Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluid Mechanics Presentation

Caricato da

Jlee LepuruDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fluid Mechanics Presentation

Caricato da

Jlee LepuruCopyright:

Formati disponibili

1

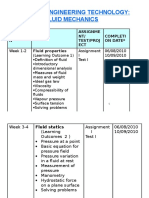

CHEMICAL ENGINEERING TECHNOLOGY:

FLUID MECHANICS

DURATION THEME

ASSIGNMENT/

TEST/PROJECT

COMPLETION

DATE*

Week 1-2 Fluid properties (Learning

Outcome 1)

-Definition of fluid

-Introductory dimensional

analysis

-Measures of fluid mass

and weight

-Ideal gas law

-Viscosity

-Compressibility of fluids

-Vapour pressure

-Surface tension

-Solving problems

Assignment I

Test I

06/08/2010

10/09/2010

2

Week 3-4 Fluid statics (Learning

Outcomes 2 )

- Pressure at a point

- Basic equation for

pressure field

- Pressure variation in a

fluid at rest

- Measurement of

pressure

- Manometry

- Hydrostatic force on a

plane surface

- Solving problems

Assignment I

Test I

06/08/2010

10/09/2010

3

Week 5- 6 Flow of fluids(Learning

Outcomes 3 )

- Conservation of

mass

- Conservation of

energy

- Conservation of

momentum

Assignment

II

Test I

03/09/2010

10/09/2010

Week 7-8

Flow in pipes(Learning

Outcomes 4 )

- General

characteristics of

pipe flow

- Fully developed

laminar flow

- Fully developed

turbulent

- Dimensional analysis

of pipe flow

Assignment

III

Test II

01/10/2010

22/10/2010

4

Week 9-10 Flow measurement

(Learning Outcomes 5 )

- Introduction

- Rotameter

- Venturi meter

- Pitot tube

- Orifice meter

- Vortex flow meter

Assignment III

Test II

01/10/2010

22/10/2010

5

Week 11-15 Centrifugal pumps

(Learning Outcomes 6 )

- Types of pumps

- Centrifugal pump theory

- Ideal pump

- Actual pump

performance

- Power transmission

- Types of impellers

- Pump cavitation

- Factors that affect pump

capacity

- Multistage centrifugal

pumps

- Leakproof centrifugal

pumps

- Pump priming

- Solving problems

Assignment IV

Test III

15/10/2010

22/10/2010

6

Course objectives

By the end of this module students should be able to:

1. Have a clear understanding of the basic properties of fluid

2. Develop a clear understanding of pressure and its

variation throughout a fluid

3. Perform mathematical calculations for fluid at rest

4. Apply the principles of conservation of mass, momentum and

energy to fluid flow

5. Apply the basic principles of fluid flow to flow of viscous,

incompressible fluids in pipes

6. Perform flow measurements calculations

7. Design centrifugal pumps

Note: If time allows, we will do flow of compressible fluids

7

Reference books

Coulson and Richardsons Chemical Engineering Vol. 1.

Butterworth Heinemann

B.R. Munson. Fundamentals of Fluid mechanics.

Wiley International Edition

James O. Wilke. Fluid Mechanics for Chemical Engineers

Assessments

Semester Tests: 2, total 50%

Assignments: 50%

Examination

40% semester mark is required for

admission

8

Chapter One: Properties of fluid

F

F

Area

Deformed

position

original

position T

1.1 What is a fluid? Consider

From engineering/scientific point of view, a fluid is defined as a

substance that deforms continuously (flow) when acted on by a

shearing stress of any magnitude. A shearing stress (force per

unit area) is created whenever a tangential force acts on a

surface.

Fluids: Water, air, petrol, oil

9

1.2 Dimensions, Dimensional homogeneity and

units

Description of fluid characteristics

1. Qualitatively: Length, time, mass, temperature

2. Quantitatively; Numerical value of 1 above

Primary quantities (for qualitative description) Length, L

Mass, M

Time, T

Temperature,u

Secondary quantities: Area = L

2

,

velocity = LT

-1

density = ML

-3

10

Dimensional homogeneity

Now consider an object initially moving at velocity V

o

. A

constant acceleration force is applied. Determine the

variation of velocity and distance with time.

V

o

V

t

Distance,

S

o

o t

t t

V V

dt

dV

a

= =

t

V V

a

o t

=

Expression for

acceleration

Since t

o

=0

V

t

= V

o

+ at

LT

-1

(LHS) = LT

-1

(RHS1) + LT

-1

(RHS 2)

Dimensionally homogeneous

dt

dS

V =

at V

dt

ds

o

+ =

dt at V dS

o

) ( + =

} }

2

2

at

t V S

o

+ =

L (LHS) = (LT

-1

)(T) (RHS1) + (LT

-2

)(T

2

) (RHS 2)

Dimensionally homogeneous

11

Table 1.1 Dimensions associated with common physical quantities

Acceleration LT

-2

Length L

Area L

2

Mass M

Density ML

-3

Time T

Force MLT

-2

Temperature u

Power ML

2

T

-3

Heat ML

2

T

-2

Pressure ML

-1

T

-2

Volume L

3

Work ML

2

T

-2

specific heat L

2

T

-2

u

-1

Example 1.1

A commonly used equation for determining the volume rate flow,

Q, of a liquid through an orifice located inside a tank is

gh A Q 2 61 . 0 =

12

Where A is the area of the orifice, g is the acceleration due to

gravity and h is the height of the liquid above the orifice.

Investigate the dimensional homogeneity of this formula

g

h

The dimensions of Q = L

3

T

-1

A = L

2

g = LT

-2

h = L

13

L

3

T

-1

= (0.61) (L

2

) (\2)(LT

-2

)

1/2

(L)

1/2

L

3

T

-1

= (0.61) (\2)( L

3

T

-1

)

These terms, when substituted into the equation, yield the

dimensional form

From the above result, it is clear that the equation is

dimensionally homogeneous i.e. both sides contain L

3

T

-1

Example 1.2

The force, P, that is exerted on a spherical particle moving

slowly through a liquid is given by the equation

P = 3tDV

Where is the fluid viscosity ( FL

-2

T), D is the particle

diameter, and V is the particle velocity. What are the

dimensions of the constant, 3t? Would you classify this

equation as a general homogeneous equation? (i.e. valid in

any system of units)

14

Solution

Dimensional homogeneity requires that

LHS = RHS

F = 3t (FL

-2

T)(L)(LT

-1

)

3t = F/ (FL

-2

T)(L)(LT

-1

) = F/F

3t has no units.

Since the constant 3t has no dimensions and the equation is dimensionally

homogeneous, the equation can be classified as general homogeneous equation.

1.3 Measures of fluid mass and weight

1.3.1 Density

Density, , is defined as mass per unit volume. It is used to characterize

the mass of a fluid system. For liquids, it shos some slight variation with

temperature (see fig 1.2)

15

950

960

970

980

990

1000

0 20 40 60 80 100

Temperature,

o

C

D

e

n

s

i

t

y

,

k

g

/

m

3

Fig.1.2 Density of water as a function of temperature.

Highest density is observed at 4

o

C

1.3.2 Specific weight

The specific weight of a fluid, designated by (N/m3) is

defined as the weight per unit volume and therefore

=g

16

1.3.2 Specific gravity

The specific gravity of a fluid, designated as SG, is defined as the ratio of the density of

the fluid to the density of water at some specified temperature (usually 4

o

C). In equation

form this is expressed as

SG = /

H2O @ 4

o

C

Since SG is a ratio of densities, the value does not depend on the system of units.

