Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DCM Sessoin

Caricato da

LakshmiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DCM Sessoin

Caricato da

LakshmiCopyright:

Formati disponibili

1

DC Motor Speed Modeling

Lecture delivered by:

V SitaramGupta

Session-3

2

DC Motor Speed Modeling

The DC motor has been the workhorse in industry for many reasons including good

torque speed characteristics.

It is a common actuator in control systems. It directly provides rotary motion and,

coupled with wheels or drums and cables, can provide transitional motion.

The electric circuit of the armature and the free body diagram of the rotor are

shown in the following Figure.

We develop here the transfer function of a separately excited armature controlled

DC motor.

Motor

Generator

Mechanical

energy

(T, e)

V

A

R

A

I

A

V

F

R

F

L

F

I

F

L

u

k

J motor & load

T

e

Field circuit Armature circuit

3

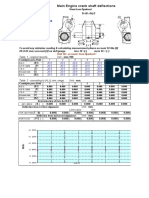

Physical Parameters

Electrical Resistance R= 1 O

Electrical Inductance L = 0.5 H

Input Voltage V

Electromotive Force Constant K = 0.01 nm/A

Moment of Inertia of the Rotor J = 0.01 kg.m

2

/s

2

Damping Ratio of the Mechanical System b = 0.1 Nms

Position of the Shaft u

The rotor and shaft are assumed to be rigid

The motor torque T is related to the armature current by a constant Kt

The back emf, e, is related to the rotational velocity

u

u u

u

K V Ri

dt

di

L

Ki b J

K e

i K T

e

t

= +

= +

=

=

4

Speed Control

Speed Control by Varying Circuit Resistance: The operating speed can only be

adjusted downwards by varying the external resistance, R

ext

Speed Control by Varying Excitation Flux:

Speed Control by Varying Applied Voltage: Wide range of control 25:1; fast

acceleration of high inertia loads.

Electronic Control.

( )

rad/s

2 2

| | |

e

a

ext a

a a

a a a

m

k

R R

k

Va

k

I R V +

=

=

1

2

2

1

|

|

e

e

=

m

m

5

Transfer Function

2

) )( (

) ( ) ( ) (

) ( ) ( ) (

K R Ls b Js

K

V

s Ks V s I R Ls

s KI s b Js s

+ + +

=

= +

= +

u

u

u

Controller Plant

R

u

u

A common actuator in control systems is the DC motor. It

directly provides rotary motion and, coupled with wheels or

drums and cables, can provide transitional motion.

The electric circuit of the armature and the free body diagram

of the rotor are shown in the following figure:

6

Physical setup and system equations

7

Specifications

For this example, we will assume the following values for the

physical parameters.

moment of inertia of the rotor (J) = 0.01 kg.m^2/s^2

damping ratio of the mechanical system (b) = 0.1 Nms

electromotive force constant (K=Ke=Kt) = 0.01 Nm/Amp

electric resistance (R) = 1 ohm

electric inductance (L) = 0.5 H

input (V): Source Voltage

output (theta): position of shaft

The rotor and shaft are assumed to be rigid

8

Modeling

The motor torque, T, is related to the armature current, i, by a

constant factor Kt. The back emf, e, is related to the rotational

velocity by the following equations:

In SI units (which we will use), Kt (armature constant) is equal

to Ke (motor constant).

From the figure above we can write the following equations based

on Newton's law combined with Kirchhoff's law:

9

Transfer Function

Using Laplace Transforms, the above modeling equations can

be expressed in terms of s.

By eliminating I(s) we can get the following open-loop

transfer function, where the rotational speed is the output and

the voltage is the input.

10

State-Space

In the state-space form, the equations above can be

expressed by choosing the rotational speed and electric

current as the state variables and the voltage as an input.

The output is chosen to be the rotational speed

11

Design Requirements

First, our uncompensated motor can only rotate at 0.1

rad/sec with an input voltage of 1 Volt (this will be

demonstrated later when the open-loop response is

simulated).

Since the most basic requirement of a motor is that it

should rotate at the desired speed, the steady-state

error of the motor speed should be less than 1%.

Design Requirements

The other performance requirement is that the motor

must accelerate to its steady-state speed as soon as it

turns on.

In this case, we want it to have a settling time of 2

seconds. Since a speed faster than the reference may

damage the equipment, we want to have an overshoot

of less than 5%.

