Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Elmes I Bab 9

Caricato da

Yosafat Try FajarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Elmes I Bab 9

Caricato da

Yosafat Try FajarCopyright:

Formati disponibili

Welding, Bonding, and Design of Permanent Joints

Introduction

Welding is the process of joining two pieces of metal

together by hammering, pressure or fusion. Filler metal

may or may not be used.

The strongest and most common method of permanently

joining steel components together.

Arc welding is the most important since it is adaptable to

various manufacturing environments and is relatively

cheap.

A weldment is fabricated by welding together a collection

of metal shapes.

Introduction

A pool of molten metal in which the components and

electrode material coalesce, forming a homogeneous whole

(ideally) when the pool later resolidifies.

The materials of components and electrode must be

compatible from the point of view of strength, ductility and

metallurgy.

The form of a welded joint is dictated largely by the layout

of the joined components.

Two most common forms are:

1. The butt joint

2. The fillet joint

Welding Symbols

Figure 9-2

Arc and gas-weld symbols

There 2 general types of welds:

1. Fillet welds for general machine elements.

2. Butt or groove welds for pressure vessels, piping systems,...

There are also others such as: ,

Fillet

groove

Bead

Bead Plug or slot

Plug

or slot

Types Of Welding

Parts to be joined must be arranged so that there is sufficient

clearance for welding operation.

Due to heat, there are metallurgical changes in the parent metal in

the vicinity of the weld.

Residual stresses may be introduced because of clamping or holding.

These residual stresses are not severe enough to cause concern.

A light heat treatment after welding is done to relive these stresses.

When the parts to be welded are thick, a preheating will also be of

benefit.

Figure 9-3

Fillet welds

Figure 9-4

The circle on the weld symbol indicates that the welding is to

go all around.

Figure 9-5

Figure 9-6

Butt and Fillet Welds

where h is the weld throat and l is the length of the weld. Notice that the

value of h does not include the reinforcement.

The reinforcement can be desirable, but it varies somewhat and does

produce stress concentration at point A in the figure. If fatigue loads

exist, it is good practice to grind or machine off the reinforcement.

Stresses in Fillet Welds

At angle u the forces

on each weldment

consists of a normal

force F

n

and a shear

force F

s

sin ,

cos n

s F F

F F

u

u

=

=

Fig. 9-8 illustrates a typical

transverse fillet weld.

In Fig. 9-9 a portion of the

welded joint has been

isolated from Fig. 9-8

Stresses in Fillet Welds

sin (cos sin )

cos (cos sin ) n

s F F

A hl

F F

A hl

u u u

t

u u u

o

+

= =

+

= =

The nominal stresses at the angle

in the weldment, and , are

The von Mises stresse at angle is

max

occurs at = 62.5

o

with a value of

max

= 2.16 F/(hl).

The corresponding values of and , are = 1.196 F/(hl) and =

0.623 F/(hl).

max

can be found by solving the equation [d()/d]=0.

The stationary point occurs at = 67.5

o

with a corresponding

max

=

1.207 F/(hl) and = 0.5 F/(hl).

( )

1 2

2 2

1 2

2 2

2 2

(cos sin cos )

' 3

3(sin sin cos )

F

hl

u u u

o o t

u u u

(

+

= + =

(

+ +

We have no analytical approach that predicts the existing stresses.

The geometry of the fillet is crude by machinery standards.

The approach has been to use a simple and conservative model,

verified by testing as conservative.

Consider the external loading to be carried by shear forces on the

throat area of the weld. By ignoring the normal stress on the throat, the

shearing stresses are inflated sufficiently to render the model

conservative.

Use the distortion energy for significant stresses

Circumscribe typical cases by code

For this model, the basis for weld analysis or design employs

which assumes the entire force F is accounted for by a shear stress in

the minimum throat area.

The approach has been to:

1.414

0.707

F F

hl hl

t = = (9.3)

Notice that this inflates the maximum estimated shear stress by a

factor of 1.414/1.207=1.17.

Further, consider the parallel fillet welds shown in Fig. 9-11 where, as

in Fig.9-8, each weld transmits a force F. However, in the case of Fig. 9-

11, the maximum shear stress is at the minimum throat area and

corresponds to Eq. (9-3).

Under circumstances of combined loading we:

Examine primary shear stresses due to external forces.

Examine secondary shear stresses due to torsional and bending

moments.

Estimate the strength(s) of the parent metal (s).

Estimate the strength of the deposited weld metal.

Estimate the permissible load(s) for parent metal(s).

Estimate permissible load for deposited weld metal.

Stresses in Welded Joints in Torsion

Figure 9-12 illustrates a cantilever of length l welded to a column by 2 fillet

welds.

The reaction at the support

of a cantilever always

consists of shear force V and

a moment reaction M.

The shear force produces a

primary shear in the welds

of magnitude

where A is the throat area of

the welds.

'

V

A

t = (9.4)

The moment at the support

produces secondary shear or

torsion of the welds, and this

stress is given by

where

r: distance from the centroid of

the weld group to the point in

the weld of interest.

