Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Defects in Materials

Caricato da

ahmedshah512Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Defects in Materials

Caricato da

ahmedshah512Copyright:

Formati disponibili

Imperfections/Defects in

Solids

An ideal crystal can be described in terms

a three-dimensionally periodic

arrangement of points called lattice and an

atom or group of atoms associated with

each lattice point called motif:

Crystal = Lattice + Motif

However, there can be deviations from this

ideality.

These deviations are known as crystal defects or

imperfections.

Imperfections in Solids

The properties of some materials are

profoundly influenced by the presence

of imperfections.

It is important to have knowledge about

the types of imperfections that exist and

the roles they play in affecting the

behavior of materials.

3

4

Atom Purity and Crystal Perfection

If we assume a perfect crystal structure

containing pure elements, then anything

that deviated from this concept or

intruded in this uniform homogeneity

would be an imperfection.

1. There are no perfect crystals.

2. Many material properties are improved by

the presence of imperfections and

deliberately modified (alloying and

doping).

5

Vacancy atoms

Interstitial atoms

Substitutional atoms

Point defects

1-2 atoms

Types of Imperfections

Dislocations

Line defects

1-dimensional

Grain Boundaries

Area defects

2-dimensional

6

o Point defects essentially zero dimensional imperfections,

such as vacancies, that are located typically at one (in some

cases a few) sites in the crystal.

o Vacancy - An atom or an ion missing from its regular

crystallographic site.

o Interstitial defect - A point defect produced when an atom is

placed into the crystal at a site that is normally not a lattice

point. Also an alien atom in one of the interstitials in a

structure

o Substitutional defect - A point defect produced when an

atom is removed from a regular lattice point and replaced with

a different atom, usually of a different size.

o Extended defects - Defects that involve several atoms/ions

and thus occur over a finite volume of the crystalline material

(e.g., dislocations, stacking faults, grain boundary).

Vacancy: A point defect

Point Defects

Interstitial defect

Formed when an extra atom or

ion is inserted into the crystal

structure at a normally

unoccupied position.

Substitutional defect

Introduced when one atom or

ion is replaced by a different

type of atom or ion.

9

Vacancies:

-vacant atomic sites in a structure.

Self-Interstitials:

-"extra" atoms positioned between atomic sites.

Point Defects in Metals

Vacancy

distortion

of planes

self-interstitial

distortion

of planes

10

Vacancies

-- vacancies exist in ceramics for both cations and anions

Interstitials

-- interstitials exist for cations

-- interstitials are not normally observed for anions because anions

are large relative to the interstitial sites

Adapted from Fig. 5.2, Callister & Rethwisch 3e.

(Fig. 5.2 is from W.G. Moffatt, G.W. Pearsall, and

J. Wulff, The Structure and Properties of

Materials, Vol. 1, Structure, John Wiley and Sons,

Inc., p. 78.)

Point Defects in Ceramics

Cation Interstitial

Cation Vacancy

Anion Vacancy

Point Defects: Impurities

12

Frenkel Defect

To maintain the charge neutrality, a cation vacancy-cation interstitial

pair occur together. The cation leaves its normal position and moves to the

interstitial site.

Schottky Defect

To maintain the charge neutrality, remove 1 cation and 1 anion;

this creates 2 vacancies.

Adapted from Fig. 5.3, Callister & Rethwisch 3e.

(Fig. 5.3 is from W.G. Moffatt, G.W. Pearsall, and

J. Wulff, The Structure and Properties of

Materials, Vol. 1, Structure, John Wiley and Sons,

Inc., p. 78.)

Point Defects: Frenkel and Schottky

Schottky

Defect

Frenkel

Defect

vacancy

Interstitial

impurity

Substitutional

impurity

Point Defects

14

Boltzmann's constant

(1.38 x 10

-23

J/atom-K)

(8.62 x 10

-5

eV/atom-K)

|

N

v

N

=

exp

Q

v

k T

|

\

|

.

|

No. of defects

No. of potential

defect sites

Activation energy

energy required for formation of vacancy

Temperature

Each lattice site

is a potential

vacancy site

Equilibrium concentration varies with temperature.

