Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Head Loss Examp

Caricato da

Mohd Amirul Mohd Yusuf0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

326 visualizzazioni8 pagineThis document discusses head loss calculation for a pumping system that transfers water from a lower storage tank to an upper gravity tank. It provides the equations used to calculate static head, pipe friction losses, minor losses, and total minimum pumping head. It also gives the step-by-step working of the example problem to find the minimum pumping head of 26.29 meters or 2.579 bar for the given system. Additionally, it lists some measures that can be taken to reduce head losses in a pipeline.

Descrizione originale:

Head Loss calculation

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses head loss calculation for a pumping system that transfers water from a lower storage tank to an upper gravity tank. It provides the equations used to calculate static head, pipe friction losses, minor losses, and total minimum pumping head. It also gives the step-by-step working of the example problem to find the minimum pumping head of 26.29 meters or 2.579 bar for the given system. Additionally, it lists some measures that can be taken to reduce head losses in a pipeline.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

326 visualizzazioni8 pagineHead Loss Examp

Caricato da

Mohd Amirul Mohd YusufThis document discusses head loss calculation for a pumping system that transfers water from a lower storage tank to an upper gravity tank. It provides the equations used to calculate static head, pipe friction losses, minor losses, and total minimum pumping head. It also gives the step-by-step working of the example problem to find the minimum pumping head of 26.29 meters or 2.579 bar for the given system. Additionally, it lists some measures that can be taken to reduce head losses in a pipeline.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

Head Loss Calculation

Once the system minor and friction losses are determined, they can be entered into Bernoullis equation to calculate the external energy required to drive the system.

Energy from a pump is designated as Ep and minor and pipe friction losses are represented as head losses hm and hf respectively.

Head Loss Calculation

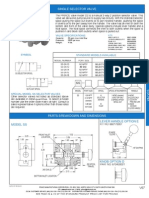

Example The pumping system shown in the figure below is required to transfer fresh water from the lower storage tank to the upper gravity tank. The bore size of all pipes and fittings are of 80mm. Pipes used are of API Schedule 40 black steel and connected to the fittings by flanges. Using the data provided, find out the minimum pumping head.

Head Loss Calculation

Solution Applying Bernoulis Equation and including Hpump and Hlosses, V12 P1 V22 P2 Z1 + ------ + ------ + Hpump = Z2 + ------ + ------ + Hlosses 2g g 2g g But V1 and V2 are small (assuming tanks have large surface) and P1 = P2 = Patmosphere Pumping head Hpump = Static head (Hstatic) + Pipe friction losses (Hf)+ Losses through fittings (Hm) Static head Hstatic = Z2 Z1 = 13 (-2) m = 15 m Flow Quantity Q = 800 litres/min = (800 x 10-3)/60 m3/s = 13.33 x 10-3 m3/s

Head Loss Calculation

Diameter of pipe D = 0.080 m Area of pipe section a = 5.03 x 10-3 m2 Since Q = a V Therefore Q 13.33 x 10-3 V = ---- = ----------------------- = 2.65 m/s a 5.03 x 10-3 Taking the temperature of fresh water to be 20o, from the kinematic viscosity table, we can get = 1.007 x 10-6 m2/s Therefore, Vd Re = ------ =

2.65 x 0.080 ------------------- = 2.1 x 105 1.007 x 10-6

It is turbulent flow.

Head Loss Calculation

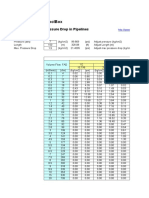

For commercial steel, wall roughness = 0.046 mm Pipe diameter D = 80 mm Relative roughness /D = 0.046/80 = 0.000575 From Moodys diagram, when Re = 2.1 x 105 and /D = 0.000575, we get friction factor f = 0.019 From the pumping system figure, we get the straight pipe length: Pipe A B 3m B C 10m D F 10m F G 7.5m Total Pipe L = 30.5m Using Darcy-Weisbach Equation: L V2 30.5 x 2.65 x 2.65 Hf = f ----- ----- = 0.019 -------------------------- = 2.59 m D 2g 0.080 x 2 x 9.81

Head Loss Calculation

Minor Losses Calculation: Fitting Coefficient K Foot Valve 10.0 Standard 90o Elbow 0.90 Pump Entry (pipe exit) 1.00 Pump Exit (enter pipe) 0.50 Globe Valve (Fully Open) 10.0 Standard 90o Elbow 0.90 Upper Tank Entry (pipe exit) 1.00 Total 24.3 V2 24.3 x 2.65 x 2.65 Hm = K ------- = -------------------------2g 2 x 9.81 = 8.70 m

Head Loss Calculation

The minimum pump head = Hstatic + Hf + Hm = 15 + 2.59 + 8.70 = 26.29 m If it is converted to bar:

P = gH = 1000 x 9.81 x 26.29 = 257904 Pa

= 2.579 bar

Measures to Reduce Head Losses

Based on the equations of minor losses and friction losses, the following measures can be considered to reduce head losses in pipe line. V2 L V2 Hm = K ------Hf = f ----- ----2g D 2g - Use biggest possible pipe diameter D V Hm Hf - Use smoothest possible pipes /d f Hf - Layout shortest possible pipe lines L Hf - Minimize the number of elbows/bends in pipelines K Hm - Use valves with smaller K value if possible - Keep the temperature of liquids higher if possible T Re

Hf

Potrebbero piacerti anche

- Numerical My BookDocumento47 pagineNumerical My BookKiran Ghimire100% (1)

- Eval Exam 2Documento3 pagineEval Exam 2Krisia MartinezNessuna valutazione finora

- Refresher PIPE Problems - Set3Documento25 pagineRefresher PIPE Problems - Set3kristan7Nessuna valutazione finora

- Mechanics sTREngth of MaterialsDocumento1 paginaMechanics sTREngth of MaterialsDenaiya Watton Leeh100% (1)

- Pre Test - (Kinematics)Documento3 paginePre Test - (Kinematics)Deyn EstoqueNessuna valutazione finora

- PADILLAMD Module 7 Exercises Problem No. 4Documento2 paginePADILLAMD Module 7 Exercises Problem No. 4Leyzer MalumayNessuna valutazione finora

- Module 7 Exercises Problem No. 1Documento3 pagineModule 7 Exercises Problem No. 1Ariel Gamboa100% (1)

- Math Prioritize Part 1Documento202 pagineMath Prioritize Part 1Vincent Andrew SibalaNessuna valutazione finora

- SteamDocumento3 pagineSteamVon A. DamirezNessuna valutazione finora

- Mesl ElementsDocumento110 pagineMesl ElementsJay Mark CayonteNessuna valutazione finora

- Practice Problems (Pumps Agitation)Documento1 paginaPractice Problems (Pumps Agitation)Lin Xian XingNessuna valutazione finora

- (Mini Project-Shaft Design) : The University of Jordan School of EngineeringDocumento5 pagine(Mini Project-Shaft Design) : The University of Jordan School of EngineeringMou'ath AlhajjajNessuna valutazione finora

- NOTES+3+Calculations PEOP1009+ALL+Topics+v2Documento34 pagineNOTES+3+Calculations PEOP1009+ALL+Topics+v2cn4dd4wy9cNessuna valutazione finora

- 4.shear Stress in Beam PDFDocumento10 pagine4.shear Stress in Beam PDFharshdeepNessuna valutazione finora

- TyDocumento102 pagineTyJay Abainza0% (1)

- Addition of Vectors: - Analytical MethodDocumento7 pagineAddition of Vectors: - Analytical MethodNikka Moreen DagdagNessuna valutazione finora

- Steel Lecture 11Documento7 pagineSteel Lecture 11Gladwin Buquiron100% (1)

- Analytic Geometry 1: Prepared By: Engr. Junie A. ValendezDocumento26 pagineAnalytic Geometry 1: Prepared By: Engr. Junie A. ValendezMerlin QuipaoNessuna valutazione finora

- Basic Engineering Sciences Reviewer - CompleteDocumento87 pagineBasic Engineering Sciences Reviewer - Completeyomz719Nessuna valutazione finora

- Machine Design Final Coaching ProblemsDocumento63 pagineMachine Design Final Coaching ProblemsasapamoreNessuna valutazione finora

- MD Problems and Solutions Variable StressesDocumento9 pagineMD Problems and Solutions Variable StressesManoy BermeoNessuna valutazione finora

- FlywheelDocumento1 paginaFlywheelAngielou SialanaNessuna valutazione finora

- Geas IecepDocumento32 pagineGeas IecepJenn BantilingNessuna valutazione finora

- Pipe Set 1Documento10 paginePipe Set 1RENE JOSHUA PECASONessuna valutazione finora

- Machine Design VipDocumento55 pagineMachine Design VipGeorgiaNessuna valutazione finora

- Duaso With AnsDocumento35 pagineDuaso With AnsLito LapidNessuna valutazione finora

- Mechanical Engineering Problems Set 4 MathDocumento43 pagineMechanical Engineering Problems Set 4 MathAizNessuna valutazione finora

- Applied Thermodynamics - DraughtDocumento22 pagineApplied Thermodynamics - Draughtpiyush palNessuna valutazione finora

- Macdes BoardsDocumento6 pagineMacdes BoardsJerdNessuna valutazione finora

- R&AC Lecture 40Documento13 pagineR&AC Lecture 40Mohammed SiddiqueNessuna valutazione finora

- CE365 Hydro, HW 1 SolutionDocumento6 pagineCE365 Hydro, HW 1 SolutionbrayanNessuna valutazione finora

