Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pumps

Caricato da

Mehmet YılmazDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pumps

Caricato da

Mehmet YılmazCopyright:

Formati disponibili

Water Pumps

Definition

Water pumps are devices designed to convert

mechanical energy to hydraulic energy.

They are used to move water from lower

points to higher points with a required

discharge and pressure head.

This chapter will deal with the basic hydraulic

concepts of water pumps

Pump Classification

Turbo-hydraulic (kinetic) pumps

Centrifugal pumps (radial-flow pumps)

Propeller pumps (axial-flow pumps)

Jet pumps (mixed-flow pumps)

Positive-displacement pumps

Screw pumps

Reciprocating pumps

This classification is based on the

way by which the water leaves the

rotating part of the pump.

In radial-flow pump the water

leaves the impeller in radial

direction,

while in the axial-flow pump the

water leaves the propeller in the

axial direction.

In the mixed-flow pump the water

leaves the impeller in an inclined

direction having both radial and

axial components

Schematic diagram of basic

elements of centrifugal

pump

Schematic diagram of axial-flow

pump arranged in vertical operation

Screw pumps.

In the screw pump a revolving shaft fitted with

blades rotates in an inclined trough and pushes the

water up the trough.

Reciprocating pumps.

In the reciprocating pump a piston sucks the

fluid into a cylinder then pushes it up causing

the water to rise.

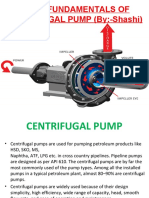

Centrifugal Pumps

Demours centrifugal pump - 1730

Theory

conservation of angular momentum

conversion of kinetic energy to potential energy

Pump components

rotating element - impeller

encloses the rotating element and seals the pressurized

liquid inside casing or housing

Centrifugal Pumps

Impeller

Vanes

Casing

Suction Eye Impeller

Discharge

Flow Expansion

Broad range of applicable flows and heads

Higher heads can be achieved by increasing the

diameter or the rotational speed of the impeller

Centrifugal Pump:

Centrifugal pumps (radial-flow pumps) are the most

used pumps for hydraulic purposes. For this reason,

their hydraulics will be studied in the following

sections.

Main Parts of Centrifugal Pumps

which is the rotating part of

the centrifugal pump.

It consists of a series of

backwards curved vanes

(blades).

The impeller is driven by a

shaft which is connected to the

shaft of an electric motor.

1. Impeller:

Main Parts of Centrifugal Pumps

Which is an air-tight

passage surrounding the

impeller

designed to direct the

liquid to the impeller

and lead it away

Volute casing. It is of

spiral type in which the

area of the flow

increases gradually.

2. Casing

3. Suction Pipe.

4. Delivery Pipe.

5. The Shaft: which is the bar by which the

power is transmitted from the motor drive to

the impeller.

6. The driving motor: which is responsible for

rotating the shaft. It can be mounted directly

on the pump, above it, or adjacent to it.

Note that a centrifugal pump can be

either submersible (wet) or dry.

Hydraulic Analysis of Pumps and Piping

Systems

Pump can be placed in two possible position in

reference to the water levels in the reservoirs.

We begin our study by defining all the

different terms used to describe the pump

performance in the piping system.

Hydraulic Analysis of Pumps and Piping Systems

H

t

h

d

H

s

t

a

t

h

s

H

m

s

H

m

d

Datum pump

center line

h

f

s

h

f

d

Case 1

H

s

t

a

t

H

m

d

H

m

s

h

d

H

t

h

s

Datum pump

center line

h

f

d

h

f

s

Case 2

The following terms can be defined

h

s

(static suction head): it is the difference in

elevation between the suction liquid level and the

centerline of the pump impeller.

h

d

(static discharge head): it is the difference in

elevation between the discharge liquid level and

the centerline of the pump impeller.

H

stat

(static head): it is the difference (or sum) in

elevation between the static discharge and the

static suction heads:

H h h

stat d s

=

H

ms

(manometric suction head): it is the suction

gage reading (if a manometer is installed just at the

inlet of the pump, then H

ms

is the height to which

the water will rise in the manometer).

H

md

(manometric discharge head): it is the

discharge gage reading (if a manometer is installed

just at the outlet of the pump, then H

md

is the

height to which the water will rise in the

manometer).

H

m

(manometric head): it is the increase of

pressure head generated by the pump:

H H H

m md ms

=

H

t

(total dynamic head): it is the total head

delivered by the pump:

H H

V

g

H

V

g

t md

d

ms

s

= + +

2 2

2 2

( )

H H

V

g

H

V

g

t md

d

ms

s

= + +

2 2

2 2

( )

Case 1

Case 2

Eq.(1)

Eq.(2)

H

t

can be written in another form as follows:

H h h h

md d f d md

= + +

H h h h

V

g

ms s f s ms

s

=

2

2

H h h h

V

g

ms s f s ms

s

= + + +

2

2

Case 1

Case 2

H h h h

V

g

h h h

V

g

V

g

t d f d md

d

s f s ms

s s

= + +

+ +

(

(

2 2 2

2 2 2

H h h

stat d s

=

but

H H h h h h

V

g

t stat f d md f s ms

d

= + +

+ + +

2

2

Substitute ino eq. (1)

Eq.(3)

Case 1

Equation (3) can be applied to Case 2 with the

exception that : H h h

stat d s

= +

In the above equations; we define:

h

fs

: is the friction losses in the suction pipe.

h

fd

: is the friction losses in the discharge (delivery) pipe.

h

ms

: is the minor losses in the suction pipe.

h

md

: is the minor losses in the discharge (delivery) pipe.

