Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SAP PP Master Data and Execution Configuration

Caricato da

Ankush ShahakarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAP PP Master Data and Execution Configuration

Caricato da

Ankush ShahakarCopyright:

Formati disponibili

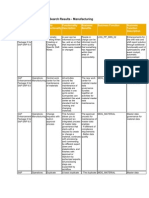

SAP PP Master Data Configuration

Configuration of every aspect of Bill of Materials including creation of Item Category,creation of BOM Usage, restricting item type plus all the other nuts and bolts of BOM creation/changes.Alternate BOM environment strategy also covered. Work Center Configuration explaining in detail the relevant fields selection, configuration of the very complex standard value key formula (an absolute winner), creating shift sequence plus all other related connects. All Aspects of Routing creation,configuration of usage for routing, indepth analysis of various user defined fields and its applicability to various transactions in SAP

SOP Configuration

Creation and Planning with product group Creation of Rough-cut planning profile Capacity check with rough-cut planning profile Disaggregation and aggregation of product group plan Configuration of activity to copy it into a different structure Version management Transferring of plan to Demand management Creation of Info structure Creation of planning type and planning hierarchy to create plan in flexible planning Configuration of Transfer profile. Version Management and transferring into Demand Management

SAP MRP and Production Planning Config

Configuration of MRP Plant parameter which describes the complete MRP related settings to operate with a new plant. Configuration of MRP type, and MRP Group

Configuration of Requirement type and Requirement Class - (A Virtual Treat and a critical element in PP as it links PP with SD Module) . Configuration of scheduling parameter for Planned orders Configuration of lot sizing procedure to control the grouping of requirements.

SAP Production Execution Configuration

Configuration of order type and defining number ranges to the order type Configuration of order type parameter which is an essential setting for PP processing Configuration of Scheduling parameter for production order - setting to determine the exact production start and end date as per the routing data and many more controls with respect to order scheduling. Confirmation parameter - controlling the sequence of confirmation, Back flush control through confirmation parameter. Defining the Back-flush error correction settings in confirmation parameter. Defining checking rule and scope of check - which is the heart of ATP setting . Defining the receipt and issue elements to be considered for ATP. Configuration of checking control - analysing in detail all the trigger points for production order creation.

SAP PP Reports

Report navigation - Helps you take baby steps to explore all the functions of the reporting structure. Order information reports - The Entire Gamet of reports based on order status, order release date and order confirmation status covered Performance of mass processing Product costing reports - (A Virtual Treat)

PP-PI

Defining Profile with Default Values

Assigning Material Types Defining Recipe Status and Usage Defining Priority Sequence for Automatic Recipe Selection Defining Order Types Defining Order Type Dependent Parameter and Number Ranges Process Management Transporting predefined characteristics Transporting predefined Message Categories Defining and set up control recipe destination Defining and Setting up Process Message Categories Defining Process Message Characteristics Defining and Setting up Message Destinations Defining Process Instruction Categories

Batch Mangement

Specifying Batch Level and Batch Activation Batch Status Management Internal Batch Assignment for Goods Receipt Maintaining Internal Batch Number Assignment Range Defining Batch Creation for Process Order Defining Batch Creation for Goods Movement Batch Valuation Batch Determination and Batch Check

Defining Process Order Access Sequence Setting Shelf Life Expiration Date and many more

SAP Quality Planning and Inspection Configuration

Configuration of Plant Parameter for Quality Management Configuration of control key - defining the payment control within quality management Configuration of Blocking reason - to restrict the vendor supply in case of quality deviation Defining catalogue type, configuration of valuation mode and sampling type Configuration of inspection type to define different types of inspection control Defining default values for inspection type - controls lot creation Configuration of Quality inspection for goods movement - responsible to create lot with respect to goods movement Defining inspection type for Plant Maintenance - important integration link with plant maintenance to inspect equipment and gauges

SAP Quality Notification & Certificate Configuration

Configuration of Notification type Configuration of screen selection and template for Notification type Defining Number Range for Notification Configuration of Notification Priority Configuration of Quality certificate type Defining the Data origin - Data to be picked up and to be printed in quality certificate is defined here plus all other integration points are included within.

