Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Finite Element Methods (FEM) : Suzanne Vogel COMP 259 Spring, 2002

Caricato da

DarmadiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Finite Element Methods (FEM) : Suzanne Vogel COMP 259 Spring, 2002

Caricato da

DarmadiCopyright:

Formati disponibili

Finite Element Methods (FEM)

Suzanne Vogel

COMP 259

Spring, 2002

The finite element method is the formulation

of a global model to simulate static or dynamic

response to applied forces.

Models: energy, force, volume,

This differs from a mass spring system, which

is a local model.

Definition of FEM

1. Set up a global model in terms of the world

coordinates of mass points of the object.

These equations will be continuous.

2. Discretize the object into a nodal mesh.

3. Discretize the equations using finite

differences and summations (rather than

derivatives and integrals).

4. Use (2) and (3) to write the global equations

as a stiffness matrix times a vector of

(unknown) nodal values.

Top-Down: Steps in FEM

Top-Down: Steps in FEM

6. Solve for the nodal values.

Static nodal values at equilibrium

Dynamic nodal values at next time step

7. Interpolate values between nodal coordinates.

5

2

3

1

4

6

7 8

u

discretize interpolate

+

global model

object

nodal mesh

interpolate values between nodes

+

local model

Bottom-Up: Steps in FEM

Nodes are point masses connected with springs.

A continuum equation is solved for the nodes,

and intermediate points are interpolated.

A collection of nodes forms an element.

A collection of elements forms the object.

5

2

3

1

4

6

7 8

u

Elements and I nterpolations

Interpolating equations for an element are

determined by the number and distribution of

nodes within the element.

More nodes mean higher degree, for smoother

simulation.

Example: Hermite as 1D Cubic

I nterpolation Equation

1. Assume

u

r

d cu bu au u r + + + =

2 3

) (

4 4 3 3 2 2 1 1

) ( ) ( ) ( ) ( ) ( r u N r u N r u N r u N u r + + + =

cubic equation

equation using shape (blending) functions

and

Example: Hermite as 1D Cubic

I nterpolation Equation

2. Normalize the element to [0,1] and rewrite

d cu bu au u r + + + =

2 3

) ( as a matrix equation

(

(

(

(

(

(

(

(

(

(

=

(

(

(

(

(

(

(

(

(

=

(

(

(

(

d

c

b

a

d

c

b

a

u u u

u u u

u u u

u u u

r

r

r

r

1 1 1 1

1

27

2

27

4

27

8

1

3

1

9

1

27

1

1 0 0 0

1

1

1

1

4

2

4

3

4

3

2

3

3

3

2

2

2

3

2

1

2

1

3

1

4

3

2

1

or

Q U R =

0 0

Example: Hermite as 1D Cubic

I nterpolation Equation

3. Solve for the coefficients Q

0 0

1

0 0 0

R M R U Q Q U R

H

= =

4. Plug the coefficients into the cubic equation

d cu bu au u r + + + =

2 3

) (

5. Rewrite the cubic equation in the form

4 4 3 3 2 2 1 1

) ( ) ( ) ( ) ( ) ( r u N r u N r u N r u N u r + + + =

Example: Hermite as 1D Cubic

I nterpolation Equation

4 + 5. are equivalent to the steps

| |

(

(

(

(

=

= = =

4

3

2

1

4 3 2 1

0 0 0

) ( ) ( ) ( ) ( ) (

) ( ) ( ) (

r

r

r

r

u N u N u N u N u r

R M U R M U Q U u r

H H

values at the 4 nodes of the element

shape (blending) functions

Example: Hermite as 1D Cubic

I nterpolation Equation

1

0

=U

shape (blending) functions within one element

Let

u

r

t u H N

i i

= = ,

1D Elements

(x) (x)

(x)

Example: bungee

2D Elements

(x,y)

(x,y)

(x,y)

Example: cloth

3D Elements

(x,y,z)

(x,y,z)

Example: skin

Static analysis is good for engineering, to find

just the end result.

Dynamic analysis is good for simulation, to

find all intermediate steps.

Static vs. Dynamic FEM

Types of Global Models

[6]

Variational - Find the position function, w(t)

that minimizes the some variational integral.

This method is valid only if the position

computed satisfies the governing differential

equations.

Rayleigh-Ritz - Use the variational method

assuming some specific form of w(t) and

boundary conditions. Find the coefficients and

exponents of this assumed form of w(t).

Example of Variational Method

[6]

0 ) ( =

c

c

+ +

- - -

t f

w

w w

c

}

O

- - -

O

|

|

.

|

\

|

+ = d fw w w c w c w J 2

2

1

) (

1

2

2

c w b w a

w

+ =

c

c

- - -

c

0 ) (

) (

) (

3

2

1

= + =

+ =

+ =

f c c

b c

a c

Minimizing the variation w.r.t. w of the

variational function

under the conditions

satisfies the governing

equation, Lagranges

Equation

Galerkin (weighted residual) - Minimize the

residual of the governing differential equation,

F(w,w,w,,t) = 0. The residual is the form of

F that results by plugging a specific form of the

position function w(t) into F. Find the

coefficients and exponents of this assumed form

of w(t).

Types of Global Models

[6]

We can approximate w(t) using Hookes Law

0 ) ( =

c

c

+ +

- - -

t f

w

w w

c

Example of Galerkin Method

[6]

If we use that equation to compute the 1st and

2nd time derivatives of w, then we can compute

the residual as

(

~

(

(

(

(

(

) (

) (

) (

) (

1 1

1 1

1

2

1

2

1

1

0 0

0 0

t w

t w

E t f

E t f

L L

L L

E

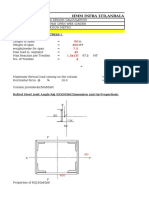

Example of Static, Elastic FEM

Problem: If you apply the pressure shown, what

is the resulting change in length?