Bernoullis equation can also be applied to find H

t

H

P V

g

Z

P V

g

Z

t

d d

d

s s

s

= + + + +

|

\

|

.

|

|

2 2

2 2

Eq.(4)

Pump Efficiency

q

p

o

i

t

i

Power output

Power input

P

P

QH

P

= = =

P

QH

i

t

p

=

q

or

Which is the power input delivered from the motor to the

impeller of the pump.

Motor efficiency :

q

m

q

m

i

m

P

P

=

P

P

m

i

m

=

q

which is the power input delivered to the motor.

q

o

q q q

o p m

=

q

o

o

m

P

P

=

Overall efficiency of the motor-pump system:

Cavitation of Pumps and NPSH

In general, cavitation occurs when the liquid pressure

at a given location is reduced to the vapor pressure of

the liquid.

For a piping system that includes a pump, cavitation

occurs when the absolute pressure at the inlet falls

below the vapor pressure of the water.

This phenomenon may occur at the inlet to a pump and

on the impeller blades, particularly if the pump is

mounted above the level in the suction reservoir.

Under this condition, vapor bubbles form (water

starts to boil) at the impeller inlet and when these

bubbles are carried into a zone of higher pressure,

they collapse abruptly and hit the vanes of the

impeller (near the tips of the impeller vanes). causing:

Damage to the pump (pump impeller)

Violet vibrations (and noise).

Reduce pump capacity.

Reduce pump efficiency

To avoid cavitation, the pressure head at the inlet should not fall

below a certain minimum which is influenced by the further

reduction in pressure within the pump impeller.

To accomplish this, we use the difference between the total head

at the inlet , and the water vapor pressure head

g

V P

s s

2

2

+

vapor

P

How we avoid Cavitation ??

Where we take the datum through the centerline of the pump

impeller inlet (eye). This difference is called the Net Positive

Suction Head (NPSH), so that

NPSH

P V

g

P

s s

vapor

= +

2

2

There are two values of NPSH of interest. The first is the required NPSH,

denoted (NPSH)

R

, that must be maintained or exceeded so that cavitation

will not occur and usually determined experimentally and provided by the

manufacturer.

The second value for NPSH of concern is the available NPSH, denoted

(NPSH)

A

, which represents the head that actually occurs for the particular

piping system. This value can be determined experimentally, or calculated if

the system parameters are known.

How we avoid Cavitation ??

For proper pump operation (no cavitation) :

(NPSH)

A

> (NPSH)

R

Determination of

(NPSH)

A

datum

h

s

applying the energy equation between

point (1) and (2), datum at pump

center line

Vapor

Vapor

L S

air

atm

A

Vapor

Vapor

L S

air

atm

Vapor

Vapor

S S

L S

air

atm S S

L

S S

S

air

atm

P

h h

P

NPSH

P

h h

P

P

g

V P

h h

P

g

V P

h

g

V P

h

P

=

= +

= +

+ + =

) (

2

2

2

2

2

2

( ) NPSH h h h

P

P

A s f s ms

atm

vapor

= +

Note that (+) is used if h

s

is above the pump centerline (datum).

2

2

o

/ 335 . 2

/ 14 . 10

20 T at

m kN P

m kN P

Vapor

atm

=

=

=

Thomas cavitation constant

The cavitation constant: is the ratio of (NPSH)

R

to

the total dynamic head (H

t

) is known as the Thomas

cavitation constant ( ) o

o =

( ) NPSH

H

R

t

Note: If the cavitation constant is given, we can find the

maximum allowable elevation of the pump inlet (eye)

above the surface of the supply (suction) reservoir.

Selection of A Pump

It has been seen that the efficiency of a pump depends on the discharge,

head, and power requirement of the pump. The approximate ranges of

application of each type of pump are indicated in the following Figure.

Selection of A Pump

In selecting a particular pump for a given system:

The design conditions are specified and a pump is selected

for the range of applications.

A system characteristic curve (H-Q) is then prepared.

The H-Q curve is then matched to the pump characteristics

chart which is provided by the manufacturer.

The matching point (operating point) indicates the actual

working conditions.

System Characteristic Curve

The total head, H

t

, that the pump delivers includes the

elevation head and the head losses incurred in the system. The

friction loss and other minor losses in the pipeline depend on

the velocity of the water in the pipe, and hence the total head

loss can be related to the discharge rate

For a given pipeline system (including a pump or a group of

pumps), a unique system head-capacity (H-Q) curve can be

plotted. This curve is usually referred to as a system

characteristic curve or simply system curve. It is a graphic

representation of the system head and is developed by plotting

the total head, over a range of flow rates starting from zero to

the maximum expected value of Q.

+ =

L stat t

h H H

System Curve

0 3 6 9 12 15 18

10

H (m)

20

30

40

50

60

70

Q (m /hr)

3

H

s

t

a

t

S

h

l

) ( ) (

1 2

Q fn z z H

p

+ =

0

20

40

60

80

100

120

0 0.2 0.4 0.6 0.8

Discharge (m

3

/s)

H

e

a

d

(

m

)

Static head (z

2

-z

1

)

System with valve partially closed

System Characteristic Curve

H H h

t stat L

= +

Pump Characteristic Curves

Pump manufacturers provide information on the performance

of their pumps in the form of curves, commonly called pump

characteristic curves (or simply pump curves).

In pump curves the following information may be given:

the discharge on the x-axis,

the head on the left y-axis,

the pump power input on the right y-axis,

the pump efficiency as a percentage,

the speed of the pump (rpm = revolutions/min).

the NPSH of the pump.