Potrebbero piacerti anche

- ICAEW Advanced Level Case Study Question & Answer Bank July 2016 To November 2019Documento657 pagineICAEW Advanced Level Case Study Question & Answer Bank July 2016 To November 2019Optimal Management Solution100% (6)

- SAP Variant Configuration: Your Successful Guide to ModelingDa EverandSAP Variant Configuration: Your Successful Guide to ModelingValutazione: 5 su 5 stelle5/5 (2)

- Exam 500895 - PPMC - Senior Capstone - Excel SpreadsheetDocumento7 pagineExam 500895 - PPMC - Senior Capstone - Excel Spreadsheetshags100% (6)

- SAP-PP&QM FlowDocumento1 paginaSAP-PP&QM Flowcprathi100% (3)

- Case Study Royal Bank of CanadaDocumento10 pagineCase Study Royal Bank of Canadandgharat100% (1)

- Optimize SAP PP Production Planning ReportDocumento34 pagineOptimize SAP PP Production Planning ReportVamshisir40% (5)

- COHV Mass TECO Variant Processing OrdersDocumento4 pagineCOHV Mass TECO Variant Processing OrdersMangesh100% (1)

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyDa EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyValutazione: 4 su 5 stelle4/5 (6)

- SAP Service Management: Advanced ConfigurationDa EverandSAP Service Management: Advanced ConfigurationValutazione: 4.5 su 5 stelle4.5/5 (3)

- SAP Guide of Long Term PlanningDocumento21 pagineSAP Guide of Long Term PlanningDario Franco100% (1)

- PI sheet and X-Step integration for process industriesDocumento32 paginePI sheet and X-Step integration for process industriesswaroopsam100% (4)

- Steps in Implementation of SAP PPDocumento12 pagineSteps in Implementation of SAP PPVelavan Arumugam100% (1)

- PP BlueprintDocumento29 paginePP Blueprintsamta_nagarNessuna valutazione finora

- SAP MRP Configuration GuideDocumento31 pagineSAP MRP Configuration Guidekanicastillo80% (5)

- SAP PP-PI Process Flow DocsDocumento25 pagineSAP PP-PI Process Flow Docsjnsingh1234589% (27)

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesDa EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNessuna valutazione finora

- SAP PPPI - Process Management - Process Instructions and Process MessagesDocumento40 pagineSAP PPPI - Process Management - Process Instructions and Process MessagesNetrananda Nayak0% (1)

- For Proc IndustryDocumento9 pagineFor Proc IndustryZoltan KerekesNessuna valutazione finora

- SAP PP ConfigurationsDocumento7 pagineSAP PP ConfigurationsArvind Sharma100% (1)

- Full list of SAP PP Production Orders tcodesDocumento70 pagineFull list of SAP PP Production Orders tcodesdurga100% (1)

- SAP PPPI ConfigurationDocumento11 pagineSAP PPPI ConfigurationVenkat Chakri100% (2)

- PP Configuration TcodesDocumento6 paginePP Configuration TcodesVenkat ChakriNessuna valutazione finora

- SAP PP Training Material: ConfidentialDocumento13 pagineSAP PP Training Material: ConfidentialMahesh Kamdey100% (1)

- SAP - Capacity LevelingDocumento14 pagineSAP - Capacity LevelingLobo BoboNessuna valutazione finora

- PP Pi.2Documento47 paginePP Pi.2Sowmitri69Nessuna valutazione finora

- MRPDocumento135 pagineMRPpersonalmail_20011078Nessuna valutazione finora

- PP Implementation PDFDocumento52 paginePP Implementation PDFDebasish GhoshNessuna valutazione finora

- SAP PP Pointers To ReviewDocumento18 pagineSAP PP Pointers To Reviewivan_robie9328100% (1)

- SAP REM Full Cycle Scenario With Basic StepDocumento12 pagineSAP REM Full Cycle Scenario With Basic StepAjay KumarNessuna valutazione finora

- SAP PP - Capacity Planning ProcessDocumento5 pagineSAP PP - Capacity Planning ProcessKoustubha KhareNessuna valutazione finora