Object

First step. Set up a continuum model:

F = force

P = pressure

A = area

L = initial length

E = Youngs modulus

|

.

|

\

|

A

= =

L

L

E

A

P

F

AE

PL

L = A

du

u h wE

PL

du

u wh E

PL

du

AE

PL

L

un

u

un

u

un

u

} } }

= = = A

0 0 0

) (

1

) (

1

Entire length:

Infinitessimal length:

Example of Static, Elastic FEM

Since the shape is regular, we can integrate to

find the solution analytically. But suppose we

want to find the solution numerically.

Next step. Discretize the object.

Example of Static, Elastic FEM

Example of Static, Elastic FEM

Discretization of object into

linear elements bounded by nodes

1

2 3

4

n

1

n

2

n

3

n

4

n

5

Example of Static, Elastic FEM

Next step. Set up a local model.

Stress-Strain Relationship (like Hookes Law)

0 , , 0 , ,

0

,

) ( ) ( L k r r k L r r k L k L

L

E

j i j i j i j i j i j i

j i

i

= = A A = o

0 , ,

) ( L k r r k

j i j i j i i j

+ + = = o o

Youngs modulus distance between adjacent nodes

stress (elastic force)

Example of Static, Elastic FEM

0 , ,

) ( L k r r k

j i j i j i i

= o

0 , ,

) ( L k r r k

j i j i j i j

+ + = o

(

=

(

+

(

=

(

j

i

j i j i

j i j i

j i j

j i i

j i

j i

j

i

j i j i

j i j i

j

i

r

r

k k

k k

L k

L k

L k

L k

r

r

k k

k k

, ,

, ,

0 ,

0 ,

0 ,

0 ,

, ,

, ,

o

o

o

o

(

=

(

+

+ + +

+ +

+ +

+

1 1 , 1 ,

1 , 1 ,

0 1 , 1

0 1 ,

j

j

j j j j

j j j j

j j j

j j j

r

r

k k

k k

L k

L k

o

o

Next step. Set up a local (element) stiffness matrix.

Rewrite the

above as a

matrix equation.

Same for the

adjacent element.

element stiffness matrix

nodal stresses

nodal coordinates

(

=

(

+

2

1

2 , 1 2 , 1

2 , 1 2 , 1

0 2 , 1 2

0 2 , 1 1

r

r

k k

k k

L k

L k

o

o

Example of Static, Elastic FEM

Now, all of the element stiffness matrices are as

follows.

(

=

(

+

3

2

3 , 2 3 , 2

3 , 2 3 , 2

0 3 , 2 3

0 3 , 2 2

r

r

k k

k k

L k

L k

o

o

(

=

(

+

4

3

4 , 3 4 , 3

4 , 3 4 , 3

0 4 , 3 4

0 4 , 3 3

r

r

k k

k k

L k

L k

o

o

(

=

(

+

5

4

5 , 4 5 , 4

5 , 4 5 , 4

0 5 , 4 5

0 5 , 4 4

r

r

k k

k k

L k

L k

o

o

1 2 3

4

n

1

n

2

n

3

n

4

n

5

r

i

is the x-coordinate of node u

i

Example of Static, Elastic FEM

Next step. Set up a global stiffness matrix.

Pad the element stiffness matrices with zeros

and sum them up. Example:

(

(

(

(

(

(

(

(

(

(

(

(

=

(

(

(

(

(

(

+

+

5

4

3

2

1

3 , 2 3 , 2

3 , 2 3 , 2

0 3 , 2 3

0 3 , 2 2

0 0 0 0 0

0 0 0 0 0

0 0 0

0 0 0

0 0 0 0 0

0

0

0

r

r

r

r

r

k k

k k

L k

L k

o

o

(

(

(

(

(

(

(

(

(

(

(

(

+

+

+

=

(

(

(

(

(

(

+

+ +

+ +

+ +

+

5

4

3

2

1

5 , 4 5 , 4

5 , 4 4 , 3 5 , 4 4 , 3

4 , 3 4 , 3 3 , 2 3 , 2

3 , 2 3 , 2 2 , 1 2 , 1

2 , 1 2 , 1

0 5 , 4 5

0 5 , 4 4 , 3 4

0 4 , 3 3 , 2 3

0 3 , 2 2 , 1 2

0 2 , 1 1

0 0 0

0 0

0 0

0 0

0 0 0

) (

) (

) (

r

r

r

r

r

k k

k k k k

k k k k

k k k k

k k

L k

L k k

L k k

L k k

L k

o

o

o

o

o

Example of Static, Elastic FEM

Final step. Solve the matrix equation for the

nodal coordinates.

Global stiffness matrix.

Captures material properties.

Nodal coordinates.

Solve for these!

Applied forces

Elastic FEM

A material is elastic if its behavior depends only

on its state during the previous time step.

Think: Finite state machine

The conditions under which an elastic

material behaves elastically are:

Force is small.

Force is applied slowly and steadily.

I nelastic FEM

A material is inelastic if its behavior depends on

all of its previous states.

A material may behave inelastically if:

Force is large - fracture, plasticity.

Force is applied suddenly and released, i.e., is

transient - viscoelasticity.

Conditions for elastic vs. inelastic depend on

the material.

Examples of Elasticity

Elasticity

Springs, rubber, elastic, with small, slowly-

applied forces

Examples of I nelasticity

Inelasticity

Viscoelasticity

Silly putty bounces under transient force (but

flows like fluid under steady force)

Plasticity

Taffy pulls apart much more easily under

more force (material prop.)

Fracture

Lever fractures under heavy load

Linear and Nonlinear FEM

Similarly to elasticity vs. inelasticity, there are

conditions for linear vs. nonlinear deformation.

Often these coincide, as in elastoplastic.

0

:

L

L

e Ee

A

= = o

= e

o

Hookes Law

Describes spring without damping

Linear range of preceding stress vs. strain graph

e a f

0

=

Elastic Deformation

Elastic vs. I nelastic FEM

e

e

t

loading unloading

0

:

L

L

e Ee

A

= = o

or

stress strain

Youngs modulus

o

o

Elastic vs. I nelastic FEM

Damped Elastic Deformation

e

e

t

loading unloading

e a e a f

0 1

+ =

-

viscous linear stress

Rate of deformation is constant.

o

o

a

1

e

.

a

1

e

.