Equilibrium Concentration:

Point Defects

15

We can get Q

v

from

an experiment.

|

N

v

N

=

exp

Q

v

k T

|

\

|

.

|

Measuring Activation Energy

Measure this...

N

v

N

T

exponential

dependence!

defect concentration

Replot it...

1/ T

N

N

v

ln

-

Q

v

/k

slope

16

Find the equil. # of vacancies in 1 m

3

of Cu at 1000C.

Given:

A

Cu

= 63.5 g/mol

= 8.4 g / cm

3

Q

v

= 0.9 eV/atom N

A

= 6.02 x 10

23

atoms/mol

Estimating Vacancy Concentration

For 1 m

3

, N =

N

A

A

Cu

x x 1 m

3

= 8.0 x 10

28

sites

8.62 x 10

-5

eV/atom-K

0.9 eV/atom

1273 K

|

N

v

N

=

exp

Q

v

k T

|

\

|

.

|

= 2.7 x 10

-4

Answer:

N

v

= (2.7 x 10

-4

)(8.0 x 10

28

) sites = 2.2 x 10

25

vacancies

Line Defects

Dislocations

18

o Dislocation - A line imperfection in a crystalline

material.

o Screw dislocation - A dislocation resulting from

complicated processes it looks like a spiral ramp

about the dislocation in the plane perpendicular to

it

o Edge dislocation - A dislocation resulting from

complicated processes it looks like an extra half

plane of atoms.

o Mixed dislocation - A dislocation that contains partly

edge components and partly screw components.

o Slip Plastic, i.e. permanent, deformation of a

metallic material by the movement of dislocations

through the crystal.

Dislocations

Missing half plane A Defect

An extra half plane

or a missing half plane

What kind of

defect is this?

A line defect?

Or a planar defect?

Extra half plane

No extra plane!

Missing plane

No missing plane!!!

An extra half plane

or a missing half plane

Edge

Dislocation

This is a line defect called an

EDGE DISLOCATION

26

In order to make up a model of an edge dislocation:

perfect crystal in (a) is cut and an extra plane of

atoms is inserted (b). The bottom edge of the extra

plane is the edge dislocation (c). The Burgers vector

b closes the loop of equal atom spacings around the

edge dislocation.

27

In order to make up a model of a screw dislocation:

perfect crystal (a) is cut and sheared one atom spacing,

(b) and (c). The line along which shearing occurs is the

screw dislocation. The Burgers vector b of the dislocation

closes the loop of equal atom spacings around the screw

dislocation.

Potrebbero piacerti anche

- Defects in Crystals-Che222Documento18 pagineDefects in Crystals-Che222mgfmhcvjhj;Nessuna valutazione finora

- Me222a - Role of Crystals (Crystal Defect)Documento28 pagineMe222a - Role of Crystals (Crystal Defect)Sahil GalaNessuna valutazione finora

- Crystal Defects: 1.0 Learning ObjectivesDocumento5 pagineCrystal Defects: 1.0 Learning ObjectivesstevenkoNessuna valutazione finora

- Chap.2 - Structure of Metals and Alloys (Part 3-Defects)Documento26 pagineChap.2 - Structure of Metals and Alloys (Part 3-Defects)Anas FazilNessuna valutazione finora

- Imperfections in SolidsDocumento50 pagineImperfections in Solidsavutu_kunduruNessuna valutazione finora

- Imperfections of SolidsDocumento60 pagineImperfections of SolidsKousik DubeyNessuna valutazione finora

- Chapter+4+ +Imperfections+in+CrystalsDocumento25 pagineChapter+4+ +Imperfections+in+Crystalspramod_kNessuna valutazione finora

- Introduction To Material Science PHY-613 B.S 7 SemesterDocumento20 pagineIntroduction To Material Science PHY-613 B.S 7 SemesterAIZA MAQBOOL BS PhysicsNessuna valutazione finora

