Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Defects Analysis Based Visual Inspection Procedures For Quality

Caricato da

Vartika VijayDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Defects Analysis Based Visual Inspection Procedures For Quality

Caricato da

Vartika VijayCopyright:

Formati disponibili

Chapter III

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

3.1 METHODOLOGY FOR ASSESSMENT OF SPECIFICATIONS

3.2 INSPECTION SYSTEMS

3.2.1 SYSTEM I (FLAW BASED) 3.2.2 SYSTEM II (4-POINT SYSTEM) 3.2.3 SYSTEM III (10-POINT SYSTEM)

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY 3.1 METHODOLOGY FOR ASSESSMENT OF SPECIFICATIONS QUALITY INSPECTION

One of the definitions of Quality is that, The totality of features and characteristics of a product or service that bears on its ability to satisfy the stated or implied needs, (ISO 8402.98). The inspection is one of the crucial stage activity in the manufacture of textile products. The products at various stages such as on receipt, during the process and final stage are normally inspected to assess the status of the product for acceptance or otherwise. Inspection is carried out mainly to appraise the quality of products in terms of manufacturing defects and adherence to the specifications and other requirements. Normally, the visual inspection is carried out on the fabric to examine the occurrence of yarn defects, fabric defects, design/colours besides specification particulars and followed by drawing the samples for testing to know the hidden quality parameters such as shrinkage, strength, colour fastness etc. In the earlier days, the inspection was mainly carried out to segregate the defective products from the good products thereby controlling the quality of products at the exit points. In the late 80s, the concept of quality has undergone total transformation from quality control to quality assurance and total quality management. In the changed scenario, the inspection is mainly carried out to ascertain that the products conform to requirement and initiate suitable corrective and preventive action if otherwise. There are two ways of doing inspection viz. 100% inspection and sampling inspection. The 100% inspection is generally carried out to segregate the products quality-wise and perform mending activity for products having mendable defects whereas the sampling inspection mainly focus on sentencing the lot or batch for acceptance or otherwise based on the sample. The entire quantity of fabrics received from the suppliers or sub-contractors and production departments (in case of units with a manufacturing facility) has to be thoroughly checked for specificational particulars, quality parameters including defects, before further processing so that the quality of the finished product can be assured. This will lead to reduction in defects in the final product, rejection level, replacement and thereby improve the quality of the final product which results in quality image in the market. Inspection and Mending is to be carried out on a flat table in a well illuminated/ ventilated place. Inspection equipments like counting glass, a good calibrated tape, metallic comb, clipper-plucker needle are to be provided to the checkers.

CHECKING OF DIMENSIONS

MEASUREMENT OF WIDTH: Width shall be measured at three different places of the fabric and recorded. While measuring width, care should be taken to remove the wrinkles/ crease gently from the fabric surface. to keep the measuring tape straight across the fabric horizontally from selvedge to selvedge. to measure the width as far as possible near the centre avoiding the ends. not to stretch the fabric while measuring.

MEASUREMENT OF LENGTH: Fabric to be measured for length and actual length recorded. Length is measured by any of the following methods By passing through metre counter fitted roller. By manually clipping the fabrics in the fold measuring frame. By counting the number of metre fold in case of folded fabrics. Care to be taken to ensure that the folds are of one metre length by measuring a few folds.

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

CHECKING OF CONSTRUCTIONAL PARTICULARS

ENDS PER INCH: Ends per inch shall be counted at two places along the width of the fabric and recorded. PICKS PER INCH: Picks per inch shall be counted at three places along the length of the fabric and recorded. Care to be taken while placing the pick glass to see that the edges of the template should coincide with the yarn. Ends/Picks per inch may be counted for one inch. Also the picks should not be counted at defective places like weft bars and cracks. WEIGHT PER SQ.MTR.: Pieces are to be weighed and recorded. Weight per square metre to be calculated and recorded. CALCULATION OF WEIGHT/SQ.MTR.: Weigh the individual piece under Inspection and note-down. Work out the sq.mtrs. of the piece by multiplying the length of the piece in mtrs. and width of the piece in mtrs. Calculate wt./sq.mtrs . as: Weight in kgs. Length in mtrs. X Width in mtrs. Example:

Let us calculate the wt./sq.mtrs. of piece of 25 mtrs. length With a width of 130 cms. (1.3 mtrs.) . The weight of the piece was found to be 4.250 kgs.

