Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Weld Cost Calc XL1.3.2mm

Caricato da

Vipin JoseCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Weld Cost Calc XL1.3.2mm

Caricato da

Vipin JoseCopyright:

Formati disponibili

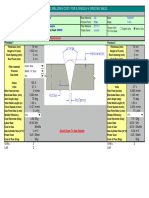

DETERMINING WELDING COST FOR A SINGLE-V GROOVE WELD

Mark Mruczek Welding Engineer Mruczek Welding Engineering Project: AWS Board Company: Subject: MMAW Example Welding process(es) Used: SMAW Base Material: Product Form: Filler Material Trade Name: CS Plate E71T-1 Lincoln Date: Page:

Choose Units For This Sheet

10/22/07 1 of 3

English Units Metric Units

Please choose units before you enter data into the fields below Process 1 Thickness (mm) 14 mm Height of H (mm) 1.000 mm Root Opening (mm) 2 mm Root Face (mm) 2 mm

Filler material Process Gas Used

Carbon Steel SMAW (14" Stick) N/A

Process 2 Thickness (mm) Height of H (mm) Root Opening (mm) Root Face (mm) Filler material Process Gas Used

14 1 2 2

mm

mm

mm mm

Carbon Steel FCAW (Gas) 75Ar-25C02

130 A Amps Volts 21 V Wire Feed (m/min) 0 m/min Electrode Diam. (mm) 3.200 mm Joint Angle (deg) 70 deg Total Weld Length (m) 1.00 m Travel Speed (m/min) 0.127 m/min Gas Flow Rate (L/min) 0 L/min Welder Efficiency 30% Cost Electrode ($/kg) 4.96 $/kg Labor Rate 45.00 $/hr Cost of Gas $/bottle Gas Cylinder Size (m^3) 0 m^3 Power Cost 0.20 $/kwh

Cost of Flux ($/kg)

Scroll Down To See Results

Amps 250 A Volts 27 V Wire Feed (m/min) 8.382 m/min Electrode Diam. (mm) 1.143 mm Joint Angle (deg) 70 deg Total Weld Length (ft) 1.00 m Travel Speed (m/min) 0.254 m/min Gas Flow Rate (L/min) 17 L/min 45% Welder Efficiency Cost Electrode ($/kg) 7.19 $/kg Labor Rate 45.00 $/hr Cost of Gas 40.00 $/bottle Gas Cylinder Size (m^3) 9.34 m^3 Power Cost 0.20 $/kwh Cost of Flux ($/kg)

2 2

$/kg

$/kg

Units = Last

Units = Last

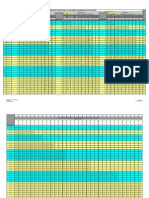

WELDING COST OUTPUT FOR A SINGLE-V GROOVE WELD

OUTPUT FOR Process 1 Amount of filler metal needed Number of passes per joint ~ Amount of shielding gas Number of Gas Bottles Required Actual welding time Deposition Rate Labor Cost Welding Electrode Cost Gas Cost Flux Cost Power Cost Initial Cost 0% Final Cost Total cost per meter of weld Filler cost per meter of weld Flux cost per meter of weld Gas cost per meter of weld Labor cost per meter of weld Shift Productivity 1.74 7 0.00 N/A 3.29 1.12 $147.95 $8.61 $0.54 $157.10 $157.10 157.10 8.61 147.95 2.70 kg m^3 hr kg/hr

Labor Cost Gas Cost Power Cost Welding Electrode Cost Flux Cost

Labor Cost 95%

$ $

Welding Electrode Cost 5%

$/m $/m $/m $/m $/m kg welded in 8 hr

Power Cost 0% Flux Cost 0%

Gas Cost 0%

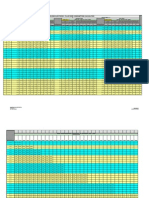

OUTPUT FOR Process 2 Amount of filler metal needed 1 Number of passes per joint ~ 6 Amount of shielding gas 0.31 Number of Gas Bottles Required 1 Actual welding time 0.69 Deposition Rate 3.56 Labor Cost $31.14 Welding Electrode Cost $9.06 Gas Cost $1.32 Flux Cost $ Power Cost $ 0.42 Initial Cost $41.94 0% $41.94 Final Cost Total cost per meter of weld 41.94 Filler cost per meter of weld 9.06 Flux cost per meter of weld Gas cost per meter of weld 1.32 Labor cost per meter of weld 31.14 12.83 Shift Productivity FCAW (Gas) Provides a 73.31%