N

P

S

H

-

m

Q (m /hr)

20

10

0 100 200

H

(

m

)

70

60

50

40

30

Pump Curve

NPSH

e

f

f

i

c

i

e

n

c

y

300

3

400

6

70%

60%

50%

40%

4

2

0

E

f

f

i

c

i

e

n

c

y

%

80%

Pumps Group

The pump characteristic curves are very important to help

select the required pump for the specified conditions.

If the system curve is plotted on the pump curves in we may

produce the following Figure:

The point of intersection is called the operating point.

This matching point indicates the actual working conditions,

and therefore the proper pump that satisfy all required

performance characteristic is selected.

Matching the system and pump curves.

15

30

10

20

0 3

Q (m /hr)

6 9

3

12

Pump Curve

H (m)

e

f

f

i

c

i

e

n

c

y

70

40

50

60

System Curve

18

N

P

S

H

-

m

4

2

0

6

40%

50%

60%

70%

E

f

f

i

c

i

e

n

c

y

%

System Characteristic Curve

H H h

t stat L

= +

Selected Pump

Elevated Tank

Selected Pump

System Curve & Pump Curve cases

Pump Curve

Pump Curve

Pump Curve

System Curve

System Curve

System Curve

Example 1

A Pump has a cavitation constant = 0.12, this pump was instructed

on well using UPVC pipe of 10m length and 200mm diameter, there

are elbow (k

e

=1) and valve (k

e

=4.5) in the system. the flow is 35m

3

and The total Dynamic Head H

t

= 25m (from pump curve)

f=0.0167

Calculate the maximum suction head

m

m

2 . 0 head pressure Vapour

69 . 9 head pressure atm.

=

=

3 25 12 0

12 0

= = =

=

. H NPSH

.

t R

m .

g

.

.

g

V

. h

S

V

283 0

2

11 1

5 4

2

5 4

2 2

= = =

063 0

2

11 1

2

2 2

.

g

.

g

V

h

S

e

= = =

m .

g

.

.

.

g

V

D

L

f h

fS

053 0

2

11 1

2 0

10

0167 0

2

2 2

= = =

( ) ( )

m . h

. . . . h

P

h h h (NPSH)

S

S

Vapor

Vapor

air

atm

mS f S S A

088 6

2 0 69 . 9 063 0 283 0 053 0 3

=

+ + =

+ =

Vapor

Vapor

air

atm

mS f S S A

P

h h h (NPSH) + =

( )

m/s .

.

.

A

Q

V

S

11 1

2 0

4

035 0

2

=

= =

Example 2

For the following pump, determine the required pipes diameter to

pump 60 L/s and also calculate the needed power.

Minor losses 10 v

2

/2g

Pipe length 10 km

roughness = 0.15 mm

h

s

= 20 m

0 10 20 30 40 50 60 70 Q

L/s

45 44.7 43.7 42.5 40.6 38 35 31 H

t

-

35 50 57 60 60 53 40

P

q

To get 60 L/s from the pump hs + h

L

must be < 35 m

Assume the diameter = 300mm

Then:

( )

m h

f D K R

s m V m A

f

S e

32 . 23

62 . 19 3 . 0

85 . 0 10000 019 . 0

019 . 0 , 0005 . 0 / , 10 25 . 2

/ 85 . 0 , 070 . 0

2

5

2

=

=

= = =

= =

( )

m

g g

V

h

m

37 . 0

2

85 . 0 10

2

10

2

2

=

=

m m h h h

m f s

35 69 . 43 > = + +

Assume the diameter = 350mm

Then:

s m V m A / 624 . 0 , 0962 . 0

2

= =

, 48 . 10

0185 . 0 , 00043 . 0 / , 10 93 . 1

5

m h

f D K R

f

S e

=

= = =

( )

m

g g

V

h

m

2 . 0

2

624 . 0 10

2

10

2

2

=

=

m m h h h

m f s

35 68 . 30 < = + +

kW W

H Q

P

p

t

i

87 . 38 8 . 38869

53 . 0

35 81 . 9 1000

1000

60

= =

= =

q

Example 3

A pump was designed to satisfy the following system

9 6 3 Q (m

3

/hr)

38 20 12 h

f

(m)

m

m

25 . 0 head pressure Vapour

3 . 10 head pressure atm.

=

=

m h

d

13 =

Pipe diameter is 50mm

( )

g

V

h

L

2

24

Part suction

2

=

Check whether the pump is suitable or not

1- Draw the system curve and check the operation point

20m 7 13 h h H

S d STAT

= + = + =

There are an operation point at:

Q = 9 m

3

/hr H =58m

NPSH

R

=4.1

Then Check NPSH

A

( )

( )

m .

g

.

h

m/s .

.

/

A

Q

V

L

0 2

2

27 1 24

27 1

05 0

4

3600 9

2

2

=

=

=

= =

4.1 1.05 (NPSH)

0.25 10.3 2 7 (NPSH)

P

h h h (NPSH)

A

A

Vapor

Vapor

air

atm

mS S S A

< =

+ =

+ =

f

pump is not suitable, the cavitation will occur

Multiple-Pump Operation

To install a pumping station that can be effectively

operated over a large range of fluctuations in both

discharge and pressure head, it may be advantageous

to install several identical pumps at the station.

Pumps in Parallel Pumps in Series

(a) Parallel Operation

Pumping stations frequently contain several (two or

more) pumps in a parallel arrangement.

Q

1

Q

2

Q

3

Pump

Pump

Pump

Manifold

Q

total

Q

total

=Q

1

+Q

2

+Q

3

In this configuration any number of the pumps can be

operated simultaneously.

The objective being to deliver a range of discharges,

i.e.; the discharge is increased but the pressure head

remains the same as with a single pump.

This is a common feature of sewage pumping stations

where the inflow rate varies during the day.