3.2 INSPECTION SYSTEMS

There are three different systems for grading the quality of fabric, which are as follows:

3.2.1 SYSTEM I (FLAW BASED)

In this system, depending upon the magnitude, defects are classified as minor, major or serious. Note: 1) Minor Flaws: Minor flaws occurring more than one in number within 15 cms. length of the cloth shall be reckoned as one minor flaw only and such minor flaw shall be reckoned at the rate of one for every 15 cms. length of the cloth. 2) Major Flaws: a) Major flaws occurring more than one in number within a length of 15 cms. of the cloth shall be reckoned as one major flaw only. b) Major flaws occurring in a consecutive length beyond 15 cms. shall be reckoned as one major flaw each for every 15 cms. or part thereof. This will not apply to major flaws where magnitude has been limited to a specific limit. 3) Selvedge Defects: a) In case of furnishing fabrics all selvedge defects like pulled in selvedge, wavy selvedge etc. of minor nature are also to be reckoned as major flaws. b) Defective or damaged selvedge exceeding 5% of the length of the piece in case of furnishing fabrics are to be reckoned as serious flaw. c) All types of selvedge defects or weaving defects very close to the selvedges are not to be reckoned in case of fabrics used for making garments/made-ups.

wt./sq.mt. in kgs. =

4.250 kgs ( weight of the piece) 25 mtrs (length) X 1.3 mtrs. (width)

= 4.250 = 0.1308 or 0.131 kgs. 32.5

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

ACCEPTABILITY CRITERIA FOR FLAWS: The acceptability level for first quality fabric is usually established by mutual agreement between the buyer and the seller. The different types of fabrics have different point levels of acceptability depending upon their end use.

Some of the commonly followed standard for acceptability for the above mentioned systems are listed in the following pages.

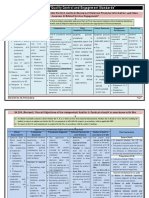

THE ACCEPTABILITY STANDARD DEVELOPED BY TEXTILES COMMITTEE FOR EXPORT OF MILL - MADE COTTON CLOTH Sample size in metres

1200 1175 1150 1125 1100 1075 1050 1025 1000 975 950 925 900 875 850 825 800 775 750 725 700 675 650

Acceptance number of major flaws

Standard A-1 Standard A

Sample size in metres

625 600 575 550 525 500 475 450 425 400 375 350 325 300 275 250 225 200 175 150 125 100

Acceptance number of major flaws

Standard A-1 Standard A

29 28 27 27 26 25 25 24 23 23 22 22 21 20 20 19 18 18 17 16 16 15 14

40 39 38 37 36 35 34 33 32 31 31 30 29 28 27 26 25 24 23 23 22 21 20

14 13 12 12 11 11 10 9 9 8 7 7 6 6 5 4 4 3 3 2 2 1

19 18 17 16 16 15 14 13 12 11 11 10 9 8 7 6 6 5 4 3 3 2

Minor flaws : @ 25 per 100 metres maximum are acceptable. Serious flaws: No serious flaw is acceptable.

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

FORMATS OF VISUAL CHECKING REPORT OF FABRIC

Once the defects are classified and graded they have to be recorded in the visual inspection report of fabric(work sheet) ANNEXURE-I Instructions for filling up the visual checking report of fabric: PART-I: Fill up the required details available with the unit which are self explanatory. PART-II : i) Piece no.: Write serial no. of the piece taken for inspection. ii) Length in mtrs./yards: Write the specified stamped length in declared column and actual length in actual column. iii) Width in inches/cms. Measure the width at three places and record the same against the respective column with average. iv) Ends per inch: Count the ends per inch at two different places and record the same against the respective columns with average. v) Picks per inch: Count the picks per inch at three different places and record the same against the respective columns with average. vi) Weight per piece in kgs.: Weigh the individual inspected piece in kilograms and record the same against the respective columns. PART III: i) Piece no.: Record the serial no. of the piece taken for inspection. ii) Serious flaws and total: Note down the serious flaws observed by giving flaw number mentioned in Chapter I and the same is to be noted in flaw number row and number of such flaws are to be recorded in respective column number with total.

