Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A 0120105

Caricato da

IJERDDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A 0120105

Caricato da

IJERDCopyright:

Formati disponibili

International Journal of Engineering Research and Development ISSN: 2278-067X, Volume 1, Issue 2 (June 2012), PP. 01-05 www.ijerd.

com

Experimental Study of Cracking Behaviour for SFRC Beams without Stirrups with Varying A/D Ratio

Vinu R. Patel1, Nikunj S. Darji2, Dr. I.I.Pandya3

Assistant Professor, Applied Mechanics Department, Faculty of Technology and Engineering, M.S.University, Baroda. M.E. Structural Engineering, Applied Mechanics Department, Faculty of Technology and Engineering, M.S.University, Baroda. 3 Associate Professor, Applied Mechanics Department, Faculty of Technology and Engineering, M.S.University, Baroda.

2 1

AbstractPaper describes an experimental study for behavior of crack and modes of failure of SFRC (Steel Fiber Reinforced Concrete) deep beams & Moderate deep beams without stirrups having various shear span (a) to overall depth ratio (D). Eight nos. of SFRC simply supported beams having different depths of 300 mm, 400 mm, 500 mm and 600 mm were tested. We have used CCT (circular corrugated type) fibers in four beams and FCT (fibrillated corrugated type) fibers in another four beams. The span (overall span of 1300 mm, effective span of 1200 mm) and width (150mm) of all the beams were kept constant. Three cubes & three cylinders were cast as control specimen. Initiation or appearance and proportion of behavior of crack and mode of failure of beams were noted. We conclude that SFRC moderate deep beams with a/D ratio<1and were failed in shear mode so they are shear predominant members which is brittle in nature. The beams having a/D ratio ranging from 1to2.5 were failed in both shear and flexure. The beams having a/D ratio more than 2.5 failed in pure flexure. KeywordsModerate deep beam ; Crack patterns; crack width; shear mode failure.

I. INTRODUCTION

Remarkable improvements in elastic modulus, tensile strength, crack resistance, crack control, durability, fatigue resistance, impact resistance, abrasion resistance etc., resulted in FRC (Fiber Reinforced Concrete) material, which arrived as a boon to overcome the drawbacks of steel-reinforced concrete. Over this short time-span, FRC has proved its worth as an economic and useful construction material for its ease of application. Varied types of synthetic fibers, acrylic, carbon, nylon, polyester, polyethylene, and polypropylene fibers apart from steel have found their way in forming FRC. Also, the fibers can prevent excessive diagonal tensile cracking and localization of the tensile crack damage. Therefore, the fibers can increase the effective stiffness of the beam after diagonal tensile cracking occurs and can decrease the deflection of the beam. Concrete has the disadvantage that it fails in a brittle manner. The fibers can make the failure mode more ductile by increasing the tensile strength of concrete. As a result, the structural performance of concrete can be maximized. The fiber reinforced concrete has found many interesting field applications such as bridge decks, highways, pavements for air fields, slope stabilizing in mining and tunneling, industrial flooring etc. The application of fibers to reinforced concrete structural members would be one of the major areas of use in structural engineering. The fibers to reinforced concrete have got an exciting future in construction in days ahead. IS 456: 20001, along with other various codes of different countries, classifies the beam into three categories; namely normal beam, moderate deep beam, and deep beam, according to their span to depth ratios. In general, it can be classified as, 1) Deep beams (a/D1.0 ) 2) Moderate deep beams (1.0 a/D 2.5) 3) Shallow beams (a/D> 2.5). Looking to the wide use of moderate deep beam in various important structures such as nuclear reactors, water tanks, halls, hotels, complex foundations, offshore structures, corbels etc. An attempt has been made through the study to understand cracking behavior of such beams under fibrous matrix.

II.

OBJECTIVES

Increasing use of Fiber based composites in engineering construction has made it important to understand the behavior of these structural materials. The fibers to reinforced concrete have got an exciting future in construction in days ahead. The objective of the present experimental investigation was to provide a systematic and comprehensive comparative study on the first Crack load, ultimate load, as well as modes of failure of SFRC moderate deep beam for varying a/D ratio.