By automatic switching according to the level in the

suction reservoir any number of the pumps can be

brought into operation.

How to draw the pump curve for pumps in

parallel???

The manufacturer gives the pump curve for a single

pump operation only.

If two or pumps are in operation, the pumps curve

should be calculated and drawn using the single pump

curve.

For pumps in parallel, the curve of two pumps, for

example, is produced by adding the discharges of the

two pumps at the same head (assuming identical

pumps).

Pumps in series & Parallel

Pumps in Parallel:

mn m3 m2 m1 m

n j

1 j

n 3 2 1

H H H H H

Q Q Q Q Q Q

= = = = =

= = + + + =

=

=

(b) Series Operation

The series configuration which is used whenever we

need to increase the pressure head and keep the

discharge approximately the same as that of a single

pump

This configuration is the basis of multistage pumps;

the discharge from the first pump (or stage) is

delivered to the inlet of the second pump, and so on.

The same discharge passes through each pump

receiving a pressure boost in doing so

Q

Pump

Pump

Pump

Q

H

total

=H

1

+H

2

+H

3

How to draw the pump curve for pumps in

series???

the manufacturer gives the pump curve for a single

pump operation only.

For pumps in series, the curve of two pumps, for

example, is produced by adding the heads of the two

pumps at the same discharge.

Note that, of course, all pumps in a series system

must be operating simultaneously

H

Q

Q

1

H

1

H

1

H

1

2H

1

H

1

3H

1

Single pump

Two pumps

in series

Three pumps

in series

Constant- and Variable-Speed Pumps

The speed of the pump is specified by the angular

speed of the impeller which is measured in

revolution per minutes (rpm).

Based on this speed, N , pumps can be divided into

two types:

Constant-speed pumps

Variable-speed pumps

Constant-speed pumps

For this type, the angular speed , N , is constant.

There is only one pump curve which represents the

performance of the pump

10

0 100 300

Q (m /hr)

200

3

400

Pump Curve

30

40

50

60

70

20

H

(

m

)

e

f

f

i

c

i

e

n

c

y

NPSH

E

f

f

i

c

i

e

n

c

y

%

4

N

P

S

H

-

m

80%

0

2

40%

50%

60%

70%

6

Variable-speed pumps

For this type, the angular

speed , N , is variable, i.e.;

pump can operate at

different speeds.

The pump performance is

presented by several pump

curves, one for each speed

Each curve is used to suit

certain operating

requirements of the system.

Similarity Laws:

Affinity laws

The actual performance characteristics curves of

pumps have to be determined by experimental testing.

Furthermore, pumps belonging to the same family,

i.e.; being of the same design but manufactured in

different sizes and, thus, constituting a series of

geometrically similar machines, may also run at

different speeds within practical limits.

Each size and speed combination will produce a

unique characteristics curve, so that for one family of

pumps the number of characteristics curves needed to

be determined is impossibly large.

The problem is solved by the application of

dimensional analysis and by replacing the variables

by dimensionless groups so obtained. These

dimensionless groups provide the similarity (affinity)

laws governing the relationships between the

variables within one family of geometrically similar

pumps.

Thus, the similarity laws enable us to obtain a set of

characteristic curves for a pump from the known test

data of a geometrically similar pump.

(a) Change in pump speed

(constant size)

If a pump delivers a discharge Q

1

at a head H

1

when running at speed N

1

, the corresponding

values when the same pump is running at speed N

2

are given by the similarity (affinity) laws:

Q

Q

N

N

2

1

2

1

=

H

H

N

N

2

1

2

1

2

=

|

\

|

.

|

P

P

N

N

i

i

2

1

2

1

3

=

|

\

|

.

|

where Q = discharge (m

3

/s, or l/s).

H = pump head (m).

N = pump rotational speed (rpm).

P

i

= power input (HP, or kw).

Therefore, if the pump

curve for speed N

1

is

given, we can construct

the pump curve for the

speed N

2

using previous

relationships.

Effect of speed change on pump

characteristic curves.

N

1

N

2

(b) Change in pump size

(constant speed)

A change in pump size and therefore, impeller

diameter (D), results in a new set of characteristic

curves using the following similarity (affinity) laws:

Q

Q

D

D

2

1

2

1

3

=

|

\

|

.

|

H

H

D

D

2

1

2

1

2

=

|

\

|

.

|

P

P

D

D

i

i

2

1

2

1

5

=

|

\

|

.

|

where D = impeller diameter (m, cm).

Note : D indicated the size of the pump

Example 4

Solution

Specific Speed

Pump types may be more explicitly defined by the

parameter called specific speed (N

s

) expressed by:

Where: Q = discharge (m

3

/s, or l/s).

H = pump total head (m).

N = rotational speed (rpm).

N

N Q

H

s

=

3

4

This expression is derived from dynamical similarity

considerations and may be interpreted as the speed in

rev/min at which a geometrically scaled model would have

to operate to deliver unit discharge (1 l/s) when generating

unit head (1 m).

The given table shows the range of N

s

values for the turbo-

hydraulic pumps:

Pump type N

s

range (Q - l/s, H-m)

centrifugal up to 2600

mixed flow 2600 to 5000

axial flow 5000 to 10 000

Example 5

A centrifugal pump running at 1000 rpm gave the following

relation between head and discharge:

Discharge (m

3

/min) 0 4.5 9.0 13.5 18.0 22.5

Head (m) 22.5 22.2 21.6 19.5 14.1 0

The pump is connected to a 300 mm suction and delivery pipe

the total length of which is 69 m and the discharge to

atmosphere is 15 m above sump level. The entrance loss is

equivalent to an additional 6m of pipe and f is assumed as

0.024.

