Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Smart Ex

Caricato da

ekoyonatanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Smart Ex

Caricato da

ekoyonatanCopyright:

Formati disponibili

Please make a selection

GARMENT DYEING

MIRACLE

SPECIFICATIONS

Standard Features 150

Capacity (kg) Drum Volume (lt) Drum Diameter (mm) Drum Depth (mm) Washing Speed Max Extraction (rpm) Max G Force (G) Door Diameter (mm) Drain Valve Dia. (inch) Chemical Inlet Motor Speed Control Washing & Spinning (kw) Total Electric Power (kw) Water Intake (inch) Steam Intake (inch) 5.5 6.5 1 1/2 3/4 7.5 8.5 1 1/2 1 1/4 760 400 710 5 700 400 850 6 150 1480 1240 1220

225

225 2280 1480 1330

340

340 3398 1720 1465 Adjustable-Variable 645 400 1000 8 1 MAIN CHEMICAL INLET Standard 11 12 2 1 1/2

500

500 4800 1720 2070

645 400 1000 8

18.5 19.5 2 1 1/2

Dimensions

Width (mm) Height (mm) Depth (mm) Weight (kg) 1610 1950 2350 3250 1915 2275 2590 5200 2175 2550 3045 6600 2200 2550 3650 9000

Patented Smart Balance System 400 G spinning power Spin Dye (JET Spraying) Process with variable dyeing speeds Direct steam and Indirect steam heating system through external heat exchanger External Chemical/Dye Kitchen with progressive dosing (3 tanks or more, main with stirrer. Main tank with bath liquor dissolving, continuous level measurements, indirect steam heating, powder/salt dissolving, hot water intake capabilities Ramp controlled heating and cooling (Cool Down) Inverter controlled motor drive PLC Controlled SWC 2000 Electronic Control System(Cool Down) 99 independent programmable recipes (up to 100 programming steps each)

Forward tilting system for unloading (N/A for Miracle 60) Single motor drive with smaller power Stainless steel front cover plate and 316 L quality stainless steel for parts coming into contact with chemicals Continuous water level measurement with industrial water counter Operating temperature up to 99 C Variable and adjustable dyeing, washing, and spinning speeds Heat insulated outer drum No hydraulics, all pneumatic control system One main chemical compartment 2 water inlet control (Hot, cold) One large drain outlet with air operated water release valve Special separated leak proof bearing system Revolution counter Viton seals around shaft with spares Automatically locked front loading door with safety lock Water sampling valve Front panel bumper rail 2 water, 1 steam valve and connection hoses Carrier wheels for easy installation and maintenance

Optional Features

PolyRib ECO Drum (Patent Pending) PH Control System Cleanseal sealing dust removal system 8 or 6 external chemical intake control Industrial type Water liter counter Backward tilting 2nd drain and 3rd water inlet control Automatic door Water sampling valve SCADA (System Controls and Data Acquisition) and Network applications Automatically controlled grease lubricator for bearings Y Drum with revolving door, sampling door synchronized with revolving door CHEMICAL/DYE KITCHEN

TOLKAR/SMARTEX Professional chemical/dye kitchens are designed to perform the most demanding garment dyeing tasks with its supreme features. 3 large tanks, main with stirrer and bath liquor dissolving, continuous level measurements, indirect steam heating, powder/salt dissolving, hot water intake and transfer to auxiliary tanks allow achieving absolute dyeing results during long processes. External heat exchanger supported system provides homogenous and precision ramp controlled heating and cooling in order to obtain a perfect penetration on fabrics.

