Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

L-5 (Marker Making)

Caricato da

KashfmmDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

L-5 (Marker Making)

Caricato da

KashfmmCopyright:

Formati disponibili

MARKER MAKING/LAY PLAN MAKING

What is a Marker? The Marker is a diagram of a precise arrangement of pattern pieces for the sizes of a specific style that are to be cut from a single spread. What is Marker Making/Lay Plan? Marker making is the process of determining the most efficient layout of pattern pieces for a specified style, fabric, and distribution of sizes. In other words, The cutting templates representing all of the individual components of a garment have to be laid out together in such a way that they fit within the confines of the fabric width as closely and efficiently as possible, in order to minimize waste. This is Lay Plan.

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan The templates have to be laid in a way that takes account of the directional properties of the fabric, such as thread directions, pattern directions, grain of nap or pile. It may also be necessary to allow for matching of stripes, checks, or designs.

So major factors to be considered are:

1. Orientation and Direction 2. Pattern Matching

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan 1. Orientation and Direction The orientation of the pattern templates will depend on the construction of the textile material and its pattern design features. There are three basic types of orientation:

i. Nonwovens ii. Cretonne iii. Corduroy

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan 1. Orientation and Direction

i.

Nonwovens Fabrics for which neither the orientation nor the direction is important. e.g. random-laid nonwoven fabrics.

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan 1. Orientation and Direction ii. Cretonne Fabrics for which the orientation is important but the templates may be laid in either direction. e.g. linings and laminated fabrics.

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan 1. Orientation and Direction iii. Corduroy Fabrics for which orientation and direction are both important. e.g. pile fabrics, fabrics with a directional pattern or pile, knitted fabrics.

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan 2. Pattern Matching The quality of a product is affected significantly by the accuracy of pattern matching. A flawless execution, especially with checks and stripes, demands high consumption of fabric and takes a great deal of time. The coloring, the repeat size, and the prominence of the pattern, as well as the degree of matching between individual garment pieces are crucial in determining the cost and difficulty in making the lay plan, in spreading the cloth, and in cutting. During spreading it is necessary to match the pattern exactly at each end of the lay and in every ply. Cutting may have to be carried out in two stages, with a preliminary rough cut being followed by more precise second cutting together with pattern matching. In making the lay plan the pattern markers cannot be laid in such a way as to minimize cutting waste; they have to be disposed according to the requirement of the fabric pattern.

7

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan 2. Pattern Matching Features of Accurate Pattern Matching: Symmetry The pattern must be symmetrical about the central axis. Examples: left and right front panels, collars backs Vertical Continuity The pattern must not be interrupted or displaced at horizontal seams. Example: pockets

MARKER MAKING/LAY PLAN MAKING

Guide Lines for the Lay Plan 2. Pattern Matching Features of Accurate Matching:

Pattern

Horizontal Continuity The pattern must not be interrupted or displaced at vertical seams or across adjacent parts. Example: arm and front panel Overall Continuity The form and the repeat of the pattern must be maintained across all seams, facings, trimmings, patches, etc. Examples: patch pockets, flaps, darts, facings.

MARKER MAKING/LAY PLAN MAKING

Dimensions of Marker There are two dimensions of marker. Length Width

Markers are used to measure yardage requirement. Marker Efficiency Marker efficiency is basically the area covered by the pattern pieces to the total area of the fabric. Marker efficiency = Area covered by pattern pieces x 100 Total area of spread Efficiency of marker goes up to 95 % in home textiles. Efficiency of marker goes up to 80-85 % in garments.

10

MARKER MAKING/LAY PLAN MAKING

Types of Marker/Lay Plan The types of marker or lay plan being used in the industry are of the following type: Half Garment Lay Whole Garment Lay Single Size Lay

Multi-Size Lay

Sectional Lay Interlocking Lay Mixed Multi-Size Lay

11

MARKER MAKING/LAY PLAN MAKING

Types of Marker/Lay Plan Half Garment Lay This includes only half of the garment pieces (e.g. the right side of the garment). They are used for folded or tubular fabrics and for fabrics which are spread face to face.

Half Garment Lay

12

MARKER MAKING/LAY PLAN MAKING

Types of Marker/Lay Plan Whole Garment Lay All of the garment pieces, left and right sides, are included in the lay. This type of lay is used for open width fabrics.

Full Garment Lay

13

MARKER MAKING/LAY PLAN MAKING

Types of Marker/Lay Plan Single Size Lay

The lay includes all of the pieces for a single size.

