Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Windfarm Report

Caricato da

nepcom9541Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Windfarm Report

Caricato da

nepcom9541Copyright:

Formati disponibili

Structural Integrity

of Offshore

Wind Turbines

Oversight of Design,

Fabrication, and Installation

lRAMSPCRlAllCM RESEARCH BCARD

CF 7HE MA7ICMAL ACADEMIE5

I 8 A N 8 F ü 8 I A I I ü N

8 E 8 E A 8 6 h

ß ü A 8 ß

8 F E 6 I A L

8 E F ü 8 I 3 0 5

Tronspor|o|ion Rosoorch Boord

Woshing|on, D.C.

2011

www.TRB.org

Structural lntegrity

ef 0ffshere \ind

1urbines

0vcrsig|t of ucsign,

|a|rication, an! |nsta||ation

8 F E 6 I A L 8 E F ü 8 I 3 0 5

tennittee en 0ffshere \ind lnergy 1urbine

Structural and 0perating Safety

TRAMSPÒRTATlÒM RESEARCH BÒARD

CF 7HE MA7ICMAL ACADEMIE5

Transportation Research Board Special Report 305

Subsciibei Categoiies:

Eneigy; biidges and othei stiuctuies

Tianspoitation Reseaich Boaid publications aie available by oideiing individual publi-

cations diiectly fiom the TRB Business Offce, thiough the Inteinet at www.TRB.oig oi

national-academies.oig/tib, oi by annual subsciiption thiough oiganizational oi indi-

vidual affliation with TRB. Affliates and libiaiy subsciibeis aie eligible foi substantial

discounts. Foi fuithei infoimation, contact the Tianspoitation Reseaich Boaid Business

Office, 500 Fifth Stieet, NW, Washington, DC 20001 (telephone 202-334-3213; fax

202-334-2519; oi e-mail TRBsalesCnas.edu).

Copyiight 2011 by the National Academy of Sciences. All iights ieseived.

Piinted in the United States of Ameiica.

NOTICE: The pioject that is the subject of this iepoit was appioved by the Goveining

Boaid of the National Reseaich Council, whose membeis aie diawn fiom the councils

of the National Academy of Sciences, the National Academy of Engineeiing, and the

Institute of Medicine. The membeis of the committee iesponsible foi the iepoit weie

chosen foi theii special competencies and with iegaid foi appiopiiate balance.

This iepoit has been ieviewed by a gioup othei than the authois accoiding to the pio-

ceduies appioved by a Repoit Review Committee consisting of membeis of the National

Academy of Sciences, the National Academy of Engineeiing, and the Institute of Medicine.

This study was sponsoied by the Buieau of Ocean Eneigy Management, Regulation,

and Enfoicement, U.S. Depaitment of the Inteiioi.

Ccver design by Debra Naylcr, Naylcr Design, Inc.

Ccver phctc. Middelgrunden cffshcre wind turbines in the strait cf Cresund, cutside

Ccpenhagen harbcr, Denmark. (Phctc by Tcre }channesen, iStcckphctc.)

Typesetting by Circle Graphics.

Library of Congress Cataloging-in-Publication Data

National Reseaich Council (U.S.). Committee on Offshoie Wind Eneigy Tuibine

Stiuctuial and Opeiating Safety.

Stiuctuial integiity of offshoie wind tuibines : oveisight of design, fabiication, and

installation / Committee on Offshoie Wind Eneigy Tuibine Stiuctuial and Opeiating

Safety, Maiine Boaid, Tianspoitation Reseaich Boaid of the National Academies.

p. cm. - (Tianspoitation ieseaich boaid special iepoit ; 305) 1. Offshoie stiuctuies-

Design and constiuction-Safety measuies-Goveinment policy-United States.

2. Wind tuibines-Design and constiuction-Safety measuies-Goveinment policy-

United States. 3. Wind powei plants-United States-Safety measuies. 4. Electiic

powei-plants, Offshoie-United States-Safety measuies. I. Title.

TC1665.N38 2011

621.4 53-dc22

2011004767

ISBN 978-0-309-16082-7

The National Academy of Sciences is a piivate, nonpioft, self-peipetuating society of

distinguished scholais engaged in scientifc and engineeiing ieseaich, dedicated to the

fuitheiance of science and technology and to theii use foi the geneial welfaie. On the

authoiity of the chaitei gianted to it by the Congiess in 1863, the Academy has a man-

date that iequiies it to advise the fedeial goveinment on scientifc and technical matteis.

Di. Ralph J. Ciceione is piesident of the National Academy of Sciences.

The National Academy of Engineering was established in 1964, undei the chaitei of the

National Academy of Sciences, as a paiallel oiganization of outstanding engineeis. It is

autonomous in its administiation and in the selection of its membeis, shaiing with the

National Academy of Sciences the iesponsibility foi advising the fedeial goveinment. The

National Academy of Engineeiing also sponsois engineeiing piogiams aimed at meet-

ing national needs, encouiages education and ieseaich, and iecognizes the supeiioi

achievements of engineeis. Di. Chailes M. Vest is piesident of the National Academy of

Engineeiing.

The Institute of Medicine was established in 1970 by the National Academy of Sciences

to secuie the seivices of eminent membeis of appiopiiate piofessions in the examination

of policy matteis peitaining to the health of the public. The Institute acts undei the

iesponsibility given to the National Academy of Sciences by its congiessional chaitei to

be an advisei to the fedeial goveinment and, on its own initiative, to identify issues of

medical caie, ieseaich, and education. Di. Haivey V. Finebeig is piesident of the Insti-

tute of Medicine.

The National Research Council was oiganized by the National Academy of Sciences in

1916 to associate the bioad community of science and technology with the Academy`s

puiposes of fuitheiing knowledge and advising the fedeial goveinment. Functioning in

accoidance with geneial policies deteimined by the Academy, the Council has become

the piincipal opeiating agency of both the National Academy of Sciences and the National

Academy of Engineeiing in pioviding seivices to the goveinment, the public, and the

scientific and engineeiing communities. The Council is administeied jointly by both

Academies and the Institute of Medicine. Di. Ralph J. Ciceione and Di. Chailes M. Vest

aie chaii and vice chaii, iespectively, of the National Reseaich Council.

The Transportation Research Board is one of six majoi divisions of the National

Reseaich Council. The mission of the Tianspoitation Reseaich Boaid is to piovide lead-

eiship in tianspoitation innovation and piogiess thiough ieseaich and infoimation

exchange, conducted within a setting that is objective, inteidisciplinaiy, and multimodal.

The Boaid`s vaiied activities annually engage about 7,000 engineeis, scientists, and othei

tianspoitation ieseaicheis and piactitioneis fiom the public and piivate sectois and

academia, all of whom contiibute theii expeitise in the public inteiest. The piogiam is

suppoited by state tianspoitation depaitments, fedeial agencies including the compo-

nent administiations of the U.S. Depaitment of Tianspoitation, and othei oiganizations

and individuals inteiested in the development of tianspoitation. www.TRB.org

www.nolionol-ocodemies.org

Committee on Offshore Wind Energy Turbine

Structural and Operating Safety

R. Keith Michel, Heibeit Engineeiing Coipoiation, Alameda,

Califoinia,

Bruce R. Ellingwood, Geoigia Institute of Technology, Atlanta

George M. Hagerman, Jr., Viiginia Coastal Eneigy Reseaich Consoitium,

Viiginia Beach

Jan Behrendt Ibsoe, ABS Consulting, Inc., Houston, Texas

Lance Manuel, Univeisity of Texas at Austin

Walt Musial, National Renewable Eneigy Laboiatoiy, Golden, Coloiado

Robert E. Sheppard, Eneigo Engineeiing, Houston, Texas

Emil Simiu, National Institute of Standaids and Technology,

Gaitheisbuig, Maiyland

Susan W. Stewart, Pennsylvania State Univeisity, State College

David J. Wisch, Chevion Eneigy Technology Company, Houston, Texas

Madeline G. Woodruff, Study Diiectoi

Although many of the woild`s laigest wind faims aie located in the

United States, these installations aie entiiely land based. Land-based

wind iesouices aie plentiful but aie located piincipally in the cential

iegions of the countiy, iemote fiom the majoi population centeis wheie

electiicity demand is giowing but tiansmission line access and capacity

aie limited. Theie aie obstacles to installing an enhanced tiansmission

system capable of connecting land-based wind faims to the highly pop-

ulated aieas, paiticulaily with iegaid to peimitting.

Costs ielated to installation and maintenance aie signifcantly highei

foi offshoie wind faims than foi those located on land. Howevei, offshoie

wind faims offei a numbei of advantages that could offset these highei

costs. Offshoie installations can be located close to coastal metiopolitan

aieas, ieducing tiansmission infiastiuctuie iequiiements. The intensity

of offshoie wind eneigy is also gieatei, allowing the offshoie wind tui-

bine to opeiate at gieatei efficiencies than a compaiable land-based

installation.

Theie aie cuiiently offshoie wind piojects planned along the U.S.

