Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PCB Capabilities

Caricato da

atsushi885Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PCB Capabilities

Caricato da

atsushi885Copyright:

Formati disponibili

TRIANGLE CIRCUITS OF PITTSBURGH MANUFACTURING PROCESS CAPABILITIES AND TOLERANCES >>> Now ITAR Registered<<<

LAMINATES RoHS Compliant - EU Directive 2002/95/EC

CTI 175 130 - 170Tg Rogers 4350B series

SOLDERMASK TYPE

Liquid Photoimageable (LPI) 0.004 Minimum Solder Dam Web IPC-SM-840 Class 2 and 3

NEMA FR-4 / IPC-4101/21/24/26 UL796 DSR and 94V-0 Rated External Base Copper - 0.5 to 6.0 oz. Internal Base Copper - 0.5 to 3.0 oz.

ANNULAR RING REQUIREMENTS FOR SOLDERMASK

(TO ACHIEVE A NO MASK ON PADS CONDITION) Liquid Photoimageable Minimum Annular Ring = 0.003"

STANDARD BOARD THICKNESS & TOLERANCE

PER IPC-4101 class B par. 3.8.4.2 (glass to glass) .020 +/- .003 .093 +/- .007 .031 +/- .004 .125 +/- .009 .062 +/- .005

LAYER-TO-LAYER REGISTRATION

Films generated by Triangle CAM system = +/- 0.003" Other films = +/- 0.005"

BOARD FLATNESS PER IPC-6012 par. 3.4.4 SURFACE MOUNT PRODUCT 0.75% of PCB diagonal measurement = 0.0075 inch / inch ALL OTHER PRODUCT 1.5% of PCB diagonal measurement = 0.015 inch / inch STANDARD CORE DIELECTRIC SELECTION .005, .008, .014, .021, .028 Other sizes, special order MAXIMUM NUMBER OF LAYERS = 14 Blind and Buried vias available CONDUCTOR WIDTH, SPACING AND THICKNESS TOLERANCES FOR FINISHED PRODUCT

PER IPC-6012 pars. 3.5.1, 3.5.2, 3.5.3 Conductor width not to exceed 20% reduction from original films. Conductor spacing not to exceed 20% reduction from original films. Conductor thickness not to exceed 20% reduction from required finished thickness ( inclusive of base copper and copper plating)

ANNULAR RING REQUIREMENTS

(TO ACHIEVE IPC-A-600 CLASS 3 - NO BREAKOUT) Minimum = 0.008" (TO ACHIEVE IPC-A-600 CLASS 2 - 90 DEG. BREAKOUT) Minimum = 0.004"

HOLE LOCATION TOLERANCES

PER IPC-2615 12 inches or less = +/- 0.003" Over 12 inches = +/- 0.004"

LOCATION TOLERANCES FOR CUTOUTS, SLOTS AND NOTCHES

PER IPC-2615 12 inches or less = +/- 0.006" Over 12 inches = +/- 0.008"

FINAL OUTSIDE BOARD DIMENSIONAL TOLERANCES

PER IPC-2615 +/- 0.005"

MINIMUM FINISHED HOLE DIAMETER

Plated through holes = 0.006" Nonplated through holes = 0.009"

MINIMUM CONDUCTOR WIDTH / SPACE

(As measured on original film) Line Width = 0.004 Space = 0.004"

FINISHED HOLE DIAMETER TOLERANCE FOR NONPLATED HOLES PER IPC-2615

0.010 - 0.032" 0.033 - 0.063" 0.064 - 0.250" Over 0.250" Tol. = +/- 0.002" Tol. = +/- 0.003" Tol. = +/- 0.004" Tol. = +/- 0.005"

MINIMUM SURFACE MOUNT PITCH = 0.019" STANDARD PLATING THICKNESS

COPPER = 0.001" - 0.002" SOLDER = Coverage and Solderable to J-STD-003 NICKEL = 50 - 200 micro inches HARD GOLD = 30 - 80 micro inches Knoop = 120 - 200 IMMERSION GOLD (ENIG) per IPC-4552 Knoop = < 90 IMMERSION WHITE TIN = 60 micro inches IMMERSION SILVER per IPC-4553

