Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4 Gas Ratios

Caricato da

drillinganacoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4 Gas Ratios

Caricato da

drillinganacoCopyright:

Formati disponibili

Dave Hawker

DATALOG

Hydrocarbon Evaluation

and Interpretation

Gas Normalization

Porosity, saturation, permeability

hole depth and diameter

penetration rate

bit type

flowrate

differential pressure

mud type and rheology

fluid movements

pressure and temperature change

trap efficiency and losses

Gas Normalization

Normalize the geometric factors so

that they can be eliminated as

variables

Cannot normalize Total Gas values

since they are qualitative, not an

absolute measurement

Chromatographic components are

totaled to give a Total

Chromatograph Gas value

Gas Normalization

Can only normalize the gas

measurement that we have; cannot

account for: -

losses of gas to atmosphere

gas retained by cuttings

phase and solubility changes

fluid movements in terms of flushing

and incursions

Normalization Formula

( )

( )

d

c

b a

N

|

|

|

|

|

.

|

\

|

-

=

t

t

100

2

2000

N = normalized gas (%)

a = pump output (m3/min)

b = ROP (min/m)

c = hole diameter (mm)

d = total chromatograph gas (%)

Comparing Adjacent Shows

0 min/m 15 0.1 Gas 100

10%

3 min/m

1 min/m

20%

10 min/m

BG 1%

Possible Causes of Difference

Lower porosity and bulk volume of gas

Lower gas saturation

Reduced permeability

Increased permeability resulting in flushing

Different gas composition

Porosity

Permeability

(increase or

decrease)

Composition

Saturation

3 min/m

10%

1 min/m 20%

12 1/4 hole

Flow 2m

3

/min

8 1/2 hole

1.4 m

3

/min

Shale Background 1%, 10min/m

Rule of Thumb vs Normalization

Sand 1 ~ 3 times

better than shale

Sand 2 ~ 2 times

better than shale

Sand 1 normalized

24.8% / BG 0.84%

Sand 2 normalized

18.0% / BG 1.22%

Shows in different wells/hole sections

Flowrate m3/min Normalized Gas %

ROP min/m Total Chromatograph %

0 3

12

8

Ratio Analysis

Comparison of chromatographic values for

individual hydrocarbon components

reservoir fluid type

gas/oil/water contacts

oil gravity

production potential; wet zones/permeability

Pixler Ratio Plot

Comparison of the methane content to each

other alkane

Only the value of the gas show above the

background level is used

eliminates variables since they affect both

only information concerning the relative

production potential is used

Pixler Ratio Plot Information

Reservoir Fluid

Oil Gravity and Gas Wetness

Production Potential

Permeability

Presence of Formation Water

Ratio Plot

NON-PRODUCTIVE GAS

PRODUCTIVE GAS

PRODUCTIVE OIL

NON-PRODUCTIVE RESIDUAL OIL

C1/C2 C1/C3 C1/C4 C1/C5

1

10

1000

100

Ratio Plot Zones

Determined from the comparison of gas

ratio data to production and test results

Can be used as a guide or reference

Regional calibration will improve the

effectiveness of the ratio plot

C1/C2 Ratio

<2 very low gravity, high density and

viscosity, non-productive, residual oil

2 - 4 low gravity oil, 10-15 API

4 - 8 medium gravity oil, 15-35 API

8 - 15 high gravity oil, API >35

10 - 20 gas condensate

15 - 65 gas

> 65 light gas, principally methane,

non-productive

Slope of the Curve

A fully positive slope confirms productive

hydrocarbons

A negative slope indicates a water bearing zone

Gradient similar to the zone lines indicates good

permeability

The steeper the slope, the tighter the formation

if C1/C2 is low in the oil section, with C1/C4 high

in the gas section, zone is probably non-productive

Evaluation of Oil Bearing Zones

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

Medium-High

API

Good

Permeability

hi

med

lo

API

Evaluation of Oil Bearing Zones

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

Medium-High

API

Tight

hi

med

lo

Evaluation of Oil Bearing Zones

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

Medium-Low

API

Fair-Good

Permeability

hi

med

lo

Evaluation of Oil Bearing Zones

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

Medium-Low

API

Water Bearing

hi

med

lo

Permeability?