1.3.2 Specific weight

The specific weight of a fluid, designated by (N/m

3

) is defined as the weight per unit

volume and therefore

=g. For water

= 1000 (kg/ m3) * 9.8 (m

2

/s) = 9.80 kN/m

3

17

1.4 Ideal gas law

Gases are highly compressible as compared to the liquids. We recall the famous ideal

gas equation

PV =n RT 1.4

This gives

P = (n/V) RT to express the number of moles in terms of mass, we multiply n by

M

w

(molar mass. Therefore we have:

P M

w

= (nM

w

/V) RT, But nM

w

/V is thus

P M

w

= RT 1.5

or

= P. M

w

/ RT 1.6

18

Fluid

Force, F

Moving

plate

Fixed plate

Force

h

Moving plate, u=V

y

V

h

y

u =

Velocity

profile

1.5 Viscosity

The properties of density and specific weight discussed in

section 1.3 are measures of heaviness of a fluid. Another

very important property of a fluid is its viscosity. The viscosity

of a fluid is a measure of resistance to flow under applied

shear stress ,t, as show in Fig. 1.3.

Consider

Fig. 1.3 (a) Fluid in shear between (b) The ensuing linear velocity profile

parallel plates

19

Let h be the separation distance between the plate, F be

the applied force

Under these circumstances, the velocity u of the fluid to

the right is found experimentally to vary linearly from

zero at the lower plate (y=0) to V itself at the upper plate

(see fig. b), corresponding to no-slip conditions (an

experimental observation that the fluid sticks to the

solid boundaries) at each plate.

At any intermediate distance y from the lower plate, the

velocity u is given by:

Since u depends on y we can write:

V

h

y

u =

Eq. 1.7

h

V

dy

du

=

20

Newtonian fluids

dy

du

o t

Experimentally determined

h

V

dy

du

t = =

Introducing proportionality

constant

v =

Kinematic viscosity

21

Rate of shear strain,

dy

du

1

oil

H

2

O, 15

o

C

H

2

O, 37

o

C

Air, 15

o

C

Fig. 1.4 Linear variation of shearing stress with

rate of shearing strain for common fluids

22

Rate of shear strain

S

h

e

a

r

i

n

g

s

t

r

e

s

s

Fig. 1.5 Shear stress vs shear strain for Newtonian

and Non-Newtonian fluids

23

Variation of viscosity of liquid with temperature

) ln exp( ln ln T b a or T b a + = + =

) exp(

T

B

D =

Andrade Equation

Variation of viscosity of gas with temperature

n

o

o

T

T

|

|

.

|

\

|

=

S T

CT

+

=

2

3

or

Sutherland

Equation

24

Hydrogen

Air

Water

Oil

Glycerin

Temperature

D

y

n

a

m

i

c

v

i

s

c

o

s

i

t

y

Fig. 1.6 Dynamic viscosity of some common fluids as a

function of temperature.

25

Example 1.3

A dimensional combination of variables that is important in the

study of viscous flow through pipes is called Reynolds number,

N

Re

, defined as VD/, where is the fluid density, V the mean

fluid velocity, D the pipe diameter and the fluid viscosity. A

Newtonian fluid having viscosity of 0.38 N.s/m

2

and specific

gravity of 0.91 flow through a 25-mm-diametre pipe with a

velocity of 2.6 m/s. Determine the value of N

Re

. Show how N

Re

,

varies with temperature.

26

Solution

( )( )( )

2

3 3

Re

/ . 38 . 0

10 25 / 6 . 2 / 1000 91 . 0

m s N

m x s m m kg x VD

N

= =

= 156 (kg.m.s

-2

)/N

But 1 N= 1 kg.m.s

-2

Therefore N

Re

= 156

) ln exp( ) / exp(

Re Re

T b a

VD

N or

T B D

VD

N

+

= =

For variation of N

Re

with temperature

27

Example 1.4

The velocity distribution for flow of a Newtonian fluid (see figure)

between two wide, parallel plates is given by the equation:

(

(

|

.

|

\

|

=

2

1

2

3

h

y

V u

Where V is the mean velocity. The fluid has a viscosity of 0.04

lb.s/ft

2

. When V=2 ft/s and h=0.2 in. Determine: (a) the shearing

stress acting on the bottom wall, and (b) the shearing stress

acting on a plane parallel to the walls and passing through the

centreline (mid plane)

u

y

h

h

u

y

h

h

28

Solution

dy

du

t =

(

(

|

.

|

\

|

=

2

1

2

3

h

y

V u

Given

expression

Newtonian fluid

(

=

2

2

0

2

3

h

y

V

dy

du

2

2

3

h

Vy

=

Taking first derivative

( )

h

V

h

h

V

dy

du 3 3

2

= =

Now along the bottom wall, y= -h

( )( )( )

( )( ) . 12 / 1 . 2 . 0

/ 2 3 / . 04 . 0 3

2

in ft in

s ft ft s lb

h

V

wall

bottom

= = t

Calculation of shearing

stress at the bottom

( ) 0 0

3

2

= =

h

V

dy

du

0

3

= =

h

V

plane mid

t

Calculation of shearing

stress mid plane

29

1.6 Compressibility of fluids

(a) Bulk modulus: When pressure is

applied to a fluid, its volume (also density)

changes i.e. it is compressed. Bulk

modulus is a property that is used to

characterise compressibility. It is defined

mathematically

=

/ d

dp

E

v

dp is the differential pressure

needed to create a differential

change in volume d of a

volume .

30

|

|

.

|

\

|

=

= =

d

d

d

dp

m

d

m

dp

m m d

dp

E

v

2 2

/

) (

) / /( ) / (

Noting that = m/ , then

/ d

d

E

v

=

-Liquids are generally incompressible

i.e E

v

>>large

-Gases are compressible.

(b) Compression and Expansion of gases

t cons

P

tan =

When gases expand/compress

at constant temperature

31

t cons

d

dP

tan =

Taking derivative

v

E

d

dP

=

But, we know

From section 1.6a

P

t cons

E

v

= = tan

E

v

= P

Isothermal

process

t cons

P

k

tan =

Isentropic process:

Frictionless and no heat

exchange with surrounding

v

p

C

C

k =

32

d k const dp

k 1

.) (

=

Taking derivative

1

.) (

=

k

k const

d

dp

kP

k

P

k

k

= =

1

kP E

d

dp

v

= =

kP E

v

= (isentropic process)

33

k

f

f

k

i

i

P

P

=

k

i

f

i f

P P

|

|

.

|

\

|

=

Example:

A cubic foot of He at an absolute pressure of 14.7 psi is

compressed isentropically to 0.5 ft

3

. What is the final pressure?

Solution:

For isentropic compression, we have;

We know that for fixed mass, a decrease of volume by a factor

of 0.5 results in an increase in density by a factor of 2.

Therefore;

66 . 1

1

2

7 . 14

|

.

|

\

|

=

f

P

Pf = 46.5 psi.

k=1.66

34

1.7 Surface tension

What happens when steel needle is gently placed on

water? It floats??

Why do small droplets of mercury form into spheres

when placed on a smooth surface? - because the

cohesive forces in the surface tend to hold all the

molecules together in a compact shape

Walking on water: Small insects such as the water

strider can walk on water because their weight is not

enough to penetrate the surface

Don't touch the tent!

Common tent materials are somewhat rainproof in that

the surface tension of water will bridge the pores in the

finely woven material. But if you touch the tent material

with your finger, you break the surface tension and the

rain will drip through.

35

Soaps and detergents

help the cleaning of clothes by lowering the surface

tension of the water so that it more readily soaks into

pores and soiled areas.