If we simulate the reference input (r) by an unit step

input, then the motor speed output should have:

Settling time less than 2 seconds, Overshoot less than

5%, Steady-state error less than 1%

12

MATLAB Representation

and open-loop response

1. Transfer Function

We can represent the above transfer function into MATLAB by defining

the numerator and denominator matrices as follows:

Create a new m-file and enter the following commands:

J=0.01;

b=0.1;

K=0.01;

R=1;

L=0.5;

num=K;

den=[(J*L) ((J*R)+(L*b)) ((b*R)+K^2)];

motor=tf(num,den);

13

14

Output Response

Now let's see how the original open-loop system performs. Add

the following commands onto the end of the m-file and run it in

the MATLAB command window:

step(motor,0:0.1:3);

title('Step Response for the Open Loop System');

The output plot is as follows:

Output Response

From the plot we see that when 1 volt is applied to

the system, the motor can only achieve a maximum

speed of 0.1 rad/sec, ten times smaller than our

desired speed.

Also, it takes the motor 3 seconds to reach its steady-

state speed; this does not satisfy our 2 seconds

settling time criterion

15

16

State Space

2. State-Space

We can also represent the system using the state-space equations. Try the

following commands in a new m-file.

J=0.01;

b=0.1;

K=0.01;

R=1;

L=0.5;

A=[-b/J K/J -K/L -R/L];

B=[0 1/L];

C=[1 0];

D=0;

motor_ss=ss(A,B,C,D);

step(motor_ss)

Run this m-file in the

MATLAB command window, and

you should get the same output as

the one shown above.

17

PID Design Method for

DC Motor Speed Control

18

Modeling

From the main problem, the dynamic equations and

the open-loop transfer function of the DC Motor are

and the system schematic looks like:

Modeling

For the original problem setup and the derivation of the above equations, please

refer to the Modeling a DC Motor page.

With a 1 rad/sec step input, the design criteria are:

Settling time less than 2 seconds

Overshoot less than 5%

Steady-stage error less than 1%

Now let's design a PID controller and add it into the system. First create a new m-

file and type in the following commands.

J=0.01;

b=0.1;

K=0.01;

R=1;

L=0.5;

num=K;

den=[(J*L) ((J*R)+(L*b)) ((b*R)+K^2)];

motor=tf(num,den);

19

Recall that the transfer function for a

PID controller is:

Proportional control

Let's first try using a proportional controller with a gain of

100. To determine the closed-loop transfer function, we use

the feedback command. Add the following code to the end of

your m-file:

Kp=100;

contr=Kp;

sys_cl=feedback(contr*motor,1);

Now let's see how the step response looks. Add the following

to the end of your m-file, and run it in the command window:

t=0:0.01:5;

step(sys_cl,t)

title('Step response with Proportional Control')

You should get the following plot:

20

Response

21

PID control

From the plot above we see that both the steady-state

error and the overshoot are too large.

Recall from the PID tutorial page that adding an

integral term will eliminate the steady-state error and

a derivative term will reduce the overshoot.

Let's try a PID controller with small Ki and Kd.

Change your m-file so it looks like the following.

Running this new m-file gives you the following plot.

J=0.01;

b=0.1;

K=0.01;

22

Program

R=1;

L=0.5;

num=K;

den=[(J*L) ((J*R)+(L*b)) ((b*R)+K^2)];

motor=tf(num,den);

Kp=100;

Ki=1;

Kd=1;

contr=tf([Kd Kp Ki],[1 0]);

sys_cl=feedback(contr*motor,1);

step(sys_cl)

title('PID Control with small Ki and Kd')

23

Result

24

Tuning the gains

Now the settling time is too long. Let's increase K

i

to

reduce the settling time. Go back to your m-file and

change K

i

to 200. Rerun the file and you should get a

plot like this:

25

Gains

Now we see that the response is much faster than

before, but the large Ki has worsened the transient

response (big overshoot). Let's increase Kd to reduce

the overshoot. Go back to the m-file and change Kd

to 10. Rerun it and you should get this plot:

26

So now we know that if we use a

PID controller with

Kp=100,

Ki=200,

Kd=10,

all of our design requirements

will be satisfied.

DC Motor Speed Modeling in Simulink

Physical setup

A common actuator in control systems is the DC

motor.