Viscoelastic Deformation

Elastic vs. I nelastic FEM

e

e

t

loading unloading

.

e a e a e a f b f b f b

0 1 2 0 1 2

+ + = + +

- - - - - -

viscous new term!

This graph is actually viscous,

but viscoelastic is probably similar

Rate of deformation is greatest

immediately after starting

loading or unloading.

depends on time t

linear stress

o o o

o

Elastoplastic Deformation

Elastic vs. I nelastic FEM

e

This graph is actually plastic,

but viscoelastic is probably similar

f

e

x

x

compare

loading

unloading

loading

x

depends on force f

o

o

o

e

e a f

0

= o

Elastic vs. I nelastic FEM

Fracture

Force response is locally discontinuous

Fracture will propogate if energy release rate

is greater than a threshold

e

x

x

loading

unloading

depends on force f

o

1. World

coordinates w

in inertial frame

(a frame with

constant velocity)

2. Object

(material)

coordinates r

in non-inertial

frame

|

u

r(w,t) = r

ref

(w,t) + e(w,t)

Elastic vs. I nelastic

FEM

4,5

world, or

inertial frame

u

ref

r

object, or

non-inertial

frame

origin of

= center of mass in

|

u

|

Transform

reference

component r

ref

elastic component e

object frame

w.r.t. world frame

|

u

r(w,t) = r

ref

(w,t) + e(w,t)

Elastic vs. I nelastic

FEM

4,5

u

ref

r

|

Elastic vs. I nelastic FEM

All these equations are specific for:

Elasticity

Viscosity

Viscoelasticity

Plasticity

Elastoplasticity

Fracture

(not mentioned) Elastoviscoplasticity

Ideally: We want a general equation that will

fit all these cases.

Elastic vs. I nelastic

FEM

4,5

A More General Approach

To simulate dynamics we can use Lagranges

equation of strain force. At each timestep, the

force is calculated and used to update the

objects state (including deformation).

stress component

of force

w

w w t w f

c

c

+ + =

- - -

c

) , (

mass density damping density

elastic potential energy

Lagranges Equation

|

.

|

\

|

c

c

=

c

c

=

c

c

w

e

L

E

w

L

w

0

0

) / (o c

w

w w t w f

c

c

+ + =

- - -

c

) , (

Elastic vs. I nelastic

FEM

4,5

Given:

Mass density and damping density are known.

Elastic potential energy derivative w.r.t. r can be

approximated using one of various equations.

The current position w

t

of all nodes of the object

are known.

Unknown:

The new position w

t+dt

of nodes is solved for at

each timestep.

v

e

c

t

o

r

v

e

c

t

o

r

m

a

t

r

i

c

e

s

next slide

Lagranges

Equation

w

w w t w f

c

c

+ + =

- - -

c

) , (

dr

r

e

r

e

r

e

r

}

O

|

|

.

|

\

|

c

c

c

c

c

c

= ,... , , ,

3

3

2

2

c

Elastic vs. I nelastic

FEM

4,5

For both elastic and inelastic deformation,

express elastic potential energy as an integral

in terms of elastic potential energy density.

elastic potential energy density

elastic potential energy

Elastic vs. I nelastic

FEM

4,5

Elastic potential energy density can be

approximated using one of various equations

which incorporate material properties.

Elastic deformation: Use tensors called metric

(1D, 2D, 3D stretch), curvature (1D, 2D

bend), and twist (1D twist).

Inelastic deformation: Use controlled-

continuity splines.

Elastic FEM

4

For elastic potential energy density in 2D, use

metric tensors G (for stretch)

curvature tensors B (for bend)

2 0 2 0

|| || || || ) (

| o

B B G G r + =

|| M || = weighted norm of matrix M

Elastic FEM

4

Overview of derivation of metric tensor

Since the metric tensor G represents stretch, it

incorporates distances between adjacent points.

( )

( )

T

j i

j i

j i

j i

j i

j i

dr

dr

dr

dr

G G

G G

dr dr

dr dr

dr dr

dr dr

G G G G dr dr G

dr dr

r

w

r

w

dw dw dL

(

=

(

(

(

(

=

|

|

.

|

\

|

c

c

|

|

.

|

\

|

c

c

= =

=

=

2

1

2

1

2 , 2 1 , 2

2 , 1 1 , 1

2 2

1 2

2 1

1 1

2 , 2 1 , 2 2 , 1 1 , 1

2 , 1 ,

,

2 , 1 ,

2

1 1

world coordinates object coordinates

Elastic FEM

4

Overview of metric and curvature tensors.

From the previous slides, we found:

Similarly:

represents stretch

represents bend

Theorem. G and B together determine shape.

|

|

.

|

\

|

c

c

|

|

.

|

\

|

c

c

=

j i

j i

r

w

r

w

r w G )) ( (

,

|

|

.

|

\

|

c c

c

=

j i

j i

r r

w

r w B

2

,

)) ( (

Elastic FEM

4

For elastic FEM, elastic potential energy

density in 2D incorporates changes in the

metric tensor G and the curvature tensor B.

2 0 2 0

|| || || || ) (

| o

B B G G r + =

|| M || = weighted norm of matrix M

weights = material properties

I nelastic FEM

5

For inelastic FEM, elastic potential energy

density is represented as a controlled-

continuity spline.

= =

|

|

.

|

\

|

c c c

c

=

p

m m j

jd j j

m

j

j

d

e

r r r

w

j j j

m

0

2

| |

2 1

2 1

... ! !... !

!

2

1

For some degree p, dimensionality d, compute

the sum of sums of all combinations of

weighted 1

st

, 2

nd

,, mth derivatives of strain e

w.r.t. node location r, where m <= p.

weighting function = material property

= =

|

|

.

|

\

|

|

|

.

|

\

|

c c c

c

c c c

c

=

p

m m j

jd j j

m

j

j

d

jd j j

m

j

m

e

r r r

w

j j j

m

r r r e

0 | |

2 1

2 1

2 1

... ! !... !