1. Calculate the discharge in m

3

per minute.

2. If it is required to adjust the flow by regulating the pump

speed, estimate the speed to reduce the flow to one-half

1) System curve:

The head required from pump =

static + friction + velocity head

H

stat

= 15 m

Friction losses (including equivalent entrance losses) =

H H h h h h

V

g

t stat f d md f s ms

d

= + + + + +

2

2

5 2

2

8

D g

Q L f

h h h h

md fd ms fs

t

= + + +

2

5 2

) 3 . 0 (

) 6 69 ( 024 . 0 8

Q

g t

+

=

2

21 . 61 Q =

where Q in m

3

/s

Velocity head in delivery pipe =

where Q in m

3

/s

Thus:

where Q in m

3

/s

or

where Q in m

3

/min

From this equation and the figures given in the problem the

following table is compiled:

2

2

2

2 . 10

2

1

2

Q

A

Q

g g

V

d

=

|

.

|

\

|

=

2

41 . 71 15 Q H

t

+ =

2 3

10 83 . 19 15 Q H

t

+ =

Discharge (m3/min) 0 4.5 9.0 13.5 18.0 22.5

Head available (m) 22.5 22.2 21.6 19.5 14.1 0

Head required (m) 15.0 15.4 16.6 18.6 21.4 25.0

Pump and Sytem Curves

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

0 2 4 6 8 10 12 14 16 18 20 22 24

Discharge, Q (m

3

/min)

H

e

a

d

,

H

t

(

m

)

Pump Curve

System Curve

From the previous Figure, The operating point is:

Q

A

= 14 m

3

/min

H

A

= 19 m

At reduced speed: For half flow (Q = 7 m

3

/min) there

will be a new operating point B at which:

Q

B

= 7 m

3

/min

H

B

= 16 m

HomeWork

How to estimate the new speed ?????

Pump and Sytem Curves

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

0 2 4 6 8 10 12 14 16 18 20 22 24

Discharge, Q (m

3

/min)

H

e

a

d

,

H

t

(

m

)

Pump Curve

System Curve

A

B

A

B

Q

Q

N

N

2

1

2

1

=

H

H

N

N

2

1

2

1

2

=

|

\

|

.

|

2

|

|

.

|

\

|

=

B B

Q

Q

H

H

2 2

2

327 . 0

7

16

Q Q H = =

This curve intersects the original curve for N

1

= 1000 rpm

at C where Q

c

= 8.2 m

3

/ hr and H

c

= 21.9 m, then

1

2

N

N

Q

Q

C

B

=

1000 2 . 8

7

2

N

=

N

2

= 855rpm

Pump and Sytem Curves

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

0 2 4 6 8 10 12 14 16 18 20 22 24

Discharge, Q (m

3

/min)

H

e

a

d

,

H

t

(

m

)

Pump Curve

System Curve

A

B

C

A

B

C

Example 6

Abbreviations:

G.V = Gate Valve

C.V = Check Valve

A.V = Air release Valve

E.R = Eccentric Reducer

C.I = Concentric increase

I.N = Inlet Nozzle

O.N = Outlet Nozzle

S.P = Suction Pipe

D.P = Delivery Pipe

W.W = Wet Well

D.W = Dry Well

Data:

1. Flow rates and dimensions:

Q

max

= 0.05 m

3

/s Q

min

= 0.025 m

3

/s

L

S.P

= 5.0 m L

D.P

= 513.5 m

D

S.P

= 250mm D

D.P

= 200mm

H

stat

= 5.3 m, h

S

= 3.0 m

2. Minor Losses Coefficients (k):

G.V = 0.1 C.V = 2.5 A.V = 0.05,

E.R = 0.1 C.I = 0.05 Elbow = 0.2

Bends in D.P = 0.05,

Entrance of S.P = 0.3 (bell mouth)

3. Coefficient of friction:

f = 0.02 (assumed constant).

| |

I N O N

mm

. .

= = 150

4. Pump characteristic curves:

Required??

The given Figure shows a pump station.

Use the pump characteristic curves and the data given above to:

a) Choose a suitable pump which satisfies the requirements of

the piping system shown,

b) Find the power and efficiency of the pump,

c) Find the overall efficiency (motor and pump) if the motor

efficiency is given to be 90%, also find the required power

input to the motor.

d) Check the pump for cavitation at T = 25

o

C

Solution

A. Pump Selection:

The first step in selecting a pump is to draw the system

curve:

To draw the system curve we need to calculate the values of

H

t

that correspond to several values of Q, using :

We start with Q

max

= 0.05 m

3

/s as the first value of Q in the

system and find the corresponding H

t

H H h

t stat L

= +

or

H H h h h h

V

g

t stat f s ms f d md

d

= + +

+ + +

2

2

Head losses in the suction pipe:

For Q

max

= 0.05 m

3

/s.

Friction losses:

Minor losses:

V

Q

A

m s

s

s

= = =

max

. *

(0. )

. /

005 4

25

102

2

t

h f

L

D

V

g

m

fs

s

s

s

= = =

2 2

2

002

50

025

102

2 981

0021 . *

.

.

*

( . )

* .

.

h

ms

V

g

m

s

= + + = =

2 2

2

03 01 01 05

102

2 981

0027 ( . . . ) . *

( . )

* .

.

Head losses in the delivery pipe:

For Q

max

= 0.05 m

3

/s.

Friction losses:

Minor losses:

V

Q

A

m s

d

d

= = =

max

. *

( . )

. /

005 4

020

16

2

t

h f

L

D

V

g

m

fd

d

d

d

= = =

2 2

2

002

5135

02

16

2 981

67 . *

.

.

*

( . )

* .