kg m^3 hr kg/hr

Labor Cost Gas Cost Power Cost

Welding Electrode Cost Flux Cost

Labor Cost 74%

Power Cost 1%

Welding Electrode Cost 22% Flux Cost 0% Gas Cost 3%

$/m $/m $/m $/m $/m kg welded in 8 hr Savings Relative To The

SMAW (14" Stick)

PERFORMANCE AND COST COMPARISONS

180.00 160.00 140.00 120.00 100.00 Process 1 80.00 60.00 40.00 20.00 Shift Productivity Deposition Rate Total cost per meter of weld Labor cost per meter of weld Process 2

Potrebbero piacerti anche

- Electrode CalculationDocumento2 pagineElectrode Calculationkoyahassan100% (10)

- Welding CalculatorDocumento10 pagineWelding Calculatorneel0% (2)

- Atom WorksheetsDocumento4 pagineAtom Worksheetsapi-271960049Nessuna valutazione finora

- Determining The Cost of WeldingDocumento22 pagineDetermining The Cost of WeldingSanjay J NNessuna valutazione finora

- Butt welding deposit and wire calculations for CS vesselDocumento2 pagineButt welding deposit and wire calculations for CS vesselAsebaho Badr100% (1)

- Zick AnalysisDocumento12 pagineZick AnalysisrksahayNessuna valutazione finora

- Fabrication NormsDocumento8 pagineFabrication NormsRenny DevassyNessuna valutazione finora

- Determining The Cost of WeldingDocumento7 pagineDetermining The Cost of WeldingGilbertoUGO0% (1)

- Productivity and EcononyDocumento69 pagineProductivity and EcononyVijayan MunuswamyNessuna valutazione finora

- Weld Cost CalculationDocumento27 pagineWeld Cost Calculation-Abdul Khodir Van Java-100% (7)

- Project Staffing and Cost BreakupDocumento33 pagineProject Staffing and Cost BreakupVinayak PujariNessuna valutazione finora

- Estimation of Welding CostDocumento41 pagineEstimation of Welding CostAnkur2592% (13)

- IIW - International Institute of WeldingDocumento3 pagineIIW - International Institute of WeldingNilesh MistryNessuna valutazione finora

- DOSF4001-Body Cream Cleanser Course NotesDocumento11 pagineDOSF4001-Body Cream Cleanser Course NotesSiglo Cero Riviera Maya Fer in TulumNessuna valutazione finora

- QA vs QC vs INSPECTION: The Key DifferencesDocumento138 pagineQA vs QC vs INSPECTION: The Key DifferencesMohd SharainiNessuna valutazione finora

- Astm b571 97 R 13pdfDocumento4 pagineAstm b571 97 R 13pdfkishor150688Nessuna valutazione finora

- SSM Su 5003 BDocumento84 pagineSSM Su 5003 Bresp-ectNessuna valutazione finora

- How To Calculate MIG Welding CostDocumento5 pagineHow To Calculate MIG Welding CostTiago FerreiraNessuna valutazione finora

- Conversion of MT To Inch DiaDocumento4 pagineConversion of MT To Inch DianikunjNessuna valutazione finora

- Electrode CalculationDocumento2 pagineElectrode CalculationTejas PatelNessuna valutazione finora

- Determining The Cost of Welding Part 1 by Duane K. Miller 2004 7pDocumento7 pagineDetermining The Cost of Welding Part 1 by Duane K. Miller 2004 7pjosea_pena100% (1)

- Welding Electrode Specification ChartDocumento2 pagineWelding Electrode Specification ChartMahesh Kumar100% (2)

