Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boiler Efficiency

Caricato da

Manoj PaneriDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Boiler Efficiency

Caricato da

Manoj PaneriCopyright:

Formati disponibili

Assessment of a Boiler 1.

Boiler performance

Causes of poor boiler performance

-Poor combustion -Heat transfer surface fouling -Poor operation and maintenance -Deteriorating fuel and water quality

Heat balance: identify heat losses

Boiler efficiency: determine deviation from best efficiency

1

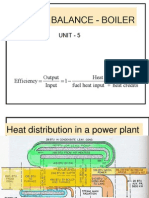

Assessment of a Boiler Heat Balance

An energy flow diagram describes geographically how energy is transformed from fuel into useful energy, heat and losses

Stochiometric Excess Air Un burnt

Stack Gas

FUEL INPUT

STEAM OUTPUT

Convection & Radiation

Blow Down

Ash and Un-burnt parts of Fuel in Ash

Assessment of a Boiler Heat Balance

Balancing total energy entering a boiler against the energy that leaves the boiler in different forms

12.7 % 8.1 % Heat loss due to dry flue gas Heat loss due to steam in fuel gas Heat loss due to moisture in fuel Heat loss due to moisture in air Heat loss due to unburnts in residue Heat loss due to radiation & other unaccounted loss

100.0 % BOILER Fuel

1.7 % 0.3 % 2.4 % 1.0 %

73.8 %

Heat in Steam

Assessment of a Boiler Heat Balance

Goal: improve energy efficiency by reducing avoidable losses

Avoidable losses include:

- Stack gas losses (excess air, stack gas temperature) - Losses by unburnt fuel - Blow down losses

- Condensate losses

- Convection and radiation

4

Assessment of a Boiler Boiler Efficiency

Thermal efficiency: % of (heat) energy input that is effectively useful in the generated steam

BOILER EFFICENCY CALCULATION

1)

DIRECT METHOD:

2) INDIRECT METHOD:

The efficiency is the different between losses and energy input

The energy gain of the working fluid (water and steam) is compared with the energy content of the boiler fuel.

Assessment of a Boiler Boiler Efficiency: Direct Method

Boiler efficiency () = Heat Input x 100 Q x (hg hf) x 100 = Heat Output Q x GCV

hg -the enthalpy of saturated steam in kcal/kg of steam hf -the enthalpy of feed water in kcal/kg of water Parameters to be monitored: - Quantity of steam generated per hour (Q) in kg/hr - Quantity of fuel used per hour (q) in kg/hr - The working pressure (in kg/cm2(g)) and superheat temperature (oC), if any - The temperature of feed water (oC) - Type of fuel and gross calorific value of the fuel (GCV) in 6 kcal/kg of fuel

Assessment of a Boiler Boiler Efficiency: Indirect Method

Efficiency of boiler () = 100 (i+ii+iii+iv+v+vi+vii)

Principle losses:

i) Dry flue gas ii) Evaporation of water formed due to H2 in fuel iii) Evaporation of moisture in fuel iv) Moisture present in combustion air v) Unburnt fuel in fly ash vi) Unburnt fuel in bottom ash vii) Radiation and other unaccounted losses

Assessment of a Boiler Boiler Efficiency: Indirect Method

Required calculation data

Ultimate analysis of fuel (H2, O2, S, C, moisture content, ash content) % oxygen or CO2 in the flue gas Fuel gas temperature in C (Tf) Ambient temperature in C (Ta) and humidity of air in kg/kg of dry air GCV of fuel in kcal/kg % combustible in ash (in case of solid fuels) GCV of ash in kcal/kg (in case of solid fuels)

8

Potrebbero piacerti anche

- Boilers Efficiency & Boiler Heat BalanceDocumento13 pagineBoilers Efficiency & Boiler Heat BalanceNipun Sabharwal100% (1)

- STEAM GENERATOR Part 1Documento62 pagineSTEAM GENERATOR Part 1Habtamu Tkubet EbuyNessuna valutazione finora