Washing with cold water

The major reason for using hot water for washing is that

its surface tension is lower and it is a better wetting

agent. But if the detergent lowers the surface tension,

the heating may be unneccessary

Define Surface tension (o = the intensity of the molecular

attraction per unit length along any line in the surface) as the

tendency of a liquid to behave like a stretched elastic membrane.

Remember that this conceptual analogy is only useful to explain

the phenomenon described above, say, why steel needle floats on

water

36

Question:

How will the shape of droplets of liquid placed gently on a

surface vary with the size of the droplet?

Answer

spherical

oval

spherical

oval

For the small droplets such as the

first two on the left hand side, the

droplets adapt a shape that is almost

perfectly spherical, because in this

configuration, there is the least

surface area for a given volume

For larger droplets, the shape becomes somewhat flatter

because of the increasingly important gravitational effects,

which is roughly proportional to r

3

, where r is the

approximate droplet radius, whereas the surface area is

proportional to only r

2

37

Capillary action

hh

rise of column for a liquid

that wets the surface

such as water

depression of column for

nonwetting liquid such as

mercury.

Adhesion>> cohesion

Adhesion<<cohesion

38

Free body diagram: Force balance

t r

2

h

2t ro

t r

2

h

2t ro

h

To determine h, we perform force

balance. At equilibrium the weight of

water in the column must balance the

surface tension i.e.

) cos ( 2

2

u o t t r h r =

Making h the subject

r

h

u o cos 2

=

39

Example

Pressures are sometimes determined by measuring the height of a

column of liquid in a vertical tube. What diameter of clean glass tubing

is required so that the rise of water at 200

o

C in a tube due to capillary

action is less than 1.00 mm?

r

h

u o cos 2

=

h

r

u o cos 2

=

Solution

so that

Property of water at 20

o

C is; o= 0.0728 N/m,

= 9.789 kN/m

3

0149 . 0

10 * 0 . 1 * 10 * 789 . 9

0 cos * 0728 . 0 * 2

3 3

= =

r

m

Thus the minimum diameter d (=2r) = 0.0298 m = 29.8 mm.

40

Chapter 2: Fluid Statics

Define Pressure as the normal force per unit area at a

given point acting on a given plane within the fluid mass of

interest

Pascals Law: The pressure at a point in a static fluid is

equal in all directions: To prove this, lets consider a fluid

element in the form of a triangular wedge

2.1 Pressure at a Point

Z

Y

X

2

z y x c c c

y x P

z

c c

x c

u

y c

s x P

s

c c

u

z x P

z

c c

s c

41

Assumptions

Fluid at rest

Zero shearing

Fluid moves as rigid body: no relative motion between

adjacent elements

Applying Newtons second Law: F=ma

Y-direction

Sum of forces in the y direction= (pressure)*(small area normal

to pressure)- (force opposing the pressure in the y direction)=

(volume of the element)*(density of the fluid)*acceleration)

y s y y

a

z y x

s x P z x P F

2

sin

c c c

= c c c c =

u

42

Z-direction

Sum of forces in the z direction= (pressure)*(small area

normal to pressure)- (force opposing the pressure in the z

direction) (weight of the element) = (volume of the

element)*(density of the fluid)*acceleration)

z s z z

a

z y x z y x

s x P y x P F

2 2

cos

c c c

=

c c c

c c c c =

u

u cos s y c = c

u sin s z c = c

It can easily be shown that

Therefore

2

y

a P P

y s y

c

=

2

) (

z

a P P

z s z

c

+ =

Y-direction

Z-direction

43

Taking limits

0 , 0 , 0 c c c x z y

P

y

= P

s

and

P

z

= P

s

Example

A hydraulic jack consists of an assembly of given dimensions. A

load of 20 kN (P2) must be supported by the jack. What should

be the force applied?

Hydraulic jacks use the

principle of transmission of

pressure.

44

Area A2 is given by

2

2

001963 . 0

5

) 05 . 0 (

2 m A = = t

Pressure P2 is the weight to be lifted per unit area

2

/ 10187838

001963 . 0

1000 * 20

2 m N P = =

Pressure P2 must balance P1 i.e. transmission of pressure

N applied Force 1800

4

) 015 . 0 (

* * 10187838

2

= = t

45

Pressure Variation in a Fluid at Rest

Hydrostatic law

The rate of increase of pressure in the vertically downward

direction, at a point in a static fluid, must equal the local

specific weight of the fluid.

Proof of the above statements

Sum of forces acting

upwards due to pressure

( ) a P a P a P P - c = - - c +

Force acting downwards

due to weight

) ( a z g weight - c - - =

z

z

P

P c

c

c

+

P

z c

Surface

z

o

46

For equilibrium upward force equals downward force

) ( a z g a P - c - - = - c

z g P c = c

g

z

P

=

c

c

For liquids or gases at rest

the pressure gradient in the

vertical direction

= =

c

c

g

z

P

Incompressible fluids

g

z

P

=

c

c

With incompressible fluids

(liquids), density is constant

z g P c = c

} }

gz P P

o

=

47

o

P gz P + =

Point O being the surface

of water and therefore P

o

is atmospheric pressure

gz P =

If we measure pressure

relative to atmospheric

pressure (gauge

pressure, then P

o

~0

Example

Calculate the pressure (gauge) for a column of

1. 0.2 m water

2. 0.2 gasoline (specific gravity=0.75)

3. 0.2m Mercury (specific gravity=13.6)

48

Solution

1. gz = 1000*9.81*0.2 = 1962 N/m

2

2. gz = 0.75*1000*9.81*0.2 = 1472 N/m

2

3. gz = 13.6*1000*9.81*0.2 = 26683 N/m

2

Compressible Fluids

RT P =

Recall, Gas law eq. R J/kgK

RT

P

=

g

RT

P

z

P

* =

c

c

} }

c =

c

2

1

2

1

z

z

P

P

z

RT

g

P

P

Integrating

( )

1 2

1

2

ln z z

RT

g

P

P

=

Isothermal,

T=const.

49

( )

(

=

RT

z z g

P P

1 2

1 2

exp

Pressure variation with z in the

vertical downward direction

( )

(

=

RT

z z g

P P

1 2

1 2

exp

Pressure variation with z in the

vertical upward direction

Manometry: Measurement of Pressure

Absolute Pressure = Gauge Pressure + Atmospheric Pressure

50

1. Barometer

-Used for measuring atmospheric

pressure

-Pressure balance

h

P

atm

= h + P

vapor

(see vacuum)

-It implies that the column of mercury will

rise till the force due to atm. pressure

balances the weight in the column plus the

force due to the vapor pressure (develops

in the space above the column)

-Since P

vapor

<< small, P

atm.

~ h

51

2. Piezometer Tube Manometer

-The simplest manometer is a tube, open at the top, which is attached to

the top of a vessel containing liquid at a pressure (higher than

atmospheric) to be measured. An example can be seen in the figure

below.

-As the tube is open to the atmosphere the pressure measured is relative

to atmospheric so is gauge pressure.

This method can only be used for liquids (i.e. not for gases) and only

when the liquid height is convenient to measure. It must not be too small

or too large and pressure changes must be detectable.

Pressure at A= Pressure due to column of liquid above A

P

A

= h

1

+ P

atm

(assumed zero for gauge

pressure.)

Pressure at B= Pressure due to column of liquid above b

PA = h

2

+ P

atm

(assumed zero for gauge pressure.)

52

3. U- Tube Manometer

Using a "U"-Tube enables the pressure of both liquids and gases to be measured with

the same instrument. The "U" is connected as in the figure below and filled with a fluid

called the manometric fluid. The fluid whose pressure is being measured should have a

mass density less than that of the manometric fluid and the two fluids should not be able

to mix readily - that is, they must be immiscible.