Evaluation of Oil Bearing Zones

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

Very low API

non-productive?

Water Bearing

hi

med

lo

Evaluation of Gas Bearing Zones

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

1

3

2

4

1. Methane

Tight, non-productive

2. Productive Gas

Good Permeability

3. Productive Gas

Tight

4. Light Gas

Permeability?

Water Bearing

Condensates ?

Indicated by C1/C2 between 10 and 20

10 - 15 also indicates high gravity oil

15 - 20 also indicates gas

20

15

10

Hi API Oil

Gas

Condensate

Condensates ?

Gas, typically yields a more definitive

C1/C2 ratio

Complication with light oils having high

Gas Oil Ratio

Prediction of Gas Condensate

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

Plots follow a similar

gradient to the upper gas

limit

C1/C2 ratio suggests a

higher proportion of

heavier hydrocarbons

Wet Gas or

Condensate ?

Prediction of Gas Condensate

GAS

OIL

NON-PRODUCTIVE

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

NON-PRODUCTIVE

Light Oil, reduced

permeability

Light Oil with high

GOR

Condensate

Correlation with Fluorescence

C1/C2 Ratio API Gravity Fluid Type Natural

Colour

Colour of

Fluorescence

2 4 10 15 Low Gravity Oil Dark brown to

black

Orange to brown

4 8 15 35 Medium Gravity

Oil

Light to medium

brown

Cream to yellow

green, gold

8 15 > 35 High Gravity Oil Clear White to bluish

white to blue

10 20 ~ 50 Gas Condensate Gasoline Violet if visible

Ratio Plot Summary

C1/C2 C1/C3 C1/C4 C1/C5

1

10

100

1000

hi

med

lo

API

Dry gas

Wet Gas

Non-productive gas

Geopressure methane

Heavy, viscous, non-productive

Residual oil, tars, waxes

Gas Condensate

Drawbacks to the Gas Ratio Plot

Difficult to determine condensate reservoirs

Optimally, requires regional re-calibration

Limited number of plots for each potential

zone

Plots are offline, so that information is apart

from the mud log

Wetness, Balance and Character Ratios

Calculated real-time for immediate

evaluation and recognition of reservoir

changes and contacts

Plotted on a depth-based log for comparison

with other mud logging and wireline data

for effective reservoir evaluation

Wetness Ratio

Increasing trend as proportion of heavy gas

increases, i.e. as gas or oil density increases

Determination of gas wetness and oil

density

100

5 4 3 2 1

5 4 3 2

|

.

|

\

|

+ + + +

+ + +

=

C C C C C

C C C C

Wh

Wetness Ratio

<0.5 non-productive dry gas;

non-associated or

geopressured methane

0.5 - 17.5 gas, increasing in wetness

17.5 - 40 oil, increasing in density

(decreasing gravity)

