Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Standard Sheetmetal Slitting Tolerances

Caricato da

sudarshanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Standard Sheetmetal Slitting Tolerances

Caricato da

sudarshanCopyright:

Formati disponibili

Technical Data

BLUE SHEET

Allegheny Ludlum Corporation Pittsburgh, PA

Flat Rolled Products

Standard Tolerances and Ordering Information

STAINLESS STEEL SHEET

Allegheny Ludlum sheet stainless steels are flat-rolled products produced by continuous mill rolling, available in coils or cut lengths. Thicknesses range from .018" to .1874" and widths range from 24" to 48". For thicknesses lighter than .018" refer to the mill.

Camber Tolerances

Width Inches 24 to 36 Inclusive Over 36 to 48 Inclusive Maximum Camber in 8 Feet* Inch 1/8 3/32

Size Tolerances

Roller Leveled - Not Resquared

Thickness Inch Under .131 Under .131 .131 and over Nominal Length Inches 120 and under Over 120 Length Tolerance Inch +1/8 -0 Nominal Width Width Tolerance Inches Inch 48 and under 48 and under 48 and under +1/16 -0

*A special camber tolerance of 1/16 inch in 20 feet is available upon individual inquiry request.

Camber is the greatest deviation of a side edge from a straight line, the measurement being taken on the concave side by placement against an 8-foot straight edge.

Flatness Tolerances

+1/16 -0

+1/4 -0

Roller Leveled - Annealed Temper

Thickness Inch .018 -.1874 Width Inches 24 to 48 incl. Flatness Tolerance* (Maximum Deviation From Horizontal Flat Surface) Inch 1/2

All

+1/4 -0

+1/16 -0

Requirements for more restrictive tolerances should be referred to the mill.

Stretcher Leveled and Resquared

Thickness Inch Under .131 Under .131 .131 and over Nominal Length Length Tolerance Inches Inch 120 and +1/16 -0 under Over 120 All +1/8 -0 +1/8 -0 Nominal Width Width Tolerance Inches Inch 48 and +1/16 -0 under 48 and under 48 and under +1/16 -0 +1/16 -0

*Suitable for levelling to 1/4 inch max. on cut line equipment.

Stretcher Leveled - Annealed Temper

Flatness Tolerance Thickness Width Length (Maximum Deviation From Inch Inches Inches Horizontal Flat Surface) Inch Under 3/16 Under 3/16 To 48 To 48 To 96 Over 96 1/8 1/4

Requirements for more restrictive tolerances should be referred to the mill.

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Standard Tolerances and Ordering Information

Visit our Website at www.alleghenyludlum.com

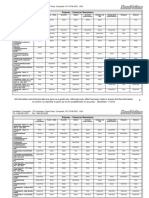

Standard Gage Tolerances

Thickness-Inch Under Including .1875 to .1451 .1451 to .1301 .1301 to .1141 .1141 to .0981 .0981 to .0831 .0831 to .0721 .0721 to .0581 .0581 to 0.401 .0401 to .0291 .0291 to .0160 Gage Number 8&9 10 11 12 13 14 15 & 16 17 to 19 20 to 22 23 to 27 Tolerance*-Inch +/.007 .006 .005 .005 .004 .004 .003 .003 .002 .0015

Allegheny Ludlum stainless strip is available within equipment limitations with any of these edges: No. 1 - Round or square produced by machining. No. 3 - Produced by slitting. No. 5 - Produced by shaving after slitting.

Specify Allegheny Ludlum when you order stainless and specialty steel strip.

Each strip product is made to your specification. With proper prints, parts and description of environmental condition, the most suitable strip supplied to your specification can best be achieved. Allegheny Ludlum offers fully integrated production of a complete line of stainless steel strip in all standard grades and finishes. These are ideal for applications requiring corrosion resistance, strength, durability and ease of cleaning. Our Precision Rolled StripTM products are tailor-made for specific end uses in the lighter strip thicknesses. These products are typically produced to very tight dimensional, surface, and metallurgical property tolerances.

*Width through 48" maximum

Note: Unless otherwise specified, the gage aim will be on the minus side of the tolerance.

Standard Finishes

The chromium-nickel and straight chromium grades of stainless steel sheets can be surface treated to provide a variety of finishes. These methods include pickling, grinding, and rolling. #1 - Hot rolled, annealed and pickled #2B - Cold rolled on polished rolls, annealed, pickled, and skin passed on polished rolls #2D - Cold rolled, annealed, pickled, and skin passed with dull blasted rolls or may be ordered without the dull skin pass for formability or surface considerations. #3 - Polish #4 - Polish

Camber

Up to and including 1-1/2" wide...1/2" maximum in any 8-foot length. Over 1-1/2" to 23.999" wide...1/4" maximum in any 8-foot length. Camber to be determined by placing an 8-foot straight edge against the concave edge of the strip.

Coatings

Adhesive vinyl coverings are available with a range of adhesive strengths for various applications.

Size Tolerances

Thickness

Series 200, 300 and 400 grades are measured 3/8" in from edge on 1" or wider and on narrower than 1" at any place on the strip.

STAINLESS STEEL STRIP

Allegheny Ludlum strip stainless steels are flat-rolled products available in coils or cut lengths. Thicknesses range from .0015" to .1874" and widths range from .1875" to 23.999".

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Precision Rolled StripTM is a trademark of Allegheny Ludlum Corporation.

