Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Moving Upto Aluminium Leaflet - en

Caricato da

Stan HonDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Moving Upto Aluminium Leaflet - en

Caricato da

Stan HonCopyright:

Formati disponibili

MOVING UP TO ALUMINIUM Light, strong and profitable

Aluminium As A complement to euRo iV & euRo V engines

The EURO IV legislation, compulsory since 1st October 2006, and the future EURO V legislation represent a dramatic reduction of NOx and particulates emissions. However, they also impose new combustion processes and exhaust after-treatment techniques representing an additional weight-penalty up to 300kg. Using more aluminium components allows the manufacturer to compensate for this weight penalty. The payload can therefore be preserved and even increased.

Aluminium hAs A high ResiduAl VAlue And is eAsily Recycled

Used aluminium vehicles have a lot of success on the second, and even third hand market, where they are usually sold for a very good price. Finally, when they have reached the end of their long service life they still have a high scrap value. This is due to the fact that aluminium is easily recycled, without loosing any of its quality and saving 95% of the primary energy input.

mAintenAnce, duRAbility & RepAiR

Aluminiums well-known corrosion resistance is an obvious advantage in road transport. It contributes to a long service life, especially in vehicles which work in conditions that can cause serious rust problems. No painting or other surface protection is required and it is easy to clean. Maintenance is therefore kept to a minimum. Some operators still fear problems with aluminium trailer chassis in heavy duty applications They should know that, if properly designed, the lifespan of a vehicle is not material related. Experienced manufacturers produce aluminium chassis offering an equivalent or longer lifespan but at a much lower weight than conventional models. They offer an efficient repair service, based on aluminium techniques that are definitely different from those of steel.

Aluminium Reduces fuel consumption

To help coping with high diesel price, aluminium reduces fuel consumption as follows: When carrying heavy goods, it allows more goods to be carried per trip. One ton saved on the dead weight saves 1.500 litres of diesel1 over 100.000 km. When carrying voluminous goods, it reduces the overall weight, lowering fuel consumption per kilometer. One ton saved on the dead weight saves 600 litres of diesel2 over 100.000 km. From an environmental point of view, 1 kg of aluminium introduced in a truck saves more than 20 kg of CO2 over its whole life-cycle3.

BENALU

1 2 3

To move the same amount of goods over the same distance, a standard vehicle would need 3.800 more vehicle-km, representing about 1.500 litres of diesel. Energy savings by light-weighting for European articulated trucks - IFEU - Institt fr Energie-und Umweltforschung Heidelberg GmbH, 2005 CO2 reduction potential of aluminium for articulated trucks - EAA European Aluminium Association, 2005. Hypothesis: 1 kg of alu lightens the vehicle by 0,83 kg; vehicle lifetime = 1.200.000km, 180.000km with heavy goods and 1.020.000km with voluminous goods.

BENALU

high stRength-to-weight And high stiffness-to-weight RAtios

Aluminium alloys used in commercial vehicles have strength-to-weight and stiffness-to-weight ratio comparable with the most advanced metals like high strength steel and titanium. Designs optimised for aluminium, are based on specific sections, smooth transitions and clever joins, which normally give 40-60% weight saving over competing materials. Comparison of weight-optimised beams made with 3 different materials and 2 design criteria4 equAl stRength

traditional material strength stiffness weight section height 1 1 1 1 = > > > high strength material 1 0,3 0,7 0,6 = < > < Aluminium alloy 1 0,6 0,4 1,2 strength stiffness weight section height traditional material 1 1 1 1 < = = =

equAl stiffness

high strength material 2,2 1 1 1 > = > < Aluminium alloy 1,5 1 0,6 1,4

The comparisons made are based on standard beam design, the so called double T. However, further weight optimisation is possible with aluminium because finite element modelling allows precise definition of most favourable sections geometry and theses sections, even if very complex, can easily be obtained through the aluminium extrusion process.

high stAbility

Achieving IRTE5 Class A6 tipping stability standard for an aluminium tipper chassis is no problem. Aluminium, according to tests carried out in the summer of 2002 has no issues with flexing and easily provides the equivalent rigidity of steel. Indeed, a full-aluminium vehicle, significantly lighter than others, passed the IRTE Class A test at 44 tonnes with its standard chassis, reminding everyone that an appropriate design leads to both lightness and torsional stiffness.

less pAin foR dRiVeRs

Mobile parts that are manipulated at each delivery, like drop-side walls or rear doors, are lighter to move when made out of aluminium. This saves a lot of effort for the drivers and reduces the risk of injuries.