Experimental Study of Cracking Behaviour for SFRC Beams without Stirrups

EXPERIMENTAL PROGRAMME:

Test materials: Pozzolona Portland Cement of 53 grade, natural river sand having fineness modulus of 2.8 and maximum size of 4.75 mm as a fine aggregate, and natural basalt gravel of maximum size 20mm as coarse aggregate were used. The concrete mix proportion was 1:1.5:3.0 (cement: fine aggregate: coarse aggregate) by weight with water cement ratio of 0.45 kept constant for all beams. While in SFRC beams, Circular corrugated steel fibers of length 50 mm, aspect ratio 80, equivalent diameter 0.625 mm, and 1% by volume of concrete were used. Two types of fibers namely CCT (Circular corrugated type) and FCT (Flat corrugated type) were used in SFRC beams. All beams were provided with anchor bars along with nominal HYSD bars of 0.3% as main longitudinal tension reinforcement (Table 1). In this experiment we didnt provide the web reinforcement. There were series of beams and for each series three cubes (150mm diameter) and three cylinders (150 mm diameter and 300 mm height) were cast as control specimens. All specimens were cured at least for 28 days. SPECIMEN DETAILS: The test specimens consist of 8 nos. moderate deep beams & deep beams divided in series having different depths of 300 mm, 400 mm, 500 mm and 600 mm with three beams in each series. The span and width of all the beams were kept constant having overall span of 1300 mm, effective span of 1200 mm and width of 150 mm. All the beams were kept simply supported and tested under two equal points loading each at a distance of of effective span (i.e. 400 mm) from the support, so that each beam is divided into three equal zones having center zone subjected to constant flexure and two outer zones subjected to constant shear throughout the zone. And also tested under center point load effective span (i.e. 600mm) from support, so each beam is divided into two equal zones. Centre part subjected to flexure and end parts subjected to shear. After the completion of curing period; surface of specimen was made smooth by removing projections if any. All the beams were white washed to easily visualize the marking on the surface of beam and the cracks on the surface of beam during testing. Notations of beams and a/D ratios were written on the surface of the beam at right corners for identification. To avoid stress concentration, and to keep bearing stresses within permissible limit to avoid crushing of concrete at the points of load application and at the points of support, 6 mm thick steel plates having dimensions 150 mm 100 mm were provided in beams. Looking to the wide use of moderate deep beam in various important structures such as nuclear reactors, water tanks, halls, hotels, complex foundations, offshore structures, corbels etc. An attempt has been made through the study to understand cracking behavior of such beams under fibrous matrix as they predominantly fail under shear. OBJECTIVES: Increasing use of Fiber based composites in engineering construction has made it important to understand the behavior of these structural materials. The fibers to reinforced concrete have got an exciting future in construction in days ahead. The objective of the present experimental investigation was to provide a systematic and comprehensive comparative study on the first Crack load, ultimate load, as well as modes of failure of SFRC moderate deep beam for varying a/D ratio.

III. DISCUSSION OF TEST RESULTS

Behavior of Cracks, their Patterns, Propagation, and Modes of Failure In all the beam specimens, initiation of flexure cracks was from the bottom of the beams. In most of the cases, all the flexure cracks were almost vertical, while most of the shear cracks were inclined and their direction of propagation was towards the nearest load point irrespective of its place of origin. Beams with a/D ratio greater than 2.5 failed in pure flexure failure by yielding of longitudinal tensilereinforcement. Size and propagation of the flexure cracks were noticeable, while shear cracks were few and very fine. Majority of flexure cracks propagated beyond height of the beam and were considerably wide at the bottom. Beams having a/D ratio between 1 to 2.5 are failing due to both flexure and shearmode. The phenomenon of all of a sudden formation of major diagonal shear cracks emerging from D/3 toD/4 height of the beam from bottom and its rapid propagation towards the nearest load and support point; was firstly seen in beams of a/D ratio varying from 1 to 2.5.Although, the shear cracks were comparable to flexure cracks .The ultimate failure of all the beams was due to the yielding of the longitudinal tensile reinforcement. Beams with a/D ratio less than 1failed in pure shear failure. Flexure cracks were few and very fine, and hardly reached up to the mid height of the beam, while shear cracks were noticeable in size and its propagation covered more than height of the beam. After sudden formation of major diagonal shear cracks beam sustained some more load before ultimate failure, which shows its reserve strength.