iii) Major flaws and total: Note down the major flaws observed by giving flaw number mentioned in Chapter I and the same is to be noted in flaw number row and number of such flaws are to be recorded in respective column number with total. iv) Minor flaws and total: Note down the minor flaws observed by giving flaw number mentioned in Chapter I and the same is to be noted in flaw number row and number of such flaws are to be recorded in respective column number with total. v) Remarks: Under this column, checker can report absence of stamping, shade variation on comparison with approved sample or any other parameters required to be inspected. PART-IV: The details are to be recorded from Part-III after summarising serious, major and minor flaws numberwise with total. PART-V: Quantity inspected in terms of pieces/metres are to be recorded from Part-II. The other details are to be recorded from Part-IV after summarising the total number of serious, major and minor flaws observed. Acceptability or otherwise can be determined as per buyer/unit requirement. PART-VI: The details are to be recorded from Part-II after summarising width, length, ends per inch, picks per inch and weight per sq.mtr. Acceptability or otherwise can be determined as per buyer/unit requirement.

Checker must sign the worksheet and summary sheet filled up by him.

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

3.2.2 SYSTEM II (4-POINT SYSTEM)

The 4-point system, also called the American Apparel Manufacturers Association (AAMA) pointgrading system for determining fabric quality, is widely used by producers of apparel fabrics and by the Department of Defence in the United States and is endorsed by the AAMA as well as the ASQC. Fabric flaws or defects are assigned point values based on the following: Length of defect in fabric, either length or width

Up to 3 in. (7.5 cms.) Over 3 in. (7.5 cms.) up to 6 in (15 cms.) Over 6 in. (15 cms.) up to 9 in. (23 cms.) Over 9 in. (23 cms.)

ACCEPTABILITY CRITERIA FOR FLAWS: Normally fabric rolls containing up to 40 points per 100 sq yds. and 48 points per 100 sq mtrs. are acceptable. However, based on the price line and end product more or less than 40/48 points per 100 sq. yds./100 sq mtrs. respectively may be accepted. Example - 1: A fabric roll of 120 yds. long and 48 in. wide contains the following defects: 2 defects up to 3 in. 5 defects over 3 in. but less than 6 in. 1 defects over 6 in. but less than 9 in. 1 defect over 9 in. 2 x 1 = 2 points 5 x 2 = 10 points 1 x 3 = 3 points 1 x 4 = 4 points TOTAL=19 points

Points allotted

1 2 3 4

Holes and openings (largest dimension)

1 in. (2.5 cms.) or less Over 1 in. (2.5 cms.) 2 4

Therefore, Points/100 sq. yds. = Total points scored in the roll x 3600 Fabric width in inches x Total yard inspected = 19 x 3600 48 x 120 = 11.9 defect points/100 sq. yds. So if the acceptance criteria is 40 points/100 sq. yds. then this roll is acceptable.

The maximum number of defect points to be counted against any one linear yard/metre is four points. Overall, fabric quality is assessed on the basis of the number of defect points per 100 sq yards/sq mtrs. of fabric.

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

Example - 2: A fabric roll of 100 metres long and 150 cms. wide contains the following defects: 3 defects up to 7.5 cms (3in). 6 defects over 7.5 cms. but less than 15 cms. (over 3 in. but less than 6 in.) 2 defects over 15 cms. but less than 23 cms. (over 6 in. but less than 9 in.) 1 defect over 23 cms. (9 in.) 3 x 1 = 3 points 6 x 2 = 12 points

iii) Width in inches/cms. Measure the width at three places and record the same against the respective column with average. iv) Ends per inch: Count the ends per inch at two different places and record the same against the respective columns with average. v) Picks per inch: Count the picks per inch at three different places and record the same against the respective columns with average. vi) Weight per piece in kgs.: Weigh the individual inspected pieces in kilograms and record the same against the respective columns.

2 x 3 = 6 points

1 x 4 = 4 points TOTAL = 25 points

Therefore, Points/100 sq.mtr = Total points scored in the roll x 10000 Fabric width in cms. x Total metre inspected = = 25 x 10000 150 x 100 16.67 defect points/100 sq.mtrs.

