Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HSMG 1

Caricato da

Kamlesh SanganiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HSMG 1

Caricato da

Kamlesh SanganiCopyright:

Formati disponibili

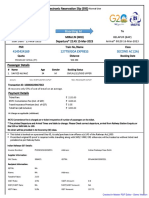

Vol.

High Speed

Machining Guide

OSG

Tap & Die, Inc.

Finishing

Roughing & Semi-Finishing

RPM

Diam.

RPM

Diam.

30-40 HrC

40-50 HrC

50-60 HrC

30-40 HrC

40-50 HrC

50-60 HrC

1/32

38,400-60,000

32,000-50,000

24,600-40,000

1/32

20,000-50,000

20,000-50,000

20,000-50,000

1/16

26,400-42,000

22,000-35,000

16,600-28,000

1/16

20,000-50,000

20,000-50,000

20,000-50,000

3/32

21,600-31,200

18,000-26,000

13,400-20,800

3/32

20,000-50,000

20,000-50,000

20,000-50,000

1/8

19,200-28.800

16,000-24,000

11,800-19,200

1/8

20,000-38,000

20,000-50,000

20,000-30,500

3/16

15,000-19,776

12,500-16,480

9,000-13,184

3/16

20,000-26,000

20,000-34,000

16,000-20,300

1/4

12,120-16,800

10,100-14,000

7,080-11,200

1/4

15,000-18,000

18,000-24,400

12,000-15,000

5/16

11,400-15,900

9,200-13,250

6,360-10,600

5/16

12,000-14,000

14,600-19,000

9,700-12,000

3/8

10,560-14,520

8,800-12,100

6,040-9,680

3/8

10,000-12,000

12,000-16,200

8,100-10,000

7/16

9,480-12,480

7,900-10,400

5,320-8,320

7/16

8,700-10,400

10,000-13,900

6,900-8,700

1/2

8,280-10,920

6,900-9,100

4,520-7,280

1/2

7,800-9,800

9,100-12,200

6,100-7,600

Chip Load per Tooth

50-60 HrC

40-50 HrC

30-40 HrC

Finishing

Rough & Semi

Rough & Semi

Finishing

Rough & Semi

Finishing

1/32

.0006-.0010

.0006-.0009

.0005-.0008

.0006-.0007

.0004-.0007

.0004-.0006

1/16

.0012-.0015

.0010-.0016

.0010-.0015

.0010-.0014

.0008-.0012

.0007-.0010

.0014-.0022

.0010-.0014

.0012-.0020

Diam.

3/32

.0020-.0025

.0014-.0024

.0015-.0020

1/8

.0025-.0030

.0019-.0028

.0020-.0027

.0019-.0026

.0015-.0020

.0017-.0022

.0030-.0040

.0030-.0039

.0023-.0031

3/16

.0035-.0042

.0032-.0043

.0032-.0041

1/4

.0050-.0060

.0040-.0053

.0050-.0057

.0040-.0051

.0040-.0050

.0038-.0048

.0052-.0063

.0051-.0062

.0046-.0054

5/16

.0063-.0070

.0053-.0068

.0053-.0066

3/8

.0070-.0080

.0062-.0079

.0062-.0077

.0054-.0065

.0060-.0072

.0050-.0061

.0060-.0078

.0066-.0080

.0053-.0070

.0070-.0090

.0078-.0090

.0062-.0081

.0068-.0086

1/2

.0087-.0100

.0080-.0094

.0080-.0092

Machining Tips

3.82 x SFM

Effective Diam.

RPM =

IPM = RPM x # Flutes x Chip Load

IPM

Chip Load =

(RPM x # Flutes)

Effective Diam. x RPM

3.82

SFM =

E.D. = 2 x (R2 (R Ad)2)

Use Helical Engagement in materials

above 40 HrC.

Ensure cusp left for next operation is

manageable.

Use two fluted end mills in all roughing

operations.

Balanced holders and tools are critical

when operating at 8000 RPM and above.

Ensure runout of cutting tool is less than

.0003 to get the best tool life.

LDR should be as short as possible.

Use Z-Level climb cutting for roughing

operations.

Use air for all applications except those

involving sticky materials such as stainless.

Formulas

Ad

.0080-.0087

Rd

7/16

.0068-.0084

30-40 HrC Axial depth = 10% of tool diameter

40-50 HrC Axial depth = 7% of tool diameter

50-60 HrC Axial depth = 5% of tool diameter

Radial depths can be up to 35%

of the cutter diameter for roughing

and semi-finishing operations.

Radial depths of cut for finishing

are determined by the surface finish

requirements unique to each application.

Just a few tools that could help you!

List 3 1 1 3 EXOCARB-HP 3m Radius Tolerance Ball End Mill

Features:

Benefits:

3m radius tolerance

OSG's patented multi-layered EXO coating

3m T.I.R. shank tolerance

Exceptional accuracy & fine finishes

Extended tool life over standard TiAlN coated tools

Extended tool life & T.I.R. accuracy at higher speeds

List 4510 EXOCARB-SHP WXS Ball End Mill

Features:

Benefits:

WXS nano coating technology

Higher oxidation temperature than TiAlN

Greater surface hardness than TiAlN

Permits higher SFM for reduced cycle times

Faster spindle speeds = faster feed rates

Longer life in hardened steels up to 70 HRC

List 7390 EXOCARB-Diamond

Rib Processing Ball End Mill for Graphite

Features:

Benefits:

Die Mold Series

OSG's patented multi-layered Diamond coating

Various reduced neck lengths

Tight tolerance for high accuracy milling

Extended tool life for non-ferrous materials such as Graphite,

Aluminum, and Copper Alloys

Greater versatility in long reach milling applications

List 9 1 1 2 EXOCARB-MAX Cermet Ball End Mill

Features:

Benefits:

Harder than carbide, for a stable cutting interface

OSG's patented multi-layered EXO coating

Mirror finishes under 40 HRC

Cutting edge retains shape longer under 40 HRC

Extended tool life over standard TiAlN coated tools

OSG TAP & DIE, INC.