.

h

md

V

g

m

d

= + + + + + + = =

2 2

2

02 005 02 005 25 01 2 005 32

16

2 981

042 ( . . . . . . * . ) . *

( . )

* .

.

Therefore

H mwc

t

= + + + + + = + = 53 0027 0021 042 67

16

2 981

53 7 3 12 6

2

. . . . .

( . )

* .

. . .

H H h h h h

V

g

t stat f s ms f d md

d

= + +

+ + +

2

2

therefore, we found the first point on the system curve:

(Q, H) = (0.05, 12.6)

which is the operating point of the system at Q

max

.

If we repeat previous step for several Q values it will possible

to draw the (Q, H) or system curve.

However, it will be very cumbersome and long procedure.

So, another procedure will be adopted:

where K is constant and it is a unique property of the given

system.

H H h

t stat L

= +

h

L

h h h h

V

g

k

f L

D

V

g

k

f L

D

f s ms f d md

s

s

s

s

d

d

d

d

= + + + = + + +

2 2

2 2

( ) ( )

h

L

Q

A g

k

f L

D

Q

A g

k

f L

D

s

s

s

s

d

d

d

d

= + + +

2

2

2

2

2 2

( ) ( )

h

L

Q K Q K Q K K = ' + '' = ' + ''

2 2 2

( ) ( ) ( )

h

L

Q K

=

2

Therefore

Thus:

) 2 . 4 35 . 51 (

2

) 5 . 0 4 (

2

2

2

2

2

+ + + =

g A

Q

g A

Q

L

h

d s

2 2

64 . 51 ) 2 . 4 35 . 51 ( 15 . 21 ) 5 . 0 4 ( Q Q

L

h + + + =

2

88 . 2963 Q

L

h =

2

88 . 2963 3 . 5 Q H

t

+ =

for a given Q

i

, we have

for Q

max

, we have

Therefore

Or

h

Li

Q K

i

=

2

h

L

Q K

max

max

=

2

h

h

Q

Q

Li

L

i

=

max

max

2

2

h

Q

Q

h

Li

i

L

=

|

\

|

.

|

max

max

*

2

From previous calculations we obtained for Q

max

= 0.05 m

3

/s. Therefore, we can use the above equation along with the

above values to find for several values of Q

i

. In order to

calculate H

ti

.

h

L

mwc

max

.

= 7 3

h

Li

System curve

Operating

point

System curve

12.6

It is clear from the above figure that the required pump is the

35-cm impeller pump

Pump Power Input and Efficiency

From the pump curve we can read P

i

= 7.5 kw

and hence

P kw HP

i

= = ~ 75

75 10

745

10

3

.

. *

q

p

o

i

t

i

P

P

QH

P

= = = = = ~

1000 981 005 12 60

75 1000

618

7 6

0824 82%

* . * . * .

. *

.

.

.

Overall Efficiency and Motor Power Input

Overall efficiency

and hence

q q q

o p m

= = = = 09 082 0738 738 . * . . . %

q

o

o

m m

P

P P

= = =

618

0738

.

.

P kw HP

m

~ = 827 112 . .

Check for Cavitation:

To prevent cavitation we must have:

(NPSH)

A

(NPSH)

R

From pump curve figure we can read:

(NPSH)

R

= 3 m at Q

max

= 0.05 m

3

/s.

For water at T=25

o

C, P

atm

= 101 kN/m

2

, and P

vapor

= 3.17 kN/m

2

.

Using the equation

we can write

no cavitation.

>

( ) NPSH

P

h h h

P

A

atm

s f s ms

vapor

= +

( )

*

* .

. .

. *

* .

NPSH

A

= +

101 1000

1000 9 81

3 0021 0027

317 1000

1000 981

( ) . NPSH m m

A

= >> 12 924 3

Home Work

Potrebbero piacerti anche

- PumpsDocumento57 paginePumpsJai Acharya100% (1)

- Laminar and Turbulent FlowDocumento10 pagineLaminar and Turbulent FlowGera DiazNessuna valutazione finora

- Basic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)Documento42 pagineBasic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)RaduIon100% (1)

- Functions of a Pump: Transfer Fluid and Produce Flow & PressureDocumento172 pagineFunctions of a Pump: Transfer Fluid and Produce Flow & PressureAdithya VKNessuna valutazione finora

- PumpsDocumento54 paginePumpsMark SantosNessuna valutazione finora

- 320A Hydraulic System OperationDocumento135 pagine320A Hydraulic System OperationZawminhtunNessuna valutazione finora

- PumpDocumento82 paginePumpkarthickNessuna valutazione finora

- Ce NT Rifu Gal Pu MP Ter MsDocumento74 pagineCe NT Rifu Gal Pu MP Ter Msaby jacob100% (2)

- Lab Report Flow Rate MeasurementDocumento12 pagineLab Report Flow Rate Measurementnorsiah92% (12)

- Pump PresentationDocumento66 paginePump PresentationAnonymous K3FaYFlNessuna valutazione finora

- ER-56.12-1 (Packing and Distance Piece Vent Systems)Documento10 pagineER-56.12-1 (Packing and Distance Piece Vent Systems)NicolasNessuna valutazione finora

- PumpsDocumento26 paginePumpsrajishrrrNessuna valutazione finora

- Chapter 2 Centrifugal PumpsDocumento96 pagineChapter 2 Centrifugal PumpsMichael MesfinNessuna valutazione finora

- Lift Station CalculationDocumento14 pagineLift Station CalculationRawan Alwan ZarifNessuna valutazione finora

- Assignment: Name Muhammad ArsalanDocumento8 pagineAssignment: Name Muhammad ArsalanMuhammad Arsalan TariqNessuna valutazione finora