>40 non-productive oil, very

low gravity, residual

Wetness Ratio

1 10 100

NON-PRODUCTIVE, RESIDUAL

OIL

POTENTIAL OIL PRODUCTION

POTENTIAL

GAS PRODUCTION

NON-PRODUCTIVE

DRY GAS

Increasing density or wetness

Increasing density

Balance Ratio

Compares light to heavy gases

Responds inversely to Wh as fluid density

increases

Used in conjunction with Wh for

interpretation

5 4 3

2 1

C C C

C C

Bh

+ +

+

=

Interpretation of Wetness and Balance

Balance Ratio Wetness Ratio Reservoir Fluid and Production Potential

> 100 Very light, dry gas

Typically non-associated and non-productive such as

the occurrence of geopressured methane

< 100 < 0.5 Possible production of light, dry gas

Wh < Bh < 100 0.5 17.5 Productive gas, increasing in wetness as the curves

converge

< Wh 0.5 17.5 Productive, very wet gas or condensate or high gravity

oil with high GOR

< Wh 17.5 40 Productive oil with decreasing gravity as the curves

diverge

<< Wh 17.5 40 Lower production potential of low gravity, low gas

saturation oil

> 40 non productive, very low gravity, residual oil

Wetness and Balance Curves

0.1 0.5 1.0 10 17.5 40 100

NON-PRODUCTIVE GAS

POSSIBLE PRODUCTIVE GAS

PRODUCTIVE GAS

GAS, OIL or CONDENSATE

PRODUCTIVE OIL

RESIDUAL OIL

DRY

WET

HI GRAV

LO GRAV

Wh

Bh

Character Ratio

Ch < 0.5

confirms productive gas phase, either Wet

Gas or Condensate

Ch > 0.5

indicates productive liquid phase, so that gas

is associated with oil

3

5 4

C

C C

Ch

+

=

Combining all Gas Ratios

1 10 17.5 40 100 0 3

Dry Gas

Increasing

Wetness

Gas or Condensate

High Gravity Oil with High GOR

Decreasing

Gravity

Residual Oil

Wetness Ratio

Balance Ratio

Character

Ratio

Summary

Ratio curves provide very effective trend

analysis on a real-time and mud log basis

Accurate determination of reservoir fluid

changes and contacts

Immediate evaluation as reservoir is being

drilled

Definitive values require, optimally, regional

calibration with test or production results

Oil Indicator

Compares Methane to Heavy Gases

Ranges 0.01 to 1, increasing with gas

and oil density

1

5 4 3

C

C C C

O

+ +

=

Inverse Oil Indicator

Inverse of the oil indicator

Ranges 1 to 100, increasing as the

fluid density decreases

5 4 3

1

C C C

C

I

+ +

=

Evaluation of the Oil Indicator Ratios

Oil Indicator Evaluation Inverse

Oil Indicator

0.01 - 0.07 dry gas, gas charged water 100 - 14.3

0.07 - 0.10 condensate, light oil with 14.3 - 10.0

high GOR

0.10 - 0.40 oil 10.0 - 2.5

0.40 - 1.0 residual oil 2.5 - 1

Using the Inverse Oil Indicator

1 10 100

Dry Gas

Condensate or

Light Oil/Hi GOR

Oil

Residual Oil

Ratio Summary

Correctly interpreted, chromatographic gas

ratios provide an excellent means of

reservoir evaluation and determination of

fluid type, contacts, permeability and the

presence of water

Regional calibration against known data

will improve their accuracy

Ratio comparisons and trend evaluation

should be used rather than direct

quantitative analysis

Ratio Limitations

Heavier oils that do not possess the lighter

range of hydrocarbons

Oils with low gas saturation

Large proportion of produced gas may lead

to false proportions

If mud type, rheology, surface system lead

to suspect gas measurements

Conventional Fluorescence

Colour under ultra-violet light being an

indication of the density of the petroleum

fluid

The intensity of the fluorescence being an

indication of the presence of water

Solvent cut as an indication of density and

mobility

Fluorescence Colour

High API gravity oil

Medium API gravity oil

Low API gravity oil

Very low gravity, typically low

intensity

Condensate

10

15

35

45

Solvent Cut

Solvent takes the fluid

into solution and

leaches it out of the

cutting

Speed and nature of

the cut reflects fluid

density, viscosity,

solubility and

permeability

The better the permeability, the

faster the cut

The lower the viscosity, the

faster the cut

Uniform blooming indicates

good permeability and mobility

Streaming cut indicates reduced

permeability and/or high

viscosity

Limitations to UV Fluorescence

Subjective colour descriptions

Presence of contaminants

Much of the fluorescence emissions fall in

the ultra-violet range of the spectrum

any fluorescence visible is only a fraction of the

total emission

Some emissions may go completely undetected

Quantitative Fluorescence Technique

Measurement of the

fluorescence intensity

which is proportional

to the quantity of oil

Old, stored cuttings

can be re-evaluated

with this technique

How representative

are the cuttings?