SCADA CONTROL SYSTEM TOLKAR/SMARTEX CAT EYE SCADA (System Control and Data Acquisition) software package is developed specially for TOLKAR & SMARTEX Garment Dyeing and Textile Washing machines for the professional user. The system concept allows the user to handle dye and wash recipes on the machine. General Information The GD series are designed to perform the most demanding garment dyeing tasks. Most of the equipment required for dyeing come along as standard features in this series: SPIN DYE dyeing method that reduces the liquor ratio to 1:5 at the reactive and direct dyeing, 1:6/1:7 at pigment dyeing, indirect steam heating, chemical/dye kitchen unit, cool down etc By using the newest technology for the garment dyeing process, called SPIN DYE SYSTEM, SMARTEX has made obsolete the Y drum partitioning of the drum. The result is higher quality, easier, more economic and competitive dyeing. As the garments do not fall, there is almost no mechanical abrasion effect on garments during the long process times. Thanks to its technology, unlike other producers, SMARTEX can produce the drums with low diameters. Besides, Tolkar is proud to introduce Ultimate Dyeing Machine called MIRACLE Series with its new invention PolyRib ECO Drum (patent pending). The Poly-Rib drum, as we named it, is a revolutionary drum structure with multiple small ribs (wings) along with 3 smaller beaters. This drum structure provides homogenous penetration of dyes onto the fabrics, therefore increasing the effectiveness of dyeing quality. Hence it is suitable for delicates by means of less mechanical action of multiple ribs. The ECO Drum is also our other revolution in dyeing/washing technologies as TOLKAR id proud to introduce the ECO Drum. During dyeing/washing, wherein the passage of water is restricted with the help of PolyRib drum structure; passed water from the drum through lessened perforations to the tub is pumped back into the drum with a circulation pump through Spin Dye injector which is placed under the drum. Comprised invention called ECO Drumthat is used along with POlyRib. With said metod the gap area between inner drum and tub is completely depleted and no water kept in this area equals to 40-50 % of total required water volume of conventional machines and provides 40-50% savings from required water. By eliminating the unessential water which normally has to be kept in the gap area, water consumption reduces dramatically and depending on saved water, all chemicals, heating energy and waste water consumptions are reduced as same.

Reducing the water filled into drum is causing to use smaller motors where friction forces between drum and water are eliminated by keeping the gap area empty. This further allows to load the machines more than usual where economizes on electricity consumption. All capacities are capable of exerting 400 G force without any vibration with the help of Smart Balancing System (Patented). Extraction at 400 G saves about 20% in energy spent on. Again independent of the load distribution within the drum, stable balancing is achieved by Smart Balancing System, thereby almost eliminating the need for restarts. All mechanical parts of the machine are not subject to the fatigue caused by vibration. Comparing with the conventional dyeing machines, SMARTEX Miracle pays back its investment within 6 to 10 months according to installed region conditions. Meet with 21st centurys technologies. A cigarette can stand vertically while spinning at max speeds.

Go to Top

HOME | COMPANY | PRODUCTS | CONTACT

Potrebbero piacerti anche

- Asphalt Batch Mix PlantDocumento4 pagineAsphalt Batch Mix Plantkesar equipmentsNessuna valutazione finora

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDa EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingValutazione: 5 su 5 stelle5/5 (3)

- IV Dam Outlet Work1Documento33 pagineIV Dam Outlet Work1hailish100% (1)

- What Is A ComputerDocumento29 pagineWhat Is A ComputerRellie CastroNessuna valutazione finora

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDa EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisValutazione: 5 su 5 stelle5/5 (1)

- 671 - BP Well Control Tool Kit 2002Documento20 pagine671 - BP Well Control Tool Kit 2002Uok Ritchie100% (1)

- Bearing Reliability Improvement-SKFDocumento55 pagineBearing Reliability Improvement-SKFAbdulrahman AlkhowaiterNessuna valutazione finora

- SK125SR SK135SR-2 Mic ASIA PDFDocumento16 pagineSK125SR SK135SR-2 Mic ASIA PDFmarettino100% (2)

- Tumble DryersDocumento20 pagineTumble DryersGrover CondoriNessuna valutazione finora

- Racor Fuel Filtration - Fuel Filtration Products - 7529Documento32 pagineRacor Fuel Filtration - Fuel Filtration Products - 7529sugiyantoNessuna valutazione finora

- Packaged Mineral Water PlantDocumento12 paginePackaged Mineral Water PlantAmjad Pervaz100% (1)