-Pressure in a continuous static

fluid is the same at any horizontal

level so

-For the left hand arm

53

For the right hand arm

As we are measuring gauge pressure we can subtract P

atm

giving

If the fluid being measured is a gas, the density will probably be very low in

comparison to the density of the manometric fluid. In this case the term gh

1

can be neglected, and the gauge pressure give by

54

4. Differential U-Tube Manometer

-If the "U"-tube manometer is connected to a pressurized vessel at two points

the pressure difference between these two points can be measured

I-f the manometer is arranged as

in the figure , then

D

Giving the pressure difference

if the fluid whose pressure difference

is being measured is a gas;

man

>>, thus

55

5. Tilted (or inclined) Manometer

-If the pressure to be measured is very small then tilting the arm provides a

convenient way of obtaining a larger (more easily read) movement of the

manometer. The above arrangement with a tilted arm is shown in the figure

below

The pressure difference is still

given by the height change of

the manometric fluid but by

placing the scale along the line

of the tilted arm and taking this

reading large movements will

be observed. The pressure

difference is then given by

Where x is the reading along the scale

above the datum

-The sensitivity to pressure change can be increased further by a

greater inclination of the manometer arm, alternatively the density of the

manometric fluid may be changed

56

6. Choice Of Manometer

Care must be taken when attaching the manometer to vessel, no burrs must be present

around this joint. Burrs would alter the flow causing local pressure variations to affect the

measurement.

Some disadvantages of manometers:

Slow response - only really useful for very slowly varying pressures - no use at all for

fluctuating pressures;

For the "U" tube manometer two measurements must be taken simultaneously to get

the h value. This may be avoided by using a tube with a much larger cross-sectional

area on one side of the manometer than the other;

It is often difficult to measure small variations in pressure - a different manometric fluid

may be required - alternatively a sloping manometer may be employed; It cannot be

used for very large pressures unless several manometers are connected in series;

For very accurate work the temperature and relationship between temperature and r

must be known;

Some advantages of manometers:

They are very simple.

No calibration is required - the pressure can be calculated from first principles

57

Example of a Piezometer

What is the maximum gauge pressure of water that can be

measured by a Piezometer of height 1.5m? And if the liquid

had a relative density of 8.5 what would the maximum

measurable gauge pressure

gauge pressure p = gh

=

water

x relative density

The maximum measurable pressure is when the tube is completely full

(h=1.5m). Any higher and the tube will overflow.

p = (0.85 x 10

3

) x 9.81 x 1.5

p = 12 508 N/m2 (or Pa)

p = 12.5 kN/m2 (or kPa)

Solution

58

An example of the U-Tube manometer

Using a u-tube manometer to measure gauge pressure of fluid density = 700

kg/m

3

, and the manometric fluid is mercury, with a relative density of 13.6.

What is the gauge pressure if:

(a) h1 = 0.4m and h2 = 0.9m?

(b) h1 stayed the same but h2 = -0.1m?

Solution

P

B

= P

C

P

B

= P

A

+ gh

1

P

B

= P

Atm

+

man

gh2

We are measuring gauge pressure so

P

atm

= 0

P

A

=

man

gh

2

- gh

1

a) P

A

= 13.6 x 10

3

x 9.81 x 0.9 - 700 x 9.81 x 0.4

= 117 327 N, 117.3 kN (1.17 bar)

b) P

A

= 13.6 x 10

3

x 9.81 x (-0.1) - 700 x 9.81 x 0.4

= -16 088.4 N, -16 kN (-0.16 bar)

The negative sign indicates that the pressure is

below atmospheric

59

Example of the u-tube for pressure difference measurement

In the figure below two pipes containing the same fluid of density = 990 kg/m

3

are connected using a u-tube manometer. What is the pressure between the

two pipes if the manometer contains fluid of relative density 13.6?

Solution

P

C

= P

D

P

C

= P

A

+ g h

a

P

D

= P

B

+ g (h

b

- h) +

man

g h

P

A

- P

B

= g (h

b

- h

a

) + hg(

man

- )

= 990 x9.81x(0.75-1.5) + 0.5x9.81 x(13.6-

0.99) x 10

3

= -7284 + 61852

= 54 568 N/m

2

(or Pa or 0.55 bar)

60

Example of an inclined manometer.

An inclined tube manometer consists of a vertical cylinder 35mm diameter. At the

bottom of this is connected a tube 5mm in diameter inclined upward at an angle of 15

to the horizontal, the top of this tube is connected to an air duct. The vertical cylinder

is open to the air and the manometric fluid has relative density 0.785.

Determine the pressure in the air duct if the manometric fluid moved 50mm along the

inclined tube.

What is the error if the movement of the fluid in the vertical cylinder is ignored?

Solution

61

for a manometer where

man

>> .

where

z

2

= x sin q, and A

1

z

1

= a

2

x

z

1

= x (d/D)

2

where x is the reading on the manometer scale.

p

1

is atmospheric i.e. p

1

= 0

And x = -50mm = -0.05m

62

If the movement in the large cylinder is ignored the term (d/D)

2

will disappear

So the error induced by this assumption is

63

Hydrostatic Force on a Plane Surface

Basic Concepts and Naming

Pressure = h

= spec gravity of water

h = depth of water

C = Center of Mass of Gate

CP = Center of Pressure on Gate

Fr = Resultant Force acts at CP

h

Pressure variation with depth

64

Now consider an open tank containing fluid as shown

below:

Specific weight=

F

R

P

Free surface P=P

m

h

For fluids at rest, Force acting

must be perpendicular to the

surface since there is no

shearing stress.

As already mentioned,

pressure varies linearly as

fluid depth i.e.

P=h

For a horizontal surface such as shown above, resultant force F

R

= PA,

where A is the x-sectional area. In terms of fluid depth we have

F

R

= h A

65

For more general case in which a submerged plane surface is inclined

as illustrated below, the determination of F

r

is painstaking.

Now, let the surface lie along the plane that intersects point O at the free

surface

Force acting on a small area A

at depth h is given by

F= h A

The sum of these forces over

the entire area gives the

resultant force i.e.

} }

c = c =

A A

r

A y A h F u sin

O

h

y

Where h=y sin u

}

c =

A

r

A y F u sin

Since and u are const.

66

F

R

= A Y

C

sinu

or F

R

= A H

c

The integral appearing on the RHS is the First Moment of Area

wrt x-axis, hence

O

h

y

As shown The Center of

Pressure Y

r

lies below

the centroid - since

pressure increases with

depth. To determine Y

r

,

we need second moment

of Area

}

= c

A

c

A y A y

Where H

c

is the vertical

distance from the fluid

surface to the centroid of

the area.

67

O

h

y

} }

c = c =

A A

r r

A y F y Y F

2

sinu

But we know

u sin

c r

AY F =

Moment of resultant force=moment of

distributed pressure.

A Y

A y

Y

c

A

r

}

c

=

2

The numerator of the above

Eq. is the second moment of

the area i.e. I

x

.

A Y

I

Y

c

x

r

=

68

2

c xc x

AY I I + =

Parallel axis theorem (review solid

mechanisms)

I

xc

= second moment of the

area wrt an axis passing

through the centroid and

parallel to x-axis.

c

c

xc

r

Y

A Y

I

Y + =

Indicates that resultant force does not pass

through the centroid.

Note: First term RHS is very small compared to

the second term.

Similarly, the x-coordinate, X

r

, for the resultant force can be

determined as follows:

} }

c = c =

A A

r r

A xy F x X F u sin

A Y

I

A Y

A xy

X

c

xy

c

A

r

=

c

=

}

c

c

xyc

r

X

A Y

I

X + =

Parallel axis

theorem

69

Example

What is the Magnitude and Location of the

Resultant force of water on the door?

