Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Production Operation Management: Prof Muhammad Ali

Caricato da

Samar IqbalDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Production Operation Management: Prof Muhammad Ali

Caricato da

Samar IqbalCopyright:

Formati disponibili

PRODUCTION OPERATION MANAGEMENT

Prof Muhammad Ali

MC10225 MC10239 MC10229 MC10211 MC10210 MC10238

Muhammad UsmanAsad Amir Yasin Ali Farasat Shoaib Hassan Abdul Ghuffar

Mazhar Hussain

1 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

ACKNOWLEDGEMENT

In the making of this project of PRODUCTION OPERATION MANAGEMENT we would like to thank ALLAH ALMIGHTY without whose blessings we would have ever been able to complete this project. We would also like to thank our course in charge for PRDUCTION OPERATION MANAGEMENT Sir Ali for his sincere cooperation, assistance and guidance that he has given us during the making of this report.

2 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

DEDICATION

We dedicate this assignment to our parents, friends and teachers who always helped and prayed for us regarding the assignment. They also appreciated and gave right direction to us. We dedicate this assignment especially to ALLAH who has created us as crown of creation and enable me to learn.

3 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

EXECUTIVE SUMMARY

The objective of this report is to study the feasibility of a milk processing plant in Pakistan. This study has been divided into five sections. The first section studies the production and consumption of milk in Pakistan. The second section is the most important in which we discuss the procurement process of milk and the supply chains of the company. The third section analyzes the processing that is to be done on the raw milk. It also includes the packaging of the milk and the equipment require for processing. The fourth section discusses the location of the plant and the location analysis for the project. The last section of the project discusses the cost and profitability of the project.

4 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT TABLE OF CONTENTS

Executive summary..04 Introduction..........................................................................................06

SECTION I

Milk production in Pakistan06 Milking conditions ...07 History of dairy industries.08

SECTION II

Milk procurement09 Systems in milk procurement ..11 Seasons for milk procurement .....12

SECTION III

Reception and processing of milk14 Milk processing systems................................................................................15 Packaging....................................................................................................17 Equipments ..18

SECTION IV

Location of the plant.19 Location of present dairy plants19 Location of the plant20

SECTION V

Cost analysis.22

Capital cost of the project22 Profitability..23

Conclusion24

5 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT INTRODUCTION

The main objective of this report is to provide a feasibility study on a production or processing plant to be established in Pakistan. For this purpose we had to select an FMCG product for which we were going to prepare this report. We choose to establish a milk processing plant in Pakistan. The reason behind this is the ever increasing demand of processed milk in Pakistan. In this report we shall mention all the requirements of a feasibility report on a milk processing plant in Pakistan. We shall first of all analyze the production and demand of milk in the country. Secondly, we have to analyze the size of the market that we shall target and see at what capacity the other plants are working to decide the capacity that we are going to install. We shall also mention the processes involved and the equipment involved. We shall discuss the distribution channels we will use and the cost-profit analysis. Lastly we shall select a suitable location according to our distribution channels. We shall end the report mentioning our opportunities and limitations for this project.

SECTION I

In this section we shall discuss the production and demand of milk in Pakistan. We shall specially focus on the statistics for processed milk and study the demand and supply for it as well. This section sets the base for the next sections in the report.

MILK PRODUCTION IN PAKISTAN:

The buffalo and the cow and to a very limited extent the goat are the main milk animals in the Indo-Pak sub-continent. The buffalo contributes some 64 per cent, the cow 33 per cent and the goat 3 per cent of the total milk produced in Pakistan. There are several well recognized breeds of cows and buffaloes in the region such as Red Sindhi, Gir, Tharparkar, and Sahiwal among the cows, and Murrah and Neeli Ravi among the buffaloes, are outstanding breeds. The milk of the buffalo is comparatively richer in fat content than that of the cow. Because of the lack of scientific animal husbandry and nutritional practices, the yield of the milk animals in Pakistan has been rather low compared to that of the dairy cow (especially) in the advanced dairy countries. The population of the cross-bred cows and the upgraded buffaloes is expected to increase the milk production significantly.