It directly provides rotary motion and, coupled with

wheels or drums and cables, can provide transitional

motion.

The electric circuit of the armature and the free body

diagram of the rotor are shown in the following

figure:

27

Specifications

For this example, we will assume the following values for the

physical parameters.

moment of inertia of the rotor (J) = 0.01 kg.m^2/s^2

damping ratio of the mechanical system (b) = 0.1 Nms

electromotive force constant (K=Ke=Kt) = 0.01 Nm/Amp

electric resistance (R) = 1 ohm

electric inductance (L) = 0.5 H

input (V): Source Voltage

output (theta): position of shaft

The rotor and shaft are assumed to be rigid

28

Modeling

The motor torque, T, is related to the armature

current, i, by a constant factor Kt.

The back emf, e, is related to the rotational velocity by

the following equations:

In SI units (which we will use), Kt (armature constant)

is equal to Ke (motor constant).

29

Building the Model

This system will be modeled by summing the torques

acting on the rotor inertia and integrating the

acceleration to give the velocity.

Also, Kirchoff's laws will be applied to the armature

circuit.

Open Simulink and open a new model window.

First, we will model the integrals of the rotational

acceleration and of the rate of change of armature

current.

30

Modeling

Insert an Integrator block (from the Linear block

library) and draw lines to and from its input and

output terminals.

Label the input line "d2/dt2(theta)" and the output

line "d/dt(theta)" as shown below. To add such a

label, double click in the empty space just above the

line.

Insert another Integrator block above the previous

one and draw lines to and from its input and output

terminals.

Label the input line "d/dt(i)" and the output line "i"

31

Simulink

32

Model

Next, we will start to model both Newton's law and Kirchoff's

law. These laws applied to the motor system give the

following equations:

The angular acceleration is equal to 1/J multiplied by the sum

of two terms (one pos., one neg.). Similarly, the derivative of

current is equal to 1/L multiplied by the sum of three terms

(one pos., two neg.).

Insert two Gain blocks, (from the Linear block library) one

attached to each of the integrators.

33

Model

Edit the gain block corresponding to angular acceleration by

double-clicking it and changing its value to "1/J".

Change the label of this Gain block to "inertia" by clicking on

the word "Gain" underneath the block.

Similarly, edit the other Gain's value to "1/L" and it's label to

Inductance.

Insert two Sum blocks (from the Linear block library), one

attached by a line to each of the Gain blocks.

Edit the signs of the Sum block corresponding to rotation to

"+-" since one term is positive and one is negative.

Edit the signs of the other Sum block to "-+-" to represent the

signs of the terms in Kirchoff's equation.

34

Simulink

35

Procedure

Now, we will add in the torques which are represented in

Newton's equation. First, we will add in the damping torque.

Insert a gain block below the inertia block, select it by single-

clicking on it, and select Flip from the Format menu (or type

Ctrl-F) to flip it left-to-right.

Set the gain value to "b" and rename this block to "damping".

Tap a line (hold Ctrl while drawing) off the rotational

integrator's output and connect it to the input of the damping

gain block.

Draw a line from the damping gain output to the negative input

of the rotational Sum block.

36

Procedure

Next, we will add in the torque from the armature.

Insert a gain block attached to the positive input of

the rotational Sum block with a line.

Edit it's value to "K" to represent the motor constant

and Label it "Kt".

Continue drawing the line leading from the current

integrator and connect it to the Kt gain block.

37

Simulink

38

Procedure

Now, we will add in the voltage terms which are represented

in Kirchoff's equation. First, we will add in the voltage drop

across the coil resistance.

Insert a gain block above the inductance block, and flip it left-

to-right.

Set the gain value to "R" and rename this block to

"Resistance".

Tap a line (hold Ctrl while drawing) off the current integrator's

output and connect it to the input of the resistance gain block.

Draw a line from the resistance gain output to the upper

negative input of the current equation Sum block.

39

Procedure

Next, we will add in the back emf from the motor.

Insert a gain block attached to the other negative

input of the current Sum block with a line.

Edit it's value to "K" to represent the motor constant

and Label it "Ke".

Tap a line off the rotational integrator output and

connect it to the Ke gain block.

40

Simulink

41

Procedure

The third voltage term in the Kirchoff equation is the

control input, V. We will apply a step input.