W

= 62.4 lbs/ft

3

Water Depth = 6 feet

Door Height = 4 feet

Door Width = 3 feet

70

Solution

Magnitude of Resultant

Force:

F

R

=

W

A H

C

F

R

= 62.4 x 12 x 4 = 2995.2 lbs

Important variables:

H

C

and Y

c

= 4

X

c

= 1.5

A = 4 x 3 = 12

I

xc

= (1/12)bh

3

= (1/12)x3x4

3

=

16 ft

4

Location of Force:

Y

R

= (I

xc

/ Y

c

A) + Y

c

Y

R

= (16 / 4x12) + 4 = 4.333 ft down

X

R

= X

c

(symmetry) = 1.5 ft from the

corner of the door

71

Example

The 4-m-diameter circular gate shown below is located in the inclined

wall of a large reservoir containing water ( =9.80 kN/m

3

). The gate is

mounted on a shaft along its horizontal diameter. For a water depth of

10 m above the shaft determine the magnitude and location of the

resultant force exerted on the gate by the water.

10 m

x

y

c

F

R

shaft

72

Solution

To determine the magnitude of the force on

water we apply;

F

R

= A H

c

= 9.80*10*(3.13*2

2

)

= 1230x10

3

N= 1.23 MN

.

Centre of

pressure

To locate the centre of resultant

force we recall

c

c

xc

r

Y

A Y

I

Y + =

c

c

xyc

r

X

A Y

I

X + =

73

Because of symmetry, the centre of pressure must lie

along the diameter A-A and therefore X

r

=0

For circular shape:

4

4

R

I

xc

t

=

c

c

xc

r

Y

A Y

I

Y + =

0 2 0

2

60 sin

10

) 2 * )( 60 sin / 10 (

) 2 )( 4 / (

+ =

t

t

r

Y

Remember sin 60

o

= 10/y

c

Y

c

= 0.0866 m + 11.55 m = 11.6 m

74

If the surface is curved the forces on each element of the surface will not be

parallel and must be combined using some vectorial method.

It is most straightforward to calculate the horizontal and vertical components and

combine these to obtain the resultant force and its direction. (This can also be

done for all three dimensions, but here we will only look at one vertical plane).

In the diagram above the liquid is resting on top of a curved base AB.

Hydrostatic Force on a Curved Surface

Consider forces acting on curved surface AB

The element

of fluid ABC is

equilibrium

(as the fluid is

at rest).

75

Horizontal forces

Considering the horizontal forces, none can act on CB as there

are no shear forces in a static fluid so the forces would act on

the faces AC and AB as shown below.

We can see that the horizontal force on AC, must equal

and be in the opposite direction to the resultant force on

the curved surface( AC is the projection of the curved

surface AB onto a vertical plane)

76

The resultant horizontal force of a fluid above a curved surface

is:

R

H

= Resultant force on the projection of the curved surface

onto a vertical plane (acts through the centre of pressure of the

projection of the curved surface onto an vertical plane).

Thus we can use the pressure diagram method to calculate the

position and magnitude of the resultant horizontal force on a

two dimensional curved surface

Vertical forces

The diagram below shows the vertical forces which act

on the element of fluid above the curved surface

77

-There are no shear force on the

vertical edges, so the vertical

component can only be due to the

weight of the fluid.

-The resultant vertical force of a

fluid above a curved surface is:

-R

V

= Weight of fluid directly above

the curved surface.

and it will act vertically downward

through the centre of gravity of the

mass of fluid.

78

Resultant force

The overall resultant force is found by combining the vertical

and horizontal components vectorialy,

The angle the resultant force makes to the horizontal is

R

V

R

H

u

79

Example

A 4 m long curved gate is located in the side of a reservior

containing water as shown below. Determine the magnitude of

the horizontal and vertical components of the force of the

water on the gate. Determine also the resultant force and the

angle it makes with the horizontal.

Water

9 m

x

3m

A

Solution

CG

W

F

H

F

1

F

V

A

C

B

Free-body diagram

80

The magnitude of F

1

is found from the equation

F

1

= A H

c

H

c

= 7.5 m, A = 4*3 (curved surface area), =9.81 kN/m

3

F

1

= 9.81*12*7.5 = 882.9 kN

But F

1

= F

H

, therefore

F

H

= 882.9 kN

W= * volume

=9.81*[(3.14*9/4)+ 3*6)]*4

= 983.6 kN

F

V

= 983.6 kN

Curved surface

Area above

curved surface

Length of curved

gate

81

F

R

= ( F

H

+ F

V

)

0.5

= (882.9 + 983.6)

0.5

=1321.7 kN

u= tan

-1

(F

H

/F

V

)

=tan

-1

(882.9/983.6)

=

82

Pressure Variation in a Fluid with Rigid-Body Motion

Recall general equation of motion

-VP - k= a

^

So that for x-axis

Fluid at rest or in motion with

no shear stress

x

a

x

p

=

c

c

For y-axis

y

a

y

p

=

c

c

For z-axis

z

a

z

p

+ =

c

c

x

y

z

If a fluid in motion is assumed to undergo rigid-body motion then

shear stress can be neglected. Eg. Fluid in container accelerating

along a straight path.

83

(a) Linear motion

y

a

y

p

=

c

c

Consider an open container translating along a straight path

at a constant acceleration a

V

Free surface

Slope= dz/dy

P

1

P

2

P

3

Constant

pressure lines

Since a

x

=0, the pressure

gradient in the x-direction is

zero and therefore it follows:

) (

z

a g

z

p

+ =

c

c

a

z

a

y

a

If we consider two points that are closely spaced:( y and y+y)

and (z and z+ z) then change in pressure can be expressed:

84

dz

z

p

dy

y

p

dp

c

c

+

c

c

=

y

a

y

p

=

c

c

) (

z

a g

z

p

+ =

c

c

dz a g dy a dp

z y

) ( + =

Recall

Along a line of constant pressure dp= o and therefore

z

y

a g

a

dy

dz

+

=

85

(b) Rigid-body rotation

Consider a fluid contained in a tank that rotates with a

constant angular velocity about an axis e

Since the path of the fluid is circular, we make use of

cylindrical polar coordinates: r, u and z

-VP - k= a

^

r, u and z directions are given by

The acceleration in the

a

r

=-rw

2 ,

a

u

=0, a

z

=0

from

2

e r

r

p

=

c

c

0 =

c

c

u

p

=

c

c

z

p

a

r

=

-

r

w

2

e

A

x

i

s

o

f

r

o

t

a

t

i

o

n

The pressure is a function of 2

variables, r and z.

dz

z

p

dr

r

p

dp

c

c

+

c

c

=

a

r

=-rw

2

e

Axis of

rotation

86

dz dr r dp e =

2

g

r

dr

dz

2

e

=

.

2

2 2

const

g

r w

z + =

Along a surface of constant pressure, such as free surface,

dp=0, so that

The equation for surfaces of constant

pressure is

dz dr r dp

} } }

= e

2

(i)

.

2

2 2

const z

r w

p + =

Equation reveals that

surfaces of constant

pressure are parabolic

x

y

z

P

1

P

2

P

3

P

4

.