How much fluid has

been retained by the

cuttings?

Fluorescence intensity

is not linear across the

range of oil gravities

Cannot be used in gas

wells

Quantitative Fluorescence Technique

Elimination of subjective descriptions

QFT measures the oil content as given by

the fluorescence intensity so that increases

can represent an increased amount or a

change in composition

Total Scanning Fluorescence (TSF)

measures the entire excitation wavelengths

of a given crude, with the peak defining the

dominant composition

QFT vs Gas/Fluorescence

Reservoir Top

Reservoir Base

Fluoresence

QFT

Total Gas

Potrebbero piacerti anche

- Wellsite GeologyDocumento185 pagineWellsite Geologyabuobida0% (2)

- Pore Pressure Basic LevelDocumento64 paginePore Pressure Basic LevelAmlk MartinezNessuna valutazione finora

- Lecture 01 - Wellsite Geology - Part 1Documento32 pagineLecture 01 - Wellsite Geology - Part 1Badut Sarkas100% (2)

- All Exams in OneDocumento33 pagineAll Exams in Onegeo_hamza100% (2)

- Gas While DrillingDocumento14 pagineGas While DrillingBAS100% (1)

- GBP-2 - Cuttings PDFDocumento32 pagineGBP-2 - Cuttings PDFisfanNessuna valutazione finora

- Assessment of Valve FailuresDocumento57 pagineAssessment of Valve FailuresSergioUlises100% (1)

- Wellbore Stability TrainingDocumento60 pagineWellbore Stability Trainingdrillinganaco100% (5)

- Formation Fluid Prediction Through Gas While Drilling AnalysisDocumento89 pagineFormation Fluid Prediction Through Gas While Drilling AnalysisIcan100% (1)

- Gas Analysis - SECTION6 Interpreting GasDocumento10 pagineGas Analysis - SECTION6 Interpreting GasMotorola M Motorola100% (8)

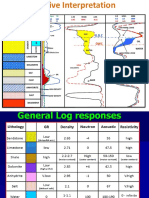

- Quick Look Log InterpretationDocumento29 pagineQuick Look Log InterpretationHemenMoNessuna valutazione finora

- Subsurface Geology Lecture Notes - DR - Mohamed Farouk - 2011-2012 - GEO PEDIADocumento82 pagineSubsurface Geology Lecture Notes - DR - Mohamed Farouk - 2011-2012 - GEO PEDIAStephen FortisNessuna valutazione finora

- Field Traing ManualDocumento280 pagineField Traing Manualdrillinganaco100% (1)

- Online Mud Logging Handbook Chapter 2 SummaryDocumento59 pagineOnline Mud Logging Handbook Chapter 2 SummaryVictorCalin100% (1)

- Wellsite Geology Manual - OMVDocumento102 pagineWellsite Geology Manual - OMVMehmet Ferit Binzet100% (8)

- NMR Logging ToolDocumento8 pagineNMR Logging Toolzapspaz100% (1)

- Formation Pressure v2-1Documento114 pagineFormation Pressure v2-1Anca Seserman100% (11)

- Crain's Petrophysical Handbook - Mud Logging and Mud Gas LoggingDocumento6 pagineCrain's Petrophysical Handbook - Mud Logging and Mud Gas LoggingMuhammad Saleem100% (1)

- Quantitative Log Interpretation Techniques for Reservoir EvaluationDocumento45 pagineQuantitative Log Interpretation Techniques for Reservoir EvaluationWSG SARIRNessuna valutazione finora