6 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

Pakistan has one of the highest per capita milk and dairy products consumption rates in Asia (150-200 liters per year) and is the fourth largest milk producing country in the world with approximately 29-32 billion liters annual milk production. Higher milk yield is indeed a notable aspect of the milk sector. According to an expert, yield per animal has gone up from 700 liters per year to 1,200 liters in the last six to seven years. This is significant in more than one way and opens the door of success wide for the livestock sector as also for national economy. In spite of the dairy sector, identified by the government as one of the key priority sectors for development, the farmers which are the key players were still facing constraints, inherent because of their small size, can not reach consumers or industry directly. They have little influence, therefore, on the price or quality of their milk. It has been estimated that over 90 percent milk is produced by a large number of small holders or landless farmers in the remote rural areas. Milk producers foremost problem is marketing the milk, a highly perishable item. The Punjabs Department of Dairy Development and Livestock is collaborating with the Idara Kisan (IK), a non-profit organization active in the procurement and marketing of milk to ensure fair rates. Their efforts now cover 13 districts in Punjab. According to SMEDA findings, it is generally understood that the primary hurdle to industrys growth is the non-availability of milk in the right quantities and of good quality, especially in the lean production months of May to August when milk consumption is also the highest. The need of a dedicated national entity for better sector management was realized by the Dairy SWOG at an early stage. The importance of a sector-level management company was further realized after study of benchmarked countries with respect to sector management. Successful models of entities working in other countries like Dairy Australia in Australia, Dairy Insight in New Zealand and National Dairy Development Board of India were studied, particularly. The concept of Dairy Pakistan has been evolved as a dedicated company in the private-public partnership (PPP). MILKING CONDITIONS: Most of the milk in Pakistan is produced in the villages by farmers with small land holdings and also by landless agricultural laborers. Although an increasing portion of the milk produced is collected by the Supplier and other organized dairies, a significant portion of the milk is still being converted into traditional dairy products due to lack of refrigeration and transportation facilities. Conditions under which milk is produced in the villages are far from satisfactory, mainly because of the economic backwardness of the producers. The milk animals are housed in a part of the living space of the family or in small closed or open yards adjacent to the family

7 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

house. Flooring is usually a plaster of mud. The cows are rarely washed before milking. Buffaloes generally wallow in ponds, especially in the hot summer months. Milking is done by hand, usually after suckling by the calf. Except in a few modern large farms, milking machines are not used. Because of the distances between the producing and consuming points, milk is unavoidably held at ambient temperatures for a significantly long time leading to high microbial growth. The high ambient temperatures in the region for the major part of the year support rapid microbial growth. The predominant types of micro flora in milk received in dairies are coliforms, micrococcus, lactic streptococci, spore-forming aerobes and corynebacteria, the majority of these being contaminants from milk utensils. There is also a high incidence of thermo uric bacteria. HISTORY OF DAIRY INDUSTRIES IN PAKISTAN: In Pakistan, modern milk processing in the dairy sector started in early 1960s, and by mid1970s 23 milk pasteurization and sterilization plants were set up. With one exception, all of them are closed due to low consumer acceptance, the short shelf-life of the product and lack of trained manpower. The first UHT plant was set up in Pakistan in 1977. The success of this plant attracted many other investors also and during 1983-87, 20 new plants were set up. In the current situation, UHT capacity in the dairy industry is more than the demand for the product. Existing plants are operating below capacity and growth in demand is not likely to keep pace with the demand for relatively high-priced UHT milk. INITIAL UHT MILK PROCESSING PLANTS:

PLANT

Milko, ltd. Lahore MilkPak limited, sheikhupura Pakistan Dairies, Sahiwal Halla, Pattoki Chaudhry Dairies, Bhai Pheru Milkways, Tandlianwala 1977 1981 1983 1984 1986 1987

START UP

INSTALLED CAPACITY (LITERS/DAY)

25,000 150,000 50,000 75,000 80,000 90,000(2)

SECTION II

8 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

In this section of the report we shall discuss the milk procurement methods commonly used in Pakistan. We shall further discuss the methods we shall adopt for the procurement of milk. We shall also have to discuss the timing, Market competition, Rate of milk, Payment system (direct/banks), Payment duration (at Spot, after week, after fortnight), Milk procurement size (larger the size of the procurement greater the quantity of milk), Company strategy and Raw milk receiving parameters. We shall first of all discuss the procurement methods.

MILK PROCUREMENT:

Milk is procured from area to fulfill the industry needs by procurement departments of the companies. This is the most important department in every dairy industry. In order to support the procurement staff a separate wing of accounts is also established. This is the department with highest number of employees. Procurement of milk is not an easy job. Every dairy industry operates at its capacity to be a profitable. So in this competitive environment to have some specific volume of raw milk some time is the biggest challenge then quality. If a procurement department is failing to achieve the target quantity, it means it is not functioning properly. This definitely affects dairy business.

MILK PROCUREMENT TYPES: Milk Procurement is the starting point of dairy industry supply chain. The procurement process starts on the farm, where producers are advised, quality is monitored and raw milk is collected daily from various Farmers/progressive farmers by mini-suppliers and village milk collection centers countrywide and transported to factories in the most cost-effective manner. Raw milk quality is the cornerstone of excellent dairy products. Milk Procurement guards this quality with an eagle eye and ensures that companys production needs are met. Through teamwork within the supply chain, procurement teams of companies ensure that raw milk losses are kept to the absolute minimum. Milk procurement is basically of two types: Suppliers collection Self collection

9 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

o SUPPLIER MILK COLLECTION SYSTEM: In this case supplier brings milk with their own sources at factory. The milk is scrutinized by quality assurance department of dairy as per their standards. If milk pass all the quality test then this milk is received other wise the milk is rejected.

o MINI/HILUX CONTRACTOR: In this type of milk collection local supplier of area collects milk with his own resources and brings this milk to companies sub center. If milk is according to companys standard that milk is received otherwise rejected. All types of collected milk are brought to sub centers, where it is chilled (by chiller or by ice) and transported to Main center either through 1.7, 5 or 9 tons of tankers depending upon the quantity of milk, here milk is chilled through chillers and transported to plant. o SELF MILK COLLECTION SYSTEM: In this system the milk is collected by the company itself or through its agents. It can also collect milk directly from the farmers as shown below.