- Lecture 4 Imperfection of Metals WileyDocumento29 pagineLecture 4 Imperfection of Metals WileyNia KurniaNessuna valutazione finora

- Crystal Defects: 1. Point Defects A. VacanciesDocumento16 pagineCrystal Defects: 1. Point Defects A. VacanciesBlue_rabbit_2012Nessuna valutazione finora

- Imperfections in Solid Materials - Ch4Documento40 pagineImperfections in Solid Materials - Ch4aa454Nessuna valutazione finora

- Metallurgy and Materials ScienceDocumento167 pagineMetallurgy and Materials SciencejuegyiNessuna valutazione finora

- CH 4Documento145 pagineCH 4Najam Ul QadirNessuna valutazione finora

- Defects in CrystalsDocumento58 pagineDefects in Crystalsgeraye0Nessuna valutazione finora

- CH 4 ImperfectionsDocumento51 pagineCH 4 ImperfectionsMusab AbdrabbuhNessuna valutazione finora

- MMEN 120 - Imperfections in SolidsDocumento42 pagineMMEN 120 - Imperfections in SolidsnattydreadfathelahNessuna valutazione finora

- 04 Crystal DefectsDocumento40 pagine04 Crystal Defectsnitesh_n2840Nessuna valutazione finora

- Ch04 Ppts Callister7e Imperfection Is SolidsDocumento32 pagineCh04 Ppts Callister7e Imperfection Is SolidsOdarie HunterNessuna valutazione finora

- Bonga University: Engineering Material (Meng2091)Documento29 pagineBonga University: Engineering Material (Meng2091)Mul'isaa JireenyaaNessuna valutazione finora

- Crystal Defects in SolidsDocumento17 pagineCrystal Defects in Solidsmunishant1Nessuna valutazione finora

- Defects in CrystalsDocumento17 pagineDefects in CrystalsSomnath SahaNessuna valutazione finora

- Tech LN04 DefectsDocumento6 pagineTech LN04 DefectsEmerZing DurgaNessuna valutazione finora

- Imperfections in Solids: Issues To Address..Documento33 pagineImperfections in Solids: Issues To Address..Anonymous IFcXxZ4Nessuna valutazione finora

- Crystal DefectsDocumento2 pagineCrystal DefectsVictory OkwuNessuna valutazione finora

- Defects in Solids-Chapter 1Documento75 pagineDefects in Solids-Chapter 1Ali akbar AbidNessuna valutazione finora

- Crystal Structure DefectsDocumento30 pagineCrystal Structure DefectsSudhanshu ShekharNessuna valutazione finora

- Solid 14 JulyDocumento34 pagineSolid 14 JulyQwertyNessuna valutazione finora

- Defects in CrystalsDocumento58 pagineDefects in CrystalsMayank Rajesh Kumar ShrivastavaNessuna valutazione finora

- Crystal Defects - SathisDocumento16 pagineCrystal Defects - SathisSathis KannanNessuna valutazione finora

- Semi Conducting Materials Misfit Dislocations March 6 2012Documento58 pagineSemi Conducting Materials Misfit Dislocations March 6 2012Pradeep SijeriyaNessuna valutazione finora

- Crystal Imperfection CH 4Documento44 pagineCrystal Imperfection CH 4anapguerraNessuna valutazione finora

- X-RAY DIFFRACTION and Crystal DefectsDocumento68 pagineX-RAY DIFFRACTION and Crystal DefectsAnjan Prasad100% (1)

- UCLA MSE104 Chapter 4Documento27 pagineUCLA MSE104 Chapter 4Miqdad RazaNessuna valutazione finora

- ENS167 Chapter 5 Imperfections in SolidsDocumento34 pagineENS167 Chapter 5 Imperfections in SolidsJerico MendañaNessuna valutazione finora

- Crystal StructureDocumento30 pagineCrystal StructureAkshat MehrotraNessuna valutazione finora

- Solids L1-L10Documento15 pagineSolids L1-L10Ankur DasNessuna valutazione finora