2

2 2

g

r w

p

1

P

2

P

3

P

4

Pressure distribution

in a rotating liquid

87

Example

The cross section for the fuel tank of an experimental vehicle is shown

below. The rectangular tank is vented to the atmosphere, and a pressure

transducer is located in its side as illustrated. During testing of the

vehicle, the tank is subjected to a constant linear acceleration, a

y

(a)

Determine an expression that relates a

y

and the pressure (in lb/ft

2

) at the

transducer for a fuel with a SG=0.65. (b) What is the maximum

acceleration that can occur before the fuel level drops below the

transducer?

a

y

vent

Air

Fuel

(2) (1)

0.75 ft 0.75 ft

V

Transducer

z

1

0.5 ft

z

y

88

Solution

For a constant horizontal acceleration the fuel will move as a rigid body.

The slope of the fuel surface can be expressed as

g

a

dy

dz

y

=

Since a

z

=0

For an arbitrary value of a

y

, the change in depth z

1

, of liquid on the right side

of the tank can be found from the Eq.

g

a

ft

z

y

=

75 . 0

1

z

1

= (0.75) (a

y

/g)

Since there is no pressure in the vertical z direction, the pressure along the

wall varies hydrostatically with depth. Thus, the pressure at the transducer

is given by

P = h

h is the depth of fuel above the transducer

P= (0.65)(62.4)[0.5-(0.750(a

y

/g )

= 20.3 30.4 (a

y

/g)

For z

1

s 0.5 ft

89

(b) The limiting value for a

y

( when the fuel level reaches

the transducer) can be found from the Eq.

z

1

= (0.75) (a

y

/g)

For z

1

= 0.5, acceleration becomes (a

y

)

max

0.5= (0.75) (a

y

)

max

/g)

(a

y

)

max

=

2g/3

90

Chapter 3 Flow of Fluids: Conservation of Mass, Energy and

Momentum

General Conservation Laws

Consideration of the conservation laws of three major

extensive quantities:

-Mass: total mass

-Total energy: the sum of internal, kinetic potential, and

pressure energy

-Momentum: both linear and angular

91

Fig. 3.1 (a) System and its surrounding (b) transfers to and from the

system

The interaction between the system and surroundings is typically by one or more of the

following mechanisms:

1. A flowing stream, either entering or leaving the system

2. A contact force on the boundary, usually normal or tangential

3.A body force, due to an external field that acts throughout the system, of which

gravity is the prime example

4.Useful work, such as electrical energy entering a motor or shaft work leaving a

turbine.

92

Let X denote mass, energy, or momentum. Over a finite

time period, the general conservation law for X is:

Nonreacting system

X

in

X

out

= AX

system

3.1

For a mass balance on species i in a reacting system

X

in

i

X

out

i

+X

created

i

X

destroyed

i

= AX

system

i

3.2

3.2 Mass Balances

If we let m

in

be the rate of addition of mass into the

system

m

out

be the rate of removal of mass from the

system

Then the transient mass balance (for nonreacting system)

is:

93

m

in

- m

out

= dM

system

/dt,

where the term on the RHS denotes the rate of

accumulation of mass in the system

Now consider one-dimensional duct showing control

volume

The Continuity Equation

94

By principle of conservation of mass and considering a

small time, At

This equation is called the continuity equation for

steady one-dimensional flow.

95

Example: Mass balance for tank evacuation

The tank shown below has a volume V= 1 m

3

and contains

air that is maintained at a constant temperature by being in

thermal equilibrium with its surroundings. If the initial absolute

pressure is P

o

= 1 bar, how long will it take for the pressure to

fall to a final pressure of 0.0001 bar if the air is evacuated at

a constant rate of v=0.001 m

3

/s, independent of the pressure

in the tank.

96

Solution

The tank is taken as the system. Mass balance becomes

Inlet to the system- rate of loss from the system= rate of accumulation

But there is no mass to the system and therefore

- rate of loss from the system= rate of accumulation

- ) ( V

dt

d

v =

dt

d

V

dt

dV

dt

d

V

= + = since volume is constant

For ideal gas we have

RT

Mp

= so that

dt

dp

RT

M

V

RT

Mp

v = since the term M/RT is common on both sides, it

cancels out so that we have:

97

p

V

v

dt

dp

= separation of the variables give

} }

=

t p

p

dt

V

v

p

dp

o

0

or

V

vt

P

P

o

= ln

The resulting solution shows an exponential decay of the tank pressure with time;

) / exp( V vt p p

o

=

Time taken is given by 5 . 153 9210

1

0001 . 0

ln

001 . 0

1

ln = = = = s

P

p

v

V

t

o

f

min

Example

Let us now examine the situation illustrated in the figure below.

A tank initially contains 1000 kg of brine containing 10% salt by

mass. An inlet stream of brine containing 20% salt by mass,

flows into the tank at a rate of 20 kg/min. The mixture in the

tank is kept uniform by stirring. Brine is removed from the tank

via an outlet pipe at a rate of 10 kg/min. Find the amount of salt

in the tank at any time t, and the elapsed time when the amount

of salt in the tank is 200 kg.

98

Solution

We have 20 kg/min getting in and 10 kg/min getting out. Therefore amount of brine lost:

10-20 = -10 kg/min

Accumulation of brine is given by ) 1000 (

1000

=

c

c

}

M

dt

d

dM

t

M

, where M is the total mass

of brine. Separating the variables and solving for M gives

M=1000 + 10t

99

Now let S be the amount of salt in the tank at any time. The concentration by weight of

salt may be expressed as

brine kg

salt kg

t

S

M

S

10 1000 +

=

Amount of salt leaving the tank at any time is given by (flow rate x concentration)

t

S

10 1000

10

+

Amount of salt entering is given by 0.2x20 = 4 kg/s

Rate of accumulation is 4-

t

S

10 1000

10

+

=

dt

dS

Thus 4

100

=

+

+

t

S

dt

dS

This is first order linear differential equation. The general solution

is

t

C

t

t t

S

+

+

+

+

=

100 100

) 200 ( 2

The constant of integration may be evaluated, using the initial condition that S=100 kg at

t=0 to give C=10,000

100

Therefore

t

t t

S

+

+ +

=

100

2 400 000 , 10

2

The elapse time necessary for S to equal 200 kg may be evaluated to give t= 36.6 min

3.3 Energy Balances

Identity of energies

-internal energy, e

-potential energy, gz

-kinetic energy, u

2

/2

-work, W

-heat, Q

-flow work/energy, P/

101

Recall

X

in

X

out

= AX

system

In the present situation, X, refers to energy. Application of this equation over small time

period gives

dM

in

(e+P/+gz+u

2

/2)

in

dM

out

(e+P/+gz+u

2

/2)

out

+ dQ-dW= d[M(e+gz+u

2

/2)]

system

(3.3)

Now, let us consider a general system given below

W(Work)

system

Outlet

q (heat)

1

2

W(Work)

system

Outlet

q (heat)

1

2

Steady-state

energy balance

102

The energy entering with the inlet stream plus the heat supplied to the system must be

equal the energy leaving with the exit stream plus work done by the system on its

surroundings. At steady state, the RHS of the general energy balance equation is zero

and dM

in

= dM

out

giving:

e

1

+P

1

/

1

+gz

1

+u

1

2

/2 +q =e

2

+P

2

/+gz

2

+u

2

2

/2 + w 3.4

where q and w denotes heat and work done per unit mass

For an infinitesimally small system in which differential changes are occurring, we

have

de + d(u

2

/2) + d(gz)+ d(pu) = dq dw 3.5

In which de is a differential change, and u=1/ is the volume per unit mass.