East Coast, the Gulf of Mexico, and the Gieat Lakes. To date, most off-

shoie wind faims have been located in the wateis of the Euiopean and

Scandinavian nations-Geimany, Denmaik, and the United Kingdom

being the most impoitant. These countiies have been the leadeis in both

technological and iegulatoiy development ielated to offshoie wind powei

geneiation. The inteinational standaids foi offshoie wind tuibine design

and ceitifcation established by the Inteinational Electiotechnical Com-

mission (IEC) aie foimally iecognized in Euiopean national iegulations.

Some of these national iegulations also iecognize the guidelines and ieg-

ulations developed by classifcation societies.

Structural lntegrity of 0ffshore Wind Turbines

In the United States, wheie offshoie wind eneigy has been much less

of a focus, iegulatoiy development has lagged. As a iesult, peimitting of

sites in U.S. wateis is pioceeding without a cleai set of national iegula-

tions foi the design, fabiication, installation, and commissioning of off-

shoie wind tuibines. The Mineials Management Seivice (MMS), which

has been ienamed the Buieau of Ocean Eneigy Management, Regula-

tion, and Enfoicement (BOEMRE), is iesponsible foi the oideily, safe,

and enviionmentally iesponsible development of offshoie ienewables on

the outei continental shelf. BOEMRE iequested that the Tianspoitation

Reseaich Boaid`s (TRB`s) Maiine Boaid conduct a study to guide the

agency in the iegulation and technical oveisight of the nascent offshoie

wind eneigy industiy in the United States.

Astudy committee consisting of 10 membeis fiom academia, national

ieseaich centeis, and industiy was appointed by the National Reseaich

Council (NRC). Membeis have expeitise in stiuctuial engineeiing, wind

eneigy, iegulation, thiid-paity veiification in offshoie platfoims and

wind tuibines, and oceanogiaphy. Biogiaphical sketches of the committee

membeis appeai at the end of this iepoit. The iepoit iepiesents the con-

sensus opinion of the committee membeis and piesents the committee`s

fndings and iecommendations on the standaids and piactices that could

be used in oveisight of U.S. offshoie wind installations, the iole of thiid-

paity ievieweis and BOEMRE in oveiseeing of the design and constiuc-

tion of offshoie wind tuibines, the necessaiy qualifcations of thiid-paity

ievieweis, and the selection piocess foi identifying and appioving thiid-

paity ievieweis.

The committee met thiee times ovei a 5-month peiiod. These face-

to-face meetings weie supplemented by numeious confeience calls. The

committee listened to piesentations fiom a wide iange of stakeholdeis,

including state and fedeial iegulatois, standaids development oigani-

zations, wind faim developeis, tuibine manufactuieis, and ieseaich

scientists and engineeis with expeitise in the wind eneigy industiy. The

committee also ieviewed vaiious studies and woikshop pioceedings

sponsoied by BOEMRE. These iesouices pioved invaluable as the com-

mittee discussed alteinative appioaches to oveisight piocesses and foi-

mulated the ideas that aie piesented in this iepoit.

ACKNOWLEDGMENTS

The committee acknowledges John Cushing, Loii Medley, and the othei

staff membeis of BOEMRE who piovided the committee with insight into

the iesponsibilities and woikings of BOEMRE and into the vaiious studies

on offshoie wind eneigy conducted undei the auspices of BOEMRE and

its piedecessoi, MMS. The committee also acknowledges the goveinment

and industiy iepiesentatives, listed below, who took time fiom theii busy

schedules to piesent backgiound infoimation and theii own ideas and

opinions to the committee at its meetings, and to the otheis who assisted

the committee by pioviding ielevant publications and answeiing questions

by telephone and e-mail.

The following individuals made piesentations at the fist committee

meeting, June 28-29, 2010:

John Cushing, BOEMRE, U.S. Depaitment of the Inteiioi;

Malcolm Shaiples, Piesident, Offshoie Risk and Technology Consult-

ing, Inc.;

Faia Couitney, Executive Diiectoi, U.S. Offshoie Wind Eneigy

Collaboiative;

Giovei Fugate, Executive Diiectoi, Rhode Island Coastal Resouices

Management Council;

Elmei °Bud" Danenbeigei, MMS (ietiied);

Kenneth Richaidson, Vice Piesident foi Eneigy Piojects, Ameiican

Buieau of Shipping;

Jan Behiendt Ibsoe, Vice Piesident foi Global Renewable Eneigy, ABS

Consulting (committee membei);

William Holley, Technical Advisoi foi the U.S. National Committee of

the IEC, Technical Committee 88, Chief Consulting Engineei, Wind

Systems, GE Eneigy; and

John Dunlop, Senioi Pioject Engineei, Ameiican Wind Eneigy

Association.

The following individuals made piesentations at the second commit-

tee meeting, August 10-11, 2010:

Thomas Lauiendine, Assistant Vice Piesident, Libeity Inteinational

Undeiwiiteis (foimeily with MMS);

Structural lntegrity of 0ffshore Wind Turbines

Jeff Shikaze, Piogiam Managei-Renewable Eneigy, Canadian Stan-

daids Association (CSA);

Richaid McNitt, Business Development Managei, CSA Inteinational;

Petei Vickeiy, Piincipal Engineei, Applied Reseaich Associates, Inc.,

IntiaRisk Division; and

Tom McNeilan, Geneial Managei, Fugio Atlantic (on behalf of the

Offshoie Wind Development Coalition).

The iepoit has been ieviewed in diaft foim by individuals chosen foi

theii diveise peispectives and technical expeitise, in accoidance with

pioceduies appioved by NRC`s Repoit Review Committee. The pui-

pose of this independent ieview is to piovide candid and ciitical com-

ments that will assist the institution in making the published iepoit as

sound as possible and to ensuie that the iepoit meets institutional stan-

daids foi objectivity, evidence, and iesponsiveness to the study chaige.

The ieview comments and diaft manusciipt iemain confdential to pio-

tect the integiity of the delibeiative piocess.

The committee thanks the following individuals foi theii ieview

of the iepoit: C. P. °Sandy" Butteifeld, Bouldei Wind Powei Inc., Bouldei,

Coloiado; Vice Admiial James C. Caid (ietiied), The Woodlands, Texas;

Kent Dangtian, Dangtian OTC, LLC, Cypiess, Texas; John Headland, Mof-

fatt & Nichol Engineeis, New Yoik, New Yoik; Maiy Hallisey Hunt, Stiate-

gic Eneigy Institute, Geoigia Institute of Technology, Atlanta, Geoigia;

Albeito Moiandi, Ameiican Global Maiitime Inc., Houston, Texas; John

Niedzwecki, Zachiy Depaitment of Civil Engineeiing, Texas A&M

Univeisity, College Station, Texas; James Schneidei, Depaitment of Civil

and Enviionmental Engineeiing, Univeisity of Wisconsin-Madison,

Madison, Wisconsin.

Although these ievieweis piovided many constiuctive comments and

suggestions, they weie not asked to endoise the committee`s fndings oi

iecommendations, noi did they see the fnal diaft of the iepoit befoie its

ielease. The ieview was oveiseen by Lawience T. Papay, PQR, LLC, and

C. Michael Walton, Univeisity of Texas at Austin. Appointed by NRC,

they weie iesponsible foi making ceitain that an independent exami-

nation of this iepoit was caiiied out in accoidance with institutional

pioceduies and that all ieview comments weie caiefully consideied.

Responsibility foi the final content of this iepoit iests entiiely with the

authoiing committee and the institution.

Madeline Woodiuff, Senioi Piogiam Officei in NRC`s Division on

Engineeiing and Physical Sciences, seived as study diiectoi and assisted

the committee in the piepaiation of its iepoit undei the supeivision

of Stephen R. Godwin, Diiectoi, Studies and Special Piogiams, TRB.

Suzanne Schneidei, Associate Executive Diiectoi of TRB, managed

the iepoit ieview piocess. Noiman Solomon edited the iepoit, Janet M.

McNaughton handled the editoiial pioduction, Juanita Gieen managed

pioduction, and Jennifei J. Weeks piepaied the manusciipt foi pie-

publication web posting, undei the supeivision of Javy Awan, Diiectoi

of Publications, TRB. Amelia Mathis and Claudia Sauls piovided assis-

tance with meeting aiiangements and communications with the com-

mittee. The committee extends its sinceie giatitude to the diligent and

capable staff of the National Academies. Without theii effoits and sup-

poit, pioducing a iepoit with the depth and quality of this study in a

ielatively shoit time would not have been possible.

Acronyms and Abbreviations

Acionyms and abbieviations used in the iepoit aie listed below. A glossaiy

piovides peitinent defnitions.

