NVRAM ProblemDocumento4 pagineNVRAM ProblemMuhammad AhmadNessuna valutazione finora

- Microprocessor - Microprocessor FundamentalsDocumento17 pagineMicroprocessor - Microprocessor FundamentalsTanveer Ahmed HakroNessuna valutazione finora

- ANALYSISTABS Sample Dashboard Sales DataDocumento232 pagineANALYSISTABS Sample Dashboard Sales Datapuran1234567890Nessuna valutazione finora

- Advance Information: JPEG Coder SD Interface 256K Embedded Display SRAM Image Processor CmosDocumento47 pagineAdvance Information: JPEG Coder SD Interface 256K Embedded Display SRAM Image Processor Cmosmailabautroixanh39Nessuna valutazione finora

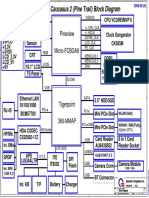

- Lenovo IdeaPad S10 - QUANTA FL2 - REV 1ASec PDFDocumento36 pagineLenovo IdeaPad S10 - QUANTA FL2 - REV 1ASec PDFu3a96e na1susNessuna valutazione finora

- Report On The Physical Count of Property, Plant and EquipmentDocumento19 pagineReport On The Physical Count of Property, Plant and EquipmentMarjorie Delrosario Pilon100% (1)

- Laptops: Mobile ComputerDocumento18 pagineLaptops: Mobile ComputerrocketraguNessuna valutazione finora

- Acer Aspire V5-132P Angel - CY 12313-1Documento102 pagineAcer Aspire V5-132P Angel - CY 12313-1Aphe TaiasuNessuna valutazione finora

- Mpi MCQDocumento83 pagineMpi MCQAKSHAY DagareNessuna valutazione finora

- Chapter 3: Principles of Scalable PerformanceDocumento41 pagineChapter 3: Principles of Scalable PerformanceHarminder SokhiNessuna valutazione finora

- Uplinq2013 Wed Hexagon DSP Access Program LRDocumento32 pagineUplinq2013 Wed Hexagon DSP Access Program LRsundar1234Nessuna valutazione finora