- S08 Diesel Power PackDocumento142 pagineS08 Diesel Power PackKarthii AjuNessuna valutazione finora

- The Affinity Laws of Centrifugal PumpsDocumento8 pagineThe Affinity Laws of Centrifugal PumpsArunkumar SubramanianNessuna valutazione finora

- Eas105 Lab Report 2Documento16 pagineEas105 Lab Report 2Jonathan AngNessuna valutazione finora

- Fluid-Flow Concepts and Basic EquationsDocumento127 pagineFluid-Flow Concepts and Basic EquationsAli Alkassem100% (1)

- Introduction To Pumps, Compressors, Fans & BlowersDocumento68 pagineIntroduction To Pumps, Compressors, Fans & BlowersSagarSatyaNessuna valutazione finora

- Fluid Flow Measurement DevicesDocumento9 pagineFluid Flow Measurement DevicesClifford Dwight RicanorNessuna valutazione finora

- Guide to Pump Selection, Classification & Performance Parameters in 40 CharactersDocumento62 pagineGuide to Pump Selection, Classification & Performance Parameters in 40 CharactersAravazhi Ramasami ThangarajNessuna valutazione finora

- Cooling SystemsDocumento30 pagineCooling SystemsTa Den AprilNessuna valutazione finora

- PumpDocumento48 paginePumpArman Malik100% (2)

- The Mathematics of Pumping Water: AECOM Design BuildDocumento9 pagineThe Mathematics of Pumping Water: AECOM Design Buildmabrouk2013Nessuna valutazione finora

- Hydraulic and Surge Analysis in A Pipeline NetworkDocumento9 pagineHydraulic and Surge Analysis in A Pipeline Networkrasnowmah2012Nessuna valutazione finora

- PumpDocumento116 paginePumpV Dhinakaran67% (3)

- PUMP TYPEDocumento63 paginePUMP TYPEKaushik SreenivasNessuna valutazione finora

- What Is A Compressor?Documento17 pagineWhat Is A Compressor?virgolost100% (2)

- How To Size A PumpDocumento6 pagineHow To Size A PumpSoe T. HtunNessuna valutazione finora

- Experiment No. 1 CompressorsDocumento9 pagineExperiment No. 1 CompressorsgmNessuna valutazione finora

- Air and Gas Compressors 14: Rayner Joel, 5 EditionDocumento13 pagineAir and Gas Compressors 14: Rayner Joel, 5 EditionJerin Cyriac0% (1)

- ValveDocumento20 pagineValveShekhar KurmiNessuna valutazione finora

- Pumps StudentsDocumento62 paginePumps StudentsAKHIL JOSEPH100% (1)

- Water Hammer - Wikipedia, The Free EncyclopediaDocumento8 pagineWater Hammer - Wikipedia, The Free Encyclopediarohan kumarNessuna valutazione finora

- Relief Valves - NCCDocumento26 pagineRelief Valves - NCCNour HNessuna valutazione finora

- Turbomachinery (Pumps) : 1. CHAPTER - 11 Frank White 2. CHAPTER-14 Yunus A. ÇengelDocumento82 pagineTurbomachinery (Pumps) : 1. CHAPTER - 11 Frank White 2. CHAPTER-14 Yunus A. ÇengelManzoor ali100% (1)

- TURBOMACHINES: Pumps PerformanceDocumento35 pagineTURBOMACHINES: Pumps PerformanceBaber H. ElahiNessuna valutazione finora

- Chapter 7Documento28 pagineChapter 7lockas222Nessuna valutazione finora

- Heat Transfer Fundamentals - 19th JuneDocumento75 pagineHeat Transfer Fundamentals - 19th JuneVivek RathodNessuna valutazione finora

- Compressors: Presented By: Andrith Fabian Güiza Zambrano 2134124 Presented To: Ing. Nicolas Santos SantosDocumento50 pagineCompressors: Presented By: Andrith Fabian Güiza Zambrano 2134124 Presented To: Ing. Nicolas Santos SantosbrandonNessuna valutazione finora

- Positive Displacement Machine TypesDocumento43 paginePositive Displacement Machine TypesCh. Muhammad Usama50% (2)

- Steam Jet Refrigeration and Vapour Absorption SystemDocumento21 pagineSteam Jet Refrigeration and Vapour Absorption SystemmohitNessuna valutazione finora

- Water and Waste Water Lecture 10Documento44 pagineWater and Waste Water Lecture 10David AquinoNessuna valutazione finora

- Dense Phase PR Drop & Pipe SizingDocumento32 pagineDense Phase PR Drop & Pipe SizingyoyoNessuna valutazione finora

- Level GaugeDocumento3 pagineLevel Gaugemerijan10Nessuna valutazione finora

- CavitationDocumento11 pagineCavitationSalim Chohan0% (1)

- INSTRUDocumento130 pagineINSTRUJustine-Denisse OngNessuna valutazione finora

- Pressure VesselDocumento9 paginePressure VesselbekkuNessuna valutazione finora

- Basics of Turbo Machines in 40 CharactersDocumento14 pagineBasics of Turbo Machines in 40 CharactersBF3nobelNessuna valutazione finora

- Pump & Compressor PositioningDocumento32 paginePump & Compressor PositioningAeffandii SamawiNessuna valutazione finora

- Module 1 - Basic Principles of Turbo MachinesDocumento12 pagineModule 1 - Basic Principles of Turbo Machinesnagendrags100% (1)

- Water Flow in PipesDocumento111 pagineWater Flow in PipesLisbeth NdaumanuNessuna valutazione finora

- Mep All QuestionsDocumento79 pagineMep All QuestionsbabaNessuna valutazione finora