Technical Data BLUE SHEET

Annealed Strip

Thickness Tolerance - Inch +/Width - Inch .1875 Over to 1 to 6 to .999 2.999 3 to 6 12 incl. incl. incl. incl. .004 .004 .003 .004 .004 .003 .004 .004 .003 .003 .003 .002 .002 .004 .003 Over Over 12 to 16 to 16 under incl. 24 .005 .004 .004 .003 .003 .002 .002 .006 .005 .004 .003 .003 .002 .002

Annealed Strip - Width (No. 3 Edge) Slit

Width Tolerance - Inch +/Width - Inch .1875 Over Over to 6 to 9 to .499 1/2 to 9 12 incl. 6 incl. incl. incl. .016 .010 .008 .005 .005 .010 .008 .005 .005 .020 .016 .010 .005 .005 .020 .016 .010 .010 .010 Over Over 20 to 12 to under 20 24 incl. incl. .031 .020 .016 .016 .016 .031 .020 .020 .020 .020

Thickness Under Incl. .161 to .100 .100 to .069 .069 to .050 .050 to .040 .040 to .035 .035 to .029 .029 to .026 .026 to .020 .020 to .015 .015 to .002

.1875 to .161 .004

Thickness Under Incl. .1875 to .161 .161 to .100 .100 to .069 .069 to .015 .015 to .002

.003 .003 .003 .0025 .0025 .0025 .002 .002 .0015 .0015 .001 .001 .001 5% .002 .002

.0015 .0015 .0015 .001 .0015 .0015 .001 5% .001 5% .0015 5%

.0015 .0015 .0015 .0015 .0015 .0015 5% 5%

Width (Nos. 1 and 5 Edges) - Round or Square 200/300 Series

Edge No. 1 5 Width Inches 1.75 or narrower 1.75 or narrower Thickness Inch Under .055 Under .055 Tolerance Inch +/.005 .005

Temper Rolled Strip

Thickness Tolerance - Inch +/Width - Inch .1875 Over to 1 to 6 to .999 2.999 3 to 6 12 incl. incl. incl. incl. .004 .004 .003 .004 .004 .003 .004 .004 .003 .003 .003 .004 .003 Over Over 12 to 16 to 16 under incl. 24 .005 .004 .004 .003 .003 .003 .0025 .002 .002 .002 5% .006 .005 .004 .004 .004 .003 .003 .003 .0025 .002 5%

Length

Length of Strip Feet Up to 5 inclusive 5 to 10 inclusive 10 to 20 inclusive

Lengths over 20 feet, refer to mill for quotation.

Thickness Under Incl. .161 to .100 .100 to .069 .069 to .050 .050 to .040 .040 to .035 .035 to .029 .029 to .026 .026 to .020 .020 to .015 .015 to .002

Tolerance - Inch All over, nothing under 3/8 1/2 5/8

.1875 to .161 .004

.003 .003 .003 .0025 .0025 .0025

.002 .002 .0025 .003 .0015 .0015 .002 .0025 .001 .001 .001 5% .0015 .0015 .001 .0015 .001 5% .001 5% .002 .002 .0015 5%

Standard Finishes

The chromium-nickel and straight chromium grades of stainless steel strip can be surface treated to provide a wide variety of finishes. #1 - Hot rolled, annealed and pickled. #1D - Cold rolled, annealed and pickled. #2D - Cold rolled, annealed, and pickled, or annealed and skin passed with dull rolls. #1B - Cold rolled on polished rolls, annealed, pickled.

Width

Narrow width tolerances are maintained on strip product, but such tolerances vary depending upon whether an as-slit edge (No. 3) or mechanically prepared edge (Nos. 1 and 5) is ordered.

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Standard Tolerances and Ordering Information

Visit our Website at www.alleghenyludlum.com

#2B - Cold rolled on polished rolls, annealed, pickled, and skin passed on polished rolls. #1BA - Cold rolled on polished rolls, annealed in a protective atmosphere retaining the as-rolled surface appearance. #2BA - Same as #1BA except the annealed strip receives a final skin pass. #1CBA - Dull cold rolled and annealed in a protective atmosphere. #2CBA - Same as #1CBA except the annealed strip receives a final skin pass. #1 Bright Hardened - Martensitic grades cold rolled on polished rolls and heat treated in a protective atmosphere, retaining the as-rolled surface appearance. #2TR - Cold rolled to a temper specified by the customer. Special finishes are available upon request.

Available shapes include rectangles, circles, rings, bars or special shapes per customer drawing. Tolerances will be applied on top of cleanup allowance specified by customer.

Size Tolerances

Sheared Mill Plate Tolerances

Series 300 rectangular and square plates in thickness 3/16" to 1" inclusive, and 400 to 500 series in thicknesses 3/16" to 3/8" inclusive, can be cut or sheared in all sizes which can be rolled. Permissible variation over or under specified width, length and diagonal measurement for thickness shown.

Dimension Width and Length Diagonal 3/16 to 1/2 incl. +1/16 -1/16 3/16 max. Thickness - Inch Over 1/2 to Over 3/4 to 1 3/4 incl. incl. +1/8 +3/16 -1/16 -1/8 1/4 max. 3/8 max.

When closer tolerances are required, they must be stated on the inquiry or order.