!

...

1

o

o

I nelastic FEM

5

Then the elastic potential energy density

derivative w.r.t. strain e is:

weighting function = material property

|

|

.

|

\

|

|

|

.

|

\

|

c

c

c

c

+

|

|

.

|

\

|

|

|

.

|

\

|

c

c

c

c

+

|

|

.

|

\

|

|

|

.

|

\

|

c c

c

c c

c

+

|

|

.

|

\

|

|

|

.

|

\

|

c

c

c

c

|

|

.

|

\

|

|

|

.

|

\

|

c

c

c

c

=

e

r

w

r

e

r

w

r

e

r r

w

r r

e

r

w

r

e

r

w

r

e w

e

2

2

2

02

2

2

2

2

1

2

20

2

1

2

2 1

2

11

2 1

2

2

01

2 1

10

1

00

! 2 ! 0

! 2

! 0 ! 2

! 2

! 1 ! 1

! 2

! 1 ! 0

! 1

! 0 ! 1

! 1

! 0 ! 0

! 0

o

o

Example: p = 2, d = 3

w

w w t w f

c

c

+ + =

- - -

c

) , (

= =

|

|

.

|

\

|

|

|

.

|

\

|

c c c

c

c c c

c

=

p

m m j

jd j j

m

j

j

d

jd j j

m

j

m

e

r r r

w

j j j

m

r r r e

0 | |

2 1

2 1

2 1

... ! !... !

!

...

1

o

o

= =

|

|

.

|

\

|

c c c

c

=

p

m m j

jd j j

m

j

j

d

e

r r r

w

j j j

m

0

2

| |

2 1

2 1

... ! !... !

!

2

1

} |

|

.

|

\

|

c

c

c

c

c

c

=

u

dr

r

e

r

e

r

e

r ,... , , ,

2

2

2

2

c

Elastic vs. I nelastic

FEM

4,5

2 0 2 0

|| || || || ) (

| o

B B G G r + =

Inelastic

Elastic

Recap

Lagranges Eqn

total force

(includes stress)

elastic

potential energy

elastic potential

energy density

4

5

5

material properties

How it has been

expanded and is continuing

to be expanded...

o

w

w w t w f

c

c

+ + =

- - -

c

) , (

( ) ( ) ( )

}

O

=

+ ~ dr B B G G r

j i

j i j i

2 , 1 ,

2

0

,

2

0

,

) ( q c

Elastic FEM

4

Continuing

2 0 2 0

|| || || || ) (

| o

B B G G r + =

( )

0

, , , ,

) ( ) , (

j i j i j i j i

G G w w r =q o ( )

0

, , , ,

) ( ) , (

j i j i j i j i

G G w w r =, |

} |

|

.

|

\

|

c

c

c

c

c

c

=

u

dr

r

e

r

e

r

e

r ,... , , ,

2

2

2

2

c

elastic

potential

energy

>0: surface wants to shrink

<0: surface wants to expand

>0: surface wants to flatten

<0: surface wants to bend

w

w w t w f

c

c

+ + =

- - -

c

) , (

I nelastic FEM

5

Continuing

} |

|

.

|

\

|

c

c

c

c

c

c

=

u

dr

r

e

r

e

r

e

r ,... , , ,

2

2

2

2

c

= =

|

|

.

|

\

|

|

|

.

|

\

|

c c c

c

c c c

c

=

p

m m j

jd j j

m

j

j

d

jd j j

m

j

m

e

r r r

w

j j j

m

r r r e

0 | |

2 1

2 1

2 1

... ! !... !

!

...

1

o

o

Deformation has been modeled by

approximating elastic potential energy.

elastic potential energy

elastic potential

energy density

strain

I nelastic FEM

5

Continuing

Now rigid-body motion and other aspects of

deformation must be computed using physics

equations of motion.

In this way, both (in)elastic deformation and

rigid-body motion can be modeled, providing a

very general framework.

r(w,t) = r

ref

(w,t) + e(w,t)

) , ( ) ( ) ( ) ( ) , ( t r e t c t t c t r w

- - - -

+ + = u

I nelastic FEM

5

Motion of object (non-inertial) frame w.r.t.

world (inertial) frame

}

O

= dr t r w r t c ). , ( ) ( ) (

dr t r w dr t r e

dt

d

c m

dt

d

f

v

. ) , ( . ) , ( ) (

} }

O

-

O

- -

+ + =

} }

O

-

O

- -

+ + = dr w r dr e r

dt

d

I

dt

d

f . . ) ( u

e

e

w r e r c e

dt

d

t f

e

o

oc

u u u u o + + + + + + =

- - - - - - - - - -

2 ) ( ) ( ) (

w

w w t w f

c

c

+ + =

- - -

c

) , (

Combines

dynamics of

deformable

and rigid

bodies

elastic

rot

trans

) , ( ) ( ) ( ) ( ) , ( t r e t c t t c t r w

- - - -

+ + = u

I nelastic FEM

5

Velocity of node of object (non-inertial) frame

w.r.t. world (inertial) frame

(radians / sec) x (radius)

Identically, in another

coordinate system,

r(w,t) =r

ref

(w,t) +e(w,t)

w.r.t. object

velocity of reference

component

velocity of elastic

component

w.r.t. world

w

w w t w f

c

c

+ + =

- - -

c

) , (

) , ( t r w

u

|

) (t u

) (t c

) (t e

} }

O

-

O

- -

+ + = dr w r dr e r

dt

d

I

dt

d

f . . ) ( u

e

I nelastic FEM

5 w

w w t w f

c

c

+ + =

- - -

c

) , (

rot

}

O

|

|

|

.

|

\

|

+

+

+

= ) (

) (

) (

) ) (

) (

2

3

2

2 2 3 1 3

3 2

2

3

2

1 1 2

3 1 2 1

2

3

2

2

t dw

w w w w w w

w w w w w w

w w w w w w

t I

angular momentum

inertia tensor

Angular momentum is conserved in the absense

of force. So a time-varying angular momentum

indicates the presence of foce.