PART III : i) Piece no.: Record the serial no. of the piece taken for inspection. ii) Hole, cut or tear: Record the flaws observed as per their magnitude in respective column giving flaw number 2.6 (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash eg. 1/2 assuming 1 flaw of 2 point is observed. iii) The defects upto 3 inches: Record the flaws observed as per their magnitude in respective column giving flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash eg. 1/1 assuming 1 flaw of 1 point is observed. iv) Over 3 inches to 6 inches: Record the flaws observed as per their magnitude in respective

So if the acceptance criteria is 48 points/100 sq. mts. then this roll is acceptable.

FORMATS OF VISUAL CHECKING REPORT OF FABRIC

Once the defects are classified and graded they have to be recorded in the visual inspection report of fabric(work sheet) ANNEXURE II Instructions for filling up the visual checking report of fabric. PART-I: Fill up the required details available with the unit which are self explanatory. PART-II: i) Piece no.: Write serial no. of the piece taken for inspection. ii) Length in mtrs./yds.: Write the specified stamped length in declared column and actual length in actual column.

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

column giving flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash eg. 1/2 assuming 1 flaw of 2 point is observed. v) Over 6 inch to 9 inch: Record the flaws observed as per their magnitude in respective column giving flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash eg. 1/3 assuming 1 flaw of 3 point is observed. vi) Over 9 inches: Record the flaws observed as per their magnitude in respective column giving flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/4 assuming 1 flaw of 4 point is observed. vii) Total flaws: It is to be recorded for each individual pieces. viii) Total points: It is to be recorded for each individual pieces. ix) Remarks: Under this column, the checker can report absence of stamping, shade variation on comparison with approved sample or any other parameters required to be inspected. PART-IV: The details are to be recorded from PartIII after summarising defects point-wise and magnitude wise and record the same against respective

flaw number with total. PART-V: Quantity inspected pieces/metres are to be recorded from Part-II. The other details are to be recorded from Part-III after summarising the total number of flaws observed, total points and points per 100 sq.yds. Acceptability or otherwise can be determined as per buyer/unit requirement. PART-VI: The details are to be recorded from PartII after summarising width, length, ends per inch, picks per inch and weight per sq.mtr. Acceptability or otherwise can be determined as per buyer/unit requirement.

Checker must sign the worksheet and summary sheet filled up by him.

3.2.3

SYSTEM III (10-POINT SYSTEM)

Under this system, fabric defects are assigned point values based on the following:Length of defect, Warp defects Up to1 inch 1 to 5 inch 5 to 10 inch 10 to 36 inch Filing defect (weft defect) Up to 1 inch 1 to 5 inch 5 inch to half-width Larger than half-width 1 3 5 10 Points allotted 1 3 5 10

No linear yard of fabric is assigned more than 10 points, no matter how bad or frequent the defects are.

DEFECTS ANALYSIS BASED VISUAL INSPECTION PROCEDURES FOR QUALITY

Acceptability criteria for flaws: Fabric is considered of first quality if the number of defect points are less than the number of yards of fabric inspected. In the case of fabrics wider than 50 in., the fabric is considered of first quality if the total defect points do not exceed the number of yards of fabric inspected by 10%. FORMATS OF VISUAL CHECKING REPORT OF FABRIC Once the defects are classified and graded they have to be recorded in the visual inspection report of fabric (work sheet) ANNEXURE III Instructions for filling up the visual checking report of fabric. PART-I : Fill up the required details available with the unit which are self explanatory. PART-II : i) Piece no.: Write serial no. of the piece taken for inspection. ii) Length in mtrs./yds.: Write the specified stamped length in declared column and actual length in actual column. iii) Width in inches/cms. Measure the width at three places and record the same against the respective column with average. iv) Ends per inch: Count the ends per inch at two different places and record the same against the respective columns with average. v) Picks per inch: Count the picks per inch at three different places and record the same against the respective columns with average. vi) Weight per piece in kgs.: Weigh the individual inspected pieces in kilograms and record the same against the respective columns.