FINISHED HOLE DIAMETER TOLERANCE FOR PLATED HOLES PER IPC-2615

0.008 - 0.032" 0.033 - 0.063" 0.064 - 0.250" Over 0.250" Tol. = +/- 0.003" Tol. = +/- 0.004" Tol. = +/- 0.005" Tol. = +/- 0.006"

ALTERNATIVE SURFACE COATINGS KEYWAYS

Minimum - 0.031 Enthone OSP - ENTEK PLUS Lead Free HASL Immersion White Tin Immersion Gold (ENIG) and Hard Gold Immersion Silver

INTERNAL SLOTS

Minimum - 0.031

QUALITY SYSTEM STANDARDS

ISO-9001-2000 Registered by QMI, ANAB ACCEPTABILITY CRITERIA IPC-A-600 (latest revision) Class 2 and 3 PERFORMANCE SPECIFICATION IPC-6012 (latest revision) Class 2 and 3 UL 796, 94V-0 File# E76719M (see page 2) CERTIFICATIONS AND REPORTS AVAILABLE Base laminates to IPC-4101 EDAX, SEM by request Microsection evaluation Impedance Thermal stress evaluation AA unit Electrical Test to IPC-9252 Ionic Contamination to IPC-6012 Solderability to J-STD-003 Xray Fluorescence and Capacitance plating thickness

ELECTRICAL TEST CAPABILITIES

Gerber Netlist testing standard Comparison to IPC-356A Single or Dual sided simultaneous, fine pitch (15 mil) surface mount. Everett Charles Trace 9090 dual grid Tester Mania Flying Probe Tester Probot Series 6D Flying Probe Tester TEST RANGES Continuity Resistance = 50 - 10K Ohm Isolation Resistance = 0 - 100 Megohms Voltages = 0 - 250 VDC STANDARD 50 Ohms 2M Ohms 100 VDC

Controlled Impedance +/- 10% THIS CHART REPRESENTS OUR STANDARD MANUFACTURING PROCESS CAPABILITIES AND TOLERANCES. TIGHTER TOLERANCES ARE AVAILABLE WITH PRIOR MANUFACTURING APPROVAL.

Production Manager: ________________________

Form MFF040-8

QA/Engineering Manager: ______________________ Date: ___________

Page 1 of 2 (over)

TRIANGLE CIRCUITS OF PITTSBURGH MANUFACTURING PROCESS CAPABILITIES AND TOLERANCES

UNDERWRITERS LABORATORIES APPROVALS - FILE NUMBER E76719

Conductor Minimum Thickness Total Int. Ext. PCB Max. Min. Thickness 0.0007" 0.025" 0.0042" 0.0007" 0.055" 0.0042" 0.00034" 0.020" 0.0042 0.00034 0.020

Designation 1-0 5-0 5-1 M-1

PCB Type S/D sided Multilayer Multilayer Multilayer

Solder Temp Time 260C 15 sec. 260C 15 sec. 274C 15 sec. 274C 15 sec.

Min. Width 0.004" 0.004" 0.004 0.004

Conductor Max. Area Dia. 3.0" 3.0" 3.0" 3.0

Min. Edge Width 0.004" 0.004" 0.004" 0.004

Max. Operating Temp 130C 105C 130C 130C

UL 94 Rating 94V-0 94V-0 94V-0 94V-0

Meets UL796 DSR ALL ALL ALL ALL

Form MFF040-8

Page 2 of 2

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- ACPL312TDocumento18 pagineACPL312Tcms_saNessuna valutazione finora

- Brochure Mercotac PDFDocumento8 pagineBrochure Mercotac PDFRoderikus Rendy MNessuna valutazione finora

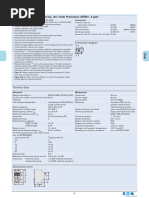

- Datasheet - NZMN3-AE630: Part No. Article No. Catalog NoDocumento12 pagineDatasheet - NZMN3-AE630: Part No. Article No. Catalog NoConstantin UdreaNessuna valutazione finora