- Installation Manual: DPS 232 Differential Positioning SystemDocumento154 pagineInstallation Manual: DPS 232 Differential Positioning SystemVladimirs Arzeninovs100% (3)

- Ficha Doosan Compresoresportatiles XHP1170 en 0Documento4 pagineFicha Doosan Compresoresportatiles XHP1170 en 0death666darkNessuna valutazione finora

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Documento9 pagineThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationNessuna valutazione finora

- Structural Design and Optimization - Part IIDocumento448 pagineStructural Design and Optimization - Part IIFranco Bontempi100% (1)

- 60 BPM CSD For 250 ML Arvind AquaDocumento17 pagine60 BPM CSD For 250 ML Arvind AquaOMKAR JADHAVNessuna valutazione finora

- SteamlocDocumento8 pagineSteamlocstuntmanzNessuna valutazione finora

- FINAL 120 BPM CSD Filling Line NewDocumento14 pagineFINAL 120 BPM CSD Filling Line NewOMKAR JADHAVNessuna valutazione finora

- Industrial Washing MachineDocumento10 pagineIndustrial Washing MachineDiêm Công ViệtNessuna valutazione finora

- STP 125 KLDDocumento9 pagineSTP 125 KLDAbhay SisodiaNessuna valutazione finora

- Abb Sas GeneralDocumento43 pagineAbb Sas Generalsabill arasyidNessuna valutazione finora

- P-Usg: Underwater Strand Pelletizing Systems For Cost-Eff Ective ProductionDocumento8 pagineP-Usg: Underwater Strand Pelletizing Systems For Cost-Eff Ective Productionruk1921Nessuna valutazione finora

- 1000-1500 1FNL Semi Automatic MWP Plant Offer STD EXPORTDocumento16 pagine1000-1500 1FNL Semi Automatic MWP Plant Offer STD EXPORTmimrusfanNessuna valutazione finora

- SBO Universal: Cut Your Bottle Blowing Costs by Up To 20 %Documento16 pagineSBO Universal: Cut Your Bottle Blowing Costs by Up To 20 %António de Amorim100% (1)

- Commercial Offer About The PET Washing Line, Capacity 1000 KG/HDocumento13 pagineCommercial Offer About The PET Washing Line, Capacity 1000 KG/HAnkitNessuna valutazione finora

- OEM Pall Prufier Brochure PDFDocumento8 pagineOEM Pall Prufier Brochure PDFhaggNessuna valutazione finora

- Biofuge Contifuge Stratos 120 200 208 240V DualDocumento103 pagineBiofuge Contifuge Stratos 120 200 208 240V DualAndrew Holmes50% (2)

- Multi-Swt Sde Sse Am04-207Documento6 pagineMulti-Swt Sde Sse Am04-207Wayne NefdtNessuna valutazione finora

- Dealcorp MexicoDocumento6 pagineDealcorp MexicoJesus DugarteNessuna valutazione finora

- HFD Catalog SentinelDocumento12 pagineHFD Catalog SentinelGuido Moreno PeredoNessuna valutazione finora

- Manual 65S Eng.V6Documento35 pagineManual 65S Eng.V6gugiNessuna valutazione finora

- 12-Product Catalog GirbauDocumento8 pagine12-Product Catalog Girbausumit11235Nessuna valutazione finora

- Leisuwash 360 Automatic Vehicle Wash System Touch Free BrochureDocumento15 pagineLeisuwash 360 Automatic Vehicle Wash System Touch Free Brochure9nvwt7dqkjNessuna valutazione finora

- h2 Generators - WM Series - Uk AsyntDocumento2 pagineh2 Generators - WM Series - Uk Asyntapi-234089277Nessuna valutazione finora

- Catalogue Import Equipment & SD@JWMPQDocumento47 pagineCatalogue Import Equipment & SD@JWMPQVin BdsNessuna valutazione finora

- Leisuwash 360 Automatic Vehicle Wash System Touch Free - BrochureDocumento15 pagineLeisuwash 360 Automatic Vehicle Wash System Touch Free - BrochureDiwakar RoyNessuna valutazione finora