Insert a Step block (from the Sources block library)

and connect it with a line to the positive input of the

current Sum block.

To view the output speed, insert a Scope (from the

Sinks block library) connected to the output of the

rotational integrator.

To provide a appropriate unit step input at t=0,

double-click the Step block and set the Step Time to

"0".

42

Simulink

43

Open-loop response

To simulate this system, first, an appropriate simulation time

must be set. Select Parameters from the Simulation menu and

enter "3" in the Stop Time field. 3 seconds is long enough to

view the open-loop response. The physical parameters must

now be set. Run the following commands at the

MATLAB prompt:

J=0.01;

b=0.1;

K=0.01;

R=1;

L=0.5;

44

Response

Run the simulation (Ctrl-t or Start on the Simulation

menu).

When the simulation is finished, double-click on the

scope and hit its autoscale button.

You should see the following output.

45

Extracting a Linear Model into MATLAB

A linear model of the system (in state space or

transfer function form) can be extracted from a

Simulink model into MATLAB.

This is done through the use of In and Out

Connection blocks and the ATLAB function linmod.

First, replace the Step Block and Scope Block with an

In Connection Block and an Out Connection Block,

respectively (these blocks can be found in the

Connections block library).

This defines the input and output of the system for the

extraction process.

46

Simulink

47

Procedure

Save your file as "motormod.mdl" (select Save As

from the File menu). MATLAB will extract the linear

model from the saved model file, not from the open

model window. At the MATLAB prompt, enter the

following commands:

[A,B,C,D]=linmod('motormodel')

[num,den]=ss2tf(A,B,C,D)

You should see the following output, providing both

state-space and transfer function models of the

system.

48

Matrix values

A = -10.0000 1.0000

-0.0200 -2.0000

B = 0 2

C = 1 0

D = 0

num = 0 0.0000 2.0000

den = 1.0000 12.0000 20.0200

49

Procedure

To verify the model extraction, we will generate an

open-loop step response of the extracted transfer

function in MATLAB. Enter the following command

in MATLAB.

step(num,den);

You should see the following plot which is equivalent

to the Scope's output.

50

Response

51

Implementing Lag Compensator Control

In the motor speed control root locus example a Lag

Compensator was designed with the following

transfer function.

To implement this in Simulink, we will contain the

open-loop system from earlier in this page in a

Subsystem block.

Create a new model window in Simulink.

Drag a Subsystem block from the Connections block

library into your new model window.

52

Simulink

53

Procedure

Double click on this block. You will see a blank window

representing the contents of the subsystem (which is currently

empty).

Open your previously saved model of the Motor Speed

system, motormod.mdl.

Select Select All from the Edit menu (or Ctrl-A), and select

Copy from the Edit menu (or Ctrl-C).

Select the blank subsystem window from your new model and

select Paste from the Edit menu (or Ctrl-V). You should see

your original system in this new subsystem window.

Close this window. You should now see input and output

terminals on the Subsystem block.

Name this block "plant model".

54

Simulink

55

Procedure

Now, we will insert a Lag Compensator into a closed-

loop around the plant model. First, we will feed back

the plant output.

Draw a line extending from the plant output.

Insert a Sum block and assign "+-" to it's inputs.

Tap a line of the output line and draw it to the

negative input of the Sum block.

56

Simulink

57

Procedure

The output of the Sum block will provide the error

signal. We will feed this into a Lag Compensator.

Insert a Transfer Function Block after the summer

and connect them with a line.

Edit this block and change the Numerator field to

"[50 50]" and the Denominator field to "[1 0.01]".

Label this block "Lag Compensator".

58

Simulink

59

Procedure

Finally, we will apply a step input and view the

output on a scope.

Attach a step block to the free input of the feedback

Sum block and attach a Scope block to the plant

output.

Double-click the Step block and set the Step Time to

"0".

60

Simulink

61

You can download our version of the closed-loop

system here

Closed-loop response

To simulate this system, first, an appropriate simulation time

must be set. Select Parameters from the Simulation menu and

enter "3" in the Stop Time field.

The design requirements included a settling time of less than 2

sec, so we simulate for 3 sec to view the output. The physical

parameters must now be set. Run the following commands at

the MATLAB prompt:

J=0.01;

b=0.1;

K=0.01;

R=1;

L=0.5;

62

Conclusion

Run the simulation (Ctrl-t or Start on the Simulation

menu).