- 500 WordsDocumento44 pagine500 Wordsibong tiriritNessuna valutazione finora

- Unit 5Documento44 pagineUnit 5jothik1992_219826838Nessuna valutazione finora

- Axial Deformation SampleDocumento3 pagineAxial Deformation SampleBobbles D LittlelionNessuna valutazione finora

- MDSP ElementsDocumento71 pagineMDSP ElementsFernan MacusiNessuna valutazione finora

- Final - Hydroelectric Power PlantDocumento67 pagineFinal - Hydroelectric Power Plantbchandri100% (1)

- Problem Set MD Day 3Documento5 pagineProblem Set MD Day 3DE GUZMAN, MELVIN CARLO A.Nessuna valutazione finora

- R05220104-Hydraulics and Hydraulic MachineryDocumento8 pagineR05220104-Hydraulics and Hydraulic MachinerySRINIVASA RAO GANTANessuna valutazione finora

- Heat Transfer by S K Mondal-3-42Documento40 pagineHeat Transfer by S K Mondal-3-42Arpit Thakur0% (2)

- Refrigeration ProblemsDocumento3 pagineRefrigeration Problemsanask15Nessuna valutazione finora

- Module 4Documento18 pagineModule 4Kean BognotNessuna valutazione finora

- 1 FansDocumento20 pagine1 FansEasy WriteNessuna valutazione finora

- MDSPproblemsetDocumento8 pagineMDSPproblemsetJustine SomentacNessuna valutazione finora

- Flywheel ProblemsDocumento51 pagineFlywheel Problemsgiriaj kokareNessuna valutazione finora

- Chapter 2 Incompressible Flow Through PipesDocumento38 pagineChapter 2 Incompressible Flow Through Pipesطريخم المشتاق100% (1)

- 1.system of Numbers and ConversionDocumento20 pagine1.system of Numbers and ConversionAmpolNessuna valutazione finora

- Rivet ProblemDocumento4 pagineRivet ProblemK ULAGANATHANNessuna valutazione finora

- Linx Refresher Sept 2012 IPD PPD Without AnswersDocumento7 pagineLinx Refresher Sept 2012 IPD PPD Without AnswersDeyn EstoqueNessuna valutazione finora

- Bangun RuangDocumento17 pagineBangun Ruangsam_raunayNessuna valutazione finora

- Miscellaneous ElementsDocumento314 pagineMiscellaneous ElementsOnline EducatorNessuna valutazione finora

- Machine Desing 1 Exam #2 Problem Solving InstructionsDocumento2 pagineMachine Desing 1 Exam #2 Problem Solving InstructionsMarc JabarNessuna valutazione finora

- Ceng 231 Tutor 1Documento11 pagineCeng 231 Tutor 1lawekushNessuna valutazione finora

- Depth of Water in Conical Tank in Upright and Inverted Positions - Solid Geometry ReviewDocumento2 pagineDepth of Water in Conical Tank in Upright and Inverted Positions - Solid Geometry ReviewimrancenakkNessuna valutazione finora

- Unit-4 Induction MotorsDocumento26 pagineUnit-4 Induction MotorsAnurag Singhal0% (1)

- ME198D Design ElemetsDocumento2 pagineME198D Design ElemetsChloe OlazoNessuna valutazione finora

- Engineering Hydraulics/Pipeline CalculationsDocumento29 pagineEngineering Hydraulics/Pipeline Calculationsbasher rajabNessuna valutazione finora

- Esp SizingDocumento17 pagineEsp SizingAmin ElfatihNessuna valutazione finora

- Pipe System DesignDocumento64 paginePipe System DesignRonald GeorgeNessuna valutazione finora

- Addi Examples Pipe3Documento10 pagineAddi Examples Pipe3Diego MorenoNessuna valutazione finora

- Compressor FundamentalsDocumento28 pagineCompressor Fundamentalsbertan dağıstanlıNessuna valutazione finora

- Reciprocating PumpsDocumento16 pagineReciprocating PumpsMahmoud AfifyNessuna valutazione finora

- Blader Accumulator HydacDocumento7 pagineBlader Accumulator HydacAkbar SajadiNessuna valutazione finora

- SMD 1 2020 Z SNF HS CAL 0001 02 Safety Relief Valve Load Calculations (AutoRecovered)Documento4 pagineSMD 1 2020 Z SNF HS CAL 0001 02 Safety Relief Valve Load Calculations (AutoRecovered)Amr TarekNessuna valutazione finora

- Parts Diag. Syntia Class-Dgt Ita-Ing (Sup037dr) Rev.01Documento6 pagineParts Diag. Syntia Class-Dgt Ita-Ing (Sup037dr) Rev.01sasizzo78Nessuna valutazione finora