- Determining The Cost of WeldingDocumento7 pagineDetermining The Cost of WeldingSriram VjNessuna valutazione finora

- Enter Data:: MM M Weld Size (Leg) Unit Weld LengthDocumento6 pagineEnter Data:: MM M Weld Size (Leg) Unit Weld Lengtharifin rizal100% (1)

- Gmaw Thumb RuleDocumento68 pagineGmaw Thumb Rule0502raviNessuna valutazione finora

- Weld WeightDocumento10 pagineWeld WeightDivyesh PatelNessuna valutazione finora

- Demo Weld Cost Calc XLDocumento10 pagineDemo Weld Cost Calc XLMarcelo Simão Do ValeNessuna valutazione finora

- Pipes PoolsDocumento3 paginePipes PoolsjorgemachigueNessuna valutazione finora

- Demo Weld Cost Calc XL-UnprotectedDocumento10 pagineDemo Weld Cost Calc XL-UnprotectedA R0% (1)

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDocumento9 pagineTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanNessuna valutazione finora

- Welding Prcesses Estimation RecordDocumento5 pagineWelding Prcesses Estimation RecorddineshshankarNessuna valutazione finora

- Calculating Welding WireDocumento6 pagineCalculating Welding WireBoodyBedaiwe50% (2)

- Pneumatic CalculationDocumento8 paginePneumatic CalculationDavid LambertNessuna valutazione finora

- 4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionDocumento9 pagine4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionNejat Ababay50% (2)

- Handbook - Calculations0Documento10 pagineHandbook - Calculations0paimpillyNessuna valutazione finora

- Welding Cost Estimation For 12 Joints in 8 NPS Sch. 80Documento1 paginaWelding Cost Estimation For 12 Joints in 8 NPS Sch. 80WeldPulse100% (2)

- Weld Consumable Calculator ComDocumento7 pagineWeld Consumable Calculator Comchetan85Nessuna valutazione finora

- AWSPipeWeld - American Welding SocietyDocumento2 pagineAWSPipeWeld - American Welding Societybarukomkss100% (1)

- Weld Cost Calc XL1.3.2mmDocumento3 pagineWeld Cost Calc XL1.3.2mmAdrian DavidNessuna valutazione finora

- Cost Calculation Program For Productivity in WeldingDocumento20 pagineCost Calculation Program For Productivity in WeldingiyigunNessuna valutazione finora

- Weld Metal Cost Calculator 3Documento1 paginaWeld Metal Cost Calculator 3Naresh Tammineedi100% (1)

- Saudi Arabian Standard SASO-443E Plug Pin 220V TestDocumento21 pagineSaudi Arabian Standard SASO-443E Plug Pin 220V TestPusertif PengadaanNessuna valutazione finora

- Welding Rod Cal (1) .Documento7 pagineWelding Rod Cal (1) .hakr5100% (1)

- Weld CalculationsDocumento12 pagineWeld Calculationshakr5100% (1)

- A Guide To Estimating The Consumption of Welding Consumables-NADocumento1 paginaA Guide To Estimating The Consumption of Welding Consumables-NAManuel Antonio Santos VargasNessuna valutazione finora

- Design, Fabrication and Inspection of Welded JointsDocumento58 pagineDesign, Fabrication and Inspection of Welded Jointsbaca88Nessuna valutazione finora

- Weld Cost Calc XLDocumento63 pagineWeld Cost Calc XLRobert WhitakerNessuna valutazione finora

- Weld Cost CalculationDocumento30 pagineWeld Cost CalculationDenial BasanovicNessuna valutazione finora

- Lesson Plan in DNA Grade 9 PracticumDocumento2 pagineLesson Plan in DNA Grade 9 PracticumHarry Chestered Gipulan Empistan100% (2)

- Nova Hunting The Elements Video GuideDocumento3 pagineNova Hunting The Elements Video GuideJaclyn Dugger100% (1)

- Electrode CalculationDocumento2 pagineElectrode Calculationtejasp8388100% (1)