Experimental Study of Cracking Behaviour for SFRC Beams without Stirrups

The mechanism of shear cracking in moderate deep beams is conceived as resulting from a modification of the internal force system, accompanied by associated deformations consistent with the altered geometry of the members after flexural cracks form. Table: - 1 Reinforcement Details

Table 2: COMPARISOCOMPARISON TABLE FOR MAXIMUM CRACKWIDTH BY VARYING a/D RATIO.

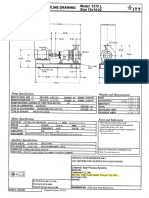

Fig. 1 TEST SETUP FOR 2 POINT LOADING.

LOAD POINT FORM

BEAM

DIAL GAUGES

Experimental Study of Cracking Behaviour for SFRC Beams without Stirrups

FCL: - 19.4

UL: - 53.20T

a/D=1.33

Fig:-2 D 30-S 0.0-SFRC(FCT)-2P

FCL: - 11.5T

UL: - 23.5T

a/D=1

Fig:-3 D 40-S 0.0-SFRC(FCT)-2P FCL: -15T UL: - 39.75a/D=0.8

Fig:-4 D 50-S 0.0-SFRC(FCT)-2P

FCL: - 17.60TUL: - 53.90

a/D=0.66

Fig:-5 D 60-S 0.0-SFRC(FCT)-2P

FCL: -5.0TUL: - 10.90

a/D=2.0

Fig:-6 D 30-S 0.0-SFRC(CCT)-1P FCL: -8.5TUL: - 16.90 a/D=1.50

Fig:-7 D 40-S 0.0-SFRC(CCT)-1P

Experimental Study of Cracking Behaviour for SFRC Beams without Stirrups

FCL: -8.90 TUL: - 27.30a/D=1.20

Fig:-8 D 50-S 0.0-SFRC(CCT)-1P

FCL: -20.50TUL: - 43.7

a/D=1.0

Fig:-9 D 60-S 0.0-SFRC(CCT)-1P FIGURES OF BEAMS SHOWING CRACKS WITH VYRING a/D RATIO

IV. CONCLUSIONS

Based on the results of this study, the following conclusions were drawn: The evaluation indicated that SFRC beams with a/D ratio less than 1 are shear predominant members and generally fails in shear mode which is brittle in nature and having a/D ratio between 1 to 2.5 are failing due to both flexure and shear. SFRC Beams with a/D ratio greater than 1 are flexure predominant member and fails in flexure mode.

V.

ACKNOWLEDGEMENTS

The authors of this paper are expressing thankfulness to the engineering and technical staff of Applied Mechanics Testing Department at the Faculty of Technology & Engineering, M.S. University Baroda, in performing of the experimental testing.

REFERENCES

[1]. [2]. [3]. [4]. [5]. Kong, F. K(1990), Reinforced Concrete Deep Beams, first edition, Blackies and son Ltd., Glasgow and London, Published by van Nostrand Reinhold, New York. Patel, S. N., and Damle, S. K (1976), Behavior of Reinforced Concrete deep Beams in flexure and shear, PhD Thesis, The M. S. University of Baroda. Kim Woo, and White, Richard N(1991), Initiation of Shear Cracking in Reinforced Concrete Beams with No Web Reinforcement, Title no.88-S32, ACI Structural Journal, V. 88, No. 3, pp. 301-308. Kotsovos, Michael D., Behavior of Reinforced Concrete Beams with a shear span-to-Depth Ratio Between 1.0 and2.5, Title no. 81-27, ACI Journal, V. 81, No. 3, May-June 1984, pp. 279-286. IS-456 (2000) Plain and Reinforced Concrete Code of Practice, Fourth Revision, Bureau of Indian Standards (BIS 2000), Fifth Reprint August 2002.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Router 1X3 - RTL Design and VerificationDocumento10 pagineRouter 1X3 - RTL Design and VerificationIJERDNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Moon-Bounce: A Boon For VHF DxingDocumento5 pagineMoon-Bounce: A Boon For VHF DxingIJERDNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Biomimicry in ArchitectureDocumento10 pagineBiomimicry in Architecturerodolfo barbosaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Investigations On Properties of Light Weight Cinder Aggregate ConcreteDocumento10 pagineInvestigations On Properties of Light Weight Cinder Aggregate ConcreteIJERDNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Emotion Detection From TextDocumento12 pagineEmotion Detection From TextIJERDNessuna valutazione finora