- SAP PP OverviewDocumento10 pagineSAP PP OverviewjayakumargjNessuna valutazione finora

- Repetitive ManufacturingDocumento14 pagineRepetitive ManufacturingAvinash Dondapaty100% (2)

- SAP PP-PI Process Flow Docs111Documento25 pagineSAP PP-PI Process Flow Docs111jnsingh123450% (1)

- Beginner's Guide For PI SheetsDocumento12 pagineBeginner's Guide For PI Sheetsshantanujana1988Nessuna valutazione finora

- SAP PP Customizing: IndexDocumento30 pagineSAP PP Customizing: IndexkjkdjfdodNessuna valutazione finora

- Unit Testing of Production Planning ModuleDocumento22 pagineUnit Testing of Production Planning ModuleVinoth Babu ViswanathanNessuna valutazione finora

- EHP5 Enhancements in PP ModuleDocumento8 pagineEHP5 Enhancements in PP ModulekiranmagarNessuna valutazione finora

- SAP REM Full Cycle Scenario With Basic Step: CommunityDocumento27 pagineSAP REM Full Cycle Scenario With Basic Step: CommunityVigneshNessuna valutazione finora

- Master Data Management in SAPDocumento60 pagineMaster Data Management in SAPFernando AFNessuna valutazione finora

- Sap PP Pi Process OrdersDocumento213 pagineSap PP Pi Process OrdersShailendra Rane100% (3)

- Rework Production OrderDocumento25 pagineRework Production Orderrvk386100% (2)

- SAP PP ConfiDocumento64 pagineSAP PP ConfiVy Nguyễn TườngNessuna valutazione finora

- MRP With HanaDocumento9 pagineMRP With HanaNeeraj KumarNessuna valutazione finora

- Rework Production OrderDocumento24 pagineRework Production Orderbalu4indiansNessuna valutazione finora

- SAP PP ContentsDocumento2 pagineSAP PP ContentsBhasker ECNessuna valutazione finora

- SAP PP Process BatchDocumento9 pagineSAP PP Process BatchvrkattulaNessuna valutazione finora

- Define Order Types and Order Dependent ParametersDocumento4 pagineDefine Order Types and Order Dependent ParametersRahul JainNessuna valutazione finora

- Sap PP Tcodes PDFDocumento32 pagineSap PP Tcodes PDFPRASAAD tripathyNessuna valutazione finora

- SAP QM WorrkshopDocumento48 pagineSAP QM WorrkshopRamhesh BabuNessuna valutazione finora

- PP-PI Process OverviewDocumento33 paginePP-PI Process OverviewLucilaNessuna valutazione finora

- SAP PPPI Process Industry Master Recipe SettingDocumento9 pagineSAP PPPI Process Industry Master Recipe SettingPradyot Kumar BhowmikNessuna valutazione finora

- Apo-Ppds Cookbook - 4Documento40 pagineApo-Ppds Cookbook - 4Rajanish MaddesiyaNessuna valutazione finora

- SAP Production VersionsDocumento3 pagineSAP Production VersionsRui AlmeidaNessuna valutazione finora

- Active Ingredient Management and Batch BalancingDocumento24 pagineActive Ingredient Management and Batch Balancingmrivo100% (1)

- Sap MRP ConfigurationDocumento31 pagineSap MRP ConfigurationtoralberNessuna valutazione finora

- Beginner's Guide to Browser-Based PI SheetsDocumento12 pagineBeginner's Guide to Browser-Based PI SheetsAmir AliNessuna valutazione finora

- SAp PP Pi StepsDocumento2 pagineSAp PP Pi StepsajithkbalanNessuna valutazione finora

- SAP Standard QM Report - SAP Blogs PDFDocumento8 pagineSAP Standard QM Report - SAP Blogs PDFVigneshNessuna valutazione finora

- Work Centre SapDocumento23 pagineWork Centre SapSimran KaurNessuna valutazione finora

- SAP - PP - Configurations XDocumento5 pagineSAP - PP - Configurations XCamran KhanNessuna valutazione finora