} }

O

-

O

- -

+ + = dr w r dr e r

dt

d

I

dt

d

f . . ) ( u

e

I nelastic FEM

5 w

w w t w f

c

c

+ + =

- - -

c

) , (

rot

indicates changing angle between position and direction of stretch

) (t r

) (t e

-

I nelastic FEM

5 w

w w t w f

c

c

+ + =

- - -

c

) , (

e

w r e r c e

dt

d

t f

e

o

oc

u u u u o + + + + + + =

- - - - - - - - - -

2 ) ( ) ( ) (

elastic

inertial centripetal Coriolis transverse damping

elastic potential energy strain

restoring

If the reference component has no translation or

rotation, then

e

e

dt

d

t f

e

o

oc

o + =

-

) ( ) (

e

t f

e

o

oc

o = ) (

Furthermore, if the elastic component has no

acceleration, then

I nelastic FEM

5 w

w w t w f

c

c

+ + =

- - -

c

) , (

Recall that non-elastic behavior is characterized

by acceleration of the elastic component

(strain)...

e

e

dt

d

t f

e

o

oc

o + =

-

) ( ) (

e

t f

e

o

oc

o = ) (

And elastic behavior is characterized by

constant velocity of strain.

loading

x

o

e

e a f

0

= o

Now Lagranges equation has been expanded.

Final Steps

Discretize using finite differences (rather than

derivatives).

Write as a matrix times a vector of nodal

coordinates (rather than a single mass point).

Solve for the objects new set of positions of

all nodes.

Elastic vs. I nelastic

FEM

4,5

w

w w t w f

c

c

+ + =

- - -

c

) , (

Discretization of FEM

4,5

w

w w t w f

c

c

+ + =

- - -

c

) , (

w

w C w M t f

c

c

+ + =

- - -

c

) (

Discretize Lagranges equation over all nodes

Procedure described in [4] but not [5]

t t t t t t t t

t t t t t t t

t t t

t t t

t t

t t t t t t t

t t t

t t t t t t t t t

t t t t t t t t

t t t t t t

v C M

t

w C

t

M

t

w w g w K

t

M

t

A

where w w g w A

v C M

t

w C

t

M

t

f

t

w w

C M

t

w C

t

M

t

f

w C

t

M

t

w M

t

f w w K

t

M

t

w w K

t

w w

C

t

w w w

M

w w K w CD w D MD

f w w K

t

w

C

t

w

M

|

.

|

\

|

+

A

|

.

|

\

|

A

+

A

|

.

|

\

|

+

A

+

A

=

|

.

|

\

|

+

A

|

.

|

\

|

A

+

A

+ ~

A

|

.

|

\

|

+

A

|

.

|

\

|

A

+

A

+ =

|

.

|

\

|

A

+

A

|

.

|

\

|

A

+ =

|

.

|

\

|

+

A

+

A

+

A

+

A

+

=

+ + ~

= +

c

c

+

c

c

A

A A +

A

A A +

A +

A A + A A +

A +

+ +

A + A + A +

2

1 1

2

1 3

) , ( , ) (

2

1 1

_ ) , (

2

1 1

2

1 3

2

1 1

2

1 3

2

1 1 2

) (

2

1 1

) (

2

2

) ( ) ( )) ( (

) (

2 2

2

2

2 2 2

2

2

2

Discretization of Elastic FEM

4

Results of Elastic FEM

4

Results of Elastic FEM

4

Results of Elastic FEM

4

3D plasticine bust of Victor Hugo.

180 x 127 mesh; 68,580 equations.

Results of I nelastic FEM

5

Results of I nelastic FEM

5

Sphere pushing through 2D mesh.

23 x 23 mesh; 1,587 equations.

Yield limit is uniform, causing linear tears.

Results of I nelastic FEM

5

2D paper tearing by opposing forces.

30 x 30 mesh; 2,700 equations.

Yield limit is perturbed stochastically,

causing randomly-propogating tears.

References

0. David Baraff. Rigid Body Simulation.

Physically Based Modeling, SIGGRAPH

Course Notes, August 2001.

1. George Buchanan. Schaums Outlines:

Finite Element Analysis. McGraw-Hill, 1995.

2. Peter Hunter and Andrew Pullan. FEM/BEM

Notes. The University of Auckland, New

Zealand, February 21 2001.

References

3. Tom Lassanske. [Slides from class lecture]

4. Demetri Terzopoulost, John Platt, Alan Barr,

and Kurt Fleischert. Elastically Deformable

Models. Computer Graphics, Volume 21,

Number 4, July 1987.

5. Demetri Terzopoulos and Kurrt Fleiseher.

Modeling Inelastic Deformation:

Viscoelasticity, Plasticity, Fracture. Computer

Graphics, Volume 22, Number 4, August 1988

Notation

density energy potential elastic

energy potential elastic

ulus s Young E

f orce stress

stretch strain e

s coordinate world w

s coordinate object r

_ _ _

_ _

mod _ '

) _(

) _(

_

_

c

o

Potrebbero piacerti anche

- Chapter 16Documento43 pagineChapter 16German ToledoNessuna valutazione finora

- Finite Element Technology: Lecture NotesDocumento63 pagineFinite Element Technology: Lecture NotesJuan Francisco Acuña ContrerasNessuna valutazione finora

- Finite Element Method: X X X F N Da FN DV X FDocumento11 pagineFinite Element Method: X X X F N Da FN DV X FChandra ClarkNessuna valutazione finora

- Mechanics of Solids Week 10 LecturesDocumento9 pagineMechanics of Solids Week 10 LecturesFlynn GouldNessuna valutazione finora