When the simulation is finished, double-click on the

scope and hit its autoscale button. You should see the

following output

63

Potrebbero piacerti anche

- Physical Setup and System Equations: Photo CourtesyDocumento5 paginePhysical Setup and System Equations: Photo CourtesySunil JainNessuna valutazione finora

- DC Motor Speed ModelingDocumento4 pagineDC Motor Speed ModelingAvinash TrivediNessuna valutazione finora

- PID Speed Control of DC MotorDocumento5 paginePID Speed Control of DC MotorSunil KumarNessuna valutazione finora

- DC MotorDocumento6 pagineDC MotorKumaran SgNessuna valutazione finora

- D CMotorSpeedDocumento8 pagineD CMotorSpeedjijo123408Nessuna valutazione finora

- Lab Manual - EEE 402 - Exp01 July2014Documento7 pagineLab Manual - EEE 402 - Exp01 July2014AhammadSifatNessuna valutazione finora

- Example: DC Motor Speed Modeling: Physical Setup and System EquationsDocumento18 pagineExample: DC Motor Speed Modeling: Physical Setup and System EquationsĐức SinhNessuna valutazione finora

- Modeling and Experimental Validation of A First Order Plant Model: DC Servo MotorDocumento17 pagineModeling and Experimental Validation of A First Order Plant Model: DC Servo Motormeghraj01Nessuna valutazione finora

- Proportional-Integral-Derivative (PID) Control: Velocity ResponseDocumento34 pagineProportional-Integral-Derivative (PID) Control: Velocity ResponseFadi AlbatshNessuna valutazione finora

- UAEU Electrical Engineering AGC Project ReportDocumento87 pagineUAEU Electrical Engineering AGC Project ReportpadmajasivaNessuna valutazione finora

- Experiment No. 02 Name of The Experiment: Modeling of Physical Systems and Study of Their Closed Loop Response ObjectiveDocumento6 pagineExperiment No. 02 Name of The Experiment: Modeling of Physical Systems and Study of Their Closed Loop Response ObjectiveMd SayemNessuna valutazione finora

- Design Problem Matlab Project TFDocumento19 pagineDesign Problem Matlab Project TFhumayun azizNessuna valutazione finora

- DCS Lab 5 Report (Zain, Umer, Abdullah)Documento9 pagineDCS Lab 5 Report (Zain, Umer, Abdullah)Muhammad UmerNessuna valutazione finora

- Control Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud) PDFDocumento183 pagineControl Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud) PDFShakil Ahmed100% (1)

- Control Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud)Documento183 pagineControl Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud)Anik PaulNessuna valutazione finora

- Exp01 EEE318Documento7 pagineExp01 EEE318Abid AbdullahNessuna valutazione finora

- Control System NotesDocumento199 pagineControl System NotesCarson R. Dick100% (2)

- 341 ReportDocumento6 pagine341 ReportNofilNessuna valutazione finora

- Speed Control of Separately Excited D.C. Motor: Chayan Kumar, Prof. (DR.) Deoraj Kumar TantiDocumento11 pagineSpeed Control of Separately Excited D.C. Motor: Chayan Kumar, Prof. (DR.) Deoraj Kumar TantiWieNessuna valutazione finora

- EE 392 Lab 2: DC Motor Speed Control DesignDocumento4 pagineEE 392 Lab 2: DC Motor Speed Control DesignAbdalla FathyNessuna valutazione finora

- Lecture I - Introduction To PID Control SystemDocumento47 pagineLecture I - Introduction To PID Control SystemR.W. SaputraNessuna valutazione finora

- Closed-Loop Control of DC Drives With Controlled RectifierDocumento40 pagineClosed-Loop Control of DC Drives With Controlled Rectifierathan19490% (1)

- Servo Motor Modelling Using Bump Test: Expt - No-8 Aditya Das 17BEE0267Documento3 pagineServo Motor Modelling Using Bump Test: Expt - No-8 Aditya Das 17BEE0267ADITYA DAS 17BEE0267Nessuna valutazione finora

- Circuit For Simulation:: Transfer Function Analysis of A DC MotorDocumento2 pagineCircuit For Simulation:: Transfer Function Analysis of A DC Motork rajendraNessuna valutazione finora