Camber Tolerances

Camber tolerance for plate mill plate is 1/8" maximum deviation from a straight line in 5 feet.

Coatings

Adhesive vinyl coverings are available with a range of adhesive strengths for various applications.

Plasma Cut Plate Tolerances

Thickness Inches Width and Length Tolerances Inch +/+/+/+/+/1/8 3/16 1/4 3/8 1/2

Oscillate Wound

Width - Inches .125 through 1.750 ID 16 Thickness - Inch .008 through .055

Coils up to 2000 lbs. (depending on width and gauge) are available as oscillate wound.

Under 1 1 to under 2 2 to under 4 4 to under 5 5 to 6 incl.

On Application

Foil is available in thicknesses less than .002. Strip gages are available in up to 48" widths.

Abrasive Saw Cut Tolerances

Thickness Inches Under 1 1 to under 2 2 to under 4 4 to under 5 5 to 6 incl. Width and Length Tolerances Inch +/+/+/+/+/1/16 3/32 1/8 3/16 1/4

STAINLESS STEEL PLATE MILL PLATE (PMP)

Allegheny Ludlum offers quality stainless plate mill plate products in a full range of sizes3/16" to 10" in thickness and over 6" in width. These are available in a variety of grades and finishes.

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Technical Data BLUE SHEET

Plate Thickness Tolerances

Width - Inches *Thickness Inches Incl. 3/16 3/8 3/4 1 2 3 4 6 8 to to to to to to to to to To Under 84 incl. 3/8 3/4 1 2 3 4 6 8 10 .045 .055 .060 .070 .125 .175 .250 .350 .450 Over 84 to 120 incl. .050 .060 .065 .075 .150 .210 .300 .420 .540 Over 120 144 incl. Over 144 .075 .085 .095 .175 .245 .350 .490 .630 .090 .100 .115 .200 .280 .400 .560

Dimensional Tolerances, Inch

* Gage +.025 - .010 Width +1/16 - .0 Roller Level Flatness 1/2 maximum ** Camber 1/8 in 8 feet *** Length +1/4 - .0 * Inquire for specific requirements for tighter than standard gage tolerances. ** Camber tolerances of 1/16 inch maximum in 20 feet available upon individual inquiry request. ** Stretcher levelled and resquared CMP available upon request. Inquire for specific width, length and squareness tolerances.

*No plate 10" thick or under shall vary more than .01" under the thickness ordered. Spot grinding not to exceed .01" under the specified thickness is permitted to remove surface imperfections on thicknesses 10" and under. Note: For thicknesses 10" or greater, refer to the mill.

Finishes

HRAP(#1) - Hot rolled, annealed and pickled. 2B Plate Finish - Also known as Allegheny Ludlum's exclusive 56 Finish. A smoother cold rolled, annealed and pickled product that is skin passed on polished rolls to approach a 2B Finish. Polish - Available on individual inquiry basis.

Flatness Tolerances

Commercial flatness per ASTM A480. Special flatness requirements for 1/2" thickness and under are available by stretcher levelling.

Finishes

Standard Finishes

HRAP - Hot rolled annealed and pickled is standard for best corrosion resistance and surface conditions. HRA - Hot rolled, and annealed suggested only for heat resisting applications. There is no guarantee on surface quality.

STAINLESS STEELS

200 Series

Cr/Mn/Ni - 201, AL 201LTM, AL 201LNTM, AL 216TM, AL 219TM 300 Series Cr/Ni - 301, 302, 302B, 303, 304, 304L, 305 Cr/Ni/Mo - 316, 316L, 316LXN, 317, 317L, 317LX, 317LXN High Cr/Ni - 309, 309S, 310, 310S, AL 310L, AL 332, AL 334 Stabilized - 321, 347, 348 High Strength - AM 362, AM 363 400 Series Straight Cr Ferritic - 405, 409, AL 409HPTM, AL 409CbTM, 410S, 430, AL 433TM, 434, 436, AL 436STM, 439, 439HPTM, AL 441, 444, 446, AL 466TM, AL 467TM, AL 468TM Martensitic Grades - See page 8 Clad Material - AL 304DA

Special Finishes

Polished Finish - Polished and ground finishes are available for special applications.

STAINLESS STEEL CONTINUOUS MILL PLATE (CMP)

Allegheny Ludlum stainless CMP steels are produced from continuous coil rolling, with availability in coil or cut lengths. Thicknesses range from .1875" to .250" and widths from 24-48".

Trademark of Allegheny Ludlum Corporation

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Standard Tolerances and Ordering Information

Visit our Website at www.alleghenyludlum.com

SPECIAL ALLOYS Magnetic Materials

Moly Permalloy (80% Ni, 4.4 % Mo, balance Fe) Available in strip and sheet for use in transformers, reactors, and communications equipment. ASTM A753 Type 4 AL 4750TM (48% Ni, balance Fe) - Available in strip and sheet for use in relays, audio transformers, instruments, communications equipment, rotors, and stators. ASTM A753 Type 2 AL 45TM (45% Ni, balance Fe) - Available in sheet and strip for use in relays, rotors, stators, glass-tometal seals. ASTM A753 Type 1

AL 52TM (50.5% Ni, balance Fe) - Available in strip and sheet for controlled expansion and glass-tometal sealing applications. (N14052)