- Module 1Documento45 pagineModule 1MD SHAHRIARMAHMUDNessuna valutazione finora

- Finite Element Shape Functions ExplainedDocumento7 pagineFinite Element Shape Functions ExplainedMusab AinekarNessuna valutazione finora

- Finite Element Methods (FEM) : Suzanne Vogel COMP 259 Spring, 2002Documento73 pagineFinite Element Methods (FEM) : Suzanne Vogel COMP 259 Spring, 2002Salam FaithNessuna valutazione finora

- 4-Noded Rectangular Element Finite Element FormulationDocumento27 pagine4-Noded Rectangular Element Finite Element FormulationMathiew EstephoNessuna valutazione finora

- Fea QBDocumento11 pagineFea QBPradeepNessuna valutazione finora

- Rigid BodyDocumento9 pagineRigid BodyChernet TugeNessuna valutazione finora

- Wave Equation Applications in Peridynamic Model: Hisham M. Ali HasanDocumento5 pagineWave Equation Applications in Peridynamic Model: Hisham M. Ali Hasansar0000Nessuna valutazione finora

- QM Identical Particles ProblemsDocumento8 pagineQM Identical Particles ProblemsStephen MitchellNessuna valutazione finora

- Preface: Gebze Institute of High TechnologyDocumento8 paginePreface: Gebze Institute of High TechnologyOnur Furkan CakıllıNessuna valutazione finora

- Physics 430 Lecture on Inertia Tensor and Principal AxesDocumento17 paginePhysics 430 Lecture on Inertia Tensor and Principal AxesKenn SenadosNessuna valutazione finora

- FEM - Course NoteDocumento73 pagineFEM - Course NoteSyh TfkNessuna valutazione finora

- Reduction of Finite Element Models of Complex Mechanical ComponentsDocumento5 pagineReduction of Finite Element Models of Complex Mechanical ComponentsAnonymous lEBdswQXmxNessuna valutazione finora

- 10-Linear Strain Triangle and Other Types of 2d ElementsDocumento31 pagine10-Linear Strain Triangle and Other Types of 2d Elementskranthi142434Nessuna valutazione finora

- Chap 1 Preliminary Concepts: Nkim@ufl - EduDocumento20 pagineChap 1 Preliminary Concepts: Nkim@ufl - Edudozio100% (1)

- Linear Statics Fem Hand OutDocumento45 pagineLinear Statics Fem Hand OutMohamed BarakizouNessuna valutazione finora

- Plane Stress and Strain Elements in Finite Element AnalysisDocumento6 paginePlane Stress and Strain Elements in Finite Element AnalysisPichak SnitsomNessuna valutazione finora

- Modeling and Mathematical Formulation: 4-1: Finite Element FormulationsDocumento24 pagineModeling and Mathematical Formulation: 4-1: Finite Element FormulationsHusseinali HusseinNessuna valutazione finora

- Week 9 Labview: "Numerical Solution of A Second-Order Linear Ode"Documento5 pagineWeek 9 Labview: "Numerical Solution of A Second-Order Linear Ode"Michael LiNessuna valutazione finora

- Paper 23-A New Type Method For The Structured Variational Inequalities ProblemDocumento4 paginePaper 23-A New Type Method For The Structured Variational Inequalities ProblemEditor IJACSANessuna valutazione finora

- Derivatives and ApplicationDocumento14 pagineDerivatives and Applicationmuhammed shwanyNessuna valutazione finora

- L05 SimpleOscillationsDocumento14 pagineL05 SimpleOscillationsliuzihan32320Nessuna valutazione finora

- SHM Review - SHM Using Differential Equations - Critical DampingDocumento18 pagineSHM Review - SHM Using Differential Equations - Critical Dampingaaljuhani123Nessuna valutazione finora

- MTamis ConstraintBasedPhysicsSolverDocumento31 pagineMTamis ConstraintBasedPhysicsSolverlucianobuglioniNessuna valutazione finora

- FEM Exam With SolutionDocumento8 pagineFEM Exam With SolutionArifian Agusta100% (2)

- Chapter 7 - Finite Element Method For Solid Mechanics (2016!10!10)Documento80 pagineChapter 7 - Finite Element Method For Solid Mechanics (2016!10!10)RickNessuna valutazione finora

- Chapter 7 - Finite Element Method For Solid Mechanics (2016!09!14)Documento17 pagineChapter 7 - Finite Element Method For Solid Mechanics (2016!09!14)RickNessuna valutazione finora

- Aim:-Study of FEM (Finite Element Method) Finite-Element MethodDocumento9 pagineAim:-Study of FEM (Finite Element Method) Finite-Element MethodAshley Silvester AnthonyNessuna valutazione finora

- Global Stiffness MatrixDocumento13 pagineGlobal Stiffness Matrixasfsaf0% (1)

- Physics430 Lecture15Documento16 paginePhysics430 Lecture15Onimash RajuNessuna valutazione finora

- Fermion Field OperatorsDocumento7 pagineFermion Field OperatorsSwarnav BanikNessuna valutazione finora

- Andersson Djehiche - AMO 2011Documento16 pagineAndersson Djehiche - AMO 2011artemischen0606Nessuna valutazione finora

- Markov Semigroups: Paolo GuiottoDocumento26 pagineMarkov Semigroups: Paolo GuiottoChristina JonesNessuna valutazione finora

- Sheet - Ansys, SpringbackDocumento9 pagineSheet - Ansys, Springbacksupersonny007Nessuna valutazione finora

- Tasi2022 002Documento11 pagineTasi2022 002lev76Nessuna valutazione finora

- An Introduction To Finite Element Methods: Jass 05 Seminar: Interplay of Mathematical Modeling and Numerical SimulationDocumento16 pagineAn Introduction To Finite Element Methods: Jass 05 Seminar: Interplay of Mathematical Modeling and Numerical Simulationaviraj2006Nessuna valutazione finora

- Flatness and Motion Planning: The Car With: N TrailersDocumento6 pagineFlatness and Motion Planning: The Car With: N TrailersgeneralgrievousNessuna valutazione finora

