Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Inventory Models

Caricato da

myraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Inventory Models

Caricato da

myraCopyright:

Formati disponibili

Inventory Control

Model

Inventory as an Important Asset

Inventory can be the most expensive and

the most important asset for an

organization

Other Assets

60%

Inventory

40%

Inventory as a

percentage of total assets

The Inventory Process

Suppliers Customers

Finished

Goods

Raw

Materials

Work in

Process

Fabrication

and

Assembly

Inventory Storage

Inventory Processing

Importance of Inventory Control

Five Functions of Inventory

Decoupling

Storing resources

Adapting to irregular supply and demand

Enabling the company to take advantage

of quantity discounts

Avoiding stockouts and shortages

Inventory Decisions

How much to order

When to order

wish to minimize total inventory cost

Inventory Costs

Cost of the items

Cost of ordering

Cost of carrying, or holding inventory

Cost of safety stock

Cost of stockouts

Ordering Costs

Developing and sending purchase orders

Processing and inspecting incoming inventory

Bill paying

Inventory inquiries

Utilities, phone bills, etc., - purchasing

department.

Salaries/wages - purchasing department

employees

Supplies (e.g., forms and paper) - purchasing

department

Carrying Costs

Cost of capital

Taxes

Insurance

Spoilage

Theft

Obsolescence

Salaries/wages - warehouse employees

Utilities/building costs - warehouse

Supplies (e.g., forms, paper) - warehouse

Inventory Usage Over Time

Costs as Functions of Order

Quantity

Annual

Cost

Order Quantity Q

*

Total Cost Curve

Carrying (holding)

Cost Curve

Ordering (set-

up)

Cost Curve

Minimum

Cost

Costs as Functions of Order

Quantity

Order Cost

Minimum Cost

Inventory Cost versus Order Quantity

Quantity

$

C

o

s

t

Optimal Quantity

Steps in Finding the Optimum

Inventory

Develop an expression for the ordering

cost.

Develop and expression for the

carrying cost.

Set the ordering cost equal to the

carrying cost.

Solve this equation for the optimum

desired.

EOQ : Basic Assumptions

Demand is known and constant

Lead time is known and constant

Receipt of inventory is instantaneous

Quantity discounts are not possible

The only variable costs are the cost of setting

up or placing an order, and the cost of holding

or storing inventory over time

Stockouts can be completely avoided if orders

are placed at the appropriate time

Annual ordering cost:

Annual holding or carrying cost:

Material Cost: DC

Total inventory cost:

Developing the EOQ

o

C

Q

D

=

=

order per units of Number

demand Annual

h

C

2

Q

Year Per Cost Carrying * Inventory Average

=

=

h o t

C

2

Q

C

Q

D

TC + + = DC

EOQ

h

C

2DC

*

Q

=

Per Unit Carrying Cost:

Percentage Carrying Cost:

IP

DC

Q

*

0

2

=

0

Inputs and Outputs of the

EOQ Model

EOQ

Models

Input Values Output Values

Annual Demand

(D)

Ordering Cost

(C

o

)

Carrying Cost

(C

h

)

Lead Time

(L)

Demand Per Day

(d)

Economic

Order

Quantity

(EOQ)

Reorder

Point

(ROP)

The Reorder Point (ROP) Curve

ROP = (Demand per day) x (Lead time for a new order, in days)

= d x L

I

n

v

e

n

t

o

r

y

L

e

v

e

l

(

U

n

i

t

s

)

Q*

ROP

(Units)

Slope = Units/Day = d

Lead Time (Days)

L

Inventory Control and the

Production Process

I

n

v

e

n

t

o

r

y

L

e

v

e

l

Demand

Portion

of Cycle

Demand

Portion

of Cycle

Maximum

Inventory

Level

Time

Production

Portion of

Cycle

Production Quantity EOQ

Annual Carrying Cost:

Annual Ordering Cost:

~ Setup Cost:

~ Ordering Costs:

h

C

p

d Q

) 1 (

2

s

C

Q

D

o

C

Q

D

Production Quantity EOQ

|

|

.