VILLAGE MILK COLLECTION (VMC):

In this case a local community nominated person (VMC agent) collect milk from local farmers on behalf of company by using company facilities. The VMC agent gets commission from company on per litter collected milk. After collection VMC agent either himself approach the near by center of company for handing over of collected milk or company vehicle collect milk from that VMC agent as per written agreement. Very good quality milk is collected through the VMCs. No doodhi is involved in this type of collection.

PROGRESSIVE FARMERS:

Having 10 adult buffalo or minimum 25 liters milk.

DIRECT FARMER:

Having one or more milk animal and bring milk directly to sub center. SYSTEMS IN MILK PROCUREMENTS: In Pakistani dairy industries following types of quality assurance system exist to assure the procurement of the best quality raw milk.

10 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

o FIRST SYSTEM: Procurement department is responsible for the procurement of good quality raw milk. o SECOND SYSTEM: Quality assurance department support the procurement department for procurement of good quality of raw milk. o FIRST SYSTEM: Procurement department is responsible for the procurement of sufficient quantity of good quality milk. Company develops a lab carrying all the testing facilities of raw milk. A procurement representative is present there to check and receive the quality of raw milk from area as per given standard of company.

BENEFITS OF THIS SYSTEM:

a. b. c. d.

Fully under control of one department. Less man power is required. Less cost to company. Under this system the objective of procurement staff become more quantity with the good quality. e. More amount of volume procured.

MILK PROCUREMENT SYSTEM OF THE COMPANY:

The main aim of mentioning the above shown methods of milk procurement is to select the method or system that we shall adopt for milk procurement. The company would adopt the first system of procurement in which the department of procurement is responsible for quality assurance and there will be no quality control department separately. We shall adopt the village milk collection method. This method is useful because if the farmers would have to bring the milk to the factory they will not be able to keep the hygiene and health standards as required by the company. So the company shall hire agents for this purpose and provide them with appropriate resources. In this way the procurement will be done and the hygiene standards of the company shall also not suffer.

11 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

DEVELOPMENT OF COLLECTION CENTERS:

For the collection of milk through the VMC method we would have to develop centers for the collection of milk through the agents. The collection centers shall be called as the milk collection centers. The collection center shall each collect a certain amount of milk daily. This amount shall be mentioned later in the report. These collection centers will be located at a nearby place to the farmers or suppliers. When the certain amount of milk will be accumulated at the collection center it will be transferred to the factory. In this way, we shall ensure that the collection of milk will be done smoothly and the quality standards will not be compromised. Now we shall mention some important points regarding the procurement process.

NUMBER OF CENTRES:

The decision as to the number of centers that we are going to have in a particular region depends upon the capacity of the region. We plan to make a collection of 5000 liters per day and the collection at each center to be 250 liters per day. So the number of centers in total will be 20 in each region. We shall have to divide the collection area into two regions. These regions will be located at approximately equal distance from the location of the plant. SEASONS FOR PROCUREMENT IN PAKISTAN: In Pakistan there are mostly three season of milk which are as under: o FLUSH SEASON (1st Jan to 15th April): During this season there is maximum production of milk in the country.

o LEAN SEASON (16th April to 30th July): In this season there is minimum production of milk in the country due to environmental temperature, less green fodder availability and natural reproduction cycle of animals. o SEMI-FLUSH SEASON (1st Aug to 31st Dec): 12 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

In this season there is about 70-80 % milk production in the country.

Now we shall discuss the procurement timing of our company. PROCUREMENT TIMING:

As we have seen in the above description, there are three seasons for procurement of milk in Pakistan. The strategy of our company would be to acquire the maximum quantity of milk in the flush season so that we would not only be able to make better supply in the market but also get an optimum rate for the purchase. This would also help to keep supply equal through out the year. As milk is a perishable item and it cannot be stored for a long period. Thus, the purchase cannot be done in one season for the whole year. We would have to make purchase for each season separately.

o PAYMENT SYSTEM (DIRECT/BANKS):

We have discussed the timing of procurement of milk as per the policy of our company. A very important point in the procurement system is the method of payment. Payment can be done directly or via banking channel. As our vendors are farmers so it will be very difficult to pay them through banks. For this reason, the payment to the farmers shall be made directly.