- SD40ADocumento2 pagineSD40AaquilesreinaNessuna valutazione finora

- Air Circuit BreakerDocumento13 pagineAir Circuit BreakercjtagayloNessuna valutazione finora

- MIC6A10 Diode DatasheetDocumento2 pagineMIC6A10 Diode DatasheetTI IgnitorsNessuna valutazione finora

- High-Linearity Analog Optocouplers: Technical DataDocumento19 pagineHigh-Linearity Analog Optocouplers: Technical DataBui Minh SinhNessuna valutazione finora

- ACB - AH TypeDocumento4 pagineACB - AH Type4usangeet50% (2)

- An 10005Documento4 pagineAn 10005ClenaNessuna valutazione finora

- Item Conductive Tile Static-Disiipative TileDocumento3 pagineItem Conductive Tile Static-Disiipative Tilebheemannadora sappaNessuna valutazione finora

- 38man SensorDocumento40 pagine38man SensorMohamed ElsayedNessuna valutazione finora

- CEM Data SheetDocumento1 paginaCEM Data SheetBiswajit Debnath OffcNessuna valutazione finora

- 1.225V Micropower Shunt Voltage Reference: DescriptionDocumento9 pagine1.225V Micropower Shunt Voltage Reference: DescriptionRicardo MosqueiraNessuna valutazione finora

- DSS41A05Documento7 pagineDSS41A05petrovi482Nessuna valutazione finora

- DRC Packaged Encoders SST Data SheetDocumento4 pagineDRC Packaged Encoders SST Data SheetElectromateNessuna valutazione finora

- Loc 110Documento6 pagineLoc 110Freezer Aurelio Pinto ParedesNessuna valutazione finora

- Datasheet Accelero 2210Documento3 pagineDatasheet Accelero 2210Vinna SeptianaNessuna valutazione finora

- Temporary Specification For ReferenceDocumento8 pagineTemporary Specification For ReferencevijayNessuna valutazione finora

- PCB Connectors: Series 851Documento4 paginePCB Connectors: Series 851Neil Benbin BarteNessuna valutazione finora

- 2W005G THRU 2W10G: Reverse Voltage - 50 To 1000 Volts Forward Current - 2.0 AmperesDocumento3 pagine2W005G THRU 2W10G: Reverse Voltage - 50 To 1000 Volts Forward Current - 2.0 AmperesAdriana QuimbitaNessuna valutazione finora

- LC0406FC3.3C LC0406FC36C: ApplicationsDocumento6 pagineLC0406FC3.3C LC0406FC36C: ApplicationsselocaNessuna valutazione finora

- Wire Spec 44 PDFDocumento5 pagineWire Spec 44 PDFAdnan khanNessuna valutazione finora

- HS25 Incremental EncoderDocumento4 pagineHS25 Incremental Encoderoswaldo58Nessuna valutazione finora

- Vacuum Gauges 45Documento20 pagineVacuum Gauges 45Sameeksha AnandNessuna valutazione finora

- Finder 16A 12V DC Relay Datasheet.Documento10 pagineFinder 16A 12V DC Relay Datasheet.velizarkoNessuna valutazione finora

- 1.8-V, Micropower, Cmos Operational Amplifiers, Zero-Drift SeriesDocumento33 pagine1.8-V, Micropower, Cmos Operational Amplifiers, Zero-Drift SeriesRicky CoxNessuna valutazione finora

- OPA335Documento32 pagineOPA335Mafer Ruiz EstudilloNessuna valutazione finora

- Burgess m2 v3Documento14 pagineBurgess m2 v3AlexanderNessuna valutazione finora

- Tdoct2014b EngDocumento2 pagineTdoct2014b Engmahmoud abuelmgdNessuna valutazione finora

- 06 Pomocni Sklopnici I RelejiDocumento55 pagine06 Pomocni Sklopnici I Relejiaksiom007Nessuna valutazione finora