- Ch1-Flow of Fluids in Pipes - StudentDocumento112 pagineCh1-Flow of Fluids in Pipes - Studentmelki blair kamga nougoueNessuna valutazione finora

- Turbomachines Intro 1Documento22 pagineTurbomachines Intro 1Mukul Goyal0% (1)

- Turbo MachineryDocumento35 pagineTurbo MachineryAbenezer ZebeneNessuna valutazione finora

- Types of Centrifugal Pumps All Classification Working PrinciplesDocumento14 pagineTypes of Centrifugal Pumps All Classification Working PrinciplesajiNessuna valutazione finora

- Flow Through OrificesDocumento9 pagineFlow Through OrificesShida Shidot100% (1)

- Introduction to Turbomachines: From Water Wheels to Modern TurbinesDocumento21 pagineIntroduction to Turbomachines: From Water Wheels to Modern TurbinesSandesh Aooum TrivediNessuna valutazione finora

- Pump PrimingDocumento1 paginaPump PrimingronakuchNessuna valutazione finora

- Fluid Mechanics PresentationDocumento37 pagineFluid Mechanics PresentationMonirul Islam MonirNessuna valutazione finora

- Basics of Heat TransferDocumento85 pagineBasics of Heat Transferchirag taterNessuna valutazione finora

- Viscous Flow in Pipes PDFDocumento71 pagineViscous Flow in Pipes PDFMuhammad Izzamir FirdausNessuna valutazione finora

- Lesson Chemical Injection and ChlorinationDocumento3 pagineLesson Chemical Injection and Chlorinationmister pogiNessuna valutazione finora

- Thermo Lec 1 ElecDocumento34 pagineThermo Lec 1 ElecWajid HussainNessuna valutazione finora

- Performance of Hydraulic MachinesDocumento14 paginePerformance of Hydraulic MachinesVINAY CHANDWANINessuna valutazione finora

- ChE354 PumpsDocumento36 pagineChE354 PumpsFA AyNessuna valutazione finora

- Convert Mechanical Energy To Hydraulic Energy.: Pumps Are Devices Designed ToDocumento35 pagineConvert Mechanical Energy To Hydraulic Energy.: Pumps Are Devices Designed ToRiaz JokanNessuna valutazione finora

- Bosch Rexroth VPV and SV Variable Volume Vane Pumps: Installation ManualDocumento2 pagineBosch Rexroth VPV and SV Variable Volume Vane Pumps: Installation ManualEng-Mohammed SalemNessuna valutazione finora

- Multi-Valve TechnologyDocumento341 pagineMulti-Valve TechnologyRjeb mohamedNessuna valutazione finora

- Valtra A Katalog A72-92 09 PLDocumento37 pagineValtra A Katalog A72-92 09 PLStanisław DuszczakNessuna valutazione finora

- Installation and Maintenance Manual for Chemical Injection PackagesDocumento10 pagineInstallation and Maintenance Manual for Chemical Injection Packagesbmanojkumar16Nessuna valutazione finora

- OMEGA AIR-TAC - Activated Carbon Towers - 950054 - enDocumento2 pagineOMEGA AIR-TAC - Activated Carbon Towers - 950054 - enJunaid AhmedNessuna valutazione finora

- Sliding Stem Control Valve SpecificationDocumento2 pagineSliding Stem Control Valve SpecificationJackNessuna valutazione finora

- High Pressure PumpsDocumento9 pagineHigh Pressure PumpsAhmed AwwadNessuna valutazione finora

- Catalogo Graco LubricationDocumento184 pagineCatalogo Graco LubricationCarlos Andrés CuelloNessuna valutazione finora

- PLC Io ListDocumento4 paginePLC Io ListVaibhav ShrivastavNessuna valutazione finora

- Handtmann Safety ValvesDocumento12 pagineHandtmann Safety Valvesmyself_riteshNessuna valutazione finora

- European Catalog Air Preparation Delta Filter 901 G 3 8 g2 Asco en 7003046Documento12 pagineEuropean Catalog Air Preparation Delta Filter 901 G 3 8 g2 Asco en 7003046giovanni1912Nessuna valutazione finora

- Boiler - Cleaver Brooks 3MW - Manual 1Documento2 pagineBoiler - Cleaver Brooks 3MW - Manual 1Vignesh MahalingamNessuna valutazione finora

- Primelub - : AccessoriesDocumento7 paginePrimelub - : AccessoriesCristi NadabaicaNessuna valutazione finora

- LPH 65320 LPH 65327Documento9 pagineLPH 65320 LPH 65327Eko WageurNessuna valutazione finora

- CheatsheetDocumento55 pagineCheatsheetPedro LeyvaNessuna valutazione finora

- Diagrama Hidraulico Del 980HDocumento2 pagineDiagrama Hidraulico Del 980HMiguel GonzalezNessuna valutazione finora

- Ceccato KompresorDocumento4 pagineCeccato KompresorRobert ShkrivaniNessuna valutazione finora

- ARCA Info Catalogue GBDocumento146 pagineARCA Info Catalogue GBcvfNessuna valutazione finora

- Valvulas de Exceso de Flujo ArgusDocumento3 pagineValvulas de Exceso de Flujo ArgusJoseNessuna valutazione finora

- Brayton Cycle Processes & Gas Turbine Efficiency (39Documento51 pagineBrayton Cycle Processes & Gas Turbine Efficiency (39Ralph Adrian MielNessuna valutazione finora

- Application Operation of Two Stage Compressors Technical Information en GB 5589016Documento17 pagineApplication Operation of Two Stage Compressors Technical Information en GB 5589016Mechanical PowerNessuna valutazione finora