- Step-by-Step Guide to SAP PP Shop Floor ConfigurationsDocumento2 pagineStep-by-Step Guide to SAP PP Shop Floor ConfigurationsLin LandOneNessuna valutazione finora

- Customer equity value and lifetime revenue importanceDocumento10 pagineCustomer equity value and lifetime revenue importanceSniper ShaikhNessuna valutazione finora

- 1019989-Industrial Trainee-Publishing and Product License SupportDocumento2 pagine1019989-Industrial Trainee-Publishing and Product License SupportSravan KumarNessuna valutazione finora

- Glass Manufacture BrochureDocumento4 pagineGlass Manufacture BrochureCristian Jhair PerezNessuna valutazione finora

- BCBS 239 Compliance: A Comprehensive ApproachDocumento7 pagineBCBS 239 Compliance: A Comprehensive ApproachCognizantNessuna valutazione finora

- Ybn Fee 2019 2020Documento5 pagineYbn Fee 2019 2020SDPMIT SHUBH DIAGNOSTICSNessuna valutazione finora

- MKT 412 Lecture 12 - Crafting The Service EnvironmentDocumento34 pagineMKT 412 Lecture 12 - Crafting The Service EnvironmentEhsan Karim100% (1)

- Transfer Pricing of Tivo and Airbag Division: RequiredDocumento7 pagineTransfer Pricing of Tivo and Airbag Division: RequiredajithsubramanianNessuna valutazione finora

- DTC Agreement Between Cyprus and United StatesDocumento30 pagineDTC Agreement Between Cyprus and United StatesOECD: Organisation for Economic Co-operation and DevelopmentNessuna valutazione finora

- Marketing Mix and PricingDocumento11 pagineMarketing Mix and PricingDiveshDuttNessuna valutazione finora

- Tour Packaging & Sales StrategyDocumento20 pagineTour Packaging & Sales StrategyWhena RiosNessuna valutazione finora

- Case Study 1Documento5 pagineCase Study 1Abubakar MoazzamNessuna valutazione finora

- 02 Kanto Region (Kaigofukushishi) 12000017Documento4 pagine02 Kanto Region (Kaigofukushishi) 12000017bnp2tkidotgodotidNessuna valutazione finora

- Engleza in AfaceriDocumento293 pagineEngleza in Afacerililiana lilianaNessuna valutazione finora

- Final (BDSM) SimulationDocumento28 pagineFinal (BDSM) SimulationusmanNessuna valutazione finora

- Ackoff Systems ThinkingDocumento2 pagineAckoff Systems ThinkingLuiz S.Nessuna valutazione finora

- Marketing Research and MISDocumento20 pagineMarketing Research and MISMithun KanojiaNessuna valutazione finora

- LA Chief Procurement OfficerDocumento3 pagineLA Chief Procurement OfficerJason ShuehNessuna valutazione finora

- Abdulghany Mohamed CVDocumento4 pagineAbdulghany Mohamed CVAbdulghany SulehriaNessuna valutazione finora

- Leads Vs ReferralsDocumento1 paginaLeads Vs ReferralsDhanalakshmi chandramohanNessuna valutazione finora

- F.W.TAYLOR Father of scientific managementDocumento7 pagineF.W.TAYLOR Father of scientific managementTasni TasneemNessuna valutazione finora

- Pump and Dump - Print 1Documento7 paginePump and Dump - Print 1Zahid FaridNessuna valutazione finora

- Cathay Pacific v. VasquezDocumento2 pagineCathay Pacific v. Vasquezrgtan3Nessuna valutazione finora

- CRM Software Services IndiaDocumento1 paginaCRM Software Services IndiaSales MantraNessuna valutazione finora

- Amazon Service Marketing Case StudyDocumento36 pagineAmazon Service Marketing Case StudyAbhiNessuna valutazione finora

- Finance Class 04 - New With TestDocumento23 pagineFinance Class 04 - New With TestMM Fakhrul IslamNessuna valutazione finora

- Strengthen PECs in DressmakingDocumento1 paginaStrengthen PECs in DressmakingLeticia AgustinNessuna valutazione finora