Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5.B. Beyond Toyota

Caricato da

snm60Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5.B. Beyond Toyota

Caricato da

snm60Copyright:

Formati disponibili

Beyond Toyota: J P Womack and D T Jones. 1996.

How to root out waste and pursue perfection - Harvard Business Review Summary by Neil Escalant, Master of Accountancy Program University of South Florida, Summer 2003 Lean Thinking The purpose of this article is to introduce the reader to the concept of lean thinking. Womack and Jones begin by stating that lean thinking is a fairly new manufacturing strategy which, since it is not well understood, has been somewhat problematic in implementing in the Western World. Then they explain the five main steps in applying a lean system, and furthermore explain how a stretch-wrapping machine producing company, Lantech, used this system successfully. The authors also provide a less detailed example of this strategy in describing how Pratt & Whitney, a turbine blade producing company, implemented a lean thinking production style. Five Steps of Lean Thinking: 1. Define value precisely from the perspective of the end customer in terms of a specific product with specific capabilities offered at a specific price and time. The authors tell us that different departments in a production line may have different goals which they want to achieve in production. For example, the workers there might be working in a manner they feel might help them advance in their jobs. Also, a department might want to make full use of all its materials available. This could lead to producing items that are not marketable in an efficient way. This is waste (or muda, the Japanese term). 2. Identify the entire value stream for each product or product family and eliminate waste. According to the article, there are three critical activities that make up the value stream. These are product definition (from design to launching), information management (from order taking to delivery), and physical transformation (from raw materials to finished goods). Identifying these activities will highlight other processes in the production line that do not add value to the finished good but are wasteful. 3. Make the remaining value-creating steps flow. It appears that this is the most difficult step in developing a lean enterprise. Too common is the batch-and-queue mentality that it is hard to create a production line that flows. According to the new plan, there should be no waiting, downtime or scrap within or between the steps of production. 4. Design and provide what the customer wants only when the customer wants it. For this to be possible, the production process must be flexible and understood fully so as to allow for any modifications. In this manner, customized products can be created and the process can be halted to produce a good that is by all purposes finished to the customer but not what was originally intended to be the final product.

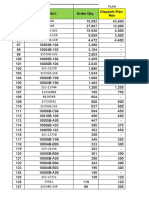

5. Pursue perfection Once the production process starts to flow, any barriers in the cycle will become more apparent. In reality, a production process can never be flawless, but through constant re-evaluation and upgrading, optimization is achieved. The Lantech Story Lantech is a company in Louisville, Kentucky that produces machines that stretch-wrap pallets of goods with plastic film. For over ten years, Lantech enjoyed a monopoly, provided by very general patents held, and was free to produce machines at low quality and high prices. However, in 1989 when Lantech lost a patent-infringement suit against a competitor, it had to revolutionize its production process. Batch-and-queue processing led to huge amounts of inventory which were expensive to keep, required excessive amounts of energy to move from one department in the production line to the other, and, due to independent production of each component, often lacked key parts that severely lengthened throughput. The batch-and-queue system also required component parts to be sent back and forth between departments during production. This proved to be quite inefficient. (See graphic illustration below). In an effort to cut down on cost and cycle time, Lantech hired Ron Hicks who had learned the fundamentals of a lean organization while working for a manufacturer of automotive repair tools in Tennessee. Hicks instantly got to work on cutting down waste in the production process. Hicks grouped the machines needed to create the four different product families into four separate cells. Smaller equipment replaced larger ones where necessary. Emphasis was placed on keeping the process flowing, regardless of whether the larger machines could produce components more quickly. When production began on Lantechs Q Model, a frame was assembled and ready within one hour, this was moved three feet to a machining station. One hour after that, the work in progress was moved four feet to the welding station. After a total of fourteen hours, the product was ready for shipment. This is a sharp contrast to the original sixteen weeks. No more will parts have to be moved to and from central storage and from department to department. This drastically cut cost and cycle time. (See the graphic illustration below). The change from a batch-and-queue production system to a lean production system required that Lantech's thinking about work and how people work together change in three ways. First, every task was standardized so that it would be performed correctly and take the same amount of time, every time. (See the Spear & Bowen summary for more on this point). Second, Hicks introduced an idea that Toyota called takt time - the time it would take to produce the requested number of orders in a given time. For example, if the company needs to fulfill orders for sixteen machines in one day and the day is comprised of an eight hour shift, then takt time is one half hour for each machine. Keeping this concept in mind, emphasis is not placed on producing to full capacity but to produce only what is needed and still make efficient use of the day. When certain machines were not in demand, time could be spent on analyzing the process and trying to perfect it. Conversely, an increase in demand, shortening takt time, would give an opportunity to augment the production to use more hands to accomplish the job as fast and efficiently

as possible, if the need arises. Third, they developed quick changeovers so that all of the variations of their machines could be produced in a continuous flow with no stoppage. Lantech was so successful with this new lean thinking, that it applied the process-flow concept to the ordering and purchasing activities and documentation and also to the new product development process. Other graphic illustrations in the article show the before and after views of these activities. Lantech experienced the following increases in efficiency: Batch-and-queue to Constant Flow Development time for a new product family from 4 years to 1 year Employee hours to make one machine.160 to 80 Manufacturing space per machine. 100 sq ft to 55 sq ft Average number of defects per delivered machine from 80 to 8 Value of in-process and finished goods inventory from $2.6 million $1.9 million Production throughput time. 16 weeks 14 hrs to 5 days Order to delivery time from 4 20 weeks to 1 4 weeks The Pratt & Whitney Story The main idea behind this interjection in the article is how Pratt & Whitney substituted large machines which could cut there turbine blades in three minutes to smaller machines that can do the job in seventy-five minutes just to provide a constant flow in the production process. The blades had to be prepared by various non-value-adding processes for the larger machines, and although the smaller machines took longer to do the job, cutting these wasteful processes out of production proved to be greatly beneficial. Cost was cut to less than half per blade, and adjusting the machinery to produce different types of blades took a lot less time (from 480 minutes to 100 seconds). The article blames the misappropriation of modern technology and resources as the main causes of economic stagnation. The authors see lean thinking as the solution to this problem. However, they also claim that too many are uninformed about this new model, or lack the energy or the innovation to make the first move to create a lean enterprise. ______________________________________