O PAYMENT DURATION:

Now we shall discuss the duration for the payment. The purchase shall be made on credit basis and the payment shall be made with in a week. The amount shall be handed over to the suppliers who are the farmers by the VMC agents of the company. o MILK PROCUREMENT SIZE: The milk procurement size refers to the quantity of milk that the company would purchase from a supplier. It has been mentioned earlier that for the procurement purpose we will divide the area into four regions each yielding 2500 liters of milk so that we can yield a supply of 10000 liters of milk daily as per requirement. In this way if we have 10 vendors in a region the size of procurement would be 250 liters from each vendor. BULK MILK TRANSPORT: 13 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

Once the milk is received from the vendors by the VMC agents hired by the company, the next stage comes where it has to be transported to the factory for processing. We would discuss the transportation of milk in the paragraph below A Milk procurement team of company would ensure that milk is collected and transported to factories daily. Milk cooled on the farm or cooling centre may be transported in bulk tankers. Bulk tankers are insulated, so the milk will remain cold until it reaches the plant by ensuring that transport is fast, i.e. short distance or good roads enabling milk to be delivered before the temperature of milk rises above 10 degree Celsius. This was all about the procurement system that our company shall adopt. In this section we have discussed what methods the company shall use to procure the raw milk. We have discussed the most important phase in milk processing. We have discussed the suppliers of the company and the quality check on raw milk before its collection. Now in the next section we shall discuss the processing that is going to be done on the milk.

SECTION III

This section of the report is related to the processing or operations involved once the milk has been procured and reached the plant for further processing. Normally after the milking, the milk will be collected either in a hygienic vessel or refrigerated storage tanks (bulk Cooler) and the same will be transported to the nearest dairy plant. We will now discuss the reception and processing of milk in our company. RECEPTION AND PROCESSING OF MILK AT PLANT: First of all we will discuss the reception of milk at the plant. It will be done as described below. MILK RECEPTION: At reaching plant quality assurance staff of reception lab takes the representative sample of whole milk tanker and analyses it for various parameters as per standards of company. The quality standards are described below. o RAW MILK RECEIVING PARAMETERS: Good quality milk is essential for production of good quality dairy products, taste and flavor, long keeping quality. Good quality raw milk must be: 14 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

a. b. c. d. Free from waste and residue Free from off-flavors. Low in bacterial numbers. Normal composition and acidity.

If milk is found as per quality norms of company the tanker is weighed and production department staff receives the milk for further processing other wise the sub standard raw milk tanker is rejected. PROCCESSING OF RAW MILK: The plant will accept or reject the milk after quality test, if the quality is positive the milk will be allowed for quantity verification by weighing a. b. In case of cans and pump through an electro magnetic flow meter In case of bulk quantity through refrigerated milk.

However, in both the cases, the milk will be subject to on line filtration. The raw milk will be sent to the insulated milk storage through milk cooler (chiller) and the refrigerated milk will be stored in the storage tank. Some more supporting equipment like Can Conveyors, Can Washers, Can Scrubbers & Can Drip Savers etc., are used based on the handling capacity. The chilled milk will be transferred to the processing plant as per the requirement. Now we shall discuss the processing of the raw milk. There are three important parts of the processing of the raw milk. These are explained in detail in the paragraphs below. MILK PROCESSING SYSTEMS: Dairy Equipment Liquid Milk Processing system generally consist of three major process parameters, they are: o CLARIFICATION: Clarification means removing the solid impurities from the milk, before homogenization and pasteurization. This machine can be used for separation of cream from milk (skimming) or standardizing the cream content in the liquid milk to be processed. o PASTEURIZATION: Pasteurization process is used to kill harmful microorganisms by heating the milk for a short time and then cooling it for storage and transportation. Pasteurized milk still is perishable, however, and must be stored cold by both suppliers and consumers. Dairies 15 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

print expiration dates on each container, after which stores will remove any unsold milk from their shelves. The process destroys the vitamin C content of the raw milk. A newer process, ultra pasteurization or ultra-high temperature treatment (UHT), heats the milk to a higher temperature for a shorter amount of time. This extends its shelf life and allows the milk to be stored unrefrigerated because of the longer lasting sterilization effect. Pasteurization process is to heat the milk to a Maximum temperature of 71.8C (this is the set temperature and can vary on many factors) and cooling the same instantly to 4C. Milk must be pasteurized before it is sold to consumers. This is to make sure that the milk is safe and healthy.

DIAGRAM 01

o HOMOGENIZATION: Homogenization means the fat globules are subjected to mechanical treatment, which breaks them down into smaller globules & uniformly dispersed in the milk, sedimentation of fat also can be effectively prevented by homogenizing the milk. Milk often is homogenized, a treatment which prevents a cream layer from separating out of the milk. The milk is pumped at high pressures through very narrow tubes, breaking up the fat globules through turbulence and cavitations. A greater number of smaller particles possess more total surface area than a smaller number of larger ones, and the original fat globule membranes cannot completely cover them.

16 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

DIAGRAM 02

o STORAGE OF PROCESSED MILK: The processed milk will be stored in Insulated Storage Tank, from there it can be transferred to the packing section as and when it is required. The packed milk will be kept in refrigerated condition at 4C. o CLEANING OF EQUIPMENT: The entire plant machineries need to be cleaned thoroughly to meet the stringent sanitary standard, to maintain the quality of milk and milk. Cleaning in place system, will clean the equipment, pipelines etc., without dismantling from its position. This is an essential system for any dairy plant to maintain the quality of their product. The combination of all these processes is the essence of Dairy Engineering. Proper engineering will help to achieve better quality products, minimum break down and less operating cost like power, steam, and refrigeration etc. Now in the last part of this section we shall discuss the packaging of the milk and the equipments required to carry out these processes. PACKAGING: Now as we have discussed the processes involved in the milk production, the last stage of the process is packaging. It is a very important part of milk processing to keep the milk with a long shelf life. We shall now discuss the material we shall use for packaging.