- DC Motor Speed Transfer Function and State-Space ModelingDocumento13 pagineDC Motor Speed Transfer Function and State-Space ModelingMohamed Elsayed HarbNessuna valutazione finora

- Simulate DC Motor Speed in SimulinkDocumento3 pagineSimulate DC Motor Speed in Simulinkarjunv_14Nessuna valutazione finora

- Research and Apply PID Hybrid Fuzzy Control TechnologyDocumento6 pagineResearch and Apply PID Hybrid Fuzzy Control TechnologyhoangepuNessuna valutazione finora

- Control Theory Project WriteupDocumento13 pagineControl Theory Project WriteupElyar AiretiNessuna valutazione finora

- Modeling and Analysis of Slip Power Recovery Controlled Induction Motor DriveDocumento4 pagineModeling and Analysis of Slip Power Recovery Controlled Induction Motor Drivesatti849Nessuna valutazione finora

- 5 Controlled Rectifier DC Drives-Closed Loop - PpsDocumento41 pagine5 Controlled Rectifier DC Drives-Closed Loop - PpsRanjan KumarNessuna valutazione finora

- Analysis of Boost Converter Using PI Control AlgorithmsDocumento3 pagineAnalysis of Boost Converter Using PI Control AlgorithmsTrương Văn TrọngNessuna valutazione finora

- Disturbance Observer Based Current Controller For A Brushed DC MotorDocumento6 pagineDisturbance Observer Based Current Controller For A Brushed DC MotorAji Brahma NugrohoNessuna valutazione finora

- Control of A Double Inverted Pendulum On ADocumento12 pagineControl of A Double Inverted Pendulum On AJoseph CassarNessuna valutazione finora

- Speed Control of DC Motor Using Pid Controller Based On MatlabDocumento8 pagineSpeed Control of DC Motor Using Pid Controller Based On MatlabAlexander DeckerNessuna valutazione finora

- Modeling DC Motor Position ControlDocumento4 pagineModeling DC Motor Position ControlKartik DetrojaNessuna valutazione finora

- Embedded Systems Interfacing Speed ControlDocumento7 pagineEmbedded Systems Interfacing Speed ControlAndy MeyerNessuna valutazione finora

- A Design of The DC Motor Control CircuitDocumento9 pagineA Design of The DC Motor Control Circuitnyskyscraper051127Nessuna valutazione finora

- CTMS Example - Motor Position Control ModelingDocumento4 pagineCTMS Example - Motor Position Control ModelingSinggih AndreansNessuna valutazione finora

- Linear Control Chapter 1Documento15 pagineLinear Control Chapter 1Himanshu SinghNessuna valutazione finora

- D.C control matlab روكانDocumento17 pagineD.C control matlab روكانMustafa AlhumayreNessuna valutazione finora

- Simulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodDocumento7 pagineSimulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodseventhsensegroupNessuna valutazione finora

- Ee 331 Design - Servo MotorDocumento5 pagineEe 331 Design - Servo MotorLa-Pierre O'MeallyNessuna valutazione finora

- 1 - Modeling DC Motor PositionDocumento4 pagine1 - Modeling DC Motor PositionHenry ArelaNessuna valutazione finora

- Control System ExperimentsDocumento47 pagineControl System ExperimentsRicky RawNessuna valutazione finora

- Servo FundamentalsDocumento11 pagineServo Fundamentalsapi-3797895Nessuna valutazione finora

- AkhilsinghDocumento13 pagineAkhilsinghalpha kumarNessuna valutazione finora

- MatLAB SimPowerSystems for Modelling and SimulationDocumento10 pagineMatLAB SimPowerSystems for Modelling and SimulationSemih Cem İlikNessuna valutazione finora

- CS LabReport 1Documento9 pagineCS LabReport 1Muhammad AfzaalNessuna valutazione finora

- Motor Speed 1Documento22 pagineMotor Speed 1Narciso VasquezNessuna valutazione finora

- FEEDCON - Lesson 08 - Closed-Loop Control Systems Part 2Documento36 pagineFEEDCON - Lesson 08 - Closed-Loop Control Systems Part 2Junaid YNessuna valutazione finora

- Designing & Building an Inclined Elevator PrototypeDocumento50 pagineDesigning & Building an Inclined Elevator Prototypef412ul_iv100% (1)