- Advanes in Chromatograph AnalysisDocumento9 pagineAdvanes in Chromatograph AnalysisbettariNessuna valutazione finora

- MGD M022 ICS PHL 0000 00701 00 Spec For Control and Safety Philosophy Rev E01Documento14 pagineMGD M022 ICS PHL 0000 00701 00 Spec For Control and Safety Philosophy Rev E01Hakeem QuadriNessuna valutazione finora

- Basic Well Log InterpretationDocumento19 pagineBasic Well Log InterpretationWessam HashemNessuna valutazione finora

- Intro-Natural Gas ProcessingDocumento45 pagineIntro-Natural Gas ProcessingJaimin PrajapatiNessuna valutazione finora

- Spe 97099 MS P PDFDocumento20 pagineSpe 97099 MS P PDFCarlos Alberto Mora100% (1)

- Drilling Rig Inspection ManualDocumento35 pagineDrilling Rig Inspection Manualdrillinganaco90% (10)

- Mud LoggingDocumento29 pagineMud LoggingDavidandy0% (1)

- Mudloggers BibleDocumento61 pagineMudloggers BibleTudor MarcusNessuna valutazione finora

- Logging Cased HoleDocumento30 pagineLogging Cased HoleDeepak RanaNessuna valutazione finora

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDa EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNessuna valutazione finora

- Blanc Et Al, 2003Documento19 pagineBlanc Et Al, 2003Daniela BecerraNessuna valutazione finora

- Mud LoggingDocumento35 pagineMud LoggingAvinash_Negi_7301100% (4)

- 30M - ConocoPhillips Optimized Cascade PDFDocumento11 pagine30M - ConocoPhillips Optimized Cascade PDFPutu Indra MahatrisnaNessuna valutazione finora

- 6 Geosteering BasicsDocumento60 pagine6 Geosteering Basicslaxmikant1983100% (2)

- 01 IntroductionDocumento49 pagine01 IntroductionSathia ShekarNessuna valutazione finora

- Screw-Type Compressors SCK 5 - SCK 22: Maintenance and Operating Instructions Spare Parts ListDocumento30 pagineScrew-Type Compressors SCK 5 - SCK 22: Maintenance and Operating Instructions Spare Parts Listjohn smith100% (4)

- Casing DesignDocumento48 pagineCasing Designdrillinganaco60% (5)

- Mudlogging OperationsDocumento54 pagineMudlogging Operationsandrzema100% (6)

- Course - Operation GeologyDocumento65 pagineCourse - Operation GeologyMichelle CalistaNessuna valutazione finora

- Advances in Mud Gas Interpretation Whilst DrillingDocumento12 pagineAdvances in Mud Gas Interpretation Whilst Drillinglakhanmukhtiar100% (1)

- The Description of SamplesDocumento62 pagineThe Description of SamplesSneetsher Crispy100% (16)

- Reservoir Saturation ToolDocumento50 pagineReservoir Saturation Toolroshan01100% (1)

- The Brief in Oil Well DrillingDocumento141 pagineThe Brief in Oil Well DrillingCarlin Babuchas100% (1)

- Mud & Wireline Logging in North DibeillaDocumento26 pagineMud & Wireline Logging in North DibeillaalphaidedjibrillaNessuna valutazione finora

- Mud LoggingDocumento16 pagineMud LoggingMuhammad Mohtashim100% (1)

- MEG Regeneration Technical Meeting SummaryDocumento122 pagineMEG Regeneration Technical Meeting Summaryprabhuarunkumar850% (1)

- Drilling an Extended Reach Well: Key ConsiderationsDocumento33 pagineDrilling an Extended Reach Well: Key ConsiderationsKutz100% (2)

- Ongc Academy Welcomes TO All Graduate TraineesDocumento70 pagineOngc Academy Welcomes TO All Graduate TraineesDebajyoti SarkarNessuna valutazione finora