17 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

MATERIALS FOR PACKAGING:

The packaging materials include paper and paper based products (coated or lined), glass, tin plate, aluminum foil, timber (wood) and plastics. The paper and paper based products form an excellent packaging material for milk and milk products. They may be wax coated paper, plastic coated paper, paper boards, solid fiber boards, liner boards, box boards etc. The papers are used in the form of boxes, bags, wrappers, cartons, cups etc. o

ADVANTAGE OF USING PAPER:

The advantage of using paper is that it is weightless, capability for printing on the surface, low cost and easy disposability. EQUIPMENTS: Dairy Equipment offers wide range of processing plants & equipment as shown below Sr.No 1 Equipment Description Plate Heat Exchangers for heating and cooling the liquid milk

2 Transport Tanks

18 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

3

Maas Cooling Tanks

Milk Pasteurization plant with Homogenizers from 100 to 1000 liters per hour capacity

In the next section we will discuss the location of the plant.

SECTION IV

In this section we shall discuss the location for the milk processing plant. Usually the plant is established in remote areas away from residential areas. We shall discuss the location of the plant in detail.

LOCATION OF PLANT:

In this section we shall discuss the location of the milk processing plant. For the location analysis we shall first of all give a detail of present dairy processing plants in Pakistan.

PRESENT DAIRY PROCESSING PLANT: Sr.No 1 2 3 4 Plant

Nestle MilkPak ltd Nestle MilkPak ltd Haleeb Foods limited Haleeb Foods limited

Location

Sheikhupura Kabirwala Bhai Pheru R.Y. khan

Manufacturer of

UHT plane milk, UHT cream, Milk powders UHT plane milk, UHT cream, Milk powders

Established

2005 2005

UHT plane milk, UHT cream, Milk powders, yogurt 1981 UHT plane milk, UHT cream, Milk powders, yogurt 1986

19 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Nirala Dairy Pvt Ltd Premier dairy Pvt. Ltd. K & K Dairy Pvt. Ltd Shaker Gunj Foods ltd Noon Pakistan Engro Foods Ltd Engro Foods Ltd Royal dairy Millac Foods Pvt. Ltd. Military Dairy Prime dairy Butt dairy Idara-e-Kisan Gourmet Adams Dairy Alpha Dairy Tandlianwala Lahore Lahore Jaranwala Bhalwal Sukkar Sahiwal Karachi Lahore Okara Lahore Tandlianwala Pattoki Lahore Sahiwal Jhung UHT milk, UHT cream, Milk powders UHT plane milk, Milk powders UHT plane milk, Milk powders UHT plane milk, UHT flavored milk, Milk powders UHT plane milk, UHT flavored milk, Milk powders UHT plane milk, UHT flavored milk, Milk powders UHT plane milk, Ice cream UHT flavored milk Milk powders Milk powder and cheese Yogurt Milk powder Pasteurized milk and Milk powder Pasteurized milk and ice cream Cheese and whey powder UHT plane milk, Milk powders 2005 2003 2003 2005 2004 2005 2003 2003 2005 2007 1981 2005 1986 2005 2004

This is a detail of the 20 dairy plants present in Pakistan. As we said earlier, most of these are located in remote areas of Punjab province. There are only two plants in Lahore and one in Karachi. The majority exists in areas close to Lahore like sheikhupura, Sahiwal and Pattoki. This makes the initial cost less in terms of land etc. LOCATION FOR MILK PROCESSING PLANT: Now we shall discuss the location of our plant. The company will establish the plant in sheikhupura. It is located in the centre of the two regions namely Lahore and Gujaranwala.

20 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

Region Lahore Gujaranwala

Distance from location 33.70 miles 33.38 miles

As we can see from the above shown map and table, we can see that sheikhupura can be an excellent location for the plant. It is a central location and located at fair distances from the four regions we selected for milk collection. Now we shall discuss the cost of the whole project. This shall include the initial cost, procurement cost, processing cost and other costs.

21 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

SECTION V

In this section we shall do a cost analysis of this project. This may cover all the types of costs that are a part of this project.

PROJECTED COST ANALYSIS:

In this part of the section we shall tell about all the costs that are involved in this project. We shall first discuss the projection cost.

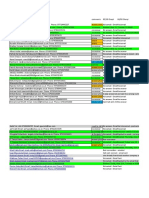

CAPITAL COST OF THE PROJECT: The estimated capital cost of this project is 450000000. This would include land, building, machinery, other capital assets and working capital. Sr.No 1 2 3 4 5 6 7 8 9

o

Description Cost of land ( 10 acres at 0.45 million/acre) Cost of construction of plant (7000sqm @ 10000/sqm) Machinery and equipment Collection chillers Other vehicles Other plant and machinery Furniture and fixtures Working capital Contingencies Total

Amount 000s (Rs.) 45000 70000 200000 30000 10000 20000 5000 50000 20000 45000000

EXPLANATION:

The above table shows the projected cost of this project for the first year. This includes the cost of land, cost of construction, cost of machinery and equipment, collection chillers, other vehicles and working capital. o

COST OF LAND:

The cost of land for this project would be about 0.45 million per acre which makes the total cost of land about 45000000.