J: second polar moment of area

of the group about the centroid

of the group.

"

Mr

J

t = (9.5)

Figure 9-13 shows 2 welds in a group. The rectangles represent the throat

areas of the welds.

Weld 1 has a throat

width b

1

= 0.707 h

1

Weld 2 has a throat

width d

2

= 0.707 h

2

Throat area of both

welds together is

A = A

1

+ A

2

= b

1

d

1

+ b

2

d

2

which is the area to be

used in Eq. (9-4)

The x-axis passes through

the centroid G

1

of the weld

1.

The second moment of

area about this axis is

Similarly, the second

moment of area about an

axis passing through G

1

parallel to the y-axis is

The second polar moment

of areas of weld 1 and weld

2 about their centroids are

3

1 1

12

x

b d

I =

3

1 1

12

y

d b

I =

3 3

1 1 1 1

1

3 3

2 2 2 2

2

12 12

12 12

G x y

G x y

b d d b

J I I

b d d b

J I I

= + = +

= + = +

The centroid G of the weld group is located at

The distances r

1

and r

2

from G

1

and G

2

are respectively given by

( )

( ) ( )

1 2

2

2

1 1

1 2

2 2

2 2 2

r x x y

r y y x x

(

= +

(

= +

1 1 2 2 1 1 2 2

Ax A x A y A y

x y

A A

+ +

= =

Using the parallel axis theorem,

the second polar moment of area

of the weld group is

( ) ( )

2 2

1 1 1 2 2 2 G G

J J Ar J A r = + + +

This is the quantity to be used in Eq. (9-5). The distance r must be

measured from G and the moment M computed about G.

The quantities and , which represent the weld width are small and

hence can be neglected.

The terms and Makes J

G1

and J

G2

linear in the weld

width.

Setting weld widths b

1

and d

2

to unity leads to the idea of treating each

fillet weld as line.

The resulting second moment of area is then a unit second polar

moment of area.

The value of J

u

same regardless of weld size.

Since throat width of a fillet weld is 0.707h, the relation between J and

the unit value is

0.707

u

J h J =

(9.6)

3

1

b

3

2

d

3

1 1

12 b d

3

2 2

12 d b

J

u

: is found from table 9.1

Fig. 9-17a shows a cantilever welded to a support by fillet welds at top

and bottom.

9-4 Stresses in Welded Joints in Bending

A FBD diagram of

the beam would

show a shear force V

and a moment

diagram M.

The shear force

produces a primary

shear in the welds of

magnitude

' t =

V

A

The moment M introduces a throat shear stress

component of 0.707 in the welds.

Treating the two welds of Fig. 9-17b as lines we find

the second moment of area to be

2

2

=

u

bd

I

(a)

(b)

The second moment of area I, based on weld throat area, is

The nominal throat shear stress is now found to be

The model gives the coefficient of 1.414, in contrast to the predictions

of Sec.9-2 of 1.197 from distortion energy, or 1.207 from maximum shear.

The second moment of area in Eq. (d) is based on the distance d

between the two welds.

Stresses in Welded Joints in Bending

2

0.707 7

2

0. 07 = =

u

I h

bd

I h

( )

( )

2

2

1.414

0.707 2

t = = =

M d

Mc M

I bd h

h bd

(c)

(d)

The Strength of Welded Joints

The matching of the electrode properties with those of parent metal is

usually not so important as speed, operator appeal, and the appearance of

the completed joint.

The properties of electrodes vary considerably, but Table 9-3 lists the

minimum properties for some electrode classes.

It is preferable, in designing welded components, to select a steel that ill

result in a fast, economical weld.

Best results are obtained for steels having a UNS specifications between

G10140 and G10230.

All these steels have a tensile strength in the hot-rolled condition in the

range of 60 to 70 kpsi.

Permissible stresses are now based on the yield strength of the material

instead of the ultimate strength, and the code permits the use of a variety of

ASTM structural steels having yield strengths varying from 33 to 50 kpsi.

For these ASTM steels, S

y

= 0.5 S

u

.

Table 9-4 lists the formulas specified by the code for calculating these

permissible stresses for various load conditions.

The fatigue stress concentration factors listed in Table 9-5 are

suggested for use. These factors should be used for the parent

metal as well as for the weld metal.

Table 9-6 gives steady-load information and minimum fillet sizes.

Static Loading

Example 9-2 (Textbook)

Table A-20, S

y

= 27.5 kpsi

h =3/8=0.375 in

t = 1/2 in

l = 2 in

CH-9 LEC 41 Slide 41

Dr. A. Aziz Bazoune Chapter 9: Welding,

Bonding, and the Design of Permanent Joints

Example 9-2 (Cont.d)

h =3/8=0.375 in

t = 1/2 in

l = 2 in

Example 9-4 (Textbook)

Table 9-3,

S

y

= 50 kpsi,

S

ut

= 62 kpsi

Table 9-2, pattern 2,

b=3/8 = 0.375 in

and d= 2in

Table A-20,

S

y

= 32 kpsi, S

ut

= 58 kpsi

Eq. 6-21

S

sy

= 0.577 S

y

E6010 electrode

Table 9-3,

S

y

= 50 kpsi,

Given n=3

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- We Are The ReasonDocumento1 paginaWe Are The ReasonAlex Sander LgNessuna valutazione finora