- 18MET503C MM L26 (1.1-1.3) 5-8-2020 U1 1Documento26 pagine18MET503C MM L26 (1.1-1.3) 5-8-2020 U1 1kgmmetNessuna valutazione finora

- Material Lecture 4 DefectsDocumento44 pagineMaterial Lecture 4 Defectsdareen180732Nessuna valutazione finora

- Lecture-7-Crystal ImperfectionDocumento11 pagineLecture-7-Crystal ImperfectionSeenipandian RaviNessuna valutazione finora

- Crystal DefectsDocumento50 pagineCrystal Defectsvijayabanu2013Nessuna valutazione finora

- Chapter 4Documento42 pagineChapter 4uae2005Nessuna valutazione finora

- Material Science and Engineering: Defects Engr. Joseph Benedict N. PrimDocumento73 pagineMaterial Science and Engineering: Defects Engr. Joseph Benedict N. PrimJOSEPH BENEDICT PRIMNessuna valutazione finora

- Module 4 Defects in SolidDocumento38 pagineModule 4 Defects in SolidRalph Andrew Silverio67% (3)

- Materials Science and Engineering - 122016Documento6 pagineMaterials Science and Engineering - 122016arcellevallesNessuna valutazione finora

- CH04Documento39 pagineCH04PnzNessuna valutazione finora

- CrystalDocumento58 pagineCrystalShivanand ArwatNessuna valutazione finora

- Crystallographic Defect: Point DefectsDocumento4 pagineCrystallographic Defect: Point DefectsMathan KumarNessuna valutazione finora

- MMMD-103 Q.2 Laws of Crystallography: Imperfections of Crystal StructureDocumento9 pagineMMMD-103 Q.2 Laws of Crystallography: Imperfections of Crystal StructureMukul SharmaNessuna valutazione finora

- Tutorial 3 PHY 351Documento8 pagineTutorial 3 PHY 351ammirulhafiz03Nessuna valutazione finora

- S-EMM 3122-CH4-Solidification-2020Documento30 pagineS-EMM 3122-CH4-Solidification-2020KHAIRUL NASHRAN BIN ANUAR / UPMNessuna valutazione finora

- Lecture17 19 DefectsDocumento40 pagineLecture17 19 DefectsGayathri Shrushti. V mm19b031Nessuna valutazione finora

- Presentation 1Documento30 paginePresentation 1venkatesh198910Nessuna valutazione finora

- Defects in CeramicsDocumento16 pagineDefects in Ceramicssiva praneethNessuna valutazione finora

- Chapter 4Documento38 pagineChapter 4Gian BanaresNessuna valutazione finora

- Materials Science and Engineering: An Introduction To Chemical Engineers (Cheg-3171)Documento48 pagineMaterials Science and Engineering: An Introduction To Chemical Engineers (Cheg-3171)habteNessuna valutazione finora

- Defects in SolidDocumento26 pagineDefects in SolidMuhammad Dicky AmrullahNessuna valutazione finora

- Lecture 3 - Imperfections in MetalsDocumento27 pagineLecture 3 - Imperfections in MetalsAkerkeMamiNessuna valutazione finora

- Crystal Imperfection CH 4Documento44 pagineCrystal Imperfection CH 4maxxolimousNessuna valutazione finora

- M. Statment Lines - Cable Instal & TestingDocumento45 pagineM. Statment Lines - Cable Instal & Testingahmedshah512Nessuna valutazione finora

- 29-Method Statement-Roadworks Over Existing 11KV CrossingDocumento2 pagine29-Method Statement-Roadworks Over Existing 11KV Crossingahmedshah512Nessuna valutazione finora

- Method Statement For Support StructureDocumento2 pagineMethod Statement For Support Structureahmedshah512Nessuna valutazione finora

- Method Statement For Core CuttingDocumento5 pagineMethod Statement For Core Cuttingahmedshah512Nessuna valutazione finora

- 27-Method Statement-RoadworksDocumento17 pagine27-Method Statement-Roadworksahmedshah512Nessuna valutazione finora