PART III: i) Piece no.: Record the serial no. of the piece taken for inspection. ii) Warp way upto 1 inch: Record the flaws observed as per their magnitude in respective column giving flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same has to be recorded below the number of the flaws already mentioned putting a slash e.g. 1/1 assuming 1 flaw of 1 point is observed. iii) Warp way 1 inch to 5 inches: Record the flaws observed as per their magnitude in respective column giving flaw number (mentioned in chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/3 assuming 1 flaw of 3 points is observed. iv) Warp way 5 inches to 10 inches: Record the flaws observed as per their magnitude in respective column giving flaw number (mentioned in chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the number of points allotted to the particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/5 assuming 1 flow of 5 point is observed. v) Warp way 10 inches to 36 inches: Record the flaws observed as per their magnitude in respective column giving flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and

10

the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/ 10 assuming 1 flaw of 10 point is observed. vi) Filling up to 1 inch: Record the flaws observed as per their magnitude in respective column, giving flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/1 assuming 1 flaw of 1 point is observed. vii) Filling 1 inch to 5 inches: Record the flaws observed as per their magnitude in respective column giving a flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/3 assuming 1 flaw of 3 point is observed. viii) Filling 5 inches to half of the width: Record the flaws observed as per their magnitude in respective column giving a flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/5 assuming 1 flaw of 5 point is observed. ix) Filling larger than half of the width: Record the flaws observed as per their magnitude in respective column giving a flaw number (mentioned in Chapter I) in the respective row. Total number of points are to be calculated by multiplying the

flaws with the points allotted to that particular flaw and the same is to be recorded below the number of flaws already mentioned putting a slash e.g. 1/10 assuming 1 flaw of 10 point is observed. x) Total flaws: It is to be recorded for each individual pieces. xi) Total points: It is to be recorded for each individual pieces. xii) Remarks: Under this column, the checker can report absence of stamping, shade variation on comparison with approved sample or any other parameters required to be inspected. PART-IV: The details are to be recorded from Part-III after summarising defects point wise and magnitude wise (warp way and filling way) and record the same against respective flaw number with total. PART-V: Quality inspected pieces are to be recorded from Part-II. The other details to be recorded from PartIII and Part IV after summarising total number of flaws observed and total points. Acceptability or otherwise can be determined as buyer/unit requirement. PART-VI: The details are to be recorded from Part-II after summarising width, length, ends per inch, picks per inch and weight per sq.mtr. Acceptability or otherwise can be determined as per buyer/unit requirement.

Checker must sign the worksheet and summary sheet filled up by him.

Potrebbero piacerti anche

- Inspection In Manufacturing A Complete Guide - 2020 EditionDa EverandInspection In Manufacturing A Complete Guide - 2020 EditionNessuna valutazione finora

- Wk-42 Fabric Delivery and Quality PerformanceDocumento1 paginaWk-42 Fabric Delivery and Quality PerformanceMd Majharul IslamNessuna valutazione finora

- Apparel IndustryDocumento53 pagineApparel Industryrajhossie9335100% (1)

- Part Approval Form Submission RequirementsDocumento22 paginePart Approval Form Submission RequirementserayNessuna valutazione finora

- ISO Commenting TemplateDocumento1 paginaISO Commenting Templatetauqeer25Nessuna valutazione finora

- SA 'S ChartsDocumento46 pagineSA 'S ChartsBharath Kumar100% (1)

- Front Body Placket Body Body Body Body BodyDocumento1 paginaFront Body Placket Body Body Body Body BodySheena BansalNessuna valutazione finora

- ARM CLIT New FormatDocumento65 pagineARM CLIT New FormatnasikroadNessuna valutazione finora

- Productspec 180275arain 002 02 Dress&Dismatic (PVT) Ltd. (Al-Muslimgroup) Imran LCWDocumento19 pagineProductspec 180275arain 002 02 Dress&Dismatic (PVT) Ltd. (Al-Muslimgroup) Imran LCWtextile028Nessuna valutazione finora

- Equipment Rental Action PlanDocumento3 pagineEquipment Rental Action PlanKenneth MedinaNessuna valutazione finora

- Agile Scrum at Glance BaselineDocumento1 paginaAgile Scrum at Glance BaselinedrustagiNessuna valutazione finora

- Va 7.3-4eDocumento4 pagineVa 7.3-4eshifaNessuna valutazione finora

- Doha West Power Station RAP Washing ScheduleDocumento4 pagineDoha West Power Station RAP Washing ScheduleASHIL PRABHAKARNessuna valutazione finora