- Springs Deflection and ApplicationsDocumento42 pagineSprings Deflection and ApplicationsYosafat Try FajarNessuna valutazione finora

- Navisworks BasicTrainingDocumento54 pagineNavisworks BasicTrainingMadhankumarNessuna valutazione finora

- Chapter 5: Operating System, Quiz With AnswersDocumento14 pagineChapter 5: Operating System, Quiz With AnswersAden Kheire Mohamed100% (1)

- Teknik Tenaga Elektrik: Buku SumberDocumento24 pagineTeknik Tenaga Elektrik: Buku SumberYosafat Try FajarNessuna valutazione finora

- BALANCING RECIPROCATING MASS 2012.ppsxDocumento20 pagineBALANCING RECIPROCATING MASS 2012.ppsxYosafat Try FajarNessuna valutazione finora

- HistoryDocumento87 pagineHistoryMatthew MathewsNessuna valutazione finora

- ST RDDocumento2 pagineST RDBalteshwar SinghNessuna valutazione finora

- Two Sigma - LeetCodeDocumento2 pagineTwo Sigma - LeetCodePeeyushNessuna valutazione finora

- IT407 Knowledge EngineeringDocumento2 pagineIT407 Knowledge EngineeringVidya ANessuna valutazione finora

- Explanation Text About RainbowDocumento11 pagineExplanation Text About RainbowBagas FatihNessuna valutazione finora

- Quiz6 AnswerDocumento8 pagineQuiz6 AnswerTrí Tạ MinhNessuna valutazione finora

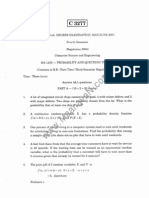

- PQT MJ07Documento6 paginePQT MJ07Raguraman BalajiNessuna valutazione finora

- Mechanical Technology Concepts: Applied ThermodynamicsDocumento45 pagineMechanical Technology Concepts: Applied ThermodynamicsLe0 GamingNessuna valutazione finora

- Quantitative Method Problem SetDocumento10 pagineQuantitative Method Problem SetConstanceNessuna valutazione finora

- ParkerDocumento106 pagineParkerJoseJSanchezNessuna valutazione finora

- Na2xckbr2y Rev 08Documento1 paginaNa2xckbr2y Rev 08dardakNessuna valutazione finora

- Inductance Calculations Working Formulas and Tables (Grover-1973)Documento153 pagineInductance Calculations Working Formulas and Tables (Grover-1973)Anonymous 2OxpGvaNW100% (1)

- Temperarura4 PDFDocumento371 pagineTemperarura4 PDFmario yanezNessuna valutazione finora

- Perez, Alonso - Unknown - The Ultimate Approach For General Arrangement Definition-AnnotatedDocumento6 paginePerez, Alonso - Unknown - The Ultimate Approach For General Arrangement Definition-AnnotatedPANJI BRAMMASTANessuna valutazione finora

- Quad Encoder Velocity Accel with CRIOLabVIEW FPGADocumento5 pagineQuad Encoder Velocity Accel with CRIOLabVIEW FPGAChâu Tinh TrìNessuna valutazione finora

- Fontargen AJ PDFDocumento282 pagineFontargen AJ PDFantonyNessuna valutazione finora

- CH1 The Foundations - Logic and ProofsDocumento106 pagineCH1 The Foundations - Logic and ProofsMOHAMED BACHARNessuna valutazione finora

- Battery ModelingDocumento6 pagineBattery ModelingmusabnajeebNessuna valutazione finora

- Scalable Analog/Addressable Fire Alarm Control System: IFP-2100ECS / IFP-2100ECSBDocumento2 pagineScalable Analog/Addressable Fire Alarm Control System: IFP-2100ECS / IFP-2100ECSBMurali DaranNessuna valutazione finora

- AerialSolution - 280 - Brochure - LT - New Design - Final - LRDocumento20 pagineAerialSolution - 280 - Brochure - LT - New Design - Final - LRRover DmsNessuna valutazione finora

- Magnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingDocumento10 pagineMagnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingedumacerenNessuna valutazione finora

- DMPA CombinedDocumento527 pagineDMPA Combinedlolzcat3454Nessuna valutazione finora

- Wind Load Sheet by Abid SirDocumento4 pagineWind Load Sheet by Abid SirMohammad KasimNessuna valutazione finora

- Testing The AdapterDocumento8 pagineTesting The AdapterrejnanNessuna valutazione finora

- Uniform ForceDocumento11 pagineUniform ForcearnoldistunoNessuna valutazione finora

- WPMD 3002Documento6 pagineWPMD 3002Adilson LucaNessuna valutazione finora

- Shape and angle detective game for kidsDocumento21 pagineShape and angle detective game for kidsbemusaNessuna valutazione finora

- ThesisDocumento32 pagineThesis783255Nessuna valutazione finora