22 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

o COST OF CONSTRUCTION OF PLANT: The cost of construction for the project that is the plant at the location described in the previous section will be Rs. 10000 per square meter which for an area of 7000 square meters equates to 70000000. o MACHINERY AND EQUIPMENT: The machinery and equipment costs would be Rs. 200000000. The details of the equipment have been shown above. o COLLECTION CHILLERS: We would require collection chillers for the transportation and storage of milk at every stage. These would cost Rs. 10000000. o WORKING CAPITAL: The working capital is also an important part of the cost. The working capital requirement for the first year would be 50000000 rupees. PROFITABILITY: Now we shall do some analysis on the profitability of this project. For the purpose we would calculate the pay back period of the project. With the use of estimated net profits and yearly depreciation, the calculated pay back period will be four years. In the first four year the initial cost of this venture will be recovered. Now we shall discuss the legal requirements of starting this project.

LEGAL REQUIREMENTS OF THE PROJECT: Following are the legal requirements for this project. 1. Obtain approval of company name through the Securities and Exchange Commission of Pakistan (SECP) E-service website. The time taken is 1 day. 2. Pay the fees for name registration and company incorporation using bank challans at the designated bank (MCB). The time taken would be one day. 3. Register the company with the Securities & Exchange Commission of Pakistan (SECP) through online E-services. This would take 2 days. The cost would bePKR 5000 23 SUPERIOR UNIVERSITY

PRODUCTION OPERATION MANAGEMENT

registration fee + PKR 2000 filing fee (Form 1, Form 21 & form 29 & copy of memorandum of association) 4. Obtain digital signatures from the National Institutional Facilitation Technologies (NIFT) through the SECP e-services. This would take 1 day. 5. Apply for a national tax number (NTN) and register for income tax. This would take 2 days. 6. Register for sales tax by applying for a Sales Tax Number (STN) at the tax facilitation center of the Regional Tax Office (RTO) of the Federal Board of Revenue (FBR) in Karachi. This would take 1 day. 7. Register for Professional Tax with the Excise & Taxation Department of the District. This would take a week. 8. Register with the Sindh Employees Social Security Institution (SESSI). This will take 11 days. 9. Register with Employees Old-Age Benefits Institution (EOBI). This would take 11 days. 10. Register under the West Pakistan Shops and Establishment Ordinance 1969 with the Labor Department of the District. This would take 7 days. CONCLUSION:

The legal process would take about 45 days to complete. At the end, we shall conclude that this report covers almost all sections of a feasibility study on processed milk plant.

24 SUPERIOR UNIVERSITY

Potrebbero piacerti anche

- Introduction of Supply Chain of Nestle MilkPakDocumento17 pagineIntroduction of Supply Chain of Nestle MilkPakSaiyed Fauzan Ali89% (44)

- First Draft Group 3Documento5 pagineFirst Draft Group 3Fahad MushtaqNessuna valutazione finora

- Visakhadairy ProjectDocumento73 pagineVisakhadairy ProjectRajasekhar Adapa75% (4)

- Haleeb Industry Analysis (P-1)Documento28 pagineHaleeb Industry Analysis (P-1)Sahr33nNessuna valutazione finora

- Akhil Appu-Converted (1) NewDocumento66 pagineAkhil Appu-Converted (1) NewAkhil SathyanNessuna valutazione finora

- Report On Study On Vehicle RoutingDocumento59 pagineReport On Study On Vehicle RoutingRonald DudleyNessuna valutazione finora

- New Microsoft Office Word DocumentDocumento3 pagineNew Microsoft Office Word DocumentDharmik MalaviyaNessuna valutazione finora

- Industrial Report On Saras DairyDocumento88 pagineIndustrial Report On Saras DairyDeepak ChelaniNessuna valutazione finora

- Financial Analysis of VerkaDocumento58 pagineFinancial Analysis of Verkaakashbrar061291% (23)

- "Sumul Dairy": AN Industrial Visit Report ONDocumento90 pagine"Sumul Dairy": AN Industrial Visit Report ONSarthak BrahmbhattNessuna valutazione finora

- Distribution Channel of OlpersDocumento32 pagineDistribution Channel of OlpersWajahat MumraizNessuna valutazione finora

- Case Study of Milk ProductionDocumento46 pagineCase Study of Milk Productionmian21100% (2)

- 11jjcma100 1Documento87 pagine11jjcma100 1anandkumar_269Nessuna valutazione finora

- NESTLÉ Milkpak - Comprehensive MarketingDocumento21 pagineNESTLÉ Milkpak - Comprehensive MarketingRao Qaisar ShahzadNessuna valutazione finora

- Vino KMF ProjectDocumento81 pagineVino KMF ProjectSandesh SandyNessuna valutazione finora