|

\

|

=

p

d

1 C

2DC

Q

h

o

*

p

Quantity Discount Models

Quantity Discount Steps

1. Calculate Q for each discount

2. Adjust Q upward if quantity is too low

for discount

3. Compute total cost for each discount

4. Select Q with the the lowest total cost

The Use of Safety Stock

I

n

v

e

n

t

o

r

y

o

n

H

a

n

d

I

n

v

e

n

t

o

r

y

o

n

H

a

n

d

Stockout

Time

Stockout

is avoided

Time

Safety Stock

The Use of Safety Stock

Known stockout costs:

Given probability of demand, find total

cost for each safety stock alternative

Unknown stockout costs:

Set service level; use normal distribution

Service Level versus Carrying

Costs

Potrebbero piacerti anche

- MKT534/531 October 2007Documento3 pagineMKT534/531 October 2007myraNessuna valutazione finora

- Features of Four Market StructuresDocumento11 pagineFeatures of Four Market StructuresmyraNessuna valutazione finora

- Brand Equity & Brand IdentityDocumento29 pagineBrand Equity & Brand IdentitymyraNessuna valutazione finora

- Statistics & SPSSDocumento49 pagineStatistics & SPSSmyraNessuna valutazione finora

- Product Management MKT 534 OCT2009Documento3 pagineProduct Management MKT 534 OCT2009myraNessuna valutazione finora

- Product Management MKT 534 OCT2008Documento3 pagineProduct Management MKT 534 OCT2008myraNessuna valutazione finora

- Product Management MKT 534 OCT2010Documento3 pagineProduct Management MKT 534 OCT2010myraNessuna valutazione finora

- MKT535/532/561/520 April 2008Documento3 pagineMKT535/532/561/520 April 2008myraNessuna valutazione finora

- MKT537/536/562 April 2008Documento5 pagineMKT537/536/562 April 2008myraNessuna valutazione finora

- Internet Marketing MKT544 OCT 2008Documento4 pagineInternet Marketing MKT544 OCT 2008myraNessuna valutazione finora

- MKT534/531 October 2007Documento3 pagineMKT534/531 October 2007myraNessuna valutazione finora

- ECO415 November 2005Documento6 pagineECO415 November 2005myra0% (1)

- Marketing Research Mkt537 April 2009Documento4 pagineMarketing Research Mkt537 April 2009myraNessuna valutazione finora

- ECO415 November 2005Documento6 pagineECO415 November 2005myra0% (1)

- Eco415 October 2007Documento5 pagineEco415 October 2007myra0% (1)

- MKT535/532/561/520 October 2009Documento3 pagineMKT535/532/561/520 October 2009myraNessuna valutazione finora

- MKT537/536/562 October 2009Documento5 pagineMKT537/536/562 October 2009myraNessuna valutazione finora

- MKT537 536 562Documento4 pagineMKT537 536 562xone1215Nessuna valutazione finora

- Marketing Research Mkt537 April 2009Documento4 pagineMarketing Research Mkt537 April 2009myraNessuna valutazione finora

- MKT 537/536 Oct 2007Documento8 pagineMKT 537/536 Oct 2007myraNessuna valutazione finora

- MKT535/532/561/520 October 2008Documento3 pagineMKT535/532/561/520 October 2008myra100% (1)

- MKT535/532/561/520 April 2009Documento3 pagineMKT535/532/561/520 April 2009myraNessuna valutazione finora

- MKT535/532/561/520 April 2008Documento3 pagineMKT535/532/561/520 April 2008myraNessuna valutazione finora

- MKT 543/541 Apr2009Documento3 pagineMKT 543/541 Apr2009myraNessuna valutazione finora

- 3R Leaflet BIoutlineDocumento1 pagina3R Leaflet BIoutlinemyraNessuna valutazione finora

- MKT 535/532/561 April 2007Documento3 pagineMKT 535/532/561 April 2007myraNessuna valutazione finora

- MKT 537/536 April 2007Documento7 pagineMKT 537/536 April 2007myraNessuna valutazione finora

- MKT 544 Apr - 2008 - MKTDocumento4 pagineMKT 544 Apr - 2008 - MKTmyraNessuna valutazione finora

- MKT 543/531 Apr2010Documento3 pagineMKT 543/531 Apr2010myraNessuna valutazione finora

- MKT 534/531/530 Apr2008Documento3 pagineMKT 534/531/530 Apr2008myraNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Inventory ErrorsDocumento8 pagineInventory ErrorsAnonymous LC5kFdtc100% (1)

- Home Office and Branch AccountingDocumento15 pagineHome Office and Branch AccountingAliah CyrilNessuna valutazione finora