- Control of DC Motor Using Different Control StrategiesDa EverandControl of DC Motor Using Different Control StrategiesNessuna valutazione finora

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorDa EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNessuna valutazione finora

- Variable Speed AC Drives with Inverter Output FiltersDa EverandVariable Speed AC Drives with Inverter Output FiltersNessuna valutazione finora

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkDa EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDa EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlValutazione: 5 su 5 stelle5/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDa EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetValutazione: 2 su 5 stelle2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDa EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNessuna valutazione finora

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsDa EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNessuna valutazione finora

- Humidity Measurement: Instrumentation Engineering DepartmentDocumento24 pagineHumidity Measurement: Instrumentation Engineering DepartmentLakshmiNessuna valutazione finora

- Sensorsinautomobiles 141008081000 Conversion Gate01Documento35 pagineSensorsinautomobiles 141008081000 Conversion Gate01LakshmiNessuna valutazione finora

- Forcemeasurement 150627102332 Lva1 App6891Documento23 pagineForcemeasurement 150627102332 Lva1 App6891LakshmiNessuna valutazione finora

- Ipi Unit 2 Flow MeasurementDocumento19 pagineIpi Unit 2 Flow MeasurementLakshmiNessuna valutazione finora

- PDCDocumento158 paginePDCLakshmiNessuna valutazione finora

- Engineering MetrologyDocumento157 pagineEngineering MetrologyKr Ish Na100% (2)

- Lecture9 p3 17Documento15 pagineLecture9 p3 17Macbook ProNessuna valutazione finora

- Foli Ap 1-1Documento4 pagineFoli Ap 1-1LakshmiNessuna valutazione finora

- ElecReadingII Motors PDFDocumento11 pagineElecReadingII Motors PDFLakshmiNessuna valutazione finora

- 6 Log Anti Log AmplifiersDocumento32 pagine6 Log Anti Log AmplifiersAnonymous eWMnRr70q0% (1)

- IPI UNIT 2 Level MeasurementDocumento21 pagineIPI UNIT 2 Level MeasurementLakshmiNessuna valutazione finora

- Lecture NotesDocumento136 pagineLecture Notestoymaker09Nessuna valutazione finora

- Lab Manual AdslatestDocumento62 pagineLab Manual AdslatestLakshmiNessuna valutazione finora

- IPI Unit Consistency Measurement DevicesDocumento18 pagineIPI Unit Consistency Measurement DevicesLakshmiNessuna valutazione finora

- Microprocessors AldosariDocumento34 pagineMicroprocessors Aldosarikavi22656Nessuna valutazione finora

- FilterDocumento4 pagineFilterJohny AugustNessuna valutazione finora

- Hy Wire CarDocumento21 pagineHy Wire CarRahul SharmaNessuna valutazione finora

- Sinus InfectionsDocumento5 pagineSinus InfectionsLakshmiNessuna valutazione finora

- Virtual Instrumentation.Documento7 pagineVirtual Instrumentation.LakshmiNessuna valutazione finora

- PID Sessoin 1Documento27 paginePID Sessoin 1LakshmiNessuna valutazione finora

- Or Based A Synchronous Binary Search Sub ADCDocumento3 pagineOr Based A Synchronous Binary Search Sub ADCLakshmiNessuna valutazione finora

- Matlab and Simulink For Control SystemDocumento35 pagineMatlab and Simulink For Control SystemLakshmiNessuna valutazione finora

- ABS Case Study Session 4Documento68 pagineABS Case Study Session 4LakshmiNessuna valutazione finora

- Chapter 2: Optimum Controller Chapter 2: Optimum Controller Settings Settings GGDocumento5 pagineChapter 2: Optimum Controller Chapter 2: Optimum Controller Settings Settings GGLakshmiNessuna valutazione finora

- Geothermal Energy Technologies and CostsDocumento3 pagineGeothermal Energy Technologies and CostsLakshmiNessuna valutazione finora

- Polytechnic Lecturers NotificationDocumento46 paginePolytechnic Lecturers NotificationsareenckNessuna valutazione finora

- Fuel Cell Green Power Los Alamos ReviewDocumento36 pagineFuel Cell Green Power Los Alamos Reviewale_xxx123Nessuna valutazione finora

- En010 104 Engineering MechanicsDocumento1 paginaEn010 104 Engineering MechanicsArun SaiNessuna valutazione finora