- PQR - Wps - PWHT P91 To CS: Tunisian Quality EngineerDocumento14 paginePQR - Wps - PWHT P91 To CS: Tunisian Quality EngineerRajeev KhantwalNessuna valutazione finora

- 101.lean - Welds Cost Calculator Customer Welding Position: HorizontalDocumento4 pagine101.lean - Welds Cost Calculator Customer Welding Position: HorizontalSamNessuna valutazione finora

- Job Method Sheet: Furnace CRU Shutdown 2013Documento30 pagineJob Method Sheet: Furnace CRU Shutdown 2013Khan ArshiNessuna valutazione finora

- Weld Cost1Documento25 pagineWeld Cost1Denis Hinojosa ZeballosNessuna valutazione finora

- How To Calculate Filler Metal Consumption For Welding ProjectsDocumento3 pagineHow To Calculate Filler Metal Consumption For Welding ProjectsEdgar Coavas PérezNessuna valutazione finora

- Fit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemDocumento1 paginaFit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemAnonymous 0rt9KWmNNessuna valutazione finora

- Electrode CalculationDocumento2 pagineElectrode CalculationKenshin HimuraNessuna valutazione finora

- ENG Structural SteelsDocumento2 pagineENG Structural SteelsOlalla CuiñaNessuna valutazione finora

- Pipe Schedule Reference ChartDocumento10 paginePipe Schedule Reference ChartRamadossK100% (1)

- Fabrication Time EstimationDocumento2 pagineFabrication Time EstimationGlen Peter MirandaNessuna valutazione finora

- Stud Bolts 2hex Nuts Weight Imperial SizesDocumento12 pagineStud Bolts 2hex Nuts Weight Imperial SizesBryan Mauricio Diaz Avila100% (1)

- WPSPQRDocumento11 pagineWPSPQR0502raviNessuna valutazione finora

- Calculating weld deposit and electrode consumptionDocumento7 pagineCalculating weld deposit and electrode consumptionAnas MaliyekkalNessuna valutazione finora

- Information About Welding Method and Joint Configuration:: Project: Test, Weld Number: Test 1Documento1 paginaInformation About Welding Method and Joint Configuration:: Project: Test, Weld Number: Test 1carrotironNessuna valutazione finora

- Abi Feed Water Inlet Nozzle No:1 Material CostDocumento1 paginaAbi Feed Water Inlet Nozzle No:1 Material CostKarthimeena MeenaNessuna valutazione finora

- Weld Cost Calc XL1.3.2mmDocumento3 pagineWeld Cost Calc XL1.3.2mmDhimas Surya NegaraNessuna valutazione finora

- Sidha Anayalasys 4.7.2022Documento37 pagineSidha Anayalasys 4.7.2022S.SHANMUGA SABAREESANNessuna valutazione finora

- Final Year ProjectnewDocumento42 pagineFinal Year ProjectnewkowshikdhevNessuna valutazione finora

- Data Rates Gate Works 6Documento21 pagineData Rates Gate Works 6vpmohammedNessuna valutazione finora

- Aluminum 6061 vs. Aluminum 6063Documento4 pagineAluminum 6061 vs. Aluminum 6063Vipin JoseNessuna valutazione finora

- International Student GuideDocumento19 pagineInternational Student GuideVipin JoseNessuna valutazione finora

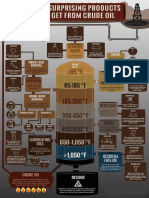

- Refinery ProcessDocumento1 paginaRefinery ProcessVipin JoseNessuna valutazione finora

- Hope-Wishful Thinking or Confident Expectation?Documento4 pagineHope-Wishful Thinking or Confident Expectation?Vipin JoseNessuna valutazione finora

- ( ) PDFDocumento440 pagine( ) PDFVipin JoseNessuna valutazione finora

- Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Documento2 pagineWelding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Anonymous 6WgvYyNessuna valutazione finora

- Effectiveness of an anti vortex device in a sump modelDocumento12 pagineEffectiveness of an anti vortex device in a sump modelVipin JoseNessuna valutazione finora

- Stainless Steels ClassificationsDocumento6 pagineStainless Steels ClassificationsVipin JoseNessuna valutazione finora