- Permanent Change and Temporary Deviation Request FormDocumento1 paginaPermanent Change and Temporary Deviation Request FormdrustagiNessuna valutazione finora

- KH 323 v2 Operation ManualDocumento55 pagineKH 323 v2 Operation ManualValdberto de Sousa Rodrigues100% (1)

- QAQC Equipment List - SET 1: 序号 Number 名称 Name 参数 parameterDocumento4 pagineQAQC Equipment List - SET 1: 序号 Number 名称 Name 参数 parameterShahril ZainulNessuna valutazione finora

- Rcca On P/N: XXX Supplier Name: XXX Person's Name: As Presented To Lam SE: Date: XXXDocumento4 pagineRcca On P/N: XXX Supplier Name: XXX Person's Name: As Presented To Lam SE: Date: XXXTarun KaushalNessuna valutazione finora

- Machines Distribution Plan: Machine Code 5 86 36 11 3 17 6 32 7 2 10 5 15 5 2 2 4 2Documento1 paginaMachines Distribution Plan: Machine Code 5 86 36 11 3 17 6 32 7 2 10 5 15 5 2 2 4 2مصطفى عبدالرحيمNessuna valutazione finora

- 4M 1T 1E Standarad ConditionDocumento1 pagina4M 1T 1E Standarad ConditionnasikroadNessuna valutazione finora

- Develop A Like The One Below:: Stakeholder Analysis MatrixDocumento3 pagineDevelop A Like The One Below:: Stakeholder Analysis MatrixAjai SrivastavaNessuna valutazione finora

- TN2-Determination of Formaldehyde in TextileDocumento3 pagineTN2-Determination of Formaldehyde in TextilelthyaguNessuna valutazione finora

- LINE FEEDING AND QUALITY INSPECTION PROCESSDocumento12 pagineLINE FEEDING AND QUALITY INSPECTION PROCESSkvNessuna valutazione finora

- Prevent Sheet Metal Burr Formation with Proper Tooling and Process ControlsDocumento5 paginePrevent Sheet Metal Burr Formation with Proper Tooling and Process ControlsMajad RazakNessuna valutazione finora

- World Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)Documento68 pagineWorld Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)zoomerfins22Nessuna valutazione finora

- Internal Customer SatisfactionDocumento30 pagineInternal Customer Satisfactionmind2008Nessuna valutazione finora

- Layout ChecklistDocumento2 pagineLayout Checklistvmohapatra8100% (1)

- Product Mismatch 8D ClosureDocumento25 pagineProduct Mismatch 8D ClosureKevin SivaNessuna valutazione finora

- Test Instrument Equipment List (Sepcoiii Lab)Documento2 pagineTest Instrument Equipment List (Sepcoiii Lab)Kuldeep ChakerwartiNessuna valutazione finora

- 1 Introduction To Statistical Quality Control, 6 Edition by Douglas C. MontgomeryDocumento66 pagine1 Introduction To Statistical Quality Control, 6 Edition by Douglas C. MontgomeryAmiluddin AmilNessuna valutazione finora

- # Chapter 9: Sub-Suppliers Management 3: SupplierDocumento1 pagina# Chapter 9: Sub-Suppliers Management 3: SupplierAnkit SainiNessuna valutazione finora

- Root Cause Analysis - ToolDocumento11 pagineRoot Cause Analysis - ToolmuneerppNessuna valutazione finora

- Control of Monitoring and Measuring EquipmentDocumento3 pagineControl of Monitoring and Measuring EquipmentLinda Setya WatiNessuna valutazione finora

- COPQ Training - EPC (Repaired)Documento15 pagineCOPQ Training - EPC (Repaired)syedfahadraza627Nessuna valutazione finora

- Quality BasicsDocumento18 pagineQuality BasicsCamyChinNessuna valutazione finora

- Business Process Master List: Level 1 Level 2Documento34 pagineBusiness Process Master List: Level 1 Level 2Meghana VastNessuna valutazione finora

- Expression of Interest: Prepared byDocumento9 pagineExpression of Interest: Prepared byAnonymous dFIemPqrNessuna valutazione finora

- Packing InstructionsDocumento1 paginaPacking Instructionsmdhiron200345Nessuna valutazione finora

- Sewing Room Defects PDFDocumento6 pagineSewing Room Defects PDFAlemu HaileNessuna valutazione finora