- Konservasi Enegri Pada Ketel Uap - CompressedDocumento66 pagineKonservasi Enegri Pada Ketel Uap - CompressedDedi HermansyahNessuna valutazione finora

- Boilers and Thermic Fluid HeatersDocumento53 pagineBoilers and Thermic Fluid HeatersAamirMalikNessuna valutazione finora

- Boilers and Thermic Fluid HeatersDocumento54 pagineBoilers and Thermic Fluid HeatersAmit ChauhanNessuna valutazione finora

- BoileroperatioDocumento53 pagineBoileroperatioSsheshan PugazhendhiNessuna valutazione finora

- Boiler EfficiencyDocumento32 pagineBoiler Efficiencyelsayed100% (1)

- Steam Generator: Safety: Critical ConcernDocumento59 pagineSteam Generator: Safety: Critical ConcernpatlninadNessuna valutazione finora

- 4.10.4 Performance Evaluation of BoilersDocumento7 pagine4.10.4 Performance Evaluation of BoilersGanti AsegarNessuna valutazione finora

- Performance Evaluation of Boilers: Avinash Raj 17BME0136Documento36 paginePerformance Evaluation of Boilers: Avinash Raj 17BME0136Rashmi KumariNessuna valutazione finora

- Boiler and Steam SystemDocumento33 pagineBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Boiler EfficiencyDocumento32 pagineBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Determining Boiler EfficiencyDocumento7 pagineDetermining Boiler EfficiencySuprio KamalNessuna valutazione finora

- Energyauditofboiler 161207011009Documento38 pagineEnergyauditofboiler 161207011009Randy PrandykaNessuna valutazione finora

- Energy Performance Assessment of BoilersDocumento43 pagineEnergy Performance Assessment of BoilersPradyumna Dhamangaonkar100% (1)

- Boiler Efficiency-An AnalysisDocumento18 pagineBoiler Efficiency-An AnalysisDebasish ChowdhuryNessuna valutazione finora

- Boiler Basics Workshop - FINALDocumento87 pagineBoiler Basics Workshop - FINALAhmed GadNessuna valutazione finora

- PC Versus FBCDocumento4 paginePC Versus FBCanilkumarv123Nessuna valutazione finora

- Boiler efficiency calculation methods direct indirectDocumento8 pagineBoiler efficiency calculation methods direct indirectVISHAL GANGWARNessuna valutazione finora

- Boiler EfficiencyDocumento28 pagineBoiler Efficiencybzkizo_sbbNessuna valutazione finora

- Boiler EfficiencyDocumento24 pagineBoiler EfficiencyAmit ChauhanNessuna valutazione finora

- 4.1 BoilerDocumento28 pagine4.1 Boilerrashm006ranjanNessuna valutazione finora

- 2 ERG 401 2015 Energy Performance Analysis of BOILERDocumento57 pagine2 ERG 401 2015 Energy Performance Analysis of BOILERnaveenNessuna valutazione finora

- 2.2 Boilers - Revised (Table Format)Documento11 pagine2.2 Boilers - Revised (Table Format)Gajanan JagtapNessuna valutazione finora

- Boiler DesignDocumento10 pagineBoiler DesignbobNessuna valutazione finora

- Boiler AnalysisDocumento52 pagineBoiler AnalysisRakesh GairolaNessuna valutazione finora

- Boilers and Thermic Fluid HeatersDocumento54 pagineBoilers and Thermic Fluid HeatersG.RameshNessuna valutazione finora

- Boiler QuestionsDocumento39 pagineBoiler Questionssk3146100% (11)

- unitiveam-140916060902-phpapp02Documento56 pagineunitiveam-140916060902-phpapp02BRAHIMNessuna valutazione finora

- Loss Optimisation in BoilersDocumento50 pagineLoss Optimisation in Boilersrashm006ranjanNessuna valutazione finora