AASHTO Ameiican Association of State Highway and

Tianspoitation Offcials

ABS Ameiican Buieau of Shipping

ACI Ameiican Conciete Institute

ACP Alteinative Compliance Piogiam

AISC Ameiican Institute of Steel Constiuction

ALARP as low as ieasonably piacticable

ANSI Ameiican National Standaids Institute

API Ameiican Petioleum Institute

ASCE Ameiican Society of Civil Engineeis

ATC Applied Technology Council

AWEA Ameiican Wind Eneigy Association

BOEMRE Buieau of Ocean Eneigy Management, Regulation,

and Enfoicement

BSH Bundesamt fui Seeschifffahit und Hydiogiaphie

(Geiman Fedeial Maiitime and Hydiogiaphic Agency)

BV Buieau Veiitas

CFR Code of Fedeial Regulations

CMS Conditioning Monitoiing System

COP constiuction and opeiations plan

CVA ceitifed veiifcation agent

DLC design load case

DNV Det Noiske Veiitas

EA enviionmental assessment

EIS enviionmental impact statement

EPACT Eneigy Policy Act of 2005

ESP electiic seivice platfoim

Structural lntegrity of 0ffshore Wind Turbines

FERC Fedeial Eneigy Regulatoiy Commission

GAP geneial activities plan

GL Geimanischei Lloyd

GOM Gulf of Mexico

GW gigawatts

IEC Inteinational Electiotechnical Commission

IMO Inteinational Maiitime Oiganization

ISO Inteinational Oiganization foi Standaidization

kV kilovolts

LRFD load and iesistance factoi design

MMS Mineials Management Seivice

MRI mean iecuiience inteival

MW megawatts

NBS National Buieau of Standaids

NDT nondestiuctive testing

NEPA National Enviionmental Policy Act

NRC National Reseaich Council

NREL National Renewable Eneigy Laboiatoiy

NTL notice to lessees

OCS outei continental shelf

OEM oiiginal equipment manufactuiei

QA quality assuiance

QC quality contiol

PBD peifoimance-based design

PBE peifoimance-based engineeiing

PE piofessional engineei

PEIS piogiammatic enviionmental impact statement

PTC pioduction tax ciedit

SAP site assessment plan

SCADA supeivisoiy contiol and data acquisition

SFPE Society of Fiie Piotection Engineeis

TA&R Technology Assessment and Reseaich piogiam

TC technical committee

USACE United States Aimy Coips of Engineeis

USCG United States Coast Guaid

USDOE United States Depaitment of Eneigy

USDOI United States Depaitment of the Inteiioi

USGS United States Geological Suivey

WSD woiking stiess design

A

Array. A gioup of wind tuibines confguied in a giid layout.

Array losses. See turbine-tc-turbine interference.

B

Bearing. A device to allow constiained ielative motion between two oi

moie paits, typically iotation oi lineai movement.

C

Capacity. The iated continuous load-caiiying ability of geneiation,

tiansmission oi othei electiical equipment, expiessed in megawatts

(MW). The °size" of a powei plant is usually chaiacteiized by its net

powei geneiation capacity in MW.

Certincation. See Box 1.3

Class (or wind turbine class). Classifcations defned by IEC foi wind

tuibines based on thiee paiameteis: the aveiage wind speed, extieme

50-yeai ietuin 10-min aveiaged gust, and tuibulence.

Classincation. See Box 1.3

Classincation society. Industiy associations and companies that supply

seivices (such as ceitifcation) to the industiy, evaluating the design,

fabiication oi installation with iefeience to its own iules oi guidelines

iathei than an exteinally developed standaid oi guideline.

Code of Federal Regulations (CFR). Rules and iegulations defned by

the U.S. fedeial goveinment having the foice of law. Title 30, pait 250

(30 CFR 250) coveis °Oil and Gas and Sulphui Opeiations in the Outei

Continental Shelf." Pait 285 (30 CFR 285) coveis °Renewable Eneigy

Alteinate Uses of Existing Facilities on the Outei Continental Shelf."

Structural lntegrity of 0ffshore Wind Turbines

Composite (tower or rotor). Engineeied mateiials made fiom two oi

moie constituent mateiials with significantly diffeient physical oi

chemical piopeities that iemain sepaiate and distinct on a macioscopic

level within the fnished stiuctuie.

Condition monitoring. Apiocess that involves a system of sensois and

monitoiing equipment used to iemotely monitoi specific piopei-

ties of a mechanical oi stiuctuial system (e.g., fluid tempeiatuies oi

mateiial stiain) foi the puipose of deteimining its ability to opeiate

noimally.

D

Deepwater. A watei depth iange foi offshoie facilities; typically beyond

500 feet (152 m) though theie is no defnitive watei depth iange.

Design basis. The extieme conditions undei which the wind tuibine is

designed to opeiate. E.g. 50- oi 100-yeai extieme wind and wave load-

ing events. Also includes potential fault conditions of the tuibine.

Developer. The entity in a wind pioject that designates and aiianges foi

the building of an infiastiuctuie on land oi an offshoie site in oidei

to pioductively exploit wind eneigy. Analysis of the land-sea and wind

iesouice chaiacteiistics aie ciucial in the development piocess.

Direct drive. A mechanism that takes the powei coming fiom a motoi

without any ieductions (such as a geaibox).

Distribution system. The pait of the electiical giid infiastiuctuie that

moves electiicity between local destinations eithei on the powei genei-

ation side oi the demand side (tiansmission systems tiansfei electiicity

ovei longei distances). The wind faim electiic powei distiibution sys-

tem consists of each tuibine`s powei electionics, the tuibine step-up

tiansfoimei and distiibution wiies, the electiic seivice platfoim (ESP),

cables to shoie, and the shoie-based inteiconnection system.

Downwind turbine. Refeis to a hoiizontal axis wind tuibine in which

the hub and blades point away fiom the wind diiection, the opposite

of an upwind tuibine.

Drivetrain. The tiansmission system of the wind tuibine that conveits

the low speed shaft iotational powei fiom the iotoi to electiical

powei via eithei a geaibox and geneiatoi assembly oi a diiect diive

mechanism.

E

Electric service platform (ESP). An offshoie platfoim seiving as a col-

lection and seivice point foi a wind faim, also called a tiansfoimei

platfoim.

Environmental Impact Statement (EIS). A document iequiied by the

National Enviionmental Policy Act (NEPA) foi ceitain actions °sig-

nifcantly affecting the quality of the human enviionment." It is a tool

foi decision making, desciibing the positive and negative enviion-

mental effects of a pioposed action and listing one oi moie alteinative

actions that may be chosen instead of the action desciibed in the EIS.

Exploratory leases. Acting undei the authoiity gianted to MMS thiough

the Eneigy Policy Act of 2005, the agency initiated the Inteiim Policy,

which allows foi exploiatoiy leases in Novembei 2007 in advance of

the fnal iegulatoiy fiamewoik in oidei to jumpstait the ieview and

potential authoiization of the ienewable eneigy development piocess.

The limited leases authoiize a teim of 5 yeais foi activities on the OCS

associated with ienewable eneigy iesouice data collection and tech-

nology testing.

F

Federal waters. Refeis to U.S. teiiitoiial wateis iegulated by the U.S. fed-

eial goveinment, as opposed to aieas iegulated by state authoiities.

Typically this is the iegion beyond 3 nautical miles fiom shoie, with

the exception of paits of the gulf coast.

G

Gear-driven. Using a mechanical system of geais oi belts and pulleys to

inciease oi deciease shaft speed.

Goal-based standards (also known as performance-based standards).

Ahieiaichical standaid in which the staiting point is a set of high-level

peifoimance objectives suppoited by a seiies of minimum peifoi-

mance ciiteiia that aie necessaiy to suppoit this objective and, fnally,

a choice of methods by which satisfaction of these ciiteiia can be

demonstiated. These methods may be piesciiptive in natuie; iational

alteinative means and methods aie peimitted, piovided that theii

acceptability can be veiifed by eithei analysis oi tests.

Structural lntegrity of 0ffshore Wind Turbines

Guidelines. See Box 3.1.

Gravity base (or gravity-based) foundation. A type of foundation that

ielies on mass and a laigei base dimension to piovide stability and

iesist oveituining.

H

Helical stage. A cylindiical geai wheel that has slanted teeth that follow

the pitch suiface in a helical mannei.

Horizontal axis turbine. A °noimal" wind tuibine design, in which

the shaft is paiallel to the giound and the blades aie peipendiculai

to the giound

Hydrokinetic. Refeiiing to devices that extiact eneigy fiom moving

watei such as iiveis, ocean cuiients, and waves.

I

Interconnection system. The electiical system of cabling, typically opei-

ating at medium voltage, that connects the tuibines to one anothei as

well as to the facility substation.

J

Jacket. Atype of offshoie stiuctuie consisting of a veitical fiaming system

with multiple legs and a piled foundation.

Jackup rig. A floating baige fitted with suppoiting legs that can be

loweied to the seabed.

L

Limit states design. Amethod of piopoitioning stiuctuial membeis, com-

ponents, and systems such that the design stiength, defned as the piod-

uct of a nominal stiength and a iesistance factoi, equals oi exceeds the

iequiied stiength undei the action of factoied load combinations (also

denoted lcad and resistance factcr design, oi LRFD, in the United States).

Load and resistance factor design (LRFD). See limit states design.