- Measurement While Drilling: Signal Analysis, Optimization and DesignDa EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNessuna valutazione finora

- Surface Logging in The Oil Industry Apr 2011Documento73 pagineSurface Logging in The Oil Industry Apr 2011Junaid Sajid100% (1)

- SPE Stavanger - Introduction To GeosteeringDocumento7 pagineSPE Stavanger - Introduction To Geosteeringtrinhtu7Nessuna valutazione finora

- Wellsite Geologist Training Report 3Documento7 pagineWellsite Geologist Training Report 3tonyxcrime100% (3)

- Petrophysics IntroDocumento28 paginePetrophysics Introabhishek bhardwaj100% (1)

- SPE Mud Gas Logging SystemDocumento26 pagineSPE Mud Gas Logging SystemBASNessuna valutazione finora

- The Acquisition of Logging Data: Part ADa EverandThe Acquisition of Logging Data: Part AValutazione: 4 su 5 stelle4/5 (3)

- Well Log Interpretation Guide for Oil & Gas ExplorationDocumento48 pagineWell Log Interpretation Guide for Oil & Gas ExplorationSaurabh Sharma75% (4)

- Mud Logging Introduction Without Mud Logging KnowledgeDocumento70 pagineMud Logging Introduction Without Mud Logging Knowledgegirilingam33% (3)

- Wetness, Balance and Character (Haworth, 1985)Documento7 pagineWetness, Balance and Character (Haworth, 1985)Bangsawan AriefNessuna valutazione finora

- Geosteering Best PracticesDocumento3 pagineGeosteering Best PracticesUsama Bin SabirNessuna valutazione finora

- Mud LoggingDocumento35 pagineMud LoggingdebNessuna valutazione finora

- Cep 202107 Optimize-ReboilerDocumento11 pagineCep 202107 Optimize-Reboilerammar fahmiNessuna valutazione finora

- PETE 220 RESERVOIR ROCK PROPERTIESDocumento64 paginePETE 220 RESERVOIR ROCK PROPERTIESrestofficalNessuna valutazione finora

- 1 - Well Log Evaluation - IntroductionDocumento29 pagine1 - Well Log Evaluation - IntroductionKyosuke HilmiNessuna valutazione finora

- Formulas and Calculations for Drilling OperationsDa EverandFormulas and Calculations for Drilling OperationsNessuna valutazione finora

- Practical Petroleum Geochemistry for Exploration and ProductionDa EverandPractical Petroleum Geochemistry for Exploration and ProductionNessuna valutazione finora

- Coring Oprations Alun Whittaker PDFDocumento184 pagineCoring Oprations Alun Whittaker PDFalvaro_massimoNessuna valutazione finora

- Qdoc - Tips LNG GlossaryDocumento93 pagineQdoc - Tips LNG GlossaryFernando Igor AlvarezNessuna valutazione finora

- Control Valve Study ReportDocumento53 pagineControl Valve Study Reportahmad santoso100% (1)

- Starting Up and Stopping of The GasplantDocumento5 pagineStarting Up and Stopping of The GasplantHendra TambunanNessuna valutazione finora

- Working Guide to Reservoir Rock Properties and Fluid FlowDa EverandWorking Guide to Reservoir Rock Properties and Fluid FlowValutazione: 3 su 5 stelle3/5 (1)

- PolySep PS 250Documento9 paginePolySep PS 250airmacmexNessuna valutazione finora

- Hydrocarbon Gas Detection & InterpretationDocumento10 pagineHydrocarbon Gas Detection & InterpretationCARLOSELSOARESNessuna valutazione finora

- Lithology Reconstruction from LogsDocumento32 pagineLithology Reconstruction from LogsSyed ShaiqNessuna valutazione finora

- Open and Case Hole LoggingDocumento33 pagineOpen and Case Hole LogginggattNessuna valutazione finora