- View Topic - QW-403Documento6 pagineView Topic - QW-403Vipin JoseNessuna valutazione finora

- Sample ProgressTracking Sheet Tank Farm Mechanical Field ErectionDocumento14 pagineSample ProgressTracking Sheet Tank Farm Mechanical Field ErectionVipin JoseNessuna valutazione finora

- Structural Steel Design and Construction 2Documento30 pagineStructural Steel Design and Construction 2qea_renNessuna valutazione finora

- Product Information Sheet: Alloy Cusn12Documento1 paginaProduct Information Sheet: Alloy Cusn12Hawraa AlbahadlyNessuna valutazione finora

- API 651 QuestionsDocumento4 pagineAPI 651 QuestionsMohammed YoussefNessuna valutazione finora

- Resin R3X1660 - Material Data Sheet - Part BDocumento4 pagineResin R3X1660 - Material Data Sheet - Part BRavie OuditNessuna valutazione finora

- June 2017 (v1) QP - Paper 6 CIE Biology IGCSEDocumento12 pagineJune 2017 (v1) QP - Paper 6 CIE Biology IGCSEbandana dekaNessuna valutazione finora

- Life's Origin TheoriesDocumento8 pagineLife's Origin TheoriesSazzad NiloyNessuna valutazione finora

- Coil Spring Attachement On Lathe Evaluation of The Springback EffectDocumento4 pagineCoil Spring Attachement On Lathe Evaluation of The Springback EffectfatinNessuna valutazione finora

- Human Respiratory System Based On Law of ThermodynamicsDocumento9 pagineHuman Respiratory System Based On Law of ThermodynamicsfatimahNessuna valutazione finora

- SemiconDocumento9 pagineSemiconRealyn PugayNessuna valutazione finora

- ATCO Gas STOPAQ-Vinylester Procedure Rev0Documento45 pagineATCO Gas STOPAQ-Vinylester Procedure Rev0mkash028Nessuna valutazione finora

- Khan Academy Carbohydrates QuestionsDocumento3 pagineKhan Academy Carbohydrates QuestionsLoraNessuna valutazione finora

- Mass-Transfer Diffusion Coefficients in Binary Systems: AppendixDocumento3 pagineMass-Transfer Diffusion Coefficients in Binary Systems: AppendixAnisaNessuna valutazione finora

- FINALDocumento16 pagineFINALdushyanth rajNessuna valutazione finora

- Pta Petrochemical ProcessDocumento27 paginePta Petrochemical ProcessMugiiz BhattiNessuna valutazione finora

- Specific Energy Curve Lab ReportDocumento8 pagineSpecific Energy Curve Lab ReportEngr Muhammad TariqNessuna valutazione finora

- Applied Clay Science: Antonio Gil, Sophia A. Korili, Raquel Trujillano, Miguel Angel VicenteDocumento9 pagineApplied Clay Science: Antonio Gil, Sophia A. Korili, Raquel Trujillano, Miguel Angel VicenteRamon AlbuquerqueNessuna valutazione finora

- AKP123Documento70 pagineAKP123goswamiphotostatNessuna valutazione finora

- Characterizing Synthetic Dyes by 2D LC-MSDocumento18 pagineCharacterizing Synthetic Dyes by 2D LC-MSM BustamanteNessuna valutazione finora

- Unit 1 - Part 2 (Chemical Bond)Documento30 pagineUnit 1 - Part 2 (Chemical Bond)Maguy H.Nessuna valutazione finora

- Afa Reviewer ADocumento28 pagineAfa Reviewer AJane CastroNessuna valutazione finora

- E.O.Paton Electric Welding Institute Activity in The FieldDocumento10 pagineE.O.Paton Electric Welding Institute Activity in The FieldMaksimovNessuna valutazione finora

- Cantilever Beam Design - RHSDocumento1 paginaCantilever Beam Design - RHSberylqz5878100% (1)

- Canadian Coast Guard Welding SpecificationDocumento39 pagineCanadian Coast Guard Welding Specificationalvin dueyNessuna valutazione finora