Electrical Resistance Material

Ohmaloy 30 and Ohmaloy 40 (13% Cr, 3.0 and 3.75% Al, balance Fe) - Available in strip and sheet for use in resistor grids for motor controls, and rheostats. (K91470)

Oxidation Resistant Materials

ALFA-ITM (13% Cr, 3% Al, .4% Ti) - Available in strip and sheet for high temperature oxidation and sulfidation resistance such as furnace parts, recuperators and synfuel equipment. (K91470) ALFA-IITM (13% Cr, 4% Al, .4% Ti) - Available in strip and sheet for high temperature oxidation and sulfidation resistance such as furnace parts, recuperators and synfuel equipment. (K91470) ALFA-IV (20% Cr, 5% Al plus Rare Earth Metals) Available in strip form for use in applications where a very high degree of oxidation resistance is required. AL 601TM (23% Cr, 1.4% Al, 60.5% Ni, 14.1% Fe) Available in plate, sheet and strip. For use in aerospace and process industry applications involving elevated temperatures. (N06601)

Relay Steels

No. 2, No. 5 (1.25% and 2.25% Si) - Available in strip and sheet for use in relays, armatures and solenoids.

Controlled Expansion Materials

AL 36TM (36% Ni, balance Fe) - Low expansion alloy available in strip and sheet for use in cryogenic containers, and bi-metallic thermostats. ASTM B753 Type T-36 (K93601) AL 42TM (42% Ni, balance Fe) - Controlled expansion alloy available in strip and sheet for use in integrated circuit leadframes and glass-to-metal sealing applications. ASTM F30 (K94100) Sealmet4 (42% Ni, 6% Cr, balance Fe) - Available in strip and sheet for use in glass-to-metal seals. ASTM F31 (K94760) Sealmet 485 (47% Ni, 6% Cr, balance Fe) - Available in strip for use in glass-to-metal seals, primarily in colored television tubes. 430 Ti (20% Cr, balance Fe) - Available in strip and sheet for use in glass-to-metal seals. ASTM F256 Type 1 (K91800) AL 22-3TM (22% Cr, 3% Ni, balance Fe) - Available in strip and sheet for use in bi-metallic thermostats. ASTM B753, Type T-22

Corrosion Resistant Materials

AL-6XN (24.5% Ni, 20.25% Cr, 6.25% Mo, .2% N2) Superaustenitic stainless steel available in plate, sheet and strip where high resistance to chloride pitting and stress corrosion are required. For use in condenser tubing, high chloride waters and corrosive environments. (N08367) AL 904LTM (24.5% Ni, 20.5% Cr, 1.5% Cu, 4.5% Mo) - Available in plate, sheet and strip for use in power generation equipment and corrosive atmospheres. (N08904) E-BRITE 26-1 (26% Cr, 1% Mo) - High purity superferritic stainless steel. Available in sheet and strip for use in chemical process equipment to combat chloride pitting and stress-corrosion cracking. Used as replacement for 28% Cr alloy in glass-tometal sealing applications. (S44627)

Registered Trademark of Allegheny Ludlum Corporation Trademark of Allegheny Ludlum Corporation

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Technical Data BLUE SHEET

AL 29-4 (29% Cr, 4% Mo) - High purity superferritic stainless steel available in sheet and strip. Excellent resistance to chloride pitting and stress-corrosion cracking environments for use in utility industry and chemical processing equipment. (S44700) AL 29-4C (29% Cr, 4% Mo, stabilized) - Available in sheet and strip. Alloy designed for excellent resistance to chloride pitting and stress corrosion and no nickel for lower product cost. Same end uses as AL 29-4 alloy plus household condensing furnaces and vent pipe. (S44735) AL 29-4-2 (29% Cr, 4% Mo, 2% Ni) - High purity superferritic stainless steel available in sheet, strip and plate for use in corrosive environments, chemical processing equipments, and utility industry. (S44800) AL 2205TM (22% Cr., 5% Ni, 3% Mo, .15% N2) Duplex stainless alloy available in sheet, strip and plate for use in oil wells and other heavy gage pipe applications. Alloy has good combination of stresscorrosion resistance and moderately high yield strength. (S31803) AL 255TM (25% Cr, 5.5% Ni, 3.5% Mo, 2% Cu, .18% N2) - A super duplex stainless steel available in plate form. Superior combination of high strength and stress corrosion resistance for a wide variety of applications. (S32550) AL 20TM (33% Ni, 20% Cr, 3% Cu, 2% Mo, balance Fe) - Available in plate, sheet and strip. For use in sulfuric acid and a variety of environments. (N08020) AL 276TM (58% Ni, 16% Mo, 15.5% Cr, 6% Fe, 3.5% W) - Available in plate, sheet and strip. Among the most corrosion resistant of the nickel-base alloys. (N10276) AL 200 and AL 201TM (Commercially pure nickel) - Available in plate, sheet and strip. For use in reducing environments, alkalies and salts.(N02200/ N02201) AL 400TM (65% Ni, 33% Cu) - Available in plate and strip. For use in marine environments, alkalies and salts. (N04400)