- 2 Finite Element MethodDocumento25 pagine2 Finite Element MethodShuhang ChenNessuna valutazione finora

- On convergence rates in central limit theoremsDocumento18 pagineOn convergence rates in central limit theoremsValerio CambareriNessuna valutazione finora

- Lecture 3Documento150 pagineLecture 3Kedir ShiferawNessuna valutazione finora

- Chapter 3 - Multiple Random Variables-UpdatedDocumento25 pagineChapter 3 - Multiple Random Variables-Updatedfarouq_razzaz2574Nessuna valutazione finora

- Discret HamzaouiDocumento19 pagineDiscret HamzaouiPRED ROOMNessuna valutazione finora

- Optimal Control of Film Casting ProcessesDocumento12 pagineOptimal Control of Film Casting ProcessesmozoceNessuna valutazione finora

- Checkerboard Instabilities in Topological Shape Optimization AlgorithmsDocumento5 pagineCheckerboard Instabilities in Topological Shape Optimization Algorithmsvishal kumar sinhaNessuna valutazione finora

- Stabilization of Euler-Bernoulli Plate Equation With Variable Coefficients by Nonlinear Boundary FeedbackDocumento21 pagineStabilization of Euler-Bernoulli Plate Equation With Variable Coefficients by Nonlinear Boundary FeedbackAndrew ThomasNessuna valutazione finora

- Formulas IPhODocumento4 pagineFormulas IPhOShivam GargNessuna valutazione finora

- Survey of Finite Element Shape FunctionsDocumento9 pagineSurvey of Finite Element Shape FunctionsvtalatsNessuna valutazione finora

- Node Nodal Degrees of Freedom: 1. The Definition of The Finite Element Method (FEM)Documento32 pagineNode Nodal Degrees of Freedom: 1. The Definition of The Finite Element Method (FEM)KomarudinNessuna valutazione finora

- Solid Mechanics Airy Stress FunctionsDocumento20 pagineSolid Mechanics Airy Stress FunctionsJoshua Mamouney100% (2)

- Some Operation Equation and ApplicationsDocumento10 pagineSome Operation Equation and ApplicationsIJMERNessuna valutazione finora

- Difference Equations in Normed Spaces: Stability and OscillationsDa EverandDifference Equations in Normed Spaces: Stability and OscillationsNessuna valutazione finora

- Geometric functions in computer aided geometric designDa EverandGeometric functions in computer aided geometric designNessuna valutazione finora

- Elementary Differential Equations with Linear AlgebraDa EverandElementary Differential Equations with Linear AlgebraNessuna valutazione finora

- A-level Maths Revision: Cheeky Revision ShortcutsDa EverandA-level Maths Revision: Cheeky Revision ShortcutsValutazione: 3.5 su 5 stelle3.5/5 (8)

- Mathematics 1St First Order Linear Differential Equations 2Nd Second Order Linear Differential Equations Laplace Fourier Bessel MathematicsDa EverandMathematics 1St First Order Linear Differential Equations 2Nd Second Order Linear Differential Equations Laplace Fourier Bessel MathematicsNessuna valutazione finora

- Daftai Isi Pengesahan Tesis DARMADIDocumento16 pagineDaftai Isi Pengesahan Tesis DARMADIDarmadiNessuna valutazione finora

- InventarisasiDocumento14 pagineInventarisasiDarmadiNessuna valutazione finora

- POint As ParigiDocumento11 paginePOint As ParigiDarmadiNessuna valutazione finora

- Domino GameDocumento2 pagineDomino GameDarmadiNessuna valutazione finora

- Pile 2013Documento5 paginePile 2013DarmadiNessuna valutazione finora

- DoktorDocumento53 pagineDoktorDarmadiNessuna valutazione finora

- CP Vehicle TrackingDocumento16 pagineCP Vehicle TrackingDarmadiNessuna valutazione finora

- Cover TRANSPORT Mass Transit OptionsDocumento1 paginaCover TRANSPORT Mass Transit OptionsDarmadiNessuna valutazione finora

- TVM Formulas (I, N)Documento2 pagineTVM Formulas (I, N)basco23Nessuna valutazione finora

- Jagakarsa KuliaheDocumento2 pagineJagakarsa KuliaheDarmadiNessuna valutazione finora

- Tunnel - Calculation Lining Design LRFDDocumento62 pagineTunnel - Calculation Lining Design LRFDDarmadiNessuna valutazione finora

- P MsgsDocumento1 paginaP MsgsDarmadiNessuna valutazione finora

- Serial Ms Project 2010Documento1 paginaSerial Ms Project 2010DarmadiNessuna valutazione finora

- B-84524-RW-PP0-PFD-ST-21-0001 - Rawa Station Storages and Pumps - IFA Rev.0BDocumento1 paginaB-84524-RW-PP0-PFD-ST-21-0001 - Rawa Station Storages and Pumps - IFA Rev.0BDarmadiNessuna valutazione finora

- B-84524-RW-PP0-PFD-ST-23-0002 - Rawa Station HP Compression and Dehydration - IFA Rev.0BDocumento1 paginaB-84524-RW-PP0-PFD-ST-23-0002 - Rawa Station HP Compression and Dehydration - IFA Rev.0BDarmadiNessuna valutazione finora

- UAS Tek LingDocumento1 paginaUAS Tek LingDarmadiNessuna valutazione finora

- B 84524 RW PP0 PID ST 3P 0008 - Central Rawa Facilities LP Production SeparatorDocumento1 paginaB 84524 RW PP0 PID ST 3P 0008 - Central Rawa Facilities LP Production SeparatorDarmadiNessuna valutazione finora

- Serial Ms Project 2010Documento1 paginaSerial Ms Project 2010DarmadiNessuna valutazione finora

- Lat UASTek LingDocumento1 paginaLat UASTek LingDarmadiNessuna valutazione finora

- Tentative ScheduleDocumento4 pagineTentative ScheduleDarmadiNessuna valutazione finora