- Wireline Logs: Interpretation of Grain-Size Profiles From Well LogsDocumento12 pagineWireline Logs: Interpretation of Grain-Size Profiles From Well LogstayofelaNessuna valutazione finora

- Geonext - A Mud Logging RevolutionDocumento8 pagineGeonext - A Mud Logging RevolutionRobertNessuna valutazione finora

- Cuttings Analysis During Mud LoggingDocumento6 pagineCuttings Analysis During Mud LoggingMuhammad MufarridNessuna valutazione finora

- Hydrocarbon Evaluation and Interpretation: DatalogDocumento79 pagineHydrocarbon Evaluation and Interpretation: DatalogdrillinganacoNessuna valutazione finora

- WCM7300Documento2 pagineWCM7300José Luis CoronadoNessuna valutazione finora

- Unconventional Gas-Dehydration-System Failure Resulting in A Gas-Hydrate BlockageDocumento12 pagineUnconventional Gas-Dehydration-System Failure Resulting in A Gas-Hydrate BlockageJose SalgadoNessuna valutazione finora

- Comparacion Planta Meg - TegpdfDocumento18 pagineComparacion Planta Meg - TegpdfJulian RomeroNessuna valutazione finora

- Piping Codes and StandardsDocumento36 paginePiping Codes and StandardssudhakarNessuna valutazione finora

- Small Gas Processing FacilityDocumento5 pagineSmall Gas Processing FacilityNhut NguyenNessuna valutazione finora

- APT10 and APT14 Automatic Pump Traps: For Effective Condensate Drainage and RemovalDocumento12 pagineAPT10 and APT14 Automatic Pump Traps: For Effective Condensate Drainage and RemovalRaduZapciroiuNessuna valutazione finora

- Technical, Economic, and Environmental Assessment of Flare Gas Recovery System: A Case StudyDocumento14 pagineTechnical, Economic, and Environmental Assessment of Flare Gas Recovery System: A Case StudyIhaw HalimNessuna valutazione finora

- Reservoir Fliud Phase BehavoirDocumento50 pagineReservoir Fliud Phase BehavoirBrian OmbogoNessuna valutazione finora

- OMV PWS (Basis of Design)Documento13 pagineOMV PWS (Basis of Design)rizwan khanNessuna valutazione finora

- SPE-187855-MS Study of The Efficiency of Methods For Enhanced Condensate Recovery, Based On Reservoir Simulation ModelsDocumento14 pagineSPE-187855-MS Study of The Efficiency of Methods For Enhanced Condensate Recovery, Based On Reservoir Simulation ModelsJamalNessuna valutazione finora

- Drawing ListDocumento6 pagineDrawing ListSandi ApriandiNessuna valutazione finora

- The Ultimate Way To Dehydrate Oils Used in The Hydrocarbon Processing IndustryDocumento2 pagineThe Ultimate Way To Dehydrate Oils Used in The Hydrocarbon Processing IndustryDelio Rafael Sánchez FernandezNessuna valutazione finora

- Liebert Ds 50Hz Technical Manual PDFDocumento32 pagineLiebert Ds 50Hz Technical Manual PDFanon_166797875Nessuna valutazione finora

- Instalacion y Mantenimiento FT FTI OKDocumento4 pagineInstalacion y Mantenimiento FT FTI OKAura RamirezNessuna valutazione finora

- Ang TPG Gen Ra 7754 00001 c01 Coating MtoDocumento17 pagineAng TPG Gen Ra 7754 00001 c01 Coating MtoJustice NnamdiNessuna valutazione finora

- Cru Start Up ProcedureDocumento2 pagineCru Start Up Procedureesakkiraj1590Nessuna valutazione finora

- Ga 30-90Documento16 pagineGa 30-90sancsa_74Nessuna valutazione finora

- Test Separator TrainingDocumento2 pagineTest Separator TrainingAna FajarNessuna valutazione finora