- Quality Assurance SOP TemplateDocumento3 pagineQuality Assurance SOP TemplateGAURAV SHARMANessuna valutazione finora

- Training Need Identification Form: HR Receipt DateDocumento3 pagineTraining Need Identification Form: HR Receipt DateAmit SinghNessuna valutazione finora

- Reference Ncpar No.: Ncpar # 14-005 (Deviation Notice) Department: QC/R&D DepartmentDocumento4 pagineReference Ncpar No.: Ncpar # 14-005 (Deviation Notice) Department: QC/R&D DepartmentSusie GorospeNessuna valutazione finora

- Quality Control PlanDocumento10 pagineQuality Control PlanGAURAV SHARMANessuna valutazione finora

- Production Process Flow ChartDocumento5 pagineProduction Process Flow ChartKenny RojasNessuna valutazione finora

- Nexteer Quality Alert: Response RequiredDocumento1 paginaNexteer Quality Alert: Response RequiredsimsonNessuna valutazione finora

- R Ew Ork M Inim IzationDocumento58 pagineR Ew Ork M Inim IzationSaptarshi Bagchi100% (2)

- Quality Manual: National Institute of Fashion Technology, GandhinagarDocumento54 pagineQuality Manual: National Institute of Fashion Technology, GandhinagarPaulos AbebeNessuna valutazione finora

- Skype: Mizan - Mehben: B SC in Textile Engineering (ADUST)Documento87 pagineSkype: Mizan - Mehben: B SC in Textile Engineering (ADUST)Fathi MustafaNessuna valutazione finora

- Glowinkowski Customer Service Directors - Behavioural Competency FrameworkDocumento12 pagineGlowinkowski Customer Service Directors - Behavioural Competency FrameworkitrejosNessuna valutazione finora

- QMS Manual Update TarasimaDocumento25 pagineQMS Manual Update TarasimasahadatNessuna valutazione finora

- Training ScheduleDocumento3 pagineTraining ScheduleJonathan TanNessuna valutazione finora

- A Root Cause Analysis Method For Industrial Plant - Reliability Improvement and Engineering Design FeedbackDocumento6 pagineA Root Cause Analysis Method For Industrial Plant - Reliability Improvement and Engineering Design FeedbackXiang LiuNessuna valutazione finora

- Apparel Quality Management - 11 Sewing Performance AnalysisDocumento36 pagineApparel Quality Management - 11 Sewing Performance AnalysisNadarajNessuna valutazione finora

- IPQC General FormatDocumento17 pagineIPQC General FormatMohd Isa HarunNessuna valutazione finora

- VM Checklist - Manufacturing: Peracha Engineering CoDocumento2 pagineVM Checklist - Manufacturing: Peracha Engineering CoPeracha EngineeringNessuna valutazione finora

- Estimating Measurement ComponentsDocumento24 pagineEstimating Measurement ComponentsLuis ConstanteNessuna valutazione finora

- Control of Monitoring and Measuring EquipmentDocumento3 pagineControl of Monitoring and Measuring EquipmentLinda Setya WatiNessuna valutazione finora

- Monitoring Control Sharp ObjectDocumento4 pagineMonitoring Control Sharp ObjectLinda Setya WatiNessuna valutazione finora

- 8-Step Problem Solving CardDocumento2 pagine8-Step Problem Solving CardAbdul RamliNessuna valutazione finora

- Yarn Quality Standards Date SheetDocumento1 paginaYarn Quality Standards Date SheetMazumder ApuNessuna valutazione finora

- Visual Inspection Procedures For Fabric Quality: Checking of DimensionsDocumento9 pagineVisual Inspection Procedures For Fabric Quality: Checking of DimensionsMaya Bharti100% (1)

- Human EyeDocumento1 paginaHuman EyeVartika VijayNessuna valutazione finora

- Paper 1Documento1 paginaPaper 1Vartika VijayNessuna valutazione finora

- ProspectusDocumento47 pagineProspectusVartika VijayNessuna valutazione finora

- Unix ManualDocumento86 pagineUnix Manualnityanandrp5392Nessuna valutazione finora

- Age PracticeDocumento3 pagineAge Practiceapi-254419358Nessuna valutazione finora