- Pile 2013Documento5 paginePile 2013DarmadiNessuna valutazione finora

- Serial Ms Project 2010Documento1 paginaSerial Ms Project 2010DarmadiNessuna valutazione finora

- Serial Ms Project 2010Documento1 paginaSerial Ms Project 2010DarmadiNessuna valutazione finora

- UAS Tek LingDocumento1 paginaUAS Tek LingDarmadiNessuna valutazione finora

- Serial Windows OfficeDocumento1 paginaSerial Windows OfficeDarmadiNessuna valutazione finora

- MIDAS Civil Analysis ManualDocumento316 pagineMIDAS Civil Analysis Manualmadepao75% (4)

- Puri Indah Mall Expansion Variation Order NotificationDocumento2 paginePuri Indah Mall Expansion Variation Order NotificationDarmadiNessuna valutazione finora

- SMP Islam Al Azhar 10 - Dar4Documento1 paginaSMP Islam Al Azhar 10 - Dar4DarmadiNessuna valutazione finora

- Tun Drum GMB-Community Forum - ViewDocumento10 pagineTun Drum GMB-Community Forum - ViewDarmadiNessuna valutazione finora

- Evaluation of Seismic Displacements of Quay WallsDocumento9 pagineEvaluation of Seismic Displacements of Quay WallsOzgur GungorduNessuna valutazione finora

- Fastening Technical Guide: Triangle Fastener CorporationDocumento28 pagineFastening Technical Guide: Triangle Fastener CorporationGerman GonzalezNessuna valutazione finora

- Experimental Rock Deformation The Brittle Field PDFDocumento2 pagineExperimental Rock Deformation The Brittle Field PDFZach0% (3)

- Material Hardness Conversion TableDocumento3 pagineMaterial Hardness Conversion TableJessicalba LouNessuna valutazione finora

- Design of FlyingWall To Box CulvertDocumento6 pagineDesign of FlyingWall To Box CulvertVivek PremjiNessuna valutazione finora

- Connection 2Documento19 pagineConnection 2Der3'am Al m7armehNessuna valutazione finora

- Lecture 4-2-2 - Design of Compression Members NewDocumento47 pagineLecture 4-2-2 - Design of Compression Members NewHarold Jackson MtyanaNessuna valutazione finora

- Lecture 27 Intro Slipline Field TheoryDocumento14 pagineLecture 27 Intro Slipline Field TheoryprasannaNessuna valutazione finora

- Seismic Design of BridgesDocumento20 pagineSeismic Design of BridgesIon PusculitaNessuna valutazione finora

- Design For Beams: Prepared By: Engr. Jo Ann C. CeledioDocumento28 pagineDesign For Beams: Prepared By: Engr. Jo Ann C. CeledioMugiwara SparrowNessuna valutazione finora

- CEG605.1 Advanced Soil Mechanics THDocumento2 pagineCEG605.1 Advanced Soil Mechanics THameykatdareNessuna valutazione finora

- 03 Mechanical Properties of MaterialsDocumento84 pagine03 Mechanical Properties of MaterialsMuhammad Khan Khoso100% (5)

- A Comprehensive Fatigue Life Predictive Model ForDocumento19 pagineA Comprehensive Fatigue Life Predictive Model ForMoeen Iqbal ShahNessuna valutazione finora

- Design calculations for 60m span open web girder trestleDocumento10 pagineDesign calculations for 60m span open web girder trestleAnonymous sfkedkymNessuna valutazione finora

- Structural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 2015Documento11 pagineStructural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 2015fahmi aballiNessuna valutazione finora

- Excel Calculation For Column 5Documento17 pagineExcel Calculation For Column 5ariaNessuna valutazione finora

- 1 - R-633 Structural Concept Report - Stage 2 - 2012-09-13Documento19 pagine1 - R-633 Structural Concept Report - Stage 2 - 2012-09-13Parth Daxini100% (1)

- CH 04Documento135 pagineCH 04RODRIGO JAVIER BRIZUELA PADILLANessuna valutazione finora

- Earth Science PuzzleDocumento2 pagineEarth Science PuzzleSSha100% (2)

- MAT Foundation DesignDocumento35 pagineMAT Foundation DesignHim Yilay100% (2)

- Seismic Analysis of High-Rise Buildings (G+30) by Using ETABSDocumento9 pagineSeismic Analysis of High-Rise Buildings (G+30) by Using ETABSHema Chandra Reddy KarimireddyNessuna valutazione finora

- Canterbury Decoding Eurocode 7Documento0 pagineCanterbury Decoding Eurocode 7Mahmoud Moustafa ElnegihiNessuna valutazione finora

- 6 - Soil Data in Orcaflex-Y.T.kimDocumento9 pagine6 - Soil Data in Orcaflex-Y.T.kimYoungtae KimNessuna valutazione finora

- Percolation Test Procedure PDFDocumento31 paginePercolation Test Procedure PDFMohamed YasinNessuna valutazione finora

- 2012 Mondal Et Al SDEE Simplified Seismic AnalysisDocumento15 pagine2012 Mondal Et Al SDEE Simplified Seismic AnalysisNishit ShandilyaNessuna valutazione finora

- Challenging Foundations for Tall BuildingsDocumento27 pagineChallenging Foundations for Tall BuildingsRENZZ IRVIN DELA TORRENessuna valutazione finora

- Time Dependent Analysis of Tunnel in Creeping RockDocumento257 pagineTime Dependent Analysis of Tunnel in Creeping RockManimaran PNessuna valutazione finora

- Development of A Hyperbolic Constitutive Model For Expanded Polystyrene (EPS) Geofoam Under Triaxial Compression TestsDocumento15 pagineDevelopment of A Hyperbolic Constitutive Model For Expanded Polystyrene (EPS) Geofoam Under Triaxial Compression TestsBao TruongNessuna valutazione finora

- Scenario For Effect of Leaching On NC and OC ClaysDocumento4 pagineScenario For Effect of Leaching On NC and OC Claysshuri080Nessuna valutazione finora