- M. Statment Lines - OHL Instal & TestingDocumento27 pagineM. Statment Lines - OHL Instal & Testingahmedshah512100% (1)

- Method Statement For Cable PullingDocumento3 pagineMethod Statement For Cable Pullingahmedshah512Nessuna valutazione finora

- Method Statement For Cable Laying, Termination, TestingDocumento10 pagineMethod Statement For Cable Laying, Termination, Testingahmedshah512Nessuna valutazione finora

- List of Material Brugg Termination Rev 01Documento1 paginaList of Material Brugg Termination Rev 01ahmedshah512Nessuna valutazione finora

- Technical Details of 24 Fibre (g652d)Documento2 pagineTechnical Details of 24 Fibre (g652d)ahmedshah512Nessuna valutazione finora

- Method Statement For FO Cable TestingDocumento1 paginaMethod Statement For FO Cable Testingahmedshah512Nessuna valutazione finora

- 98-349 MTA SSG WindowOS SSG Without CropDocumento65 pagine98-349 MTA SSG WindowOS SSG Without CropAlexandra VilceanuNessuna valutazione finora

- RA 012 Taking Trial PitsDocumento2 pagineRA 012 Taking Trial Pitsahmedshah512100% (1)

- OTDRs and TestingDocumento10 pagineOTDRs and Testingahmedshah512Nessuna valutazione finora

- Atomic Bonding Lecture 2Documento49 pagineAtomic Bonding Lecture 2ahmedshah512Nessuna valutazione finora

- Installation - and - Testing - Guideline - en of Fiber Optic Cable PDFDocumento150 pagineInstallation - and - Testing - Guideline - en of Fiber Optic Cable PDFahmedshah512Nessuna valutazione finora

- DiodesDocumento27 pagineDiodesAhmad ShahNessuna valutazione finora

- Lecture 4Documento19 pagineLecture 4ahmedshah512Nessuna valutazione finora

- Books To Be Followed: Course Code-Ece 301 Based System DesignDocumento6 pagineBooks To Be Followed: Course Code-Ece 301 Based System Designahmedshah512Nessuna valutazione finora

- Thermal Spray ProcessDocumento11 pagineThermal Spray ProcessAshok Kumar100% (1)

- Digital Communication NotesDocumento12 pagineDigital Communication Notesravindarsingh50% (2)

- Ch7-Mechanical PropertiesDocumento24 pagineCh7-Mechanical Propertiesahmedshah512100% (1)

- Project ReportDocumento20 pagineProject Reportahmedshah512Nessuna valutazione finora

- Atomic Bonding Lecture 2Documento49 pagineAtomic Bonding Lecture 2ahmedshah512Nessuna valutazione finora

- An Agent Formal Model For Autonomous Decision-Making: Linjin Wu, Dongying Wu, Jiayong Chen, Wenxiong LiDocumento4 pagineAn Agent Formal Model For Autonomous Decision-Making: Linjin Wu, Dongying Wu, Jiayong Chen, Wenxiong Liahmedshah512Nessuna valutazione finora

- Logicore Ip Adder/Subtracter v11.0Documento10 pagineLogicore Ip Adder/Subtracter v11.0ahmedshah512Nessuna valutazione finora

- InstructionsDocumento14 pagineInstructionsahmedshah512Nessuna valutazione finora

- Block Diagram of INTEL 8085: Introduction To 8085Documento6 pagineBlock Diagram of INTEL 8085: Introduction To 8085ahmedshah512Nessuna valutazione finora

- Autonomous Systems Report 09Documento19 pagineAutonomous Systems Report 09ahmedshah512Nessuna valutazione finora

- Physics 5054/3: MCM Nkana Secondary SchoolDocumento5 paginePhysics 5054/3: MCM Nkana Secondary SchoolJedediah PhiriNessuna valutazione finora

- Past Papers IGCSE 2023 43Documento8 paginePast Papers IGCSE 2023 43David ThydetNessuna valutazione finora