- Q A BoilerDocumento19 pagineQ A Boilerlavpandey8719Nessuna valutazione finora

- Heat Losses in BoilersDocumento5 pagineHeat Losses in Boilersgad480Nessuna valutazione finora

- Energy Conservation: Topic "Boiler"Documento38 pagineEnergy Conservation: Topic "Boiler"Ghazanfar GulNessuna valutazione finora

- lect-6-Boiler AnalysisDocumento38 paginelect-6-Boiler Analysiskhan janNessuna valutazione finora

- Waste Heat Recovery Devices and ApplicationsDocumento18 pagineWaste Heat Recovery Devices and Applicationsdivyank3dNessuna valutazione finora

- Unit Heat RateDocumento7 pagineUnit Heat RateSelvaNessuna valutazione finora

- Y.pabbI - 28 July 15 - EE ImpOperatg PlantsDocumento56 pagineY.pabbI - 28 July 15 - EE ImpOperatg Plantsamerie joy onateNessuna valutazione finora

- Boilers 101 PDFDocumento27 pagineBoilers 101 PDFsppatilNessuna valutazione finora

- HEAT BALANCE BOILER UNIT 5Documento18 pagineHEAT BALANCE BOILER UNIT 5hafidhrahadiyan2Nessuna valutazione finora

- 3) Module - 1 Performance of Steam GeneratorsDocumento22 pagine3) Module - 1 Performance of Steam GeneratorsA48Rayan PereiraNessuna valutazione finora

- WASTE HEAT RECOVERY (HRSG) PerformanceDocumento17 pagineWASTE HEAT RECOVERY (HRSG) PerformanceEjaz AhmedNessuna valutazione finora

- Energy Audit & Efficiency Improvement of Operating Power PlantsDocumento56 pagineEnergy Audit & Efficiency Improvement of Operating Power Plantsmhdsoleh100% (1)

- Energy Conservation BoilerDocumento38 pagineEnergy Conservation BoilerDeepak Kumar SinghNessuna valutazione finora

- Boiler RatingDocumento5 pagineBoiler RatingEdy Suprayitno0% (1)

- Boiler-Questions - AnswersDocumento38 pagineBoiler-Questions - AnswersKapil_1983100% (3)

- Heat Required in Kcal For Unit Generation of ElectricityDocumento18 pagineHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNessuna valutazione finora

- Furnaces in Power BoilerDocumento34 pagineFurnaces in Power BoilerMohammed AzharuddinNessuna valutazione finora

- Waste Heat RecoveryDocumento32 pagineWaste Heat RecoveryManish Tiwari100% (1)

- Draft, Performance indicators, efficiency evaluation of furnaces and boilersDocumento59 pagineDraft, Performance indicators, efficiency evaluation of furnaces and boilersmujeebmehar100% (3)

- Energy conservation opportunities in steam systemsDocumento32 pagineEnergy conservation opportunities in steam systemsPrudhvi RajNessuna valutazione finora

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDa EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNessuna valutazione finora

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentDa EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNessuna valutazione finora

- Geothermal Heat Pump and Heat Engine Systems: Theory And PracticeDa EverandGeothermal Heat Pump and Heat Engine Systems: Theory And PracticeNessuna valutazione finora

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesDa EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNessuna valutazione finora

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsDa EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNessuna valutazione finora

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Da EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Nessuna valutazione finora

- Process Intensification for Sustainable Energy ConversionDa EverandProcess Intensification for Sustainable Energy ConversionNessuna valutazione finora

- Outline of Condition Diagnosis Technique: Syunsuke Yamato, Former Vice-President Nittetsu Yawata Engineering CO., LTDDocumento1 paginaOutline of Condition Diagnosis Technique: Syunsuke Yamato, Former Vice-President Nittetsu Yawata Engineering CO., LTDManoj PaneriNessuna valutazione finora