- Niagara 381 381 L UkDocumento8 pagineNiagara 381 381 L UkFABIAN ALEXANDER ROA LAGUNANessuna valutazione finora

- A4 Depliant Gradoadroit EngDocumento3 pagineA4 Depliant Gradoadroit Engductoan32Nessuna valutazione finora

- Presentación ILPRADocumento45 paginePresentación ILPRAjohanpataNessuna valutazione finora

- AAT - LSS - Product - Range PDFDocumento24 pagineAAT - LSS - Product - Range PDFJuan Carlos Lehmann SphanNessuna valutazione finora

- T2000 UKrev4Documento2 pagineT2000 UKrev4Servicii Curatenie ChisinauNessuna valutazione finora

- Herramientas de Produccion S.A. de C.V.: The Power of CleanDocumento5 pagineHerramientas de Produccion S.A. de C.V.: The Power of CleanCarolina FloresNessuna valutazione finora

- Catalogo Maquinas de Lavado AcpmDocumento32 pagineCatalogo Maquinas de Lavado AcpmWilliam AlvaradoNessuna valutazione finora

- Racor FiltryDocumento32 pagineRacor FiltryMuhammadObaidullahNessuna valutazione finora

- Hob ArtDocumento8 pagineHob ArtonezienNessuna valutazione finora

- Sweepers CatalogDocumento56 pagineSweepers CatalogNewVersion_FacilityManagementNessuna valutazione finora

- Data Sheet Lyonomic en 0Documento4 pagineData Sheet Lyonomic en 0Matias RivarolaNessuna valutazione finora

- TapelineDocumento4 pagineTapelineusmankhawaja100% (1)

- Sales Manual 65SDocumento41 pagineSales Manual 65SgugiNessuna valutazione finora

- High Pure Water Machine Producing Water Specialized For LaboratoryDocumento30 pagineHigh Pure Water Machine Producing Water Specialized For LaboratoryFaizNessuna valutazione finora

- Frigomilk G9 IngDocumento2 pagineFrigomilk G9 IngAlberto Salazar OrrilloNessuna valutazione finora

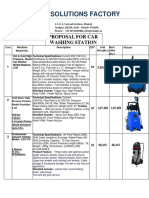

- Proposal For Car Washing StationDocumento2 pagineProposal For Car Washing StationVishal BhagatNessuna valutazione finora

- SEBAC FiltersDocumento2 pagineSEBAC FiltersN PrasaddNessuna valutazione finora

- Process Pigging SystemDocumento22 pagineProcess Pigging Systemkingathur26681100% (1)

- Range Overview Multi Housing Line5000 LowDocumento8 pagineRange Overview Multi Housing Line5000 LowCarlos Castillo UrrunagaNessuna valutazione finora

- Fluid Bed Dryer - FBDDocumento4 pagineFluid Bed Dryer - FBDsagunswashNessuna valutazione finora

- HFD Catalog PVS PDFDocumento11 pagineHFD Catalog PVS PDFPartsGopher.comNessuna valutazione finora

- IF Commercial Ironer Feeder Folder Brochure PDFDocumento2 pagineIF Commercial Ironer Feeder Folder Brochure PDFAl AdcockNessuna valutazione finora

- Hydrolink General Product CatalogueDocumento17 pagineHydrolink General Product CatalogueMarcoAlbaNessuna valutazione finora

- Alto Shaam 20-20ESI Combi OvenDocumento4 pagineAlto Shaam 20-20ESI Combi Ovenwsfc-ebayNessuna valutazione finora

- 3M High Flow Series Filer SystemsDocumento12 pagine3M High Flow Series Filer SystemsRahimd Fox100% (1)

- Brosur Lavatrice LD SeriesDocumento10 pagineBrosur Lavatrice LD SeriesImanudinNessuna valutazione finora

- Proceco Eco-Smart MVRDocumento2 pagineProceco Eco-Smart MVRZlatko Partlič100% (1)