- 3 SuperjunctionDocumento5 pagine3 SuperjunctionharibadriNessuna valutazione finora

- Beam Calculator Online (Calculate The Reactions, Draws Bending Moment, Shear Force, Axial Force) PDFDocumento5 pagineBeam Calculator Online (Calculate The Reactions, Draws Bending Moment, Shear Force, Axial Force) PDFEngr Ishfaque TunioNessuna valutazione finora

- 9702 m22+s22 P1Documento65 pagine9702 m22+s22 P1Zubair AhmadNessuna valutazione finora

- UPSEE Full Paper 2004Documento38 pagineUPSEE Full Paper 2004kapilNessuna valutazione finora

- NMR SplittingDocumento36 pagineNMR SplittingsabbysamuraNessuna valutazione finora

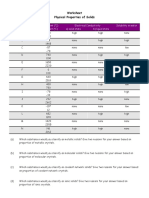

- 8 WORKSHEET Properties of SolidsDocumento1 pagina8 WORKSHEET Properties of Solidskomal sheikhNessuna valutazione finora

- 003 - Option B Chapter 14 Engineering Physics PDFDocumento62 pagine003 - Option B Chapter 14 Engineering Physics PDFyuke kristinaNessuna valutazione finora

- Quiz 3 ReviewDocumento26 pagineQuiz 3 ReviewameliawendelNessuna valutazione finora

- Audio Spotlighting NewDocumento30 pagineAudio Spotlighting NewAnil Dsouza100% (1)

- High Voltage Lecture - 8Documento33 pagineHigh Voltage Lecture - 8Mansoor SarwarNessuna valutazione finora

- Expand of Alkhoms 30KV Power Distribution NetworkDocumento5 pagineExpand of Alkhoms 30KV Power Distribution Networkعبدالله أبورويصNessuna valutazione finora

- Saas-Fee Advanced Course 36Documento381 pagineSaas-Fee Advanced Course 36Maria TeresaNessuna valutazione finora

- Molecular Symmetry 2Documento5 pagineMolecular Symmetry 2Kirk BorromeoNessuna valutazione finora

- Open Channel FlowDocumento166 pagineOpen Channel FlowJuan HeroNessuna valutazione finora

- Sand Liquefaction by Hypoplastic ModelDocumento7 pagineSand Liquefaction by Hypoplastic ModelAnna SuuNessuna valutazione finora

- Heat Balance GCLDocumento6 pagineHeat Balance GCLIrshad HussainNessuna valutazione finora

- Overhead Line DesignDocumento37 pagineOverhead Line DesignPramod B.Wankhade100% (4)

- Fundamentals of Heat Exchanger DesignDocumento972 pagineFundamentals of Heat Exchanger DesignNgô Linh Đan80% (5)

- Tests On RocksDocumento27 pagineTests On RocksdeadromeoNessuna valutazione finora

- Tutorial Problems 1,2,3Documento3 pagineTutorial Problems 1,2,3Chloe OlazoNessuna valutazione finora

- Tipler and Mosca Physics For Scientists and Engineers Solutions Manual Chapter 13Documento102 pagineTipler and Mosca Physics For Scientists and Engineers Solutions Manual Chapter 13Nate LinxNessuna valutazione finora

- EXP - 4 Chip MorphologyDocumento2 pagineEXP - 4 Chip MorphologyRaju SaiNessuna valutazione finora

- A Review of Polarization Index and IEEE Standard 43-2000Documento5 pagineA Review of Polarization Index and IEEE Standard 43-2000vasanth11kvNessuna valutazione finora

- PhysicsDocumento18 paginePhysicsNelsonNessuna valutazione finora

- 06 PlateTheory 08 VibrationsDocumento6 pagine06 PlateTheory 08 Vibrationsvhj gbhjNessuna valutazione finora

- RC Design For STPDocumento14 pagineRC Design For STPafiqNessuna valutazione finora

- Chapter 9: Center of Gravity and CentroidDocumento19 pagineChapter 9: Center of Gravity and CentroidNezie Tacay GondalesNessuna valutazione finora