- Datasheet - NZMN3-AE630: Part No. Article No. Catalog NoDocumento12 pagineDatasheet - NZMN3-AE630: Part No. Article No. Catalog Nosampath sarangaNessuna valutazione finora

- Relay PDFDocumento6 pagineRelay PDFankursharma17Nessuna valutazione finora

- 6008 SERIES: Standard Product OfferingDocumento2 pagine6008 SERIES: Standard Product OfferingSezgin BayrakNessuna valutazione finora

- 2Kbp005M Thru 2Kbp10M Series 3N253 THRU 3N259: Glass Passivated Single-Phase Bridge RectifierDocumento3 pagine2Kbp005M Thru 2Kbp10M Series 3N253 THRU 3N259: Glass Passivated Single-Phase Bridge Rectifierjavier258Nessuna valutazione finora

- 220kV Subsattion.Documento20 pagine220kV Subsattion.sanju0156100% (1)

- 200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CDocumento9 pagine200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CselocaNessuna valutazione finora

- 2N6027Documento9 pagine2N6027mariogizziNessuna valutazione finora

- 000-I-Ts-102 - DS - 2 PitDocumento42 pagine000-I-Ts-102 - DS - 2 PitCristian RománNessuna valutazione finora

- CA2KN22P7 DocumentDocumento2 pagineCA2KN22P7 DocumentRavi SankarNessuna valutazione finora

- Air Circuit Breakers - AH TypeDocumento12 pagineAir Circuit Breakers - AH TypeSanjay JoshiNessuna valutazione finora

- 4N39 40Documento8 pagine4N39 40cagh21Nessuna valutazione finora

- ERL Metal Film Resistors, Military/Established Reliability, MIL-PRF-39017 Qualified, Type RLRDocumento3 pagineERL Metal Film Resistors, Military/Established Reliability, MIL-PRF-39017 Qualified, Type RLRSatÁnNessuna valutazione finora

- Catalogo Er70s3Documento3 pagineCatalogo Er70s3upedro26Nessuna valutazione finora

- Optical Con Field Assembly - Technical Info v1.0Documento14 pagineOptical Con Field Assembly - Technical Info v1.0Mariano AcostaNessuna valutazione finora

- Hcmos Compatible, High CMR, 10 MBD OptocouplersDocumento16 pagineHcmos Compatible, High CMR, 10 MBD Optocouplersnithinmundackal3623Nessuna valutazione finora

- 511 Pressure TransmitterDocumento5 pagine511 Pressure TransmitterDhp CiaNessuna valutazione finora

- CAT L-200 20 Switches Pages 613-654Documento42 pagineCAT L-200 20 Switches Pages 613-654Miguel Angel Beltran VelazquezNessuna valutazione finora

- Pressure Control BrochureDocumento12 paginePressure Control Brochurebkpaul3107Nessuna valutazione finora

- FN 7925Documento14 pagineFN 7925praveen_banthiNessuna valutazione finora

- Eaton Afdd Catalog Tech en UsDocumento4 pagineEaton Afdd Catalog Tech en UsjenelbNessuna valutazione finora

- RCB600 :: ROAL Living EnergyDocumento10 pagineRCB600 :: ROAL Living EnergyroalscribdNessuna valutazione finora

- 3 KTA DesignguideDocumento32 pagine3 KTA Designguideodin_auerNessuna valutazione finora

- HTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistors - OA (English)Documento4 pagineHTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistors - OA (English)crplzNessuna valutazione finora

- 1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 AmperesDocumento2 pagine1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 Amperesjsalinas78Nessuna valutazione finora

- 56 SDMS 01Documento14 pagine56 SDMS 01Ayman SaberNessuna valutazione finora

- Hydrogen-Related R&D - DTU Wind - Nov 2023Documento29 pagineHydrogen-Related R&D - DTU Wind - Nov 2023gisele.goesNessuna valutazione finora

- Monitor LG M227wap-Pm (LCD)Documento32 pagineMonitor LG M227wap-Pm (LCD)Ryan Brady0% (1)