- Moisture DeterminationDocumento3 pagineMoisture DeterminationSamuel PelayoNessuna valutazione finora

- Gate 2004Documento8 pagineGate 2004Shailendra Mishra100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- 03 Structural AuditDocumento94 pagine03 Structural AuditAnupriya T MNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Glazed Alum Curtain Wall - Vendors ListDocumento3 pagineGlazed Alum Curtain Wall - Vendors ListKiran Kumar AkulaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- App 10093Documento9 pagineApp 10093Omkar BordeNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Four Probe MethodDocumento5 pagineFour Probe MethodSarthakJainNessuna valutazione finora

- Practical Rheology HandbookDocumento120 paginePractical Rheology Handbookkseshu100% (2)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Heat Transfer RevisedDocumento26 pagineHeat Transfer Revisedpriyanka236Nessuna valutazione finora

- Sugar Industry: Presented by Aparna Prasenan Enroll. No.-12519001Documento41 pagineSugar Industry: Presented by Aparna Prasenan Enroll. No.-12519001Jasdeep SinghNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Precipitation Module (TC-PRISMA) User Guide. Thermo-Calc Version 2018aDocumento111 paginePrecipitation Module (TC-PRISMA) User Guide. Thermo-Calc Version 2018aamanai.gupta98Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Titrimetric Methods of AnalysesDocumento10 pagineTitrimetric Methods of AnalysesJason BakerNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Recent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4Documento12 pagineRecent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4sebjangNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Pru ReportDocumento70 paginePru ReportAravind MenonNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- ConstructionDocumento63 pagineConstructionpulilathaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Steel HandbookDocumento276 pagineSteel HandbookYu chung yin100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- NDT Method SummaryDocumento3 pagineNDT Method SummaryNguyen Anh TungNessuna valutazione finora

- MSENSE® DGA 9 Technical Data 03 2021 enDocumento4 pagineMSENSE® DGA 9 Technical Data 03 2021 enTa Huy CuongNessuna valutazione finora

- Physicochemical Surface Modification of Materials Used in MedicineDocumento19 paginePhysicochemical Surface Modification of Materials Used in MedicineLopez Cons Ivana ValeriaNessuna valutazione finora

- Aisi 4140 En8 En19Documento1 paginaAisi 4140 En8 En19Jose KurianNessuna valutazione finora

- Atom, Molekul, Dan IonDocumento28 pagineAtom, Molekul, Dan IonFelix V SNessuna valutazione finora

- Shear Stress - 2D Pure ShearDocumento2 pagineShear Stress - 2D Pure Shearcena3135Nessuna valutazione finora

- Major Items of Supply Proposed Manufacturers NationalityDocumento1 paginaMajor Items of Supply Proposed Manufacturers NationalityAvinash Lal100% (1)

- Canning of FoodDocumento4 pagineCanning of Foodkolita kamalNessuna valutazione finora

- 0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantDocumento35 pagine0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantzufriateguiNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Corrosion Science: M.J. Muñoz-Portero, J. García-Antón, J.L. Guiñón, R. Leiva-GarcíaDocumento11 pagineCorrosion Science: M.J. Muñoz-Portero, J. García-Antón, J.L. Guiñón, R. Leiva-GarcíaFadli IkhsanNessuna valutazione finora

- Fire ExtinguisherDocumento21 pagineFire ExtinguisherAbdulrahman JradiNessuna valutazione finora

- A Comprehensive Review of Recent Advances On Surfactant Architectures and Their Applications For Unconventional ReservoirsDocumento47 pagineA Comprehensive Review of Recent Advances On Surfactant Architectures and Their Applications For Unconventional ReservoirsRuth Santos NaranjoNessuna valutazione finora

- SM-204-TechReport 01 2022 AnsichtDocumento4 pagineSM-204-TechReport 01 2022 AnsichtDanny DoanNessuna valutazione finora

- Model 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationDocumento6 pagineModel 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationJavier Fernando Agudelo GómezNessuna valutazione finora

- Makrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsDocumento2 pagineMakrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsAbdelmajid HmNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)