- Submitted Towards The Partial Fulfillment of Master of Business Administration Awarded by Rajasthan Technical University, KotaDocumento61 pagineSubmitted Towards The Partial Fulfillment of Master of Business Administration Awarded by Rajasthan Technical University, KotaHarsh PahariyaNessuna valutazione finora

- The Karmali Dudh Utpadak Shahkari Mandali LimitedDocumento76 pagineThe Karmali Dudh Utpadak Shahkari Mandali LimitedSalim NoratNessuna valutazione finora

- RESEARCH PROJECT REPORT MonikaDocumento36 pagineRESEARCH PROJECT REPORT MonikaMeenu RaniNessuna valutazione finora

- Verka Milk PlantDocumento71 pagineVerka Milk Plantamandeepkaursandhu0% (1)

- Pakistan Milk IndustryDocumento16 paginePakistan Milk IndustryShaheen_8367% (3)

- Verka Milk PlantererrDocumento52 pagineVerka Milk PlantererrTejinderpal Kaur Bhangu71% (7)

- Verka PlantDocumento51 pagineVerka PlantAshish ChaudhaRyNessuna valutazione finora

- Raza Saddique: Supply Chain Management MS (Project Management) Final Project CMS No. 17055Documento33 pagineRaza Saddique: Supply Chain Management MS (Project Management) Final Project CMS No. 17055Muhammad Hassan IqbalNessuna valutazione finora

- Full ProjectDocumento72 pagineFull ProjectShilpa K R0% (1)

- Document PDFDocumento2 pagineDocument PDFAdnan AzizNessuna valutazione finora

- Thirumala MilkDocumento25 pagineThirumala MilkSanthosh Kumar33% (3)

- KMF - DharwadDocumento69 pagineKMF - DharwadkodiraRakshithNessuna valutazione finora

- Study On Promotional Activities of Nandini Milk and Its Products (Repaired) (Repaired)Documento78 pagineStudy On Promotional Activities of Nandini Milk and Its Products (Repaired) (Repaired)manjunatha TK100% (1)

- Outlook of Buffalo Dairy Farms in Pakistan: January 2015Documento15 pagineOutlook of Buffalo Dairy Farms in Pakistan: January 2015Masood HassanNessuna valutazione finora

- Hassan Co Operative Milk Producers Society Union Limited HASSANDocumento63 pagineHassan Co Operative Milk Producers Society Union Limited HASSANPrashanth PB80% (10)

- Final SMMDocumento16 pagineFinal SMMSajad AslamNessuna valutazione finora

- Project Report632Documento69 pagineProject Report6327329 MehakNessuna valutazione finora

- Student Ready Programme: Sam Higginbottom University of Agriculture, Technology and SciencesDocumento73 pagineStudent Ready Programme: Sam Higginbottom University of Agriculture, Technology and SciencesIsha ChatterjeeNessuna valutazione finora

- SL No Particulars Page No: MP State Cooperative Dairy FederationDocumento58 pagineSL No Particulars Page No: MP State Cooperative Dairy FederationJitendra Kumar VermaNessuna valutazione finora

- 0rganisational StudyDocumento49 pagine0rganisational StudyGaneshgouda PatilNessuna valutazione finora

- RAZ IV PojectDocumento25 pagineRAZ IV PojectRazique MusthafaNessuna valutazione finora

- Introduction of FoodDocumento27 pagineIntroduction of FoodAmna KarimNessuna valutazione finora

- Example of A Supply ChainDocumento30 pagineExample of A Supply ChainLong Dong MidoNessuna valutazione finora

- Aman Rawe Report 3 - RemovedDocumento10 pagineAman Rawe Report 3 - Removedshaliniindiamart7491Nessuna valutazione finora

- Dairy ProductsDocumento40 pagineDairy Productsgnreddy_14100% (2)

- A Project Report On Consumer Satisfaction Towards Amul Milk and Milk Products at Udaipur CityDocumento78 pagineA Project Report On Consumer Satisfaction Towards Amul Milk and Milk Products at Udaipur Cityjainvaishali100% (1)

- Chapter 1Documento11 pagineChapter 1JohnNessuna valutazione finora

- Verka Consumer BehaviourDocumento88 pagineVerka Consumer BehaviourAmanda Baker100% (1)

- Amul StrategyDocumento18 pagineAmul StrategyAkram Ul Hoque100% (12)

- Mother DairyDocumento20 pagineMother Dairyno nameNessuna valutazione finora

- Status of Dairy Farming in Nagaland A Descriptive StudyDocumento5 pagineStatus of Dairy Farming in Nagaland A Descriptive StudyEditor IJTSRDNessuna valutazione finora

- Vimal DairyDocumento120 pagineVimal Dairyrushabhbholo83% (6)

- THESISDocumento69 pagineTHESISChaithanya KumarNessuna valutazione finora

- Dairy Industry1Documento16 pagineDairy Industry1salman00Nessuna valutazione finora

- Sales Distribution of Parag Milk Summer Training ProDocumento94 pagineSales Distribution of Parag Milk Summer Training Proa5436686Nessuna valutazione finora