- Henk Colijn 040 Fontana Labs Colijn.1@osu - Edu 292-0674Documento66 pagineHenk Colijn 040 Fontana Labs Colijn.1@osu - Edu 292-0674Charles HoNessuna valutazione finora

- Newtonian Fluid - WikipediaDocumento5 pagineNewtonian Fluid - Wikipediaamit kumar guptaNessuna valutazione finora

- Introduction To Random MatricesDocumento508 pagineIntroduction To Random Matricesjorelex100% (1)

- Toshiba Just Vision 200Documento2 pagineToshiba Just Vision 200kazugawa100% (4)

- Qa TableDocumento9 pagineQa Tableapi-299403846Nessuna valutazione finora

- TOP 10 PAKISTANI SCIENTISTSDocumento5 pagineTOP 10 PAKISTANI SCIENTISTSabsarNessuna valutazione finora

- Moc3011 PDFDocumento7 pagineMoc3011 PDFAlvaro Mompi RuizNessuna valutazione finora

- Learning Objectives-2: Uniform MotionDocumento7 pagineLearning Objectives-2: Uniform MotionBryanHarold BrooNessuna valutazione finora

- Nitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's EncyclopediaDocumento49 pagineNitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's Encyclopediapoly6icsNessuna valutazione finora

- Induction MotorDocumento27 pagineInduction MotorNandhini SaranathanNessuna valutazione finora

- Part Number 26-84: Illustrated Parts BreakdownDocumento90 paginePart Number 26-84: Illustrated Parts BreakdownJesus OliverosNessuna valutazione finora

- Unconfined Compression Test: Experiment No. 3Documento6 pagineUnconfined Compression Test: Experiment No. 3Patricia TubangNessuna valutazione finora

- CBSE Physics Lab Manual Part 6Documento19 pagineCBSE Physics Lab Manual Part 6ArasuArunNessuna valutazione finora

- STRATEGIES TO IMPROVE TOEFL STRUCTURE EXERCISE PERFORMANCEDocumento5 pagineSTRATEGIES TO IMPROVE TOEFL STRUCTURE EXERCISE PERFORMANCENIARAMLINessuna valutazione finora

- Smart MaterialsDocumento48 pagineSmart Materialsmjrobust05Nessuna valutazione finora

- EdmDocumento2 pagineEdmOmkar RahateNessuna valutazione finora

- Astm 1784Documento4 pagineAstm 1784arifin rizalNessuna valutazione finora

- Solutions ManualDocumento5 pagineSolutions ManualYoni BenshaharNessuna valutazione finora

- Crankweb Deflections 9 Cyl ELANDocumento2 pagineCrankweb Deflections 9 Cyl ELANСлавик МосинNessuna valutazione finora

- Catalog WefatermDocumento55 pagineCatalog WefatermAlin NicolaeNessuna valutazione finora

- Lukac Perkowski Book Introduction and Quantum MechanicsDocumento104 pagineLukac Perkowski Book Introduction and Quantum MechanicsSitalk TeresNessuna valutazione finora

- Teaching Quantum Mechanics On An Introductory Level PDFDocumento10 pagineTeaching Quantum Mechanics On An Introductory Level PDF24263537Nessuna valutazione finora

- SBT Mechanics TH 1Documento535 pagineSBT Mechanics TH 1Shreyas Singh100% (2)

- Circuit BreakerDocumento70 pagineCircuit BreakerBADAL CHOUDHARYNessuna valutazione finora

- The Evolution of Consciousness According to Bhagavad-GitaDocumento14 pagineThe Evolution of Consciousness According to Bhagavad-Gitatrabajo mpdNessuna valutazione finora

- Analysis of Buckling of Piles Fully Embedded in Ground According To Finite Element MethodDocumento5 pagineAnalysis of Buckling of Piles Fully Embedded in Ground According To Finite Element Methodctlim88Nessuna valutazione finora

- ZL - 205Documento2 pagineZL - 205Fraz AhmadNessuna valutazione finora

- All Ceramic Material SelectionDocumento6 pagineAll Ceramic Material SelectionERIKA BLANQUETNessuna valutazione finora

- High Pressure Vessel Thickness CalculationsDocumento11 pagineHigh Pressure Vessel Thickness CalculationsShriyash DeshpandeNessuna valutazione finora