Restricting the lay to a single size makes order planning and laying up the fabric easier, but the disadvantage is a somewhat higher material consumption, compared to multi-size lays.

Single Size Lay

14

MARKER MAKING/LAY PLAN MAKING

Types of Marker/Lay Plan Multi-Size Lay Sectional Lay The lay is made in at least two distinct rectangular sections. Each section contains all of the parts of a single size. Adjacent sections may be the same or a different size.

Sectional Multi-size Lay for Two Sizes

15

MARKER MAKING/LAY PLAN MAKING

Types of Marker/Lay Plan Multi-Size Lay Interlocking Lay Two or more sections, one after the other, usually different sizes, but the sections are not confined to strict rectangular areas; the pieces for the different sections may merge at the borders.

Interlocking Multi-size Lay for Two Sizes

16

MARKER MAKING/LAY PLAN MAKING

Types of Marker/Lay Plan Multi-Size Lay Mixed Multi-Size Lay In this case there are no distinct sections; the pieces for the two or more different garment sizes are intermingled. This is the arrangement which normally gives the best material utilization.

Mixed Multi-size Lay for Three Sizes

17

Potrebbero piacerti anche

- Nursing Practice Skills: Adult Intensive Care Unit PatientsDocumento10 pagineNursing Practice Skills: Adult Intensive Care Unit PatientsMona Doria67% (3)

- BNB SB0114Documento4 pagineBNB SB0114graziana100% (2)

- Basic Resistance Training GP5Documento20 pagineBasic Resistance Training GP5matt.tubieron23Nessuna valutazione finora

- Quality Aspects of Garment - A ReviewDocumento4 pagineQuality Aspects of Garment - A ReviewSazid RahmanNessuna valutazione finora

- Spreading ParametersDocumento23 pagineSpreading ParameterssagarNessuna valutazione finora

- Vocal TractDocumento16 pagineVocal TractniroelNessuna valutazione finora

- Knitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1Documento25 pagineKnitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1shahinrezaNessuna valutazione finora

- DefectsDocumento31 pagineDefectsKawsar HamidNessuna valutazione finora

- Carr and Latham's Technology of Clothing ManufactureDa EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerValutazione: 4 su 5 stelle4/5 (1)

- SuctioningDocumento58 pagineSuctioningAyusa PradhanNessuna valutazione finora

- The Foods of Italy BookDocumento92 pagineThe Foods of Italy BookmanupopNessuna valutazione finora

- Aspects of Knitting ScienceDocumento3 pagineAspects of Knitting ScienceNiaz IslamNessuna valutazione finora

- Cutting Room TechnologiesDocumento52 pagineCutting Room TechnologiesMuhammad Iqbal ShaikhNessuna valutazione finora

- Obs and Gynae PassmedDocumento7 pagineObs and Gynae PassmedrahulNessuna valutazione finora

- SpreadingDocumento39 pagineSpreadingPratik MinjNessuna valutazione finora

- Naisargi SCAP End TermDocumento11 pagineNaisargi SCAP End TermNaisargiNessuna valutazione finora

- Sample Section:It Is The First Section Of: Garment Manufacturing ProcessDocumento6 pagineSample Section:It Is The First Section Of: Garment Manufacturing ProcesssantumysoreNessuna valutazione finora

- Marker Planning, Spreading Process & Equipments: Deepika Agarwal, Gayathri V.S, Greeshma V, Santhi BijuDocumento51 pagineMarker Planning, Spreading Process & Equipments: Deepika Agarwal, Gayathri V.S, Greeshma V, Santhi BijuGreeshmaNessuna valutazione finora

- Merchandising in An Apparel Industry: Source: Textile ReviewDocumento8 pagineMerchandising in An Apparel Industry: Source: Textile ReviewAnnette HendricksNessuna valutazione finora

- 18.estimating Thread ConsumptionDocumento4 pagine18.estimating Thread ConsumptionSugar Lipss0% (1)

- Barge 180Ft Deck Load Capacity & Strength-Rev1Documento52 pagineBarge 180Ft Deck Load Capacity & Strength-Rev1Wahyu Codyr86% (7)

- Manual SpreadingDocumento4 pagineManual SpreadingarunkadveNessuna valutazione finora

- Marker MakingDocumento12 pagineMarker MakingsachipalNessuna valutazione finora

- In-Plant Training Report PresentationDocumento60 pagineIn-Plant Training Report Presentationrajhossie9335100% (3)