- Dairy Dissertation 02Documento73 pagineDairy Dissertation 02Aditya Pratap0% (1)

- Amul MarkeionDocumento150 pagineAmul MarkeionRohit PatilNessuna valutazione finora

- Internship Report PonlaitDocumento42 pagineInternship Report PonlaitDjeoshva Belies DNessuna valutazione finora

- Amul WordDocumento8 pagineAmul WordPawan MamaniyaNessuna valutazione finora

- Dairy Farming : Modern Approaches to Milk Production and ProcessingDa EverandDairy Farming : Modern Approaches to Milk Production and ProcessingNessuna valutazione finora

- Augmentation of Productivity of Micro or Small Goat Entrepreneurship through Adaptation of Sustainable Practices and Advanced Marketing Management Strategies to Double the Farmer’s IncomeDa EverandAugmentation of Productivity of Micro or Small Goat Entrepreneurship through Adaptation of Sustainable Practices and Advanced Marketing Management Strategies to Double the Farmer’s IncomeNessuna valutazione finora

- Milk and Dairy Products as Functional FoodsDa EverandMilk and Dairy Products as Functional FoodsAra KanekanianNessuna valutazione finora

- Completed NGC3 ReportDocumento4 pagineCompleted NGC3 ReportTiCu Constantin100% (1)

- Kuper ManualDocumento335 pagineKuper Manualdonkey slap100% (1)

- Community-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDocumento28 pagineCommunity-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDiane Rose LacenaNessuna valutazione finora

- 2 and 3 Hinged Arch ReportDocumento10 pagine2 and 3 Hinged Arch ReportelhammeNessuna valutazione finora

- h6811 Datadomain DsDocumento5 pagineh6811 Datadomain DsChristian EstebanNessuna valutazione finora

- Company Law Handout 3Documento10 pagineCompany Law Handout 3nicoleclleeNessuna valutazione finora

- Land Use Paln in La Trinidad BenguetDocumento19 pagineLand Use Paln in La Trinidad BenguetErin FontanillaNessuna valutazione finora

- Oops in PythonDocumento64 pagineOops in PythonSyed SalmanNessuna valutazione finora

- BS en Iso 11666-2010Documento26 pagineBS en Iso 11666-2010Ali Frat SeyranNessuna valutazione finora

- Common Base AmplifierDocumento6 pagineCommon Base AmplifierMuhammad SohailNessuna valutazione finora

- Medical Devices RegulationsDocumento59 pagineMedical Devices RegulationsPablo CzNessuna valutazione finora

- Ting Vs Heirs of Lirio - Case DigestDocumento2 pagineTing Vs Heirs of Lirio - Case DigestJalieca Lumbria GadongNessuna valutazione finora

- Chapter 123 RevisedDocumento23 pagineChapter 123 RevisedCristy Ann BallanNessuna valutazione finora

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDocumento2 paginePradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalNessuna valutazione finora

- DevelopmentPermission Handbook T&CPDocumento43 pagineDevelopmentPermission Handbook T&CPShanmukha KattaNessuna valutazione finora

- Ambient Lighting Vol 6 CompressedDocumento156 pagineAmbient Lighting Vol 6 Compressedadvait_etcNessuna valutazione finora

- Crivit IAN 89192 FlashlightDocumento2 pagineCrivit IAN 89192 FlashlightmNessuna valutazione finora

- Coca-Cola Summer Intern ReportDocumento70 pagineCoca-Cola Summer Intern ReportSourabh NagpalNessuna valutazione finora

- X HM11 S Manual AUpdfDocumento228 pagineX HM11 S Manual AUpdfAntonio José Domínguez CornejoNessuna valutazione finora

- WVU's Response Letter To Campbell Regarding HugginsDocumento4 pagineWVU's Response Letter To Campbell Regarding HugginsJosh JarnaginNessuna valutazione finora

- Computerized AccountingDocumento14 pagineComputerized Accountinglayyah2013Nessuna valutazione finora

- Corporation Law Review Test Midterms 2019Documento4 pagineCorporation Law Review Test Midterms 2019Van NessaNessuna valutazione finora

- Surge Arrester: Technical DataDocumento5 pagineSurge Arrester: Technical Datamaruf048Nessuna valutazione finora

- The Website Design Partnership FranchiseDocumento5 pagineThe Website Design Partnership FranchiseCheryl MountainclearNessuna valutazione finora

- 1 075 Syn4e PDFDocumento2 pagine1 075 Syn4e PDFSalvador FayssalNessuna valutazione finora

- Statable 1Documento350 pagineStatable 1Shelly SantiagoNessuna valutazione finora

- TNCT Q2 Module3cDocumento15 pagineTNCT Q2 Module3cashurishuri411100% (1)

- Hyundai Himap BcsDocumento22 pagineHyundai Himap BcsLim Fung ChienNessuna valutazione finora

- Mathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Documento6 pagineMathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Kenneth NuñezNessuna valutazione finora

- Comparative Analysis of Mutual Fund SchemesDocumento29 pagineComparative Analysis of Mutual Fund SchemesAvinash JamiNessuna valutazione finora