- Gesc103 PDFDocumento11 pagineGesc103 PDFbalajiNessuna valutazione finora

- DLL - Tle-He 6 - Q3 - W5Documento5 pagineDLL - Tle-He 6 - Q3 - W5Jayjay Roniel100% (2)

- Janome Memory Craft 10001 Sewing Machine Instruction ManualDocumento181 pagineJanome Memory Craft 10001 Sewing Machine Instruction ManualiliiexpugnansNessuna valutazione finora

- Cleo Kitty SlippersDocumento2 pagineCleo Kitty SlippersPattillo100% (1)

- Imperfections 1Documento26 pagineImperfections 1Mugunthan KrishnaNessuna valutazione finora

- Grey Cat PortraitDocumento14 pagineGrey Cat PortraitCarolina Jaramillo100% (3)

- Technical-Vocational Education: DressmakingDocumento13 pagineTechnical-Vocational Education: DressmakingDenise KhálilNessuna valutazione finora

- 3 Crochet Stitches for BlanketsDocumento13 pagine3 Crochet Stitches for BlanketsNurmuliana Abdul WahabNessuna valutazione finora

- Easter Marshmallow BunniesDocumento3 pagineEaster Marshmallow BunniesDenise MahanyNessuna valutazione finora

- Mami DollDocumento21 pagineMami DollKatherine Lyra Luiz60% (5)

- Knook Sampler ScarfDocumento6 pagineKnook Sampler ScarfJill KrahlingNessuna valutazione finora

- Fashion Tourism in Andhra Pradesh: Arts, Crafts and TextilesDocumento9 pagineFashion Tourism in Andhra Pradesh: Arts, Crafts and Textilesdpsingh86Nessuna valutazione finora

- Schappe Techniques TPFLDocumento49 pagineSchappe Techniques TPFLar11111111Nessuna valutazione finora

- Extraction From Babul (Acacia Nilotica) Bark and Efficacy of Natural Colour On Woollen YarnDocumento5 pagineExtraction From Babul (Acacia Nilotica) Bark and Efficacy of Natural Colour On Woollen YarnpkksjpNessuna valutazione finora

- Cactus PatternDocumento2 pagineCactus PatternRene NyilNessuna valutazione finora

- Sentiments Quilt: Nancy MurtyDocumento5 pagineSentiments Quilt: Nancy MurtyAlina Pop100% (1)

- Ashford Traveller BagDocumento3 pagineAshford Traveller BagckmeadorsNessuna valutazione finora

- A Manual of Worsted Work For Those Who Knit and CrochetDocumento146 pagineA Manual of Worsted Work For Those Who Knit and CrochetCharlotte100% (2)

- Thomas The TigerDocumento9 pagineThomas The TigerAnneNessuna valutazione finora

- Aquariwool - Jumbo - The - ElephantDocumento9 pagineAquariwool - Jumbo - The - ElephantKristina Lerner100% (3)

- Fashion Merchandising: Garment CostingDocumento9 pagineFashion Merchandising: Garment CostingGopalakrishnan PalaniappanNessuna valutazione finora

- Cac0126 026931MDocumento2 pagineCac0126 026931MGomu TomuNessuna valutazione finora

- KTH Eriskaymotifs ChartsDocumento3 pagineKTH Eriskaymotifs ChartsTrần Thị Kim LiênNessuna valutazione finora

- Crochet Now March 2019Documento128 pagineCrochet Now March 2019Chris Chrys100% (23)

- 1.5 - Classification of FabricsDocumento3 pagine1.5 - Classification of Fabricsmaya_muth100% (1)

- The Rieter Manual of Spinning Vol. 7 2451-v1 en Original 68509 PDFDocumento78 pagineThe Rieter Manual of Spinning Vol. 7 2451-v1 en Original 68509 PDFVishnuMaliNessuna valutazione finora

- Amigurumi Gılbert Baby Free Crochet PatternDocumento11 pagineAmigurumi Gılbert Baby Free Crochet PatternLydiaNessuna valutazione finora

- UdaanDocumento1 paginaUdaanAmAn KumarNessuna valutazione finora

- 3 Colette 1037 Sorbetto Sizes 0 16 All PDFDocumento52 pagine3 Colette 1037 Sorbetto Sizes 0 16 All PDFLesley KimberleyNessuna valutazione finora