- Water PollutionDocumento21 pagineWater PollutionManoj PaneriNessuna valutazione finora

- Alkali Boil Out Procedure by Natural Circulation MethodDocumento31 pagineAlkali Boil Out Procedure by Natural Circulation MethodManoj PaneriNessuna valutazione finora

- Viteee 2017Documento6 pagineViteee 2017Manoj PaneriNessuna valutazione finora

- Quality ObservationDocumento6 pagineQuality ObservationManoj PaneriNessuna valutazione finora

- Bolt TighteningDocumento6 pagineBolt TighteningȘtefan PogrebanNessuna valutazione finora

- Fabric Filter DesignDocumento16 pagineFabric Filter DesignDragan GasicNessuna valutazione finora

- Fan Sizing CalculationsDocumento1 paginaFan Sizing CalculationsWONG TSNessuna valutazione finora

- ORBIT AnalysisDocumento4 pagineORBIT AnalysisManoj PaneriNessuna valutazione finora

- The Indian Boilers Act 1923Documento16 pagineThe Indian Boilers Act 1923Anand Swami100% (1)

- Alignment TolerancesDocumento1 paginaAlignment TolerancesMohsin MurtazaNessuna valutazione finora

- Radiography TestingDocumento83 pagineRadiography TestingManoj PaneriNessuna valutazione finora

- Calculation of V-Belt LengthDocumento1 paginaCalculation of V-Belt LengthShantanu DuttaNessuna valutazione finora

- Conveyor Belt Design PDFDocumento9 pagineConveyor Belt Design PDFManoj PaneriNessuna valutazione finora

- Thermal Power Plant Training OverviewDocumento192 pagineThermal Power Plant Training OverviewManoj PaneriNessuna valutazione finora

- Central Academy Sr. Sec. School Bangar Nagar BeawerDocumento41 pagineCentral Academy Sr. Sec. School Bangar Nagar BeawerManoj PaneriNessuna valutazione finora

- Diagnostic Techniques For Vibration Analysis of BearingsDocumento9 pagineDiagnostic Techniques For Vibration Analysis of BearingsMohd Asiren Mohd Sharif100% (1)

- Water PollutionDocumento21 pagineWater PollutionManoj PaneriNessuna valutazione finora

- 561214Documento19 pagine561214Manoj PaneriNessuna valutazione finora

- Review About Opportunities of Ae Acoustic Emission TechniquDocumento8 pagineReview About Opportunities of Ae Acoustic Emission TechniquManoj PaneriNessuna valutazione finora

- Tec Fan SizDocumento1 paginaTec Fan SizManoj PaneriNessuna valutazione finora

- Aws A2.4 Weld Symbols PDFDocumento2 pagineAws A2.4 Weld Symbols PDFbastonspestalode67% (3)

- TT Turbine Oil Condition Monitoring Training Guide PDFDocumento8 pagineTT Turbine Oil Condition Monitoring Training Guide PDFalvaedison00Nessuna valutazione finora

- 1026Documento5 pagine1026Manoj PaneriNessuna valutazione finora

- Miettinen Paper On AEDocumento10 pagineMiettinen Paper On AERaman AuarNessuna valutazione finora

- Miettinen Paper On AEDocumento10 pagineMiettinen Paper On AERaman AuarNessuna valutazione finora

- Acoustic Emission As Large Cracked Foundation Response On Static and Dynamic LoadingDocumento8 pagineAcoustic Emission As Large Cracked Foundation Response On Static and Dynamic LoadingManoj PaneriNessuna valutazione finora

- Mesh To Micron ConverterDocumento1 paginaMesh To Micron ConverterAniket royNessuna valutazione finora

- 6z10c Vib of Conc FoundDocumento33 pagine6z10c Vib of Conc FoundManoj PaneriNessuna valutazione finora

- Mesh Size EquivalentsDocumento2 pagineMesh Size EquivalentsFrancisco Chavez ContrerasNessuna valutazione finora