AL 600TM (15% Cr, 75% Ni) - Available in plate, sheet and strip. For use from cyrogenic to elevated temperatures. Chemical and nuclear applications. (N06600) JS700 (25% Ni, 21% Cr, 4.5% Mo, .25% Cb, Balance Fe) - Available in plate. Applications where pitting or crevice corrosion are of primary concern, such as fertilizer manufacturing equipment. (N08700) AL 800 and AL 800H and AL 800ATTM (21% Cr, 32% Ni, balance Fe) - Available in plate, sheet and strip for high temperature applications. (N08800/ N08810/N08811) AL 825TM (21% Cr, 40% Ni, 3% Mo, 3% Cu, balance Fe) -Available in plate, sheet and strip . For use in neutral or moderately oxidizing environments. (N088251) Alloy B2 (30% Mo, balance Ni) - Excellent resistance to HCl acid, halogens and other corrosive catalysts as well as hot sulfuric acid. Available in plate form. (N10665) Alloy G3 (48% Ni, 22% Cr, 7% Mo, 2% Cu, .2% Cb, 20% Fe) - Resists pitting and stress-corrosion cracking in acid and alkaline environments. Applications in chemical processing, pulp and paper manufacturing. Available in plate form. (N06985) Alloy 22 (60% Ni, 21% Cr, 13% Mo, 3% W) Similar applications as AL 276, with better corrosion resistance in oxidizing environments. Available in plate. (N06022)

High Temperature Materials

Altemp A286 (25.5% Ni, 15% Cr, 2.1% Ti, 1.25% Mo, balance Fe) - Available in plate, sheet and strip. For use in jet engines, gas turbines and other heat resisting applications. (S66286) Altemp 625 (22% Cr, 9% Mo, 4% Fe, 3.5% Cb plus Ta, balance Ni) - Available in plate, sheet and strip. For use in jet engines and a variety of corrosive environments. (N06625) Altemp HX (22% Cr, 18% Fe, 9% Mo, balance Ni) Available in plate, sheet and strip. For use in gas turbine and heat resisting applications. (N06002)

Registered Trademark of Allegheny Ludlum Corporation Trademark of Allegheny Ludlum Corporation

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Standard Tolerances and Ordering Information

Visit our Website at www.alleghenyludlum.com

Altemp 718 (19% Cr, 16% Fe, 5.25% Cb plus Ta, 3% Mo, balance Ni) - For use in gas turbine and heat resisting applications. (N07718)

AL 15-7TM (15% Cr, 7% Ni, 2% Mo, 1.1% Al, balance Fe) - Available in sheet and strip. Uses similar to AL 17-7 alloy. (S15700) AL 17-4TM (17% Cr, 4% Ni, 3.5% Cu, balance Fe) Available in plate. For use in fasteners, military equipment and air frame parts. (S17400) AL 15-5TM (15% Cr, 4.5% Ni, 3.5% Cu) - Available in plate. Uses similar to AL 17-4 alloy. (S15500)

High Strength Materials

AL 219TM (21% Cr, 6% Ni, 9% Mn, .30% N2, balance Fe) - Available in sheet, strip and plate. Intended for high-strength non-magnetic applications and aircraft parts. (S21904) Comparable to Alloy 21-6-9. AM 350TM (16.5% Cr, 4.3% Ni, 2.75% Mo, .8% Mn, balance Fe) - Available in sheet and strip. For use in high-strength aerospace applications. (S35000) AM 355TM (15.5% Cr, 4.3% Ni, 2.75% Mo, .95% Mn, balance Fe) - Available in sheet and strip. For use in high-strength aerospace applications. (S35500) AL 30 (16% Cr, 8% Mn, 2.2% Ni, .2% N2, balance Fe) - Nitrogen-strengthened austenitic stainless steel with higher strength than 304 for use in structural applications where improved stress corrosion resistance is needed. (S20400) AL 33TM (18.5% Cr, 14% Mn, 3.0% Ni, .27% N2, balance Fe) - Nitrogen-strengthened austenitic stainless steel for heat exchangers, structural support systems and chemical equipment. Improved galling resistance over AL 30. Low magnetic permeability. Suitable for cryogenic applications. Available in plate form. (S24000) AL 40TM (21% Cr, 6% Ni, 9% Mn, .3% N2, balance Fe)- Nitrogen-strengthened austenitic stainless steel with good stress corrosion resistance and cryogenic temperature toughness. Low magnetic permeability. Available in plate, sheet, and strip. (S21904, same as AL 219) AL 50TM (21% Cr, 12.5% Ni, 5% Mn, 2% Mo, .3% N2, balance Fe) - Nitrogen-strengthened austenitic stainless steel for petrochemical, pulp and paper and food processing industries. Available in plate form. (S20910) AL 17-7 (17% Cr, 7% Ni, 1.1% AL, balance Fe) Available in plate, sheet and strip. For use in high strength springs, bellows and aerospace applications. (S17700)

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

TM TM

Martensitic Stainless Steels

AL 410TM (12% Cr, .1%C) - A general purpose corrosion and heat resisting hardenable straight chromium grade. Available in strip and plate mill plate. (S41000) AL 410HCTM (12% Cr, .2% C, balance Fe) Available in sheet or strip for applications requiring a higher hardness than 410 such as cutlery and garbage disposal parts. AL 418TM Special (13% Cr, 3% W, 2% Ni, balance Fe) Available in strip. For use in aerospace applications. AL 420TM and AL 420HCTM (13% Cr, .37% C) Available in sheet or strip for use in cutlery, valve parts, brake discs and forgings. (S42000) AL 425TM Modified (13.5% Cr, 1% Mo, .53% C) Available in strip for use in top quality cutlery. AL 440ATM (16.5% Cr, .63% C, balance Fe) Available in strip for cutlery end use. (S44002) AL 440CTM (16.5% Cr, 1% C) - Hardenable to high hardness levels for wear resistance applications and corrosion resistance above carbon steel. Typical uses in bearings, valve parts, cutlery and industrial knives. Available in plate mill plate. (S44004)

ELECTRICAL STEELS GRAIN-ORIENTED TYPES

Silectron (M-2 .007", M-3 .009", M-4 .011", M-6 .014") - Available in widths ranging from 3/4" to 34" inclusive with minimal edge burr and is most often used in the manufacture of distribution transformers, power transformers, and specialty industrial and commercial transformers.