676 E. Fullerton Avenue Glendale Heights IL 60139

800.837.2223 FAX: 800.837.3334 www.osgtool.com

Copyright 2006 OSG Tap & Die, Inc. All rights reserved. Printed in USA. EDP# 80059CA

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- VMA FCC ComplaintsDocumento161 pagineVMA FCC ComplaintsDeadspinNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Solved Acme Realty A Real Estate Development Company Is A Limited PDFDocumento1 paginaSolved Acme Realty A Real Estate Development Company Is A Limited PDFAnbu jaromiaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Basic Laws On The Professionalization of Teaching PD 1006 Edited Oct 11 2019Documento6 pagineBasic Laws On The Professionalization of Teaching PD 1006 Edited Oct 11 2019Renjie Azumi Lexus MillanNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- CA CHP555 Manual 2 2003 ch1-13Documento236 pagineCA CHP555 Manual 2 2003 ch1-13Lucas OjedaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 12779/GOA EXPRESS Second Ac (2A)Documento2 pagine12779/GOA EXPRESS Second Ac (2A)Altamash ShaikhNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Online Auction: 377 Brookview Drive, Riverdale, Georgia 30274Documento2 pagineOnline Auction: 377 Brookview Drive, Riverdale, Georgia 30274AnandNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- BACK EmfDocumento12 pagineBACK Emfarshad_rcciitNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Performance Bank Guarantee FormatDocumento1 paginaPerformance Bank Guarantee FormatSRIHARI REDDINessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Consti (Taxation)Documento2 pagineConsti (Taxation)Mayra MerczNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Tale of Education Policy in BangladeshDocumento13 pagineTale of Education Policy in BangladeshSammi bithyNessuna valutazione finora

- Sample IPCRF Summary of RatingsDocumento2 pagineSample IPCRF Summary of RatingsNandy CamionNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- ENTU NI 28 JuneDocumento4 pagineENTU NI 28 JuneZm KholhringNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Company Law-I Types of Company, (PPT No-8) PDFDocumento8 pagineCompany Law-I Types of Company, (PPT No-8) PDFAbid CoolNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 09-01-13 Samaan V Zernik (SC087400) "Non Party" Bank of America Moldawsky Extortionist Notice of Non Opposition SDocumento14 pagine09-01-13 Samaan V Zernik (SC087400) "Non Party" Bank of America Moldawsky Extortionist Notice of Non Opposition SHuman Rights Alert - NGO (RA)Nessuna valutazione finora

- Payroll in Tally Erp 9Documento13 paginePayroll in Tally Erp 9Deepak SolankiNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Topic 2Documento5 pagineTopic 2Karl Anthony Tence DionisioNessuna valutazione finora

- G.O.Ms - No.1140 Dated 02.12Documento1 paginaG.O.Ms - No.1140 Dated 02.12bksridhar1968100% (1)

- Eada Newsletter-May-2015 (Proof3)Documento2 pagineEada Newsletter-May-2015 (Proof3)api-254556282Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Soon Singh Bikar v. Perkim Kedah & AnorDocumento18 pagineSoon Singh Bikar v. Perkim Kedah & AnorIeyza AzmiNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Exception Report Document CodesDocumento33 pagineException Report Document CodesForeclosure Fraud100% (1)

- Carl Schmitt and Donoso CortésDocumento11 pagineCarl Schmitt and Donoso CortésReginaldo NasserNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- TM-9-2350-314-10-HR Μ109Α6Documento30 pagineTM-9-2350-314-10-HR Μ109Α6Thoukididis Thoukididou100% (1)

- SSC CGL Updates - Validity of OBC CertificateDocumento1 paginaSSC CGL Updates - Validity of OBC CertificateKshitijaNessuna valutazione finora

- RLW Midterms ExamDocumento7 pagineRLW Midterms ExamMatthew MadlangbayanNessuna valutazione finora

- Arvind Fashions Limited Annual Report For FY-2020 2021 CompressedDocumento257 pagineArvind Fashions Limited Annual Report For FY-2020 2021 CompressedUDIT GUPTANessuna valutazione finora

- Case Report Cirilo Paredes V EspinoDocumento2 pagineCase Report Cirilo Paredes V EspinoJordan ProelNessuna valutazione finora

- 24 Land Empires in The Age of ImperialsimDocumento8 pagine24 Land Empires in The Age of ImperialsimJonathan Daniel KeckNessuna valutazione finora

- LT Bill Dec16Documento2 pagineLT Bill Dec16nahkbceNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- HSN Table 12 10 22 Advisory NewDocumento2 pagineHSN Table 12 10 22 Advisory NewAmanNessuna valutazione finora

- Tecno Spark Power 2 Misty Grey, 64 GB: Grand Total 9999.00Documento2 pagineTecno Spark Power 2 Misty Grey, 64 GB: Grand Total 9999.00Lucky KumarNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)