Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Managing Production and ServiceOperations

Caricato da

James Kevin IgnacioDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Managing Production and ServiceOperations

Caricato da

James Kevin IgnacioCopyright:

Formati disponibili

Managing Production and Service Operations

Process

that accepts inputs and uses resources to change those inputs in useful way.

Transformation Process

Equipment Procedures Technology

Inputs

Land Labor Capital Entrepreneurship

Outputs

Products Services

The Production Process

Industrial Chemicals Services Electrical Products Electronic Products

Mechanical Devices

Engineering Consultancy Services

The

process of planning, organizing, and controlling operations to reach objectives efficiently and effectively.

The

engineer manager is expected to produce some output at whatever management level he is.

Job

Shop

Typically a manufacturing facility that generates a

variety of products in relatively low numbers or upon how many the customers needs.

Batch

Flow

A process where lots of generally own designed

products are manufactured.

Continuous

Flow

Rapid rate at which items move through the

system.

Batch/Continuous

Flow Hybrid

Combination of batch and continuous flow.

Worker-Paced

and Machine-Paced

Assembly Line

Assembly line refers to a production layout

arranged in a sequence to accommodate processing of large volumes of standardized products or services.

Service

Factory

A place where there is customer service in

addition to a place where products are manufactured and bought.

Service

Shop

A place that provides a diverse mix of service.

Mass

Service

A place that provides services to a large number

of people simultaneously.

Professional

Service

A place that provides specialized services to other

firms or individuals.

Product Design The process of creating a set of product specifications

appropriate to the demands of the situation.

Production Planning and Scheduling Phase that involves forecasting demand and

translating the demand forecast into a production plan that optimizes the company's objective. Phase of production control in developing timetables that specify how long each operation in the production process takes.

Purchasing

and Materials Management

The approach that seeks efficiency of operation

through integration of all material acquisition, movement, and storage activities in the firm

Inventory

Control

Process of establishing and maintaining

appropriate levels of reserve stocks of goods.

Work

Flow Layout

Process of determining the physical arrangement

of the production system.

Quality

Control

Refers to the measurement of products or

services against standards set by the company.

Potrebbero piacerti anche

- OperationDocumento2 pagineOperationJames Kevin IgnacioNessuna valutazione finora

- Production and Operations ManagementDocumento18 pagineProduction and Operations ManagementkarangagNessuna valutazione finora

- Presentation SlidesDocumento35 paginePresentation SlidesAkash SuryaNessuna valutazione finora

- 8 - The Conversion Cycle WfaDocumento70 pagine8 - The Conversion Cycle WfaShandy MojicaNessuna valutazione finora

- XFVBGDDocumento32 pagineXFVBGDSyed AnsafNessuna valutazione finora

- Production and Operations Management: Lear Ning Goa LsDocumento18 pagineProduction and Operations Management: Lear Ning Goa LsJuha PropertiesNessuna valutazione finora

- Forecasting, Process Management, Capacity Planning, Facility Location and LayoutDocumento121 pagineForecasting, Process Management, Capacity Planning, Facility Location and Layoutarvind jangirNessuna valutazione finora

- PPC-ch-5 Manufacturing Process Selaction&DesignDocumento39 paginePPC-ch-5 Manufacturing Process Selaction&DesignantehenNessuna valutazione finora

- Production & Total Quality ManagementDocumento57 pagineProduction & Total Quality ManagementAtif AnsariNessuna valutazione finora

- Process Design and AnalysisDocumento22 pagineProcess Design and AnalysisAhmed HamzaNessuna valutazione finora

- Manufacturing ProcessDocumento14 pagineManufacturing Processayushichaudhary72Nessuna valutazione finora

- Facility Location: Where Should A Plant or Service Facility Be Located?Documento33 pagineFacility Location: Where Should A Plant or Service Facility Be Located?shahadat112Nessuna valutazione finora

- SEWP ZC 241: Principles of Management Productivity, Operations Management, and Total Quality ManagementDocumento63 pagineSEWP ZC 241: Principles of Management Productivity, Operations Management, and Total Quality ManagementMervin SastrilloNessuna valutazione finora

- Manufacturing Processes: Chapter SevenDocumento15 pagineManufacturing Processes: Chapter SevenVinayak SaxenaNessuna valutazione finora

- Introduction To The Production Planning and Inventory ControlDocumento80 pagineIntroduction To The Production Planning and Inventory ControlAngelina WattssNessuna valutazione finora

- Tutorial Class SKB - Session 2Documento24 pagineTutorial Class SKB - Session 2Shafa Alya FirdausyaNessuna valutazione finora

- Pharmaceutical Production Planning and Controlling: Guide Jyothi.V Assistant Professor of Pharmacology A.RavitejaDocumento17 paginePharmaceutical Production Planning and Controlling: Guide Jyothi.V Assistant Professor of Pharmacology A.Ravitejamd kuku mumuNessuna valutazione finora

- Student POM Unit - 1Documento16 pagineStudent POM Unit - 1Janhavi JoshiNessuna valutazione finora

- Manufactuiring ConceptsDocumento79 pagineManufactuiring ConceptsBharath SrNessuna valutazione finora

- Ilovepdf MergedDocumento35 pagineIlovepdf MergedMark Angelo NioscoNessuna valutazione finora

- Manufacturing Planning and ControlDocumento17 pagineManufacturing Planning and Controlvipulruiwale100% (4)

- Operations Management Unit-1: By: Mohd. Sadaf AhmadDocumento38 pagineOperations Management Unit-1: By: Mohd. Sadaf Ahmadsadafahmed007Nessuna valutazione finora

- 01 - The Operations OfficeDocumento15 pagine01 - The Operations OfficeJaripNessuna valutazione finora

- BoeingDocumento40 pagineBoeingTina Vaz0% (1)

- AIS6e.ab - Az Ch07Documento51 pagineAIS6e.ab - Az Ch07Pamela MabizaNessuna valutazione finora

- Lean BasicsDocumento20 pagineLean BasicsKannanSarathyNessuna valutazione finora

- Module 3Documento49 pagineModule 3Ananda KrishnanNessuna valutazione finora

- Unit 3 - POM NewDocumento26 pagineUnit 3 - POM NewYogitha GowdaNessuna valutazione finora

- Concepts Related To Production Planning: Topic 4Documento25 pagineConcepts Related To Production Planning: Topic 4Frank Eric ZombokoNessuna valutazione finora

- AppcDocumento21 pagineAppcniceneha_nehaNessuna valutazione finora

- Introduction To ManufacturingDocumento46 pagineIntroduction To ManufacturingBalamurugan ThangaveluNessuna valutazione finora

- Production and Operations Management (Finished)Documento11 pagineProduction and Operations Management (Finished)kingfearless27Nessuna valutazione finora

- Production Systems BBA 6th Sem 7 12 r93OLsHZSkDocumento21 pagineProduction Systems BBA 6th Sem 7 12 r93OLsHZSkVISHAL MISHRANessuna valutazione finora

- Career Opportunities For Operations Management Organizational PositionsDocumento13 pagineCareer Opportunities For Operations Management Organizational PositionssjugliNessuna valutazione finora

- Objectives of Production ManagementDocumento16 pagineObjectives of Production ManagementSaleha GaffarNessuna valutazione finora

- Production and Operation Management (MAN406) Lesson 3Documento34 pagineProduction and Operation Management (MAN406) Lesson 3sharee khanNessuna valutazione finora

- Conversation CycleDocumento35 pagineConversation CycleMarian RaagasNessuna valutazione finora

- Process Selection and Facility LayoutDocumento59 pagineProcess Selection and Facility LayoutKhietNessuna valutazione finora

- PPT8-Production and Operations ManagementDocumento33 paginePPT8-Production and Operations ManagementSofyyNessuna valutazione finora

- Process Selection & Facility LayoutDocumento52 pagineProcess Selection & Facility LayoutNikki D. ChavezNessuna valutazione finora

- Ch10-Managing Production and Service OperationsDocumento17 pagineCh10-Managing Production and Service OperationsAlthea Mendoza67% (3)

- Accounting Information System-Chapter 5 ProductionDocumento49 pagineAccounting Information System-Chapter 5 ProductionMelisa May Ocampo AmpiloquioNessuna valutazione finora

- Managing Production AND: Service OperationsDocumento14 pagineManaging Production AND: Service Operationsbroomer27Nessuna valutazione finora

- Managing Production and Service OperationsDocumento17 pagineManaging Production and Service OperationsEmmanuelDalesAlquizolaNessuna valutazione finora

- Process Selection, Design, Analysis & LayoutsDocumento81 pagineProcess Selection, Design, Analysis & LayoutsVishesh DwivediNessuna valutazione finora

- Engineering Management Chapter 4Documento39 pagineEngineering Management Chapter 4julito paquitNessuna valutazione finora

- Order-Winner or Qualifier Review Current Performance Typical ImprovementsDocumento1 paginaOrder-Winner or Qualifier Review Current Performance Typical ImprovementslightknowNessuna valutazione finora

- Prod Sys For Focused FactoryDocumento30 pagineProd Sys For Focused FactorymandydamleNessuna valutazione finora

- Form Through Chemical or Mechanical Process To Create or Enhance The Utility of The Product To The User."Documento16 pagineForm Through Chemical or Mechanical Process To Create or Enhance The Utility of The Product To The User."Binit Kumar ChhantyalNessuna valutazione finora

- Chapter 1.1 Production SystemDocumento28 pagineChapter 1.1 Production SystemSarahjane TerradoNessuna valutazione finora

- Om Unit IiiDocumento60 pagineOm Unit Iiivamsi thotaNessuna valutazione finora

- Accounting Information System Chapter 7 (James Hall)Documento47 pagineAccounting Information System Chapter 7 (James Hall)Cassie50% (2)

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocumento53 pagineJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDivya SudarsananNessuna valutazione finora

- ERP Core Applications: By: Alexis O. KingDocumento7 pagineERP Core Applications: By: Alexis O. KingAlexis KingNessuna valutazione finora

- Shop Floor ControlDocumento9 pagineShop Floor ControlSUBASHININessuna valutazione finora

- Process DesignDocumento22 pagineProcess Designayushi LakumNessuna valutazione finora

- Unit 1pomDocumento38 pagineUnit 1pomGitu SinghNessuna valutazione finora

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionDa EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNessuna valutazione finora

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowDa EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowValutazione: 4 su 5 stelle4/5 (1)

- DepreciationDocumento35 pagineDepreciationJames Kevin IgnacioNessuna valutazione finora

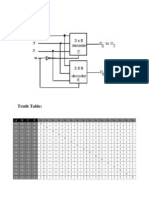

- 7-Segment Display With DecoderDocumento4 pagine7-Segment Display With DecoderJames Kevin Ignacio100% (1)

- DecoderDocumento2 pagineDecoderJames Kevin IgnacioNessuna valutazione finora

- Half/Full Adder AndHalf/Full SubtractorDocumento6 pagineHalf/Full Adder AndHalf/Full SubtractorJames Kevin Ignacio100% (10)

- Familiarization With The Logic GatesAnd BreadboardingDocumento5 pagineFamiliarization With The Logic GatesAnd BreadboardingJames Kevin IgnacioNessuna valutazione finora

- Sample 2: 3. IllustrationsDocumento2 pagineSample 2: 3. IllustrationsAtLeeNessuna valutazione finora

- Inventory ManamementDocumento30 pagineInventory ManamementBELAL AHAMADNessuna valutazione finora

- Summary Slide: Figure 11-1Documento15 pagineSummary Slide: Figure 11-1Emmanuel CherianNessuna valutazione finora

- Material Stock Release FormDocumento1 paginaMaterial Stock Release FormChad Cannon100% (1)

- Module 2 Accounting For MaterialsDocumento32 pagineModule 2 Accounting For MaterialsGhillian Mae GuiangNessuna valutazione finora

- Accounting Annual Report ProjectDocumento6 pagineAccounting Annual Report Projectapi-242011284Nessuna valutazione finora

- Simulation-Based Inventory Planning For The Digital Supply Chain EraDocumento21 pagineSimulation-Based Inventory Planning For The Digital Supply Chain EraDavid Gomez SchwartzNessuna valutazione finora

- CH 13 Key IdeasDocumento1 paginaCH 13 Key IdeasZenn Low Wai ChenNessuna valutazione finora

- Krajewski OM11ge C09-Managing-InventoriesDocumento97 pagineKrajewski OM11ge C09-Managing-InventoriesMhmd AlKhreisatNessuna valutazione finora

- SAP Good Movement Types in SAP MM and SAP WM (With Tables)Documento5 pagineSAP Good Movement Types in SAP MM and SAP WM (With Tables)sanjanasingh29100% (1)

- PGPM 32 - NICMAR AssignmentsDocumento13 paginePGPM 32 - NICMAR AssignmentsVinod VasanNessuna valutazione finora

- Chapter No. 2Documento26 pagineChapter No. 2Afzaal AhmedNessuna valutazione finora

- HP Case StudyDocumento20 pagineHP Case Studymwaqasiqbal67% (3)

- Available Check1508506Documento4 pagineAvailable Check1508506syamsu866764Nessuna valutazione finora

- Review of Related LiteratureDocumento9 pagineReview of Related LiteratureNoel San MiguelNessuna valutazione finora

- Materials Management Manual June 2014Documento204 pagineMaterials Management Manual June 2014sagarthegameNessuna valutazione finora

- TugasDocumento4 pagineTugasNatali antariNessuna valutazione finora

- Course Outline-MANACDocumento7 pagineCourse Outline-MANACdkrirayNessuna valutazione finora

- Practice Questions On Fin AcctgDocumento6 paginePractice Questions On Fin AcctgMateen HashmiNessuna valutazione finora

- Receiving and Issuing Out of Goods: Introduction: This Document Describes Procedures To Receive Finished Goods ThatDocumento5 pagineReceiving and Issuing Out of Goods: Introduction: This Document Describes Procedures To Receive Finished Goods ThatFaysal AhmedNessuna valutazione finora

- RMC No 57 - Annexes A-CDocumento13 pagineRMC No 57 - Annexes A-CRACNessuna valutazione finora

- The PAR Stock, Reorder Point and Safety Stock andDocumento3 pagineThe PAR Stock, Reorder Point and Safety Stock andJorge Yeshayahu Gonzales-LaraNessuna valutazione finora

- Common Notes To The Financial StatementsDocumento2 pagineCommon Notes To The Financial StatementsBaischenarizah AbdulNessuna valutazione finora

- CV Blas Jaime Hernández Contreras - EnGLISHDocumento3 pagineCV Blas Jaime Hernández Contreras - EnGLISHBlas HernandezNessuna valutazione finora

- WHBM08 - Inventory & Cost of Goods SoldDocumento64 pagineWHBM08 - Inventory & Cost of Goods SoldMuhammad Salman RasheedNessuna valutazione finora

- Depreciation Practice in BangladeshDocumento17 pagineDepreciation Practice in BangladesharafatNessuna valutazione finora

- Sap SCM Colgate CsDocumento8 pagineSap SCM Colgate Csapi-3725984100% (1)

- Mutummas AssignmentDocumento3 pagineMutummas AssignmentMame AbrarNessuna valutazione finora

- Sport Obermeyer CaseDocumento7 pagineSport Obermeyer CaseAndy VibgyorNessuna valutazione finora

- How To Resolve Costing ErrorsDocumento37 pagineHow To Resolve Costing Errorshsk12100% (1)