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- FORD Acronyms BookletDocumento696 pagineFORD Acronyms Bookletsnm6085% (13)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- GM ApqpDocumento106 pagineGM Apqpsnm60Nessuna valutazione finora

- Project Guidelines: Visteon Lean AcademyDocumento7 pagineProject Guidelines: Visteon Lean Academysnm60Nessuna valutazione finora

- 4.a. Stephens Valve CompanyDocumento2 pagine4.a. Stephens Valve Companysnm60Nessuna valutazione finora

- VMOS Lean ManagementDocumento18 pagineVMOS Lean Managementsnm60Nessuna valutazione finora

- Trial Manufacture of A Fluid-Type Static Induction TransistorDocumento4 pagineTrial Manufacture of A Fluid-Type Static Induction TransistorStanley ClermontNessuna valutazione finora

- Safety Data Sheet 84989 41 3 enDocumento4 pagineSafety Data Sheet 84989 41 3 enAdhiatma Arfian FauziNessuna valutazione finora

- Rigaku Progeny Spec Sheet LTR 3.14Documento2 pagineRigaku Progeny Spec Sheet LTR 3.14DATA24Nessuna valutazione finora

- Aeroshell Fluid 41 PdsDocumento2 pagineAeroshell Fluid 41 Pdsja.moreno930Nessuna valutazione finora

- MILL Series GB-1007 01Documento20 pagineMILL Series GB-1007 01Ady IonutNessuna valutazione finora

- BurnerDocumento4 pagineBurnerAhmed Mohamed KhalilNessuna valutazione finora

- Antikythera MechanismDocumento25 pagineAntikythera MechanismchetansergiurazvanNessuna valutazione finora

- Bubbling Kun NiDocumento7 pagineBubbling Kun NiBelen CRNessuna valutazione finora

- BSR NH Circle Jaipur 2016Documento103 pagineBSR NH Circle Jaipur 2016vikash kumar50% (4)

- Mega PostDocumento5 pagineMega PostandreyfgNessuna valutazione finora

- The Reef Wayfinding Plan and Signage Design Concept 28 August 2019Documento51 pagineThe Reef Wayfinding Plan and Signage Design Concept 28 August 2019Michele MontoloNessuna valutazione finora

- ISO 9001:2015 Questions Answered: Suppliers CertificationDocumento3 pagineISO 9001:2015 Questions Answered: Suppliers CertificationCentauri Business Group Inc.100% (1)

- HiraDocumento30 pagineHiravijay kumar singhNessuna valutazione finora

- Order Qty Vs Dispatch Plan - 04 11 20Documento13 pagineOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNessuna valutazione finora

- 27C ChainDocumento19 pagine27C ChainyanaziNessuna valutazione finora

- Eje Delantero BMW F10Documento94 pagineEje Delantero BMW F10Daniel Muñoz SotomayorNessuna valutazione finora

- EM230 BR BM3 Fitting InstructionsDocumento2 pagineEM230 BR BM3 Fitting InstructionsRoman BabaevNessuna valutazione finora

- Psychrometric Chart - Us and Si UnitsDocumento1 paginaPsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914Nessuna valutazione finora

- BM 81004 MuvDocumento52 pagineBM 81004 MuvHamza Abbasi AbbasiNessuna valutazione finora

- SQ Presentation 2021-r2Documento43 pagineSQ Presentation 2021-r2nadeem4ahmed-805026Nessuna valutazione finora

- Fluid Mechanics Seventh Edition by Frank M. WhiteDocumento1 paginaFluid Mechanics Seventh Edition by Frank M. WhiteDarKaiserNessuna valutazione finora

- CLS 747 200Documento158 pagineCLS 747 200Rodrigo Adam100% (8)

- Elevator Traffic Analysis - Passanger Elevators Option-1Documento5 pagineElevator Traffic Analysis - Passanger Elevators Option-1Amit GuptaNessuna valutazione finora

- Pioneer XDP - 30R ManualDocumento213 paginePioneer XDP - 30R Manualmugurel_stanescuNessuna valutazione finora

- Module002 LaboratoryExercise002Documento2 pagineModule002 LaboratoryExercise002Joaquin SmithNessuna valutazione finora

- Deep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Documento67 pagineDeep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Tina CleoNessuna valutazione finora

- Jacky Smith Resume Project ManagerDocumento1 paginaJacky Smith Resume Project ManagerGrey GrayNessuna valutazione finora

- JNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIDocumento2 pagineJNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIMRUDULA KULAKARNINessuna valutazione finora

- 25252525Documento38 pagine25252525Ivan GonzalezNessuna valutazione finora

- Le22a1321 AocDocumento130 pagineLe22a1321 AocEchefisEchefisNessuna valutazione finora