- Operating Instructions 4427, 4428, 4429.: Always On The Safe SideDocumento14 pagineOperating Instructions 4427, 4428, 4429.: Always On The Safe SideMxScribdNessuna valutazione finora

- Pw5 Transformer v1Documento5 paginePw5 Transformer v1Hairul Anuar MasrolNessuna valutazione finora

- f77 f55 User Manual PDFDocumento180 paginef77 f55 User Manual PDFGabi GabrielNessuna valutazione finora

- High Power LASERDocumento22 pagineHigh Power LASERVIJEESH PNessuna valutazione finora

- TM - 5ce - 2016Documento48 pagineTM - 5ce - 2016Jf OngNessuna valutazione finora

- Unops JMPC 00085788 Itb Elec Works LoadschedDocumento97 pagineUnops JMPC 00085788 Itb Elec Works LoadschedAlerick VelascoNessuna valutazione finora

- Project 2011 Spring VLSIDocumento14 pagineProject 2011 Spring VLSIstarstarstar123Nessuna valutazione finora

- 1.1 Background of The StudyDocumento5 pagine1.1 Background of The StudyKarlyn CalimponNessuna valutazione finora

- Electronic Dice Using At89C2051: IdeasDocumento2 pagineElectronic Dice Using At89C2051: IdeaschakralabsNessuna valutazione finora

- Mod. SMK/EV: Solar Energy Mini LaboratoryDocumento2 pagineMod. SMK/EV: Solar Energy Mini Laboratoryessam essNessuna valutazione finora

- Method Statement For Fire Alarm SystemDocumento4 pagineMethod Statement For Fire Alarm SystemNethajiNessuna valutazione finora

- STK412 150 Sanyo PDFDocumento4 pagineSTK412 150 Sanyo PDFroger.Nessuna valutazione finora

- Flight Radar 24 Instruction SetDocumento7 pagineFlight Radar 24 Instruction SetRafael CamposNessuna valutazione finora

- PROJECT - PhysicsDocumento8 paginePROJECT - PhysicsAtul TiwariNessuna valutazione finora

- BB130Documento4 pagineBB130Anonymous CdUZMZJq73Nessuna valutazione finora

- Silicon NPN Power Transistors: Inchange Semiconductor Product SpecificationDocumento3 pagineSilicon NPN Power Transistors: Inchange Semiconductor Product Specificationtonny lethantNessuna valutazione finora

- XLi EDGE SmartGuard ManualDocumento66 pagineXLi EDGE SmartGuard ManualTaner ineviNessuna valutazione finora

- DSO Nano Manual: PCB Version: V1.50 Software Verion: V1.40Documento13 pagineDSO Nano Manual: PCB Version: V1.50 Software Verion: V1.40xrs666Nessuna valutazione finora

- Site Visit Checklist - SampleDocumento5 pagineSite Visit Checklist - SampleMiko QuijanoNessuna valutazione finora

- EDEPRO0146 0116 1 en Prospekt Multicond Data SheetDocumento10 pagineEDEPRO0146 0116 1 en Prospekt Multicond Data SheetMartín LópezNessuna valutazione finora

- Feedback in AmplifiersDocumento2 pagineFeedback in AmplifiersDinesh VelNessuna valutazione finora

- RDSO Secification IRS S 99 2023 Amndt 4 Uploaded in RDSO Website For Comments27 April 2023Documento91 pagineRDSO Secification IRS S 99 2023 Amndt 4 Uploaded in RDSO Website For Comments27 April 2023Priya SinghNessuna valutazione finora

- Esr 21 SeriesDocumento40 pagineEsr 21 SeriesJoaquim FerreiraNessuna valutazione finora

- Lec5 A-Transmission Characteristics 1Documento68 pagineLec5 A-Transmission Characteristics 1Sheref HeshamNessuna valutazione finora

- LR 3410Documento11 pagineLR 3410karimNessuna valutazione finora

- Resume Yogesh VermaDocumento2 pagineResume Yogesh VermaKalpana VermaNessuna valutazione finora