The increase in internal energy arises from frictional work d dissipated into heat,

heat addition dq from the surroundings, less work pdu done by the fluid.

de = d+dq-pdu

103

Now eliminating the change in the internal energy and noting that d(pu)= pdu + udp

(d+dq-pdu) + d(u

2

/2) + d(gz)+ (pdu + udp) = dq dw, which simplifies to the

differential form of the mechanical energy balance, in which heat terms are absent

d(u

2

/2) + d(gz)+ dw + 1/(dp) + d = 0 3.6

For a finite system, for flow fro point 1 to point 2, Eq. 3.6 integrates to

( ) 0

2

2

1

2

= + + + A +

|

|

.

|

\

|

A

}

f w

dp

gz

u

3.7

in which a finite change is consistently the final minus the initial value, for example:

2 2 2

2

1

2

2

2

u u u

=

|

|

.

|

\

|

A

104

A steady state balance for an incompressible fluid of constant density permits the

integral to be evaluated easily, giving

( ) 0

2

2

= + +

A

+ A +

|

|

.

|

\

|

A f w

p

gz

u

3.8

Since g is constant, we have

0

2

2

= + +

A

+ A +

|

|

.

|

\

|

A f w

p

z g

u

3.9

which is the generalized Bernoulli equation.

Note: Since its practically impossible to convert heat entirely into useful work, the term

cannot be negative

105

Example

The figure below shows an arrangement for pumping n-pentane (= 39.3 lb

m

/ft

3

) at

25

o

C from one tank to another, through a vertical distance of 40 ft. All piping is 3-in.

I.D. Assume that the overall frictional losses in the pipes are given by:

= 2.5 u

2

m

For simplicity, however, you may ignore friction in the short length of pipe leading to

the pump inlet. Also, the pump and its motor have a combined efficiency of 75%. If

the mean velocity u

m

is 25 ft/s, determine the following:

(a) The power required to drive the pump

(b) The pressure at the inlet of the pump, and compare it with 10.3 psia, which is the

vapour pressure of n-pentane at 25

o

C.

(c) The pressure at the pump exit

4 ft

40 ft

flow

Supply

tank

Storage

tank

1

2

4

3

pump

Vent

Vent

4.5 ft

4 ft

40 ft

flow

4 ft

40 ft

flow

Supply

tank

Storage

tank

1

2

4

3

pump

Vent

Vent

4.5 ft

106

Solution

The x-sectional area is given by A= 3.14/4(3/12)

2

= 0.0491 ft

2

The mass flow rate is m = u

m

A = 39.3 x25x0.0491 = 48.2 lb

m

/s.

For large supply tank, u

1

can be assumed to be zero since the liquid/vapour interface

in it is descending only very slowly.

0

2

2

= + +

A

+ A +

|

|

.

|

\

|

A f w

p

z g

u

0 25 5 . 2 0 ) 40 2 . 32 (

2

0 25

2

2

= + + + +

x w x

Hence, the work per unit mass flowing is:

w= -3163 ft

2

/s

2

= (- 3163 ft

2

/s

2

)/(32.2 lb

m

ft/ lb

f

s

2

) = -98.3 (ft lb

f

)/(lb

m

),

107

in which he minus sign indicates that work is done on th liquid. The power required

to drive the pump motor is:

P= (mass flow rate x work)mw = (48.2x98.3)/(737.6x0.75) = 8.56 kW.

The pressure at the inlet to the pump is obtained by applying Bernoullis equation

between points 1 and 2:

2

2

2

2

1

1

2

1

2 2

gz

p u

gz

p u

+ + = + +

Note: The pipe has a uniform diameter of 3 in., the velocity u

2

entering the pump is the

same as that in the vertical section of the pipe, namely, 25 ft/s. Solving the pressure at the

pump inlet,

p

2

= [ g(z

1

-z

2

)- u

2

2

/2 ] = (39.3)/(32.2x144) [ (32.2x4.5 25

2

/2) ]

= -1.42 psig = 14.7 1.42 = 13.28 psia.

(Note: p

2

is more than vapour pressure of n-pentane. If it were less, the pump would not

work because of cavitation).

0 = +

A

+ A w

p

z g

Since p

2

= -1.42 psig, w= -3.163 ft

2

/s

2

and Az = 25.2 psig

p

3

= -1.42 + 39.3/(32.2x144)x (3163- 32.2x0.5) = 25.2 psig.

108

3.4 The Bernoullis Equation

Situations frequently occur in which the following

simplifying assumptions can reasonably be made:

1. The flow is steady

2. There are no work effects; that is, the fluid neither

performs work (as in a turbine), nor has work

performed on it (as in a pump). Thus, w= 0.

3. The flow is frictionless, so that =0. This assumption

is not true for long pipes

4. The fluid is incompressible, that is, the density is

constant.

109

Under the above circumstances, the general energy balance reduces

to:

0

2

2

=

A

+ A +

|

|

.

|

\

|

A

p

z g

u

3.10

Eq. 3.10 is the famous Bernoullis equation. For flow between

points 1 and 2 on the same streamline, or for any two points in a

fluid under static equilibrium (in which case the velocities are

zero), Eq. 3.10 becomes:

energy outlet Total energy inlet Total

p

gz

u p

gz

u

2

2

2

2 1

1

2

1

2 2

+ + = + + 3.11

Eq. 3.11 states that although the kinetic, potential, and pressure

energies may vary individually, their sum remains constant.

110

Momentum Balances

If an object of mass, m, moves with velocity, u, then momentum of the object is defined

as the product mass and velocity i.e.

= mu where is momentum.

Now if a system, such as a river, consists of several parts each moving with different

velocities u, the total momentum of the system is obtained by over all its mass:

= m d u

m

}

m

u

Momentum= mu

m

1

m

2

m

3

m

4

m

5

u

1

u

2

u

3

u

4

u

5

u

n

m

n

m d u

m

}

111

The law of conservation of momentum

The net rate of transfer of momentum into a system equals the

rate of increase of momentum of the system. Momentum is

transferred by two modes: by a force and by convection.

1. A force: In fluid mechanics, the most frequently occurring

forces are those due to pressure (acting normal to the

surface), shear stress (acting tangentially to the surface)

and gravity (acting vertically downwards). Pressure and shear

stress are examples of contact forces, since they occur over

some region of contact with the surroundings of the system.

Gravity is a body force since it acts throughout a system.

112

.Consider a free fall of an object of mass m.

If momentum is taken as positive in the downwards

direction,

then, the rate of transfer of momentum to the system is

the gravitational force mg and ie equated to the rate of

increase of downwards momentum of the mass i.e.

dt

d

mg F = = ( )

dt

du

m mu

dt

d

= = ) (

g

dt

du

= (for free fall)

113

Now lets consider a steady flow of fluid is a pipe of length L

and diameter D. The upstream pressure p1 exceeds the

downstream pressure p2 and thereby provides a driving

force for flow from left to the right. The shear stress tw

exerted by the wall on the fluid tends to retard the motion.

D

P

1

P

2

L

Direction

of flow

Wall shear stress t

w

D

P

1

P

2

L

Direction

of flow

Wall shear stress t

w

dt

d

DL p p

D

w

= t t

t

) (

4

2 1

2

()

Momentum balance in

the right direction

114

At steady state,

dt

d

( )= 0 and hence

L

D p p

w

4

) (

2 1

= t (equation for determining wall shear stress).