Mechanical characteristics [Yield strength (MPa), E-Modulus (Mpa), Density (kg/m3)]: Traditional material [350, 210000, 7800], High strength material [760, 210000, 7800], Aluminium alloy [250, 70000, 2700]. Calculation based on finite element modelling. Results are typical values and not contractual. Institute of Road Transport Engineers, UK 6 Class A standard states that a trailer should be able to tilt sideways 7 without falling with a fully loaded and raised body.

4 5

STAS

Aluminium impRoVes RoAd sAfety

Aluminium systems make it possible to absorb significantly more crash energy per unit of weight than traditional systems. As a rule of thumb, the light-weighting potential exceeds 40%. For this reason, aluminium is very well suited for front, rear and side bumpers. Aluminium elements can also be used to improve the energy absorbing potential of front and rear end under-run protection devices, and may also be used to build soft deformable truck noses. Last but not least, extra safety features always mean additional weight, which can be balanced by replacing heavy materials by aluminium.

some Aluminium ApplicAtions & weight sAVings

Components for tractors & rigid trucks cabin & doors: -200kg chassis: -350kg powertrain parts: -125kg suspension parts: -110kg Complete superstructures rigid body: 90m = -800kg tipping body: -800 to -2000kg ADR fuel tank: 43000l = -1100kg self-discharging body silo

2

Components for superstructures curtain rails: 2x13.5m = -100kg front wall: -85kg rear door: -85kg side boards: 600mm = -240kg stanchions: 10x600mm= -50kg reefer floor

Safety parts front bumpers: -15kg rear bumpers: -15kg side bumpers: -20kg front and rear under-run protections

Trailers sub-structures chassis: 13.5m = -700kg chassis: 6m = -300kg chassis+floor: 13.5m = -1100kg legs: -35kg

Accessories air pressure vessels: 6x60l = -54kg diesel tank: 600l = -35kg toolbox: -15kg tail lift: -150kg wheels: 14 rims = -300kg

cAlculAte youR pRofits

Increased payload + Higher residual value = Additional incomes Fuel saving + long life + reduced maintenance = Cost savings Calculate your payback and discover other advantages on www.alutransport.org

Potrebbero piacerti anche

- FORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATDocumento6 pagineFORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATStan HonNessuna valutazione finora

- Pros & ConsDocumento1 paginaPros & ConsStan HonNessuna valutazione finora

- Accuracy To Size For AssemblyDocumento1 paginaAccuracy To Size For AssemblyStan HonNessuna valutazione finora

- Series GBV100/101 - Stainless Steel: 1-pc Body Reduced Ball ValveDocumento1 paginaSeries GBV100/101 - Stainless Steel: 1-pc Body Reduced Ball ValveStan HonNessuna valutazione finora

- Century Battery NX110-5L (80D26L-MF)Documento1 paginaCentury Battery NX110-5L (80D26L-MF)Stan HonNessuna valutazione finora

- ASTM A36 Steel plate propertiesDocumento1 paginaASTM A36 Steel plate propertiesStan HonNessuna valutazione finora

- BANDO V Belt Design ManualDocumento38 pagineBANDO V Belt Design ManualJie Lee Chuin Chee100% (1)

- Mudguard PoleDocumento1 paginaMudguard PoleStan HonNessuna valutazione finora

- Academic Calendar Year 2011-2012 - COGS Program - 28 Jun 11Documento1 paginaAcademic Calendar Year 2011-2012 - COGS Program - 28 Jun 11gmoxxsNessuna valutazione finora

- swr-10012 - Esab Mig-6Documento2 pagineswr-10012 - Esab Mig-6Stan HonNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Country Analysis Briefs: South China SeaDocumento8 pagineCountry Analysis Briefs: South China SeaSteeljaw ScribeNessuna valutazione finora