- Excela-Flo: First Stage / High Pressure Industrial RegulatorsDocumento1 paginaExcela-Flo: First Stage / High Pressure Industrial RegulatorsDavidNessuna valutazione finora

- Manual de Mantenimiento S1FDocumento41 pagineManual de Mantenimiento S1FpatricioNessuna valutazione finora

- Turbo Assign1-Turbo AllamDocumento10 pagineTurbo Assign1-Turbo AllamAbd El-Rahman NasserNessuna valutazione finora

- Steam Turbine FFCDocumento31 pagineSteam Turbine FFCTaha KhanNessuna valutazione finora

- Interview Questions On ME FMDocumento7 pagineInterview Questions On ME FMRitesh UpadhyayNessuna valutazione finora

- Rim 10Documento8 pagineRim 10Jeff BiggsNessuna valutazione finora

- The Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesDocumento6 pagineThe Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesMinh TranNessuna valutazione finora

- DFH High Pressure Duplex Filter AssembliesDocumento5 pagineDFH High Pressure Duplex Filter AssembliesAryoSatrioNessuna valutazione finora

- FTO Vs FTCDocumento6 pagineFTO Vs FTCRizky WahyuNessuna valutazione finora

- CALTEC General Presentation Oct 2015 Rev BDocumento48 pagineCALTEC General Presentation Oct 2015 Rev BIzzy IzzyNessuna valutazione finora

- 06.GPD155-F All New Nmax 155 Connected Version Radiator & HoseDocumento2 pagine06.GPD155-F All New Nmax 155 Connected Version Radiator & Hoseandi yusufNessuna valutazione finora

- Breakaway Valve TB - AUS4W-50 Break-Away ValveDocumento2 pagineBreakaway Valve TB - AUS4W-50 Break-Away Valveapi-3752216Nessuna valutazione finora

- Saep 311Documento30 pagineSaep 311GulfamNessuna valutazione finora

- Stress Analysis of Pump PipingDocumento5 pagineStress Analysis of Pump PipingSamNessuna valutazione finora

- 3A - Centrifugal PumpDocumento11 pagine3A - Centrifugal PumpM Afuw MudhaffarNessuna valutazione finora

- Shumatt 320D C7C9C-9 Spare Parts 2023-7-10 ListDocumento3 pagineShumatt 320D C7C9C-9 Spare Parts 2023-7-10 ListHéctor MujicaNessuna valutazione finora

- CLDFS - 2019 - Sauermann SI-1801 23 DATA SHEET - 01Documento2 pagineCLDFS - 2019 - Sauermann SI-1801 23 DATA SHEET - 01Miguel Ángel SaloméNessuna valutazione finora

- Spare Parts List: (1.081-200.0) SE 5.100 EUDocumento14 pagineSpare Parts List: (1.081-200.0) SE 5.100 EUgeorge pefanisNessuna valutazione finora

- RTA-71 Retrofit For Fuel Injection Pump Block For RTA96C and C-B EnginesDocumento14 pagineRTA-71 Retrofit For Fuel Injection Pump Block For RTA96C and C-B EnginesCatalin CataNessuna valutazione finora

- As Built: Ministry of Electricity, IRAQ QUDUS / 3 Gas Turbine Power PlantDocumento25 pagineAs Built: Ministry of Electricity, IRAQ QUDUS / 3 Gas Turbine Power Plantحارث اكرمNessuna valutazione finora

- ACT001-Mounting Kit Chart Rev AGDocumento18 pagineACT001-Mounting Kit Chart Rev AGJezie ReyesNessuna valutazione finora

- Prince Hydraulics - SS Selector Valve Offered by PRC Industrial SupplyDocumento1 paginaPrince Hydraulics - SS Selector Valve Offered by PRC Industrial SupplyPRC Industrial SupplyNessuna valutazione finora

- Reciprocating PumpsDocumento10 pagineReciprocating PumpsMae Ann Dolor EstrellanaNessuna valutazione finora

- H Pump PC 100-5Documento13 pagineH Pump PC 100-5eka sukandaNessuna valutazione finora

- Danuhm Bush Air Cooled Roof Top PACU-50HZ PDFDocumento16 pagineDanuhm Bush Air Cooled Roof Top PACU-50HZ PDFFalak KhanNessuna valutazione finora

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDa EverandArizona, Utah & New Mexico: A Guide to the State & National ParksValutazione: 4 su 5 stelle4/5 (1)

- The Bahamas a Taste of the Islands ExcerptDa EverandThe Bahamas a Taste of the Islands ExcerptValutazione: 4 su 5 stelle4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDa EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNessuna valutazione finora

- New York & New Jersey: A Guide to the State & National ParksDa EverandNew York & New Jersey: A Guide to the State & National ParksNessuna valutazione finora

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDa EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptValutazione: 5 su 5 stelle5/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDa EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoValutazione: 5 su 5 stelle5/5 (1)