- Glycol Dehydration Systems BrochureDocumento2 pagineGlycol Dehydration Systems BrochureJenny BuchananNessuna valutazione finora

- Fluitec ccs218 1310r1Documento2 pagineFluitec ccs218 1310r1api-221802169Nessuna valutazione finora

- Drying Automatik PelletizerDocumento8 pagineDrying Automatik PelletizerSharad NaikNessuna valutazione finora

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceDa EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNessuna valutazione finora

- 310 011 SDocumento34 pagine310 011 SvigneshwaranmNessuna valutazione finora

- ADA FileDocumento34 pagineADA FileTanisha ShrivasNessuna valutazione finora

- Chameleon ChipDocumento2 pagineChameleon ChipChetan KumarNessuna valutazione finora

- Arduino - Wikipedia PDFDocumento70 pagineArduino - Wikipedia PDFJheremy BayonetaNessuna valutazione finora

- 4333105.56 Ledenvo Led ST 60w 757 Vs1 Osram-TrfDocumento12 pagine4333105.56 Ledenvo Led ST 60w 757 Vs1 Osram-TrfFathulNessuna valutazione finora

- Bipolar Junction Transistor ModelsDocumento21 pagineBipolar Junction Transistor ModelsecedepttNessuna valutazione finora

- Machine Translation: A Presentation By: Julie Conlonova, Rob Chase, and Eric PomerleauDocumento31 pagineMachine Translation: A Presentation By: Julie Conlonova, Rob Chase, and Eric PomerleauemailmynameNessuna valutazione finora

- 125 Tractor: (Specifications and Design Subject To Change Without Notice)Documento5 pagine125 Tractor: (Specifications and Design Subject To Change Without Notice)Gary LarsonNessuna valutazione finora

- Question Bank - PolyDocumento16 pagineQuestion Bank - Polyمحمود صابرNessuna valutazione finora

- 4 A Short History of Islamic Science From Genesis To Decline ShortversionDocumento24 pagine4 A Short History of Islamic Science From Genesis To Decline ShortversionKateryna KuslyvaNessuna valutazione finora

- Hybrid ModelDocumento9 pagineHybrid ModelanjulNessuna valutazione finora

- 20 - Low-Cycle Fatigue of Turbocharger Compressor Wheels Online Prediction and Lifetime ExtensionDocumento12 pagine20 - Low-Cycle Fatigue of Turbocharger Compressor Wheels Online Prediction and Lifetime ExtensionlochtayNessuna valutazione finora

- GGDocumento8 pagineGGGaurav SharmaNessuna valutazione finora

- New EM Quiz13Documento4 pagineNew EM Quiz13Singh KaranNessuna valutazione finora

- 02 Bateria 12V - 150AHDocumento2 pagine02 Bateria 12V - 150AHRafael AlvarezNessuna valutazione finora

- Total Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsDocumento14 pagineTotal Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsAhmad HidayahNessuna valutazione finora

- 1 - A Biomechanical Model To Predict Hand-Arm Vibration When UsingDocumento7 pagine1 - A Biomechanical Model To Predict Hand-Arm Vibration When Usingkamel atiiaNessuna valutazione finora

- Figure of MeritDocumento33 pagineFigure of MeritmuhammadmaihadisiNessuna valutazione finora

- Delamination With AbaqusDocumento13 pagineDelamination With AbaqusSchmetterling TraurigNessuna valutazione finora

- Vinco Lesson Plan CO2 2022 EditedDocumento8 pagineVinco Lesson Plan CO2 2022 EditedAdrianalover RescofanaticsNessuna valutazione finora

- Visvesvaraya Technological University: "Dijkstra'S Algorithm"Documento34 pagineVisvesvaraya Technological University: "Dijkstra'S Algorithm"RASHMINessuna valutazione finora

- 6991 1570 01a Symmetrix Catalogue English Lowres Tcm830-1777630Documento66 pagine6991 1570 01a Symmetrix Catalogue English Lowres Tcm830-1777630Jacky_LEOLEONessuna valutazione finora