- 1st Reading of The Week - Introduction To Activity Based CostingDocumento4 pagine1st Reading of The Week - Introduction To Activity Based CostingDANIELANessuna valutazione finora

- Chapter 12. Safety InventoryDocumento61 pagineChapter 12. Safety InventoryShalako450% (1)

- A Project Report On Working Capital Management of Arss Infrastructure LimitedDocumento82 pagineA Project Report On Working Capital Management of Arss Infrastructure LimitedBabu BalaNessuna valutazione finora

- What Was John Connelly's Role in CCS As A Leader?Documento1 paginaWhat Was John Connelly's Role in CCS As A Leader?karthikawarrierNessuna valutazione finora

- US Economic Indicators: Corporate Profits in GDP: Yardeni Research, IncDocumento16 pagineUS Economic Indicators: Corporate Profits in GDP: Yardeni Research, IncJames HeartfieldNessuna valutazione finora

- C-ADAPTER Items Added: New Product NewsDocumento3 pagineC-ADAPTER Items Added: New Product NewsAnonymous HPlNDhM6ejNessuna valutazione finora

- Productivity: DR. Zeny J. LontocDocumento27 pagineProductivity: DR. Zeny J. LontocAnthony RoyupaNessuna valutazione finora

- Chapter 4 ICADocumento6 pagineChapter 4 ICAAndrew MarchukNessuna valutazione finora

- Production Planning and ControlDocumento44 pagineProduction Planning and Controlsukma fajarNessuna valutazione finora

- Rockwood 6 and 8 Inch ClassicDocumento4 pagineRockwood 6 and 8 Inch ClassicWorld Outdoor EmporiumNessuna valutazione finora

- Chapter 1Documento37 pagineChapter 1bhawesh agNessuna valutazione finora

- Maf151 Chapter 3Documento63 pagineMaf151 Chapter 3Aiman Zikry bin AzmiNessuna valutazione finora

- Inventory ManagementDocumento96 pagineInventory ManagementNavishta TayyabaNessuna valutazione finora

- CH 05Documento72 pagineCH 05Chang Chan ChongNessuna valutazione finora

- SAP CO-PC Product Costing in SAP ERP6.0 OneDocumento34 pagineSAP CO-PC Product Costing in SAP ERP6.0 Onefaysal2523535100% (3)

- MM Reports in SAP - SAP Materials, Documents, TutorialsDocumento2 pagineMM Reports in SAP - SAP Materials, Documents, TutorialsPratikJadhavNessuna valutazione finora

- Somera ProjMgtExer3Documento2 pagineSomera ProjMgtExer3john johnNessuna valutazione finora

- JIT Lean SolutionsDocumento15 pagineJIT Lean SolutionskuhafaNessuna valutazione finora

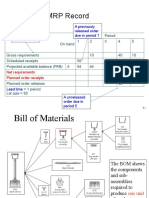

- Basic MRP Record: A Previously Released Order Due in Period 1 Requirements From All SourcesDocumento12 pagineBasic MRP Record: A Previously Released Order Due in Period 1 Requirements From All Sourcesajeng.saraswatiNessuna valutazione finora

- Haldiram Casse Study PDFDocumento6 pagineHaldiram Casse Study PDFMaha SathiyaNessuna valutazione finora

- Matching QuestionsDocumento2 pagineMatching QuestionsttoraddoraNessuna valutazione finora

- Plant Layout of PharmaDocumento21 paginePlant Layout of PharmaDontYou KnowMe100% (4)

- JIT & Backflush CostingDocumento5 pagineJIT & Backflush CostingMaureen LobinNessuna valutazione finora

- Job-Order Costing: (Cost Accounting)Documento20 pagineJob-Order Costing: (Cost Accounting)Jamille Victorio BautistaNessuna valutazione finora

- Ammo FlowchartDocumento4 pagineAmmo Flowchartjameswilliford100% (1)

- ACC118-AssDocumento6 pagineACC118-AssRiezel PepitoNessuna valutazione finora

- Activity 1 MAS1 AnswersDocumento2 pagineActivity 1 MAS1 Answersangel mae cuevasNessuna valutazione finora

- ACC 604 Chapter 4 Systems DesignDocumento59 pagineACC 604 Chapter 4 Systems DesignMedalla NikkoNessuna valutazione finora