Registered Trademark of Allegheny Ludlum Corporation Trademark of Allegheny Ludlum Corporation

Technical Data BLUE SHEET

TOOL STEELS

Jessop Econ-O-Miser , Decarb-Free Plates and Flat Bars Saw Cut From Plate

Ground or machined, flattened and saw cut to size

Thickness Inches 1/4 through 8 *Standard Sizes Available Width Length Inches Feet To 36 maximum 7 to 12 (Varies by Thickness)

A7 (2.3% C, 5.25% Cr, 4.75% V, 1.1% Mo, 1.1% W) An air hardening grade with outstanding abrasion resistance but lower toughness than D2. For use on tooling for maximum production runs. (T30107) D2 (1.5% C, 12% Cr, 1% Mo, .8% V) - An air hardening grade with good nondeforming properties. Widely used in applications requiring high abrasion resistance and high compressive strength, such as blanking, forming and stamping dies, forming and scanning rolls, slitters and gages. (T30402) S7 (.5% C, 3.25% Cr, 1.4% Mo, .7% Mn) - An air hardening grade with excellent toughness and suitable for shock resisting service for both hot and cold work tooling applications. Typical uses in blanking, forming and perforating dies, shear blades, chisels, plastic molds, punches, hot gripper and header dies and hot swaging dies. (T41907) H13 (.37% C, 5% Cr, 1.35% Mo, 1% V, 1% Si) - An excellent hot work grade with an outstanding combination of shock resistance, red hardness, and abrasion resisting properties. Typical applications include die casting dies, hot forging dies, hot press dies, die holder blocks, hot work punches and plastic molding dies. (T20813) M2 (.84% C, 4.15% Cr, 4.65% Mo, 5.65% W, 1.85% V) - A high speed steel with an excellent combination of wear resistance, toughness and hot hardness. Suitable for general purpose cutting tool applications, such as boring tools, broaches, chasers, cutters drills, lathe tools, and forming dies. (T11302) M3 (1.07% C, 4% Cr, 5.1% Mo, 5.5% W, 2.4% V) Slightly higher wear resistance and lower toughness than M2. Typical applications similar to that of M2. (T11313) 420ESR (.35% C, 13% Cr) - This stainless steel grade is an air or oil hardening mold steel having superior internal cleanliness combined with good corrosion resistance. Capable of providing excellent polished surface quality. (S42000) Grades S5, L6 and O2 as well as many other tool steels or tooling related grades are available in heat lot quantities. Submit requirements on an individual inquiry basis.

*Non-standard sizes will be considered on individual inquiry.

*Oversize (Cleanup) Tolerances, Inches Specified Thickness 1/4 through 4 Over 4 Oversize Allowance Oversize Allowance on Width, Bars Cut on Thickness from Plate +.015 to .035 +.062 to .093 +.015 to +.077 +.062 to +.124

*Produced to ASTM specifications.

Grades 01, 06, A2, A6, A7, D2, S7, H13, M2, M3 and 420 ESR are available from inventory. 01 (.9% C, .5% Cr, .5% W, .15% V, 1% Mn) - General purpose, non-deforming oil hardening tool steel for applications where maximum dimensional accuracy is required during hardening. Typical applications include blanking dies, gages, shims, machine ways, blades, cutters, and cams. (T31501) 06 (1.45% C, 1.25% Si, 1% Mn) - An oil hardening grade with a fine dispersion of graphitic carbon for improved machinability and resistance to galling. Typical applications include gages, punches, forming dies, jigs, and machine parts such as spindles, cams, arbor wear plates, bushings and guides. (T31506) A2 (1% C, 5% Cr, 1% Mo, .25% V) - An air hardening cold work grade less expensive than high C - high Cr tool steels, with excellent nondeforming properties. For use in dies, rolls, blanking punches, slitting cutters, trimmer dies and gages. (T30102) A6 (.7% C, 1% Cr, 1.3% Mo, 2% Mn) - An air hardening cold work grade with superior nondeforming properties. Particularly attractive for dies, punches, gages and other tools where close size tolerance is important. (T30106)

Jessop Econ-O-Miser is a registered trademark.

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Standard Tolerances and Ordering Information

Visit our Website at www.alleghenyludlum.com

Precision Ground Flat Stock

Decarb-Free, precision ground, flattened, straightened tool steel stock

*Standard Sizes Available, Inches Thickness 1/64 through 4 Width Up to 14 Length 18 or 36 (Low Carbon - 24)

QUALITY SYSTEM PROGRAM

The Allegheny Ludlum Quality System is customer driven, strives for continuous improvement, and positions Allegheny Ludlum at the leading edge of quality technology. The Allegheny Ludlum Quality System is ISO 9001 certified for the design, melting and finishing of stainless steels, high technology alloys and silicon electrical steels. Allegheny Ludlum maintains a documented Quality System Program as a means of ensuring that products meet or exceed specified customer quality standards as well as other stringent requirements including Aerospace and Nuclear. Customers requiring special certification may survey our Quality System to verify conformance to their standards.

*Special sizes will be considered on individual inquiry.

Grades available from inventory:

01, A2, A6, D2, S7, M2, and Low Carbon Other grades available upon individual inquiry consideration.

*Tolerances, Inches Length Regular: +1/16 minimum Width Thickness +.005 - .000 .001 thru 1.250 .002 over 1.250 Oversize: +1/16 minimum +.010 to .015 +.010 to .015

*Special tolerances available on request.

Referenced data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown above.

Registered Trademark of Allegheny Ludlum Corporation Trademark of Allegheny Ludlum Corporation

10

Technical Data BLUE SHEET

G65/ED8/898/SW

Copyright, Allegheny Ludlum Corporation 1998

Printed in U.S.A.

Potrebbero piacerti anche

- En 10051Documento2 pagineEn 10051sskamalakannanNessuna valutazione finora

- MachiningDocumento12 pagineMachiningwardendavid5591100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Motor Manufacturing Process FlowDocumento8 pagineMotor Manufacturing Process FlowcmashtamoorthyNessuna valutazione finora

- En 10029Documento3 pagineEn 10029hamoody_007100% (1)

- Standard EN10029Documento4 pagineStandard EN10029Florin JipaNessuna valutazione finora

- En 10029Documento3 pagineEn 10029Nuran ZorNessuna valutazione finora

- Thikness TolerenceDocumento5 pagineThikness TolerencemuneeshwaraperumalNessuna valutazione finora

- Ii - B B248Documento12 pagineIi - B B248omsingh1988Nessuna valutazione finora

- Astm A 572Documento2 pagineAstm A 572Vijay KumarNessuna valutazione finora

- En 10029 (Detail)Documento3 pagineEn 10029 (Detail)muhammad chilmiNessuna valutazione finora

- ASTM A572 Grade 50 Plate: AnalysisDocumento2 pagineASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoNessuna valutazione finora

- Propiedades Grado 50 A572Documento2 paginePropiedades Grado 50 A572daniel moreno jassoNessuna valutazione finora

- Clotan Steel IBR Brochure DigitalDocumento6 pagineClotan Steel IBR Brochure DigitalPieter SteenkampNessuna valutazione finora

- Cold Rolling MillDocumento4 pagineCold Rolling MillArslan BohioNessuna valutazione finora

- Hot Dip GalvanisedDocumento20 pagineHot Dip Galvanisedepsa333100% (1)

- Continuously Cast Stainless Steel Slab, Bloom & BilletDocumento2 pagineContinuously Cast Stainless Steel Slab, Bloom & BilletZachary PierceNessuna valutazione finora

- Al - 1050ADocumento2 pagineAl - 1050Adejo1986100% (1)

- Datasheet Strenx 100 XFDocumento2 pagineDatasheet Strenx 100 XFLuis Alberto BelmonteNessuna valutazione finora

- Sheet Metal Gauge Chart - SheetMetal PDFDocumento3 pagineSheet Metal Gauge Chart - SheetMetal PDFsunilbholNessuna valutazione finora

- Rolling Threads DetailsDocumento0 pagineRolling Threads DetailsfastenersworldNessuna valutazione finora

- Rectangular-K27 Duct and Fittings Dimensions: Table 1Documento31 pagineRectangular-K27 Duct and Fittings Dimensions: Table 1Shaun SullivanNessuna valutazione finora

- LUMBERLOK Timber Connectors & BOWMAC Structural BracketsDocumento30 pagineLUMBERLOK Timber Connectors & BOWMAC Structural BracketsDinh Nam NguyenNessuna valutazione finora

- Din RailDocumento4 pagineDin RailraoNessuna valutazione finora

- En 10029 PDFDocumento5 pagineEn 10029 PDFmanuela vilas boasNessuna valutazione finora

- En 10029Documento5 pagineEn 10029manuela vilas boasNessuna valutazione finora

- American StandardDocumento24 pagineAmerican StandardmitulfavsNessuna valutazione finora

- Stramit Monoclad: Product Technical ManualDocumento8 pagineStramit Monoclad: Product Technical Manualchillerz69Nessuna valutazione finora

- General Information Theory - LindabDocumento27 pagineGeneral Information Theory - LindabaudithanNessuna valutazione finora

- Billet: Direct Cast Billets For Long Steel ProductsDocumento6 pagineBillet: Direct Cast Billets For Long Steel ProductsMada TetoNessuna valutazione finora

- AME Clad Metal BrochureDocumento4 pagineAME Clad Metal BrochureEalumalai MuthuNessuna valutazione finora

- Grating CatalogueDocumento16 pagineGrating CataloguePrashant Dhotre100% (1)

- PB Alumec EnglishDocumento12 paginePB Alumec EnglishByron RodriguezNessuna valutazione finora

- KS1000 RW Panel UK Roof Poduct Data SheetDocumento6 pagineKS1000 RW Panel UK Roof Poduct Data SheetThe Lone GunmanNessuna valutazione finora

- Stamping Design GuidelineDocumento13 pagineStamping Design GuidelineVikram Borkhediya100% (1)

- Lysaght OptimaDocumento8 pagineLysaght OptimaAgung PriambodhoNessuna valutazione finora

- Non Standarad Dowel PinDocumento4 pagineNon Standarad Dowel Pinjaskaran singhNessuna valutazione finora

- Aalco Datasheet ST ST TubeDocumento2 pagineAalco Datasheet ST ST TubebinaywatchNessuna valutazione finora

- Shine MaxDocumento12 pagineShine MaxSales Shree Bajrang SteelNessuna valutazione finora

- ST Lawrence Ultra-MetDocumento6 pagineST Lawrence Ultra-Metmpcd07Nessuna valutazione finora

- Mr. Shims Offers A Wide Variety of Aluminum, Plastic And: E-MailDocumento3 pagineMr. Shims Offers A Wide Variety of Aluminum, Plastic And: E-MailWaqasNessuna valutazione finora

- ToleranceDocumento9 pagineTolerancemarkom123Nessuna valutazione finora

- Fibre Cement Slates Fixing GuideDocumento26 pagineFibre Cement Slates Fixing GuideMuhammad HafizuddinNessuna valutazione finora

- Rhino Grating PDFDocumento16 pagineRhino Grating PDFoluomo1Nessuna valutazione finora

- Jis G3141Documento0 pagineJis G3141johnnyquest_86Nessuna valutazione finora

- Catálogo RIBADocumento28 pagineCatálogo RIBAAna BatistaNessuna valutazione finora

- Steel Sheet PileDocumento8 pagineSteel Sheet PileTee Bun PinNessuna valutazione finora

- Tolerante Table Groase Laminate La Cald EN 10029-2011 PDFDocumento2 pagineTolerante Table Groase Laminate La Cald EN 10029-2011 PDFDaniel C.Nessuna valutazione finora

- Flaktwoods SilencersDocumento14 pagineFlaktwoods SilencersBenjamín AlainNessuna valutazione finora

- Shearing and Slitting Steel Sheet and StreepDocumento8 pagineShearing and Slitting Steel Sheet and StreepgrtunaNessuna valutazione finora

- Sproule WR 1200 Perlite TDSDocumento2 pagineSproule WR 1200 Perlite TDSnaseema1Nessuna valutazione finora

- HRCA SteelDocumento30 pagineHRCA SteelShankar PranavNessuna valutazione finora

- Core Grating Products09Documento20 pagineCore Grating Products09Donald HamiltonNessuna valutazione finora

- Bimetal-Strip-Steel 2017 Rev.1Documento14 pagineBimetal-Strip-Steel 2017 Rev.1humberto cerda gonzalezNessuna valutazione finora

- Alumec PDFDocumento7 pagineAlumec PDFetamil87Nessuna valutazione finora

- DS Gypframe ProfilesDocumento12 pagineDS Gypframe ProfilesAleem UllahNessuna valutazione finora

- An Introduction to Metal-Working (Illustrated)Da EverandAn Introduction to Metal-Working (Illustrated)Valutazione: 2.5 su 5 stelle2.5/5 (2)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDa EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersValutazione: 3.5 su 5 stelle3.5/5 (2)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopDa EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopValutazione: 4.5 su 5 stelle4.5/5 (2)

- Themal Management of Solid State RelaysDocumento5 pagineThemal Management of Solid State RelayssudarshanNessuna valutazione finora

- The Physics of Rubber PDFDocumento11 pagineThe Physics of Rubber PDFsudarshanNessuna valutazione finora

- Mechanical and Microstuctural Analysis of Dissimilar Metal Welds PDFDocumento9 pagineMechanical and Microstuctural Analysis of Dissimilar Metal Welds PDFsudarshanNessuna valutazione finora

- Gentle Yoga Volume 1Documento24 pagineGentle Yoga Volume 1gigyyyyfyigiyNessuna valutazione finora

- Process CapabilityDocumento35 pagineProcess CapabilitysudarshanNessuna valutazione finora

- Design For The Life CycleDocumento3 pagineDesign For The Life CyclesudarshanNessuna valutazione finora

- Polymer - Physical PropertiesDocumento31 paginePolymer - Physical PropertiessudarshanNessuna valutazione finora

- E-Flute Corrugated CartonDocumento1 paginaE-Flute Corrugated CartonsudarshanNessuna valutazione finora

- Surya Namaskar (Sun Salutations) : Sthiti: Tadasana With Namaskara MudraDocumento5 pagineSurya Namaskar (Sun Salutations) : Sthiti: Tadasana With Namaskara MudrasudarshanNessuna valutazione finora

- Design 1Documento28 pagineDesign 1Munah KausarNessuna valutazione finora

- Ergonomic Design GuideDocumento66 pagineErgonomic Design GuideAnonymous p2cFoXbjD100% (2)

- Misumi Technical Data PDFDocumento1 paginaMisumi Technical Data PDFtnchsg100% (1)

- All About BoxesDocumento6 pagineAll About BoxessudarshanNessuna valutazione finora

- Box Manf CertificateDocumento1 paginaBox Manf CertificatesudarshanNessuna valutazione finora

- Yoga Postures Yogasanas PDFDocumento59 pagineYoga Postures Yogasanas PDFAndy DragomirNessuna valutazione finora

- Gentle Yoga Volume 1