- Wellhead Equipment and Flow Control DevicesDocumento40 pagineWellhead Equipment and Flow Control DevicesFranklyn Frank0% (1)

- Class A1A2Documento8 pagineClass A1A2luisfer811Nessuna valutazione finora

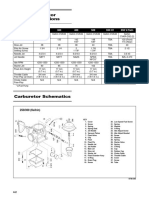

- Carburador KeihinDocumento8 pagineCarburador KeihinSofía Cerinni100% (1)

- Post Macondo Inflow TestsDocumento40 paginePost Macondo Inflow TestsfwsrffNessuna valutazione finora

- Charan SeminorDocumento19 pagineCharan SeminorSai Krishna SKNessuna valutazione finora

- HyvaDocumento2 pagineHyvaRudi SyamNessuna valutazione finora

- REZEL Saudi Arabia Introduction 20170724jth PDFDocumento27 pagineREZEL Saudi Arabia Introduction 20170724jth PDFAnonymous 5o9BbzArNessuna valutazione finora

- GENELITE GC130S Cummins DieselDocumento1 paginaGENELITE GC130S Cummins DieseltemproNessuna valutazione finora

- Material Balances With Chemical ReactionDocumento19 pagineMaterial Balances With Chemical Reactionjeas grejoyNessuna valutazione finora

- Spe Eec - Pta From SurfaceDocumento15 pagineSpe Eec - Pta From SurfaceMuhammad Arif FadilahNessuna valutazione finora

- IOC Annual Report 2014-15Documento240 pagineIOC Annual Report 2014-15Sunny SinghNessuna valutazione finora

- Engine Technology InternationalDocumento76 pagineEngine Technology InternationalLiviu MihonNessuna valutazione finora

- RICE electric generating facilityDocumento5 pagineRICE electric generating facilityJosé NunesNessuna valutazione finora

- Civil Engineer with 17 Years Oil & Gas ExperienceDocumento3 pagineCivil Engineer with 17 Years Oil & Gas ExperienceMuzaffarNessuna valutazione finora

- Blank FMEA Rev 00 (Example)Documento180 pagineBlank FMEA Rev 00 (Example)DEBASIS GUHANessuna valutazione finora

- Oxygen Contamination of Hydrocarbon FeedstocksDocumento6 pagineOxygen Contamination of Hydrocarbon FeedstocksChristine HendrixNessuna valutazione finora

- Fire ServiceDocumento4 pagineFire ServiceAnonymous WN66RaVcBNessuna valutazione finora

- 546 E-1Documento723 pagine546 E-1Mihai Gherghisan100% (5)

- Flash Point Lab ReportDocumento14 pagineFlash Point Lab ReportNesha Arasu67% (3)

- Johnson EvinrudefuelsystemcomponentsDocumento9 pagineJohnson Evinrudefuelsystemcomponentswguenon100% (1)

- Top MonthlyPresentation 201905Documento83 pagineTop MonthlyPresentation 201905Aniket SharmaNessuna valutazione finora

- Hardness Test ProcedureDocumento5 pagineHardness Test Proceduremanojballa100% (1)

- ShowDocumento136 pagineShowengrfvNessuna valutazione finora

- Lectut CHN-102 PDF ReactiveDocumento4 pagineLectut CHN-102 PDF ReactiveTanmaysainiNessuna valutazione finora

- Carbon Extraction From Automobile ExhautDocumento14 pagineCarbon Extraction From Automobile ExhautGhjkl GhjklNessuna valutazione finora

- 40 150 PDFDocumento68 pagine40 150 PDFChap Boon GohNessuna valutazione finora

- Track DrillDocumento28 pagineTrack DrillMarco Antonio Aquino AquinoNessuna valutazione finora

- Motor SCH AJM ATJDocumento11 pagineMotor SCH AJM ATJaritmeticsNessuna valutazione finora

- Heat Capacities and Property Changes of Formation TablesDocumento4 pagineHeat Capacities and Property Changes of Formation TablesAlejandra Fajardo ApoloNessuna valutazione finora