2. By Convective transfer. Lets consider a

situation given below in which water from a hose

of x-sectional area A impinges with velocity u on

the far side of the trolley of mass m.

m

v

jet

u

C

B

A

Nozzle of

area A

Mass flow

uA

m

v

jet

u

C

B

A

Nozzle of

area A

Mass flow

uA

Rate of

momentum

transfer = Au

2

(momentum per

unit time)

115

Two scenarios

(a)Control surface moving with trolley. When the control surface

moves at the same velocity as the trolley, an observation

perceives water entering the system across BC not with velocity

u but with a relative velocity (u-v) so that the convection of mass

into the control volume is A(u-v).

m

v

jet

C

B

A

Water

supply

Stationery

observer

u

System is moving

with velocity v

m

v

jet

C

B

A

Water

supply

Stationery

observer

u

System is moving

with velocity v

Stationery

Observer-

moving system

116

A momentum balance (positive direction to the right) gives:

Rate of addition of momentum= Rate of increase of momentum

A(u-v)u =

dt

dm

v

dt

dv

m mv

dt

d

+ = ) (

Because of water supply by the nozzle, the rate of mass increase of the system is

given by

) ( v u A

dt

dm

= and therefore

A(u-v)u= ]) [ ( v u A v

dt

dv

m + expanding we get

A(u

2

-vu)- A(uv-v

2

) =

dt

dv

m

If we set dv/dt = a (acceleration), then

2

) ( v u

m

A

a =

117

(b) Control volume fixed. The control volume is fixed so that

the trolley moves within it and that part of the jet of length L

inside the control surface is lengthening in space at a rate

dL/dt = v and increasing its momentum at ALu.

m

v

jet

C

B

A

Water

supply

Stationery

observer

u

System is

stationery

L

m

v

jet

C

B

A

Water

supply

Stationery

observer

u

System is

stationery

m

v

jet

C

B

A

Water

supply

Stationery

observer

u

System is

stationery

L

Stationery observer-fixed system

118

Av

dt

dm

AL

dt

d

dt

dm

Au + = + = ) (

dt

dL

Au

dt

dm

v

dt

dv

m ALu mv

dt

d

Au + + = + = ) (

2

Auv

dt

dm

v ma + +

A mass balance gives:

Rate of addition of mass= rate of increase of mass

since dL/dt= v

Momentum balance gives

Rate of addition = Rate of increase

=

since dv/dt=a and dL/dt=v

=

From mass balance equation dm/dt = A(u-v)

119

Therefore

Au

2

= ma + v [A(u-v)] + Auv

Au

2

- A(uv-v

2

+uv) = ma

A(u

2

-2uv-v

2

) = ma

2

) ( v u

m

A

a =

verifying the equivalence of the two approaches.

Example: Impinging jet of water

The figure below shows a plan of a jet of water impinging

against a shield that is held stationery by a force F opposing

the jet, which divides into several radially outwards streams,

each leaving at the right angles to the jet. If the total water flow

rate is Q=1 ft

3

/s and its velocity is u= 100 ft/s, find F (lbf)

120

shield

Force, F

m

u

Jet impinging against

a shield

The exiting streams have no momentum to the right.

The opposing force amounts to the rate of addition of momentum F

to the left and hence at steady state

Solution

Taking the right direction as

positive and assuming fluid

mass flow as m the rate of

transfer of momentum into

the system by convection is

mu

mu-F= 0

So that F= mu = Qu =

f

lb

x x

8 . 193

2 . 32

100 1 4 . 62

=

121

Chapter Five: Flow Measurements

In process industries, Flowing systems require energy,

typically provided by

-pumps and compressors,

The two produce a pressure difference as the driving force

Wide variety of methods and instruments for

measuring flow

-Devices based on Bernoulli principle; orifice plate, rotameter, Pitot-static

tube, venturi meter

-Weir and Notch

- Meters: Turbine meter, Target meter, Thermal flow meter

122

Turbine flow meter

Turbine flow meter consists of a small in-line turbine

placed inside a section of pipe, the rotation speed,

which can be transmitted electrically to a recorder,

depends on the flow rate.

123

Target flow meter

Typically consisting of a disk mounted on flexible arm

and placed normal to the flow in a pipe. The

displacement of the disk, and hence the flow rate, is

determined from the output of a strain gauge attached

to the arm

124

Devices based on Bernoulli Principle

Orifice plate meter

An orifice plate is a very simple device installed in a straight run

of pipe. The orifice plate contains a hole smaller than the

pipe diameter. The flow constricts, experiences a pressure

drop, and then the differential pressure can be related to a

flow.

A

1

A

2

1 2

A

1

A

2 A

1

A

2

1 2

125

It is also important to note that relating differential

pressure to flow across an orifice depends on the location

of the pressure taps in relation to the orifice. In the Figure

below, the pressure taps are designated as P1 and

P2. "D" is the diameter of the pipe and "d" is the diameter

of the orifice.

126

Let apply Bernoullis equation at points 1 and 2

(see orifice plate arrangement above) which have the

same elevation (z

1

=z

2

)

2

2

2 1

2

1

2 2

p u p u

+ = +

Conservation of mass between point 1 and 2 gives continuity equation

u

1

A

1

= u

2

A

2

5.2

Elimination of u

2

gives in Eq. 5.1 gives

2

2

2

2

1

2

1 1

2

1

2 2

p

A

A u p u

+ = + 5.3

5.1

127

Solution for u

1

yields

|

|

.

|

\

|

=

1

) ( 2

2

2

2

1

2 1

1

A

A

p p

u

5.4

So that the volumetric flow rate Q is :

|

|

.

|

\

|

=

|

|

.

|

\

|

= =

1

) ( 2

1

) ( 2

2 2

2

1

2 1

1

2

1

2

1

2 1

1 1 1

o c

A C

A

p p

A

A

A

p p

A A u Q

5.5

Where the coefficient of contraction C

c

is approximately 0.63. In most cases you will

find the following equation that uses a dimensionless discharge coefficient C

D

to be

most frequently used.

|

|

.

|

\

|

=

1

) ( 2

2

2

1

2 1

1

o

D

A

A

p p

A C Q

5.6

The values of C

D

depends on the N

Re

and are usually presented graphically.

128

Pitot tube

The Pitot tube (named after Henri Pitot in 1732) measures

a fluid velocity by converting the kinetic energy of the

flow into potential energy. The conversion takes place at

the stagnation point, located at the Pitot tube entrance

(see the schematic below). The device is based on

Bernoulli principle and is used in finding the velocity of a

moving craft such as a boat and airplane.

d

1

water

Stagnation point

h

2

d

1

water

Stagnation point

h

2

129

Let u

1

be the upstream velocity of approaching water. Opposite the Pitot tube, the

oncoming water decelerates and in fact comes to rest at the stagnation point at the tip of

the tube.

) ( 0 0

2

2 1

2

1

d h g

p p u

+ + + = + +

5.7

The first zero on the LHS is taken for z

1

=0 (datum) and at stagnation point u

2

=0.

From hydrostatics, the pressure at point 1 is given by

P

1

=P

2

+ gd 5.8

Combining Eqs. 5.7 and 5.8 we get

gh u 2

1

= 5.9

130

Pitot-static tube

For pipe flow, we make use of pitot-static tube as shown

below for measuring velocity at

liquid

Stagnation point

u

1

h

movable

Pipe wall

Velocity

profile

liquid

Stagnation point

u

1

h

movable

Pipe wall

Velocity

profile

different radial locations in a pipe. Two tubes are used. The

left hand tube simply measures the pressure and the movable

right-hand one is essentially a Pitot tube as before. As was

before the velocity u

1

is given by

gh u 2

1

=

131

A venturi meter is a tube with a constricted throat that increases

velocity and decreases pressure. They are used for measuring the

flowrate of compressible and incompressible fluids in pipeline

3. Venturi meter

Pipe Pipe

Throat

V

1

D

1

D

2

V

2

D

1

High-pressure tap Low-pressure tap

p

1

p

2

Contracting

section

Expanding

section

132

Apply Bernoullis equation and law of mass conservation between between stations 1 and

2:

c

2

2 2 2

c

2

1 1 1

g 2

V p

g 2

V p o

+ = + (5.10)

2 2 1 1

V A V A = (5.11)