M

Marine spatial planning. A tool that biings togethei multiple useis of

the ocean, including eneigy, industiy, goveinment, conseivation, and

iecieation, to make infoimed and cooidinated decisions about how

to use maiine iesouices sustainably.

Memorandum of understanding (MOU). A document that defnes an

agieement between two goveinmental agencies iegaiding how they will

inteiact in an aiea of shaied oveisight. Foi example, theie is an MOU

between the foimei MMS and the Fedeial Eneigy Regulatoiy Com-

mission (FERC) that claiifes the ioles each oiganization has in the

oveisight of eneigy piojects in the OCS.

Monopole. A tuibine foundation stiuctuie composed of a laige steel

tube diiven into the seabed.

Multi-pile. See

N

Nacelle. The poition of a wind tuibine that sits atop the towei piotect-

ing the mechanical and electiical components (i.e., the diivetiain,

contiollei, and biake) fiom the elements.

O

Outer Continental Shelf (OCS). Refeis to all submeiged lands, its

subsoil, and seabed that belong to the United States and aie lying

seawaid and outside of the states` juiisdiction, the lattei defined as

the °lands beneath navigable wateis" in Title 43, Chaptei 29, Sub-

chaptei I, Section 1301 of the U.S. code, The United States OCS has

been divided into foui leasing iegions: Gulf of Mexico, Atlantic,

Pacific, and Alaska.

P

Performance-based design. A design appioach that identifies an

appiopiiate stiuctuial system and design paiameteis based on the

desiied levels of peifoimance (oi peifoimance taigets) of the facil-

ity of which the stiuctuie is pait; often used in seismic and blast-

iesistant design.

Pitch. The angle between the edge of the blade and the plane of the

blade`s iotation. Blades aie tuined, oi pitched, out of the wind to con-

tiol the iotoi speed.

Planetary stage. An outei geai that ievolves about a cential sun geai of

an epicyclic tiain.

Power electronics. The application of solid-state electionics foi the con-

tiol and conveision of electiic powei.

Structural lntegrity of 0ffshore Wind Turbines

Prescriptive. Aiegulatoiy enviionment in which paiticulai activities and

schedules and paiameteis aie piesciibed a piioii iathei than deiived

fiom peifoimance taigets.

Prevailing wind. The piedominant diiection fiom which the wind

blows.

Production tax credit (PTC). Afedeial incentive piogiam that is designed

to help level the playing feld of eneigy pioduction wheie othei foims

of eneigy aie subsidized. At the time of piess, the PTC is cuiiently

offeied to wind piojects in seivice by Decembei 31, 2012, ovei the fist

10 yeais of opeiation, at a value of 2.2 cents/kWh (which incieases

with inßation).

Project certification. A piocess to veiify that the wind tuibine and its

suppoit stiuctuies meet the site-specific conditions. Use of a type-

ceitified wind tuibine is a pieiequisite.

R

Recommended practices. A type of standaid oi guideline developed by

a standaids-development body.

Regulations. See Box 3.1.

Return period. The aveiage inteival of time between iecuiiences of

an event such as an eaithquake oi stoim of a ceitain size oi intensity,

used in iisk analysis. A stoim of a given intensity that has a ietuin

peiiod of 10 yeais would have a 1-in-10 piobability of being exceeded

(in intensity) in any given yeai.

Risk-informed basis. An integiated decision paiadigm in which tiadi-

tional deteiministic engineeiing evaluations aie suppoited by insights

deiived fiom piobabilistic iisk assessment (PRA) methods that take

into account unceitainties due to iandomness, modeling, and com-

pleteness. Decisions may be based on both qualitative and quantita-

tive factois and considei tiaditional engineeiing infoimation and the

iisk signifcance of the decision.

Rotor. A complete system of blades that supplies all the foice diiving a

wind geneiatoi. The iotoi has thiee blades manufactuied fiom

fibeiglass-ieinfoiced epoxy, mounted on a hub. The blades aie

pitch-iegulated to continually contiol theii angle to the wind and aie

designed to optimize eneigy pioduction and to geneiate minimal noise.

S

SCADA (supervisory control and data acquisition). The wind faim

monitoiing system that allows the ownei oi the tuibine manufactuiei,

oi both, to be notifed of faults oi alaims, iemotely contiol tuibines,

and ieview opeiational data.

Scour. The effect of ocean waves and cuiients displacing seabed mateiial

aiound the base of fxed stiuctuies

Shallow water. A watei depth iange foi offshoie facilities; typically

less than 200 feet (61 m), although theie is no definitive watei depth

iange.

Siting. The piocess of deteimining a suitable location foi a wind pioject

development.

Standards. See Box 3.1.

State waters. U.S. teiiitoiial wateis iegulated by state authoiity`s gov-

einment, as opposed to aieas iegulated by the fedeial goveinment,

typically within 3 nautical miles of shoie.

Stationkeeping (nautical). Maintaining a fxed position in the watei iel-

ative to othei vessels oi to a stationaiy object oi given location.

Step-up transformer. Equipment designed to inciease the voltage of an

electiic powei system.

Substation. A pait of an electiic system in which tiansfoimeis aie used

to step up oi step down the voltage in utility powei lines foi tiansition

between long-distance tiansmission and local pioduction oi distii-

bution lines.

Switchgear. A device within an electiic system used to contiol the ßow

of electiicity fiom one pait of the system to anothei.

T

Transformer. An electiical device used to tiansfei powei fiom one cii-

cuit to anothei using magnetic induction, usually to step voltage up

oi down.

Transition piece. The connectoi between the foundation and the towei,

e.g., ftted aiound the section of the monopole that piotiudes above

the wateiline.

Tripod. An offshoie jacket stiuctuie with thiee legs.

Turbine spacing. The distance between wind tuibines within an aiiay.

Structural lntegrity of 0ffshore Wind Turbines

Turbine-to-turbine interference. The aeiodynamic losses expeiienced

in a wind tuibine aiiay as the upstieam tuibines affect the eneigy cap-

tuie of the tuibines downstieam within the aiiay.

Type certincation. Obtained by the wind tuibine manufactuiei (fiom

an independent body) to demonstiate that a wind tuibine geneiatoi

system oi installation (facility) meets specifed standaids foi key ele-

ments such as identifcation and labeling, design, powei peifoimance,

noise emissions, and stiuctuial integiity.

U

Upwind turbine. A hoiizontal axis wind tuibine in which the hub and

blades aie in fiont of the towei in the diiection of the incoming wind

(the opposite of a downwind tuibine). Yaw contiol is iequiied to main-

tain the upwind oiientation.

V

Verincation. See Box 1.3.

W

Wind farm. A set of wind tuibines oi one oi moie tuibines, when con-

sideied togethei with the iest of the equipment involved in tiansfei-

iing electiicity fiom the tuibines to shoie.

Wind resource. The aveiage wind speed and diiection at a iange of

heights on a site; iequiied to deteimine the viability of a wind tuibine.

Wind shear. Changes in wind velocity with elevation.

Wind turbine generator. A iotating machine that pioduces electiicity

fiom the wind.

Working stress design. Amethod of design in which stiuctuies oi mem-

beis aie piopoitioned foi piesciibed woiking loads at stiesses that aie

well below theii ultimate values. The allowable stiesses aie deteimined

by applying safety factois to the ultimate values.

Y

Yaw. To iotate aiound a veitical axis, such a tuibine towei. The yaw

diive is used to keep an upwind tuibine iotoi facing into the wind as

the wind diiection changes.

Executive Summary 1

1 Introduction 5

Study Chaige and Scope 10

Committee Appioach 12

Oiganization of the Repoit 14

2 Offshore Wind Technology and Status 17

Wind Technology 17

Status of Offshoie Wind Installations 28

Offshoie Wind Eneigy foi the United States 32

3 Standards and Practices 38

Inteiactions Between Nonstiuctuial Failuies and

Wind Tuibine Stiuctuial Integiity 38

Inteinational Electiotechnical Commission 41

API Standaids 45

IEC and API Diffeiences 46

ISO Standaids 48

Classifcation Society Guidelines 49

Det Noiske Veiitas 49

Geimanischei Lloyd 50

Ameiican Buieau of Shipping 51

Geiman Standaids and Pioject Ceitifcation Scheme 52

Ongoing Standaids Development and Related Reseaich:

National and Inteinational 53

Aieas of Limited Expeiience and Majoi Defciencies

in Standaids 56

Findings foi Task I: Chaptei 3 58

4 A Risk-Informed Approach to Performance Assurance 62

Risks to Human Life and the Enviionment Posed

by Stiuctuial Failuie of Offshoie Facilities 63

Regulatoiy Options and Policy Consideiations 66

Seeking the Right Regulatoiy Balance 68

Regulatoiy Evolution in the Oil and Gas, Maiine,

and Civil Infiastiuctuie Industiies 68

Tiansition fiom Piesciiptive to

Peifoimance-Based Regulations 76

Risk Mitigation Thiough Peifoimance-Based Engineeiing 77

Alteinative Appioaches to Regulating the U.S. Offshoie

Wind Industiy 80

Goal-Based Standaids foi Offshoie Wind Tuibines 82

Oveiview of Piojected BOEMRE Role 89

Implementation: Capacity and Expeitise 91

Findings foi Task I: Chaptei 4 92

Recommendations foi Task I: Chapteis 3 and 4 92

5 Role of Third-Party Oversight and Certined

Verincation Agents 96

Backgiound 96

Offshoie Oil and Gas: Histoiy of Use of CVAs 97

Cuiient BOEMRE Regulatoiy Pioposals foi Offshoie

Wind Tuibines and Use of CVAs 102

Scope of Reviews 102

CVAs and Goal-Based Standaids 104

Summaiy 106

Findings and Recommendations foi Task II 106

6 Qualincations Needed by Certined Verincation Agents 109

Suivey of Qualifcations foi Othei Thiid-Paity Reviews 109

U.S. Regulations foi Offshoie Wind Tuibine

CVA Qualifcations 114

Evaluation of Accieditation Appioaches 115

Offshoie Wind Tuibine CVA Qualifcations 117

Filling the Expeiience Gap 121

Findings and Recommendations foi Task III 123

7 Summary of Key Findings and Recommendations 127

Finding: Safety and the Enviionment 127

Findings and Recommendations: Standaids

and Piactices (Task I) 128

Findings and Recommendations: Role of the CVA (Task II) 131

Findings and Recommendations:

CVA Qualifcations (Task III) 133

Findings and Recommendations: Implementation 135

Appendices

A Risk-Infoimed Appioaches to Safety Regulation 137

B Text of Peitinent Regulations 148

Study Committee Biographical Information 160

Executive Summary

The U.S. Depaitment of the Inteiioi`s Buieau of Ocean Eneigy Man-

agement, Regulation, and Enfoicement (BOEMRE) is iesponsible foi

the oideily, safe, and enviionmentally iesponsible development of off-

shoie ienewable eneigy on the outei continental shelf (OCS). The com-

mittee that authoied this iepoit was tasked with ieviewing BOEMRE`s

pioposed appioach to oveiseeing the design of offshoie wind tuibines foi

stiuctuial integiity. The committee was asked to ieview the applicability

and adequacy of standaids and piactices that could be used foi the design,

fabiication, and installation of offshoie wind tuibines. It was also asked

to ieview the iole of thiid-paity ceitifed veiifcation agents (CVAs) and

the expeitise and qualifcations needed to caiiy out the iole of a CVA.

Because of eailiei development of offshoie wind eneigy in Euiope,

Euiopean countiies have taken the lead in matteis ielated to the iegulation,

installation, and opeiation of offshoie wind faims. Theii national iegula-

tions iecognize and incoipoiate Inteinational Electiotechnical Commis-

sion (IEC) standaids foi the design of offshoie wind tuibines. Because

the IEC standaids, on theii own, do not covei all aspects of the design

and constiuction of offshoie wind tuibines, they have geneially been

supplemented by national iegulatoiy iequiiements, othei standaids

and guidelines, and iecommended piactices developed by industiy. The

committee found that even such packages of iegulations, standaids, and

guidelines have cleai defciencies, paiticulaily if applied to planned instal-

lations along the U.S. East Coast and Gulf of Mexico.

Safety and enviionmental peifoimance aie the basis foi most U.S. ieg-

ulations goveining the offshoie oil and gas, maiitime, and civil infiastiuc-

tuie industiies. The committee found that the iisks to human life and the

enviionment associated with offshoie wind faims aie substantially lowei

Structural lntegrity of 0ffshore Wind Turbines

than foi these othei industiies, because offshoie wind faims aie piimai-

ily unmanned and contain minimal quantities of hazaidous substances.

This fnding implies that, in iemedying defciencies in standaids and

piactices, an appioach with signifcantly less iegulatoiy oveisight may be

taken foi offshoie wind faims than foi the othei industiies mentioned

above. The U.S. goveinment, howevei, having expiessed a policy com-

mitment to the development of alteinative eneigy souices including

offshoie wind, has a vested inteiest in the success and peifoimance of off-

shoie wind tuibines. On this basis, the committee iecommends that the

BOEMRE iegulations go beyond safety and enviionmental iisks and also

considei policy consequences. Because fuithei impiovements in cost,

ieliability, and effciency aie needed if offshoie wind is to be a competi-

tive eneigy souice, iegulations need to allow foi innovative technologies

and encouiage the intioduction of novel concepts.

To facilitate the oideily development of offshoie wind eneigy and

suppoit the stable economic development of this nascent industiy, the

United States needs a set of cleai iequiiements that can accommodate

futuie design development. Theie is a sense of uigency, because plan-

ning and design effoits foi a numbei of offshoie wind faims to be located

in state wateis and on the OCS aie alieady undei way. The committee

iecommends that BOEMRE immediately develop a set of iequiiements

that establish goals and objectives with iegaid to stiuctuial integiity,

enviionmental peifoimance, and eneigy geneiation.

Undei this appioach, industiy would be iesponsible foi pioposing

sets of standaids and iecommended piactices that meet the peifoimance

iequiiements established by BOEMRE. It is anticipated that classifcation

societies and standaids development gioups will be inteiested in offeiing

packages of standaids and guidelines that meet the BOEMRE peifoimance

iequiiements. BOEMRE should be piepaied to ieview the packages, iden-

tify theii defciencies, and appiove them. Such pieappioved standaids and

guidelines will expedite the iegulatoiy ieview piocess and piovide indus-

tiy with a well-defned appioach foi pioceeding with the development of

offshoie wind tuibines on the OCS. A developei should also be peimitted

to submit a package of standaids and guidelines on a pioject-specifc basis,

with the undeistanding that a CVA will fist ieview and agiee to the pio-

posed appioach.

Erecuti.e Suaao|]

Detailed fndings and iecommendations on CVAs can be found in

Chapteis 5 thiough 7. The committee was asked to ieview the iole of CVAs

(Chaptei 5). The committee notes that such thiid-paity ieview should be

anintegial pait of the iegulatoiy piocess. The ieview should include assess-

ment of the blades, tuibine contiol systems, toweis and foundations,

infeld cables and expoit cables, and ancillaiy stiuctuies such as the elec-

tiic seivice platfoims. Oveisight iesponsibility should include design, fab-

iication and manufactuiing, tianspoitation, and installation. Consistent

with cuiient inteinational piactice, type and pioject ceitifcation may be

integial to the wind tuibine pioject and used in a thiid-paity design ieview.

The thiid-paity ieview team should veiify that the design and instal-

lation meet the BOEMRE goal-based iequiiements as well as the stan-

daids and guidelines applicable to that paiticulai pioject. In peiiodic

iepoits to BOEMRE, the thiid-paity ievieweis should desciibe the extent

of theii ieview, indicate the level of compliance, and cleaily identify any

disciepancies oi conceins. Responsibility foi fnal appioval should iest

with BOEMRE.

The committee was also asked to assess the expeitise and qualifcations

needed by potential CVAs (Chaptei 6). In evaluating the qualifcations of

potential CVAs, BOEMRE should seek oiganizations and individuals that

aie independent and objective, have the necessaiy expeitise, have a man-

agement stiuctuie with well-defned ioles and iesponsibilities with ovei-

sight by a iegisteied piofessional engineei, and have an auditable quality

plan and iecoid-keeping piocesses. The committee iecommends that

BOEMRE appiove CVAs on a pioject-specifc basis as opposed to having

a list of pieappioved CVAs. BOEMRE should actively manage the CVA

piocess foi offshoie wind facilities by disseminating lessons leained fiom

the CVA piocess to piomote best piactices to the industiy.

The success of offshoie wind eneigy in U.S. wateis may depend in

pait on how quickly and effectively BOEMRE develops the iegulations

and oveisees compliance. It is ciitical that BOEMRE establish within the

agency a substantial coie competency with the capacity and expeitise to

lead the development of the peifoimance-based standaids, ieview the

iules and guidelines submitted by thiid-paity iulemaking bodies and

developeis, and ieview the competency of pioposed CVAs. BOEMRE

should be fully engaged in the national and inteinational piocesses foi

Structural lntegrity of 0ffshore Wind Turbines

developing standaids foi offshoie wind tuibines, paiticulaily in stan-

daids and guidelines issued by the IEC technical committees and othei

ielevant national and inteinational committees. BOEMRE should also

considei cieating an expeit panel to piovide feedback and guidance foi

the initial offshoie wind development piojects as a means to fll the expe-

iience gap foi both industiy and iegulatois.

Introduction

The United States is poised to begin building its fist offshoie wind eneigy

powei plants. Seveial piojects have been pioposed oi aie undei develop-

ment, piimaiily along the Eastein Seaboaid and the Gieat Lakes. In Apiil

2010, the Cape Wind pioject, to be located off the Massachusetts coast,

became the fist to be appioved by fedeial and state authoiities.

Cential to the pioject appioval piocess is the Depaitment of the Inte-

iioi`s Mineials Management Seivice (MMS), iecently ienamed the Buieau

of Ocean Eneigy Management, Regulation, and Enfoicement (BOEMRE).

The Eneigy Policy Act of 2005

1

assigned it iesponsibility foi the oideily,

safe, and enviionmentally iesponsible

2

development of ienewable eneigy

iesouices in U.S. fedeial wateis, also known as the outei continental shelf

(OCS)

3,4

(see Box 1-1). BOEMRE has exclusive juiisdiction ovei non-

hydiokinetic piojects on the OCS.

On Apiil 29, 2009, BOEMRE published a final iule, codified at

30 CFR 285,

5

goveining ienewable eneigy pioject activities on the

OCS. Figuie 1-1 lays out the iegulatoiy piocess stipulated by the iule.

The iegulations iequiie submission of seveial documents foi BOEMRE

appioval of a pioposed facility. Chief among them aie thiee iepoits

coveiing facility design, fabiication, and installation. The BOEMRE

1

P.L. 109-58, Section 388.

2

74 FR 81, p. 19638.

3

On June 8, 2010, MMS was ienamed the Buieau of Ocean Eneigy Management, Regulation, and

Enfoicement. Foi convenience, this iepoit uses the lattei name in iefeiiing to this oiganization,

despite the fact that some of the actions discussed took place befoie the name change.

4

The teim °outei continental shelf " iefeis to those submeiged lands, subsoil, and seabed that belong

to the United States and lie seawaid of state watei boundaiies (http://www.boemie.gov/

AboutBOEMRE/ocsdef.htm, accessed Dec. 19, 2010).

5

Exceipts fiom this iule aie given in Appendix B of this iepoit.

Structural lntegrity of 0ffshore Wind Turbines

ß0X 1-1

Regulatory Timeline for Renewable Energy

Development on the U.S. OCS

2005 The Eneigy Policy Act of 2005, Section 388, authoiizes

MMS to do the following, among othei things:

Act as the lead agency foi fedeial offshoie ienewable

eneigy and alteinative uses of offshoie public lands

(also known as the OCS);

Ensuie consultation with states and othei stakeholdeis;

giant easement, leases, oi iights-of-way foi ienewable

eneigy-ielated uses of the fedeial OCS; and

Puisue appiopiiate enfoicement actions in the event

that violations occui.

2007 In Novembei, MMS issued the final piogiammatic envi-

ionmental impact statement (PEIS) in suppoit of the

establishment of a piogiam foi authoiizing ienewable and

alteinative use activities on the OCS. The fnal PEIS exam-

ined the potential enviionmental effects of the piogiam

on the OCS and identifed policies and best management

piactices that could be adopted foi the piogiam.

In Decembei, the Recoid of Decision was ieleased, affim-

ing that MMS would pioceed with establishment of the

Renewable Eneigy Piogiam foi the OCS on the basis of the

analysis piesented in the PEIS.

2007 In Novembei, MMS announced an inteiim policy foi

authoiizing the installation of offshoie data collection

and technology testing facilities on the OCS. The policy

was designed to jump-stait baseline data collection effoits

in advance of fnal iegulations.

(On June 23, 2009, fve exploiatoiy leases weie gianted

foi ienewable wind eneigy iesouice assessment on the

OCS offshoie Delawaie and New Jeisey.)

lrt|cJucticr

On Apiil 9, MMS signed a memoiandum of undeistand-

ing with the Fedeial Eneigy Regulatoiy Commission

(FERC). The memoiandum claiifed that MMS has exclu-

sive juiisdiction with iegaid to the pioduction, tianspoita-

tion, oi tiansmission of eneigy fiom nonhydiokinetic

ienewable eneigy souices, including wind and solai. FERC

has exclusive juiisdiction to issue licenses foi the con-

stiuction and opeiation of hydiokinetic piojects, includ-

ing wave and cuiient, but companies will be iequiied fist

to obtain a lease thiough MMS.

On Apiil 29, MMS published a fnal iule (30 CFR Pait 285,

74 FR 81, pp. 19638-19871) establishing a iegulatoiy

fiamewoik foi leasing and managing ienewable eneigy pioj-

ect activities on the U.S. OCS. The iegulations aie intended

to encouiage oideily, safe, and enviionmentally iesponsi-

ble development of ienewable eneigy souices on the OCS.

Subpait G coveis the technical iepoits that must be sub-

mitted on the fnal design, fabiication, and installation of

facilities. It also lays out a thiid-paity veiifcation piocess

that iequiies use of a °ceitifed veiifcation agent" (CVA)

to veiify and ceitify that piojects aie designed, fabiicated,

and installed in confoimance with accepted engineeiing

piactices and with the submitted iepoits.

The iegulations specify that pait of the CVA`s iesponsibil-

ity in the design phase is to conduct an independent assess-

ment to ensuie that the facility is designed to withstand the

enviionmental and functional load conditions appiopii-

ate foi the intended seivice life at the pioposed location.

The iegulations also specify that pait of the CVA`s iespon-

sibility in the fabiication and installation phases is to use

good engineeiing judgment and piactices in conducting

an independent assessment of fabiication and installation

(ccntinued cn next page)

Structural lntegrity of 0ffshore Wind Turbines

ß0X 1-1 (ccntinued)

Regulatory Timeline for Renewable Energy Development on the U.S. OCS

activities. The CVA is also to ensuie that these activities aie

conducted accoiding to the appioved applications.

2009 On August 3, MMS published its °Guidelines foi the Min-

eials Management Seivice Renewable Eneigy Fiamewoik,

July 2009." The guidelines aie divided into six chapteis,

coveiing qualifcation iequiiements; defnitions; and lease

and giant conveyance, administiation, and payments.

The guidelines state that five additional chapteis will be

°posted at a latei date." One of them, Chaptei 9, will

°explain the iequiiements foi facility design, fabiication,

and installation." Chaptei 10 will covei iequiiements foi

enviionmental and safety management, inspection, and

facility assessment. Chaptei 11 will discuss decommis-

sioning iequiiements.

2010 MMS decided that, iathei than publishing the fve chapteis

above as pait of the °Guidelines foi the Mineials Manage-

ment Seivice Renewable Eneigy Fiamewoik," it would

develop sepaiate guidelines foi each topic and issue them as

°Notices to Lessees" (peisonal communication, J. Cushing,

BOEMRE, Oct. 1, 2010).

SOURCE: MMS n.d.

iegulations set out in gieat detail what must be included in these iepoits-

foi example, stiuctuial diawings, a summaiy of the enviionmental data

used in the design, a complete set of design calculations, a geotechnical

iepoit, the industiy standaids pioposed foi use in fabiication, and details

on the offshoie equipment to be used foi installation.

6

Howevei, the ieg-

6

The list is not complete. See 30 CFR 285 foi details.

lrt|cJucticr 9

ulations do not specify standaids oi detailed iequiiements that the facil-

ity must meet foi BOEMRE to appiove the iepoits.

Instead, the iegulations iequiie that a thiid paity, a °ceitifed veiifca-

tion agent" (CVA),

7

conduct an independent assessment of the facility

design on the basis of °good engineeiing judgment and piactices" and cei-

tify to BOEMRE that the facility is designed to withstand the enviionmen-

tal and functional load conditions appiopiiate foi the intended seivice life

at the pioposed location. Accoiding to the iegulations, the CVA must also

ceitify to BOEMRE that pioject components aie fabiicated and installed

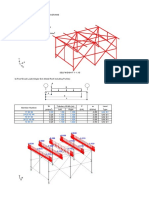

FIßü8E 1-1 Approval process for offshore wind turbines set forth in 30 CFR 283.

(There is also a noncompetitive path.) ¦NOTE: The Coastal Zone Management

Act (CZMA) consistency piovision (15 CFR 930) iequiies that fedeial agency

activities be consistent with the enfoiceable policies of a coastal state`s fedeially

appioved coastal management piogiam. COP constiuction and opeiations

plan, RE ienewable eneigy, and SAP site assessment plan. SOURCE: Piesenta-

tion to the committee by John Cushing, BOEMRE.]

7

In some ciicumstances, BOEMRE may waive the iequiiement to use a CVA (see Appendix B).

Structural lntegrity of 0ffshore Wind Turbines

in accoidance with °accepted engineeiing piactices" and with the appioved

iepoits and opeiating plans.

Standaids and guidelines foi the design, fabiication, installation, and

opeiation of offshoie wind tuibines

8

have been developed by inteina-

tional bodies as well as by individual companies and countiies, piedom-

inantly in Euiope (see Chaptei 3). Howevei, none of these standaids oi

guidelines has been accepted by U.S. agencies, noi has the United States

developed its own. Standaids and guidelines exist foi othei offshoie

activities in U.S. wateis, such as oil and gas development and wateiboine

shipping. Othei ielevant standaids covei items such as the enviionment

and woikplace health and safety. But BOEMRE has not specifed any cii-

teiia that offshoie wind tuibine piojects must meet to secuie appioval.

STUDY CHARGE AND SCOPE

In the absence of such standaids and guidelines foi the United States,

BOEMRE asked the National Reseaich Council (NRC) to ieview its

appioach to oveiseeing the development and safe opeiation of wind

tuibines on the OCS, with a focus on stiuctuial safety. The chaige to

the study committee is given in Box 1-2.

The committee`s scope was limited to stiuctuial safety, in accoidance

with discussions with the sponsoi at the fist committee meeting.

9

Hence,

although the teim °Stiuctuial and Opeiating Safety" appeais in the com-

mittee`s title, the committee limited its tieatment of opeiational safety to

those aspects that could be affected by stiuctuial design, fabiication, and

installation. It included within its scope the design, fabiication, and instal-

lation of subsea cables. As illustiated in Figuie 1-2, the committee chai-

acteiized its scope as °fiom design to commissioning."

One caveat is that stiuctuial integiity cannot be consideied in isolation.

In complex engineeiing systems such as wind tuibines, theie aie non-

stiuctuial components and systems whose failuie and malfunctioning

8

In this iepoit, °wind eneigy tuibine geneiatois" aie often iefeiied to simply as °wind tuibines."

A set of wind tuibines is often iefeiied to as a °wind faim." One oi moie tuibines, when consid-

eied togethei with the iest of the equipment involved in tiansfeiiing electiicity fiom the tuibines

to shoie, can also be iefeiied to as a °wind faim" oi, alteinatively, a °wind eneigy powei plant."

9

°Backgiound Infoimation and Study Goals," piesentation to the committee by John Cushing,

BOEMRE, July 28, 2010.

lrt|cJucticr

NRC Committee on Offshore Wind Energy

Turbine Structural and Operating Safety

Statement cf Task

The study will piovide guidance to MMS on the diiection and

intent of its pioposed appioach to oveiseeing the development

and safe opeiation of offshoie wind tuibines. The study will pio-

vide fndings iegaiding:

Task I. Standards and Practices. The applicability and ade-

quacy of existing standaids and piactices foi the design,

fabiication, and installation of offshoie wind tuibines.

Task II. Rcle cf Certified Verificaticn Agents (CVAs). The

expected iole of the CVA in identifying standaids to be

used (including deteimining the compatibility-the

acceptability of mixing and matching-of standaids

fiom diffeient souices), and the expected iole of the

CVA in conducting monitoiing and onsite inspections

to veiify compliance with the standaids.

Task III. CVA Qualifcaticns. The expected expeiience level,

technical skills and capabilities, and suppoit equip-

ment and computei haidwaie/softwaie needed to be

consideied a qualifed CVA.

The focus of the study will be limited to the safety of stiuctuial

and opeiational chaiacteiistics of offshoie wind tuibines, includ-

ing tuibine design, fabiication, and installation.

can tiiggei oi iesult in stiuctuial oveiload oi failuie. Chaptei 3 notes how

these inteiactions aie accounted foi.

As shown in Figuie 1-1, the enviionmental hazaids associated with

the establishment and opeiation of offshoie wind eneigy facilities aie

coveied thiough the National Enviionmental Policy Act (NEPA) piocess.

12 Structural lntegrity of 0ffshore Wind Turbines

These hazaids include effects on biids, othei wildlife, and the seabed.

BOEMRE will piepaie enviionmental assessments (EAs) oi enviionmen-

tal impact statements (EISs), as iequiied by NEPA, foi offshoie wind pioj-

ect pioposals.

This iepoit does not ieview the enviionmental hazaids that aie assessed

in EAs oi EISs. As noted eailiei, the committee`s chaige is limited to con-

sideiation of hazaids iesulting fiom stiuctuial failuies.

COMMITTEE APPROACH

The committee`s fist task was to assess the applicability and adequacy of

existing standaids and piactices foi the design, fabiication, and installa-

tion of offshoie wind tuibines.

In iesponse to this chaige, the committee ieviewed standaids and

guidance documents (the lattei encompassing iules, guidelines, iecom-

mended piactices, and othei similai documents) that have been devel-

oped by classifcation societies (nongoveinmental oiganizations and

piivate companies), industiy associations, and Euiopean goveinments. It

identifed some of the defciencies in these standaids and documents that

would have to be iemedied if they weie to be applied in the United States.

As discussed in Chaptei 3, the committee found that many existing

standaids and guidance documents could appiopiiately be applied in

FIßü8E 1-2 Scope of this study. (SOURCE: Geneiated by the committee.)

lrt|cJucticr

the United States but that no one set was complete. All have defciencies

in theii coveiage (foi example, stoims and huiiicanes on the Atlantic

coast and in the Gulf of Mexico) oi theii analysis methods that would

have to be iemedied befoie they could be used in the United States.

To iespond fully to its chaige, howevei, the committee believed that it

had to do moie than ieview existing standaids and guidance and indicate

theii defciencies. Othei iepoits have identifed at least some of the def-

ciencies, and the committee has diawn on these iepoits foi its assessment.

The committee`s view was that, to piovide BOEMRE with useful feedback,

the committee should offei its peispectives on how BOEMRE might iem-

edy those defciencies. It believed that it should step back and examine not

only the mechanics of iemedying the defciencies but also the undeilying

philosophies that could guide the development of additional standaids oi

guidance documents foi offshoie wind tuibines in the United States.

In applying this bioadei peispective, the committee ieviewed the

appioaches to oveisight of offshoie wind tuibines taken by Euiopean

countiies. It noted that cuiient standaids and guidance in Euiope

iange fiom veiy detailed and piesciiptive to high-level and less pie-

sciiptive. The committee also ieviewed how the safety of engineeied

stiuctuies is oveiseen in othei U.S. industiies-oil and gas pioduction,

wateiboine shipping, and buildings. It noted that iegulation in these

industiies has been moving away fiom a detailed, piesciiptive model

and towaid a moie peifoimance-based model.

As discussed in Chaptei 4, the committee`s consensus is that

peifoimance-based oveisight is the most effective appioach to ieme-

dying deficiencies in standaids and piactices foi offshoie wind instal-

lations. This appioach will help to fulfill two goveinment objectives:

The safe, oideily, and enviionmentally iesponsible development of

ienewable eneigy on the OCS, which is the chaige of BOEMRE; and

The bioad exploitation of the offshoie wind iesouice, which is an objec-

tive of the U.S. Depaitment of Eneigy and is in line with the adminis-

tiation`s stated piioiities.

Stiuctuial failuies in offshoie wind faims pose lowei iisk to human

health and the enviionment than do stiuctuial failuies in oil and gas

platfoims. In the committee`s view, howevei, successful exploitation of

Structural lntegrity of 0ffshore Wind Turbines

offshoie wind eneigy will iequiie not only that tuibines opeiate with

low iisk to human health and the enviionment but also that they piove

highly ieliable (to avoid negative peiceptions of the industiy) and become

economically competitive with othei souices of electiicity. The com-

mittee sees peifoimance-based oveisight as the iegulatoiy model most

compatible with fosteiing innovation, which it views as key in devel-

oping a viable U.S. industiy and biinging down the cost of electiicity

geneiated fiom offshoie wind.

Duiing its woik, the committee was cognizant of the iapid pace at

which offshoie wind piojects weie being pioposed foi specifc sites and

of the woik in seveial states to develop iegulatoiy stiuctuies foi piojects

in state wateis. It iecognized the need foi the fedeial goveinment to spec-

ify, faiily soon, how it will evaluate the acceptability of pioposed piojects

foi the OCS, so that pioject developeis will have suffcient infoimation

to move theii piojects foiwaid and to attiact the necessaiy fnancing.

The committee also noted that, although BOEMRE is conceined with

piojects outside of state wateis, fedeial guidance would also be of help to

states as they develop theii ciiteiia foi appioving piojects in state wateis.

In iecognition of BOEMRE`s need to act quickly in specifying the

iequiiements that pioposed piojects on the OCS must meet, the com-

mittee has set out inteiim measuies that could be implemented soon as

well as options foi longei-teim appioaches to oveisight.

In caiiying out its chaige, the committee met thiee times. At its fist

two meetings, it ieceived biiefngs on the development of standaids foi

offshoie wind eneigy in Euiope and on cuiient industiy effoits to develop

consensus standaids foi the United States. Repiesentatives fiom non-

goveinmental oiganizations, industiy associations, and one state pio-

vided peispectives fiom stakeholdeis on the development of offshoie

wind eneigy. The committee was also able to take advantage of an NRC

woikshop on offshoie wind eneigy that was held on Maich 25-26, 2010.

10

ORGANIZATION OF THE REPORT

Box 1-3 piovides defnitions foi some key concepts that aie used exten-

sively in Chapteis 3 and 4. Chaptei 2 piovides a biief oveiview of the

motivation foi the United States in developing offshoie wind eneigy. It

10

See http://www.tib.oig/MaiineBoaid/MaiineBoaid.aspx.

lrt|cJucticr

Key Concepts: Verincation, Certincation,

and Classincation

Verincation. Veiifcation is the piocess of deteimining whethei

a design, pioceduie, measuiement, oi othei activity follows a

specified standaid, guideline, design basis, oi othei definition

as specifed foi a pioject. Veiifcation can apply to design, fabii-

cation, oi installation. Foi instance, if the intent is that a pioject`s

tuibines be designed accoiding to the Inteinational Electio-

technical Commission 61400-3 standaid, a veiifei would assess

whethei the iequiiements of that standaid weie followed and weie

coiiectly applied, good piactice was followed, and no signifcant

defciencies weie evident. A veiifei may peifoim independent cal-

culations oi tests.

Certincation. Ceitifcation of a design, fabiication, oi installation

implies a highei level of iesponsibility on the pait of the ieviewei

than does veiifcation. To ceitify a design, foi instance, indepen-

dent design calculations oi testing would likely be peifoimed by

the ceitifei as a check, iathei than the ceitifei simply assessing

whethei the design was in accoidance with the specifed standaid

and design basis and whethei the iesulting design is accuiate.

The teim °ceitifcation" was likely deiived fiom the statutoiy

iequiiement in the United Kingdom that an offshoie oil and gas

facility ieceive a °ceitifcate of ftness" fiom an appointed ceiti-

fying authoiity on the basis of an independent assessment of the

design, method of constiuction, and opeiations manual and

associated suiveys caiiied out by suiveyois appointed by the

ceitifying authoiity.

Classincation. Nongoveinmental oiganizations and piivate com-

panies that establish and maintain technical iules and guidelines

foi the design, constiuction, and opeiation of ships and offshoie

stiuctuies aie commonly known as °classification societies."

(ccntinued cn next page)

Structural lntegrity of 0ffshore Wind Turbines

then ieviews offshoie wind eneigy pioduction woildwide and desciibes

the technologies involved in cuiient offshoie tuibine geneiatois.

The next two chapteis addiess the fiist element of the committee`s

chaige (Task I). Chaptei 3 ieviews existing standaids, the diffeiences

among them, and the woik undei way to identify defciencies and develop

new standaids. Chaptei 4 sets out the iegulatoiy philosophies undeilying

vaiious oveisight iegimes and how they might be incoipoiated into stan-

daids and guidance foi application in the United States. Chaptei 5 taigets

the second pait of the committee`s chaige (Task II) by ieviewing the iole

of thiid-paity oveisight and CVAs. Chaptei 6 assesses the qualifcations

needed by CVAs (Task III).

The fnal chaptei summaiizes the committee`s key fndings and iecom-

mendations foi stiuctuial and opeiating safety of offshoie wind eneigy

tuibine geneiatois.

REFERENCE

Abbrevíatíon

MMS Mineials Management Seivice

MMS. n.d. The Role of MMS in Renewable Eneigy. Fact sheet. http://www.mms.gov/

offshoie/ienewableeneigy.

ß0X 1-3 (ccntinued)

Key Concepts: Verincation, Certincation, and Classincation

As used in ielation to a classification society, classification is a

vaiiation on the concept of ceitification. The diffeience is that

the classifcation society is evaluating the design, fabiication, oi

installation with iefeience to its own iules oi guidelines iathei

than an exteinally developed standaid oi guideline.

Offshore Wind Technology and Status

Chaptei 2 piovides a biief oveiview of the motivation foi the United

States in developing offshoie wind eneigy. Offshoie wind eneigy pio-

duction woildwide is ieviewed, and the technologies involved in cuiient

offshoie tuibine geneiatois aie desciibed.

WIND TECHNOLOGY

Land-Based Wind Energy Technology

Wind tuibines conveit the kinetic eneigy of moving aii into electiicity.

Modein wind tuibines emeiged out of the U.S. goveinment`s initial push

foi ienewable eneigy development in iesponse to the oil ciises of the

1970s and the coiiesponding shaip iises in eneigy piices. Accoiding to

the Ameiican Wind Eneigy Association, at the end of 2009 moie than

35,000 MW of wind eneigy was installed in the United States, enough to

powei 9.7 million homes (AWEA 2010). By the end of 2010, installed

capacity had giown to moie than 40,000 MW. This capacity is entiiely

land based, and the vast majoiity of it piovides powei at a utility scale

of geneiation by aggiegating multiple wind tuibines into aiiays (wind

faims) to foim wind powei plants that can ieach sizes of up to 500 MW

pei pioject.

When the commeicial wind industiy began, wind tuibines aveiaged

aiound 50 kW, coiiesponding to iotoi diameteis of about 15.2 m (50 ft).

Today, land-based wind tuibine sizes have ieached 5,000 kW (5 MW),

coiiesponding to iotoi diameteis of moie than 126 m (413 ft), oi neaily

twice the wingspan of a Boeing 747 aiiciaft. This piogiession of scale

ovei time is shown in Figuie 2-1.

18 Structural lntegrity of 0ffshore Wind Turbines

FIßü8E 2-1 Wind turbine growth over time: modern wind turbine rotors

exceed 400 ft in diameter, or almost twice the wingspan of a Boeing 747.

(SOURCE: National Renewable Eneigy Laboiatoiy.)

Why Go Offshore?

Renewable souices foi electiicity geneiation, such as wind and solai

eneigy, can be exploited only wheie these iesouices aie available in suf-

fcient quantities-windy aieas foi wind, and so on. As demand incieases

foi electiicity geneiated fiom wind eneigy, additional sites with suff-

cient wind iesouices must be identifed.

In the United States, land-based wind iesouices aie abundant but aie

concentiated in the centei of the countiy. Adding wind-eneigy capacity

in these locations to seivice distant maikets with lowei wind iesouices is

feasible but may be limited by insuffcient electiicity tiansmission access

and capacity and by the cost of adding to this capacity. Moieovei, the

densely populated coastal eneigy maikets do not have good sites foi

onshoie wind, and given the lack of available land, siting new facilities in

such aieas can be diffcult.

Offshoie wind does not suffei fiom these diawbacks and has the

advantage that offshoie winds aie stiongei and steadiei than those on

land, allowing highei powei output. Of the contiguous 48 states, 28 have

a coastal boundaiy, so that tiansmission iequiiements fiom offshoie wind

to load centeis in these aieas can be minimized (Musial and Ram 2010).

U.S. electiicity use data show that these same states use 78 peicent of the

nation`s electiicity (USDOE 2008). Coastal iegions pay moie foi electiic-

300

280

260

240

220

200

180

160

140

120

100

80

60

40

20

1980-

1990

17 m

75 kW

30 m

300 kW

50 m

750 kW

70 m

1,500 kW

80 m

1,800 kW

100 m

3,000 kW

125 m

5,000 kW

150 m

10,000 kW

250 m

20,000 kW

Future wind

turbines

Rotor Diameter (m)

Rating (kW)

1990-

1995

1995-

2000

2000-

2005

2005-

2010

2010-? 2010-? Future Future

0

0íís|c|e wirJ Tec|rclc¸] orJ Stotus

ity ielative to the iest of the countiy, making electiicity fiom offshoie

wind moie economically competitive with othei souices of electiicity

geneiation in these iegions (Musial and Ram 2010, Section 2, 10-22).

Offshore Wind Technology

Figuie 2-2 shows a schematic of a typical offshoie wind tuibine, and

Figuie 2-3 shows photogiaphs of the common offshoie wind tuibines.

Most offshoie wind tuibines aie iobust veisions of pioven land-based

tuibine designs. They aie placed on fieestanding steel monopiles oi con-

ciete giavity-base substiuctuies. Although theii aichitectuie mimics that

of conventional land-base tuibines, offshoie wind tuibines incoipoiate

signifcant enhancements to account foi ocean conditions. The modifca-

tions include stiengthening of the towei to handle the added loading fiom

waves, piessuiization of the nacelles, addition of enviionmental contiols

to keep coiiosive sea spiay away fiom ciitical diivetiain and electiical com-

ponents, upgiades to electiical systems, and addition of peisonnel access

platfoims to facilitate maintenance and piovide emeigency sheltei. Most

exteiioi components of offshoie tuibines iequiie coiiosion piotection sys-

tems and high-giade maiine coatings. Most of the tuibine`s blades, nacelle

coveis, and toweis aie painted light giay to minimize visual impacts.

Lightning piotection is mandatoiy foi both land-based and offshoie

tuibines. Tuibine aiiays may be equipped with aiiciaft waining lights,

biight maikeis on towei bases, and fog signals foi ieasons of navigational

safety. To ieduce opeiational costs and yield bettei maintenance diag-

nostic infoimation, offshoie tuibines aie often equipped with condition

monitoiing systems (CMSs). The CMS measuies vibiation at vaiious

points thioughout the diivetiain (including the main shaft beaiings,

geaibox, and geneiatoi). The CMS also monitois opeiational paiame-

teis such as above-nacelle wind speed and diiection, geneiatoi electiical

output, geneiatoi winding tempeiatuie, main shaft iotational speed,

beaiing tempeiatuies, and ßuid tempeiatuies and piessuies of geaibox

lubiicating oil and hydiaulic contiol systems. Offshoie tuibines aie also

usually equipped with automatic beaiing lubiication systems, onboaid

seivice cianes, and oil tempeiatuie iegulation systems, all of which exceed

the typical maintenance piovisions foi land-based tuibines.