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDocumento14 pagineDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazNessuna valutazione finora

- Marker EfficiencyDocumento2 pagineMarker EfficiencyGaurav ShakyaNessuna valutazione finora

- Marker ModesDocumento2 pagineMarker ModesGaurav Shakya100% (1)

- Chapter One PDFDocumento24 pagineChapter One PDFKibromGereNessuna valutazione finora

- Export House PresentationDocumento8 pagineExport House PresentationSantosh BishtNessuna valutazione finora

- Glossary of Defect TerminologyDocumento7 pagineGlossary of Defect TerminologymnswamyNessuna valutazione finora

- Productivity in Apparel ManufacturingDocumento7 pagineProductivity in Apparel ManufacturingAmar Nath PrasadNessuna valutazione finora

- Procedures Practiced For Quality Control and Assurance in FusingDocumento18 pagineProcedures Practiced For Quality Control and Assurance in FusingP. Lakshmanakanth100% (1)

- Marketing Activities of MerchandiserDocumento49 pagineMarketing Activities of MerchandiserzahidNessuna valutazione finora

- Lecture # 8 SamplingDocumento9 pagineLecture # 8 SamplingwamohsinNessuna valutazione finora

- Spreading and Cutting HandoutDocumento7 pagineSpreading and Cutting HandoutAlemu HaileNessuna valutazione finora

- Steps To Garment MakingDocumento12 pagineSteps To Garment MakingKhandaker Sakib FarhadNessuna valutazione finora

- Understanding Apparel Quality: Abhinav Krishna Bft/18/1044 Amisha Sahu Bft/18/734Documento10 pagineUnderstanding Apparel Quality: Abhinav Krishna Bft/18/1044 Amisha Sahu Bft/18/734kashorina AgarwalNessuna valutazione finora

- Mizan HowladerDocumento65 pagineMizan HowladerRejaul Karim Bhuiyan RockyNessuna valutazione finora

- Apparel Marketing and MerchandisingDocumento4 pagineApparel Marketing and Merchandisingmeghana rajNessuna valutazione finora

- Marker Making ModesDocumento15 pagineMarker Making ModessamchikkuNessuna valutazione finora

- Outsourcing in Apparel IndustryDocumento13 pagineOutsourcing in Apparel IndustryPriyanshu GuptaNessuna valutazione finora

- Defects in GarmentsDocumento2 pagineDefects in GarmentsAbul HasanNessuna valutazione finora

- Internship Report On Marchandising in Garments IndustryDocumento47 pagineInternship Report On Marchandising in Garments IndustryHimuSunNessuna valutazione finora

- Factory Report 2Documento6 pagineFactory Report 2Chen Wei Sassei-KetsuNessuna valutazione finora

- Typs of MarkerDocumento2 pagineTyps of MarkerarunkadveNessuna valutazione finora

- Apparal Merchandizing and Sources Asif MangatDocumento8 pagineApparal Merchandizing and Sources Asif MangatAsif MangatNessuna valutazione finora

- 1c. Cutting TrainingDocumento1 pagina1c. Cutting Trainingjahazi1Nessuna valutazione finora

- Denimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Documento6 pagineDenimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Thamara Dananjaya GunarathnaNessuna valutazione finora

- Product Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem ViiDocumento29 pagineProduct Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem Viimaduvats100% (1)

- Sample ActivityDocumento5 pagineSample ActivityHasan TarekNessuna valutazione finora

- Fabric Quality ControlDocumento4 pagineFabric Quality ControlShazzad HossaInNessuna valutazione finora

- GMM - Fabric Cutting AssignmentDocumento10 pagineGMM - Fabric Cutting AssignmentsatexNessuna valutazione finora

- Fabric CuttingDocumento10 pagineFabric CuttingRatul HasanNessuna valutazione finora

- Preparatory Apparel Production ProcessDocumento151 paginePreparatory Apparel Production ProcessNesar Ahmad Shaown100% (1)

- Knit Asia Operation ProcessDocumento12 pagineKnit Asia Operation ProcessParvezMridhaNessuna valutazione finora

- GMTDocumento22 pagineGMTEusha NightangelNessuna valutazione finora

- ShirtsDocumento18 pagineShirtsAkash SinghNessuna valutazione finora

- Methods of SpreadingDocumento10 pagineMethods of Spreadingarunkadve67% (3)

- Potential Reasons For Broken, Skipped or Missing StitchesDocumento6 paginePotential Reasons For Broken, Skipped or Missing StitchesgetNessuna valutazione finora

- Sample Room DepartmentDocumento5 pagineSample Room DepartmentRajib DasNessuna valutazione finora

- Merchandising Practice in Apparel IndustryDocumento53 pagineMerchandising Practice in Apparel IndustryrafsanNessuna valutazione finora

- Viva Questions and Answers For Garments and Merchandising Job (Part-1) - Textile Learner PDFDocumento1 paginaViva Questions and Answers For Garments and Merchandising Job (Part-1) - Textile Learner PDFMABVUTO TEMBONessuna valutazione finora

- Stitch ClassificationDocumento27 pagineStitch Classificationrgvarma123Nessuna valutazione finora

- Water Proof Breathable FabricDocumento13 pagineWater Proof Breathable Fabricjack omeNessuna valutazione finora

- Advancements in Garment Manufacturing TechnologyDocumento19 pagineAdvancements in Garment Manufacturing TechnologyShanmugeshwari MuthiahNessuna valutazione finora

- Thread Consumption MethodsDocumento5 pagineThread Consumption MethodsRejaal100% (1)

- BSP Short Questions From First Five ChaptersDocumento4 pagineBSP Short Questions From First Five ChaptersKashfmmNessuna valutazione finora

- InterviewDocumento1 paginaInterviewKashfmmNessuna valutazione finora

- Shah Distribution: Upper Bound Base CaseDocumento8 pagineShah Distribution: Upper Bound Base CaseKashfmmNessuna valutazione finora

- Final Presentation: Managerial Economics Presented ToDocumento13 pagineFinal Presentation: Managerial Economics Presented ToKashfmmNessuna valutazione finora

- Infant of A Diabetic MotherDocumento17 pagineInfant of A Diabetic MotherLovina Falendini AndriNessuna valutazione finora

- Odd Semester Time Table Aug - Dec22 Wef 22.08.2022.NEWDocumento4 pagineOdd Semester Time Table Aug - Dec22 Wef 22.08.2022.NEWKiran KumarNessuna valutazione finora

- 10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtDocumento145 pagine10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtVuong DiepNessuna valutazione finora

- CatalogDocumento52 pagineCatalogtalabiraNessuna valutazione finora

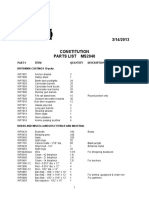

- MS2040 Constitution Parts ListDocumento6 pagineMS2040 Constitution Parts ListTemptationNessuna valutazione finora

- IMDB - ColaboratoryDocumento10 pagineIMDB - Colaboratory4416 LikhithaNessuna valutazione finora

- Form 03B Heritage Bell 1Documento2 pagineForm 03B Heritage Bell 1ValNessuna valutazione finora

- Bold Face Actions - G 450Documento4 pagineBold Face Actions - G 450sohaib arifNessuna valutazione finora

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Documento1 paginaProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanNessuna valutazione finora

- Global Environment Unit 2Documento13 pagineGlobal Environment Unit 2Se SathyaNessuna valutazione finora

- Al Khudari Company Profile FP PDFDocumento14 pagineAl Khudari Company Profile FP PDFAnonymous bgYdp4Nessuna valutazione finora

- Astro 429 Assignment 2 AlbertaDocumento2 pagineAstro 429 Assignment 2 AlbertatarakNessuna valutazione finora

- Us 5596162Documento9 pagineUs 5596162Stanley PinesNessuna valutazione finora

- Lake Superior RoadmapDocumento2 pagineLake Superior RoadmapWDIV/ClickOnDetroitNessuna valutazione finora

- A Very Old MachineDocumento20 pagineA Very Old MachineSwathi G. SalemNessuna valutazione finora

- TMJDocumento38 pagineTMJAnonymous 6kAmeZzINessuna valutazione finora

- Economics 526 - Mathematics For Economists: Day(s) Time LocationDocumento5 pagineEconomics 526 - Mathematics For Economists: Day(s) Time LocationGaurav JakhuNessuna valutazione finora

- Listening DictationDocumento3 pagineListening DictationThảo ĐinhNessuna valutazione finora

- Fact Sheeton Canola OilDocumento15 pagineFact Sheeton Canola OilMonika ThadeaNessuna valutazione finora

- Catalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFDocumento123 pagineCatalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFBruno CecattoNessuna valutazione finora

- CPHL 214 Assignment 6Documento2 pagineCPHL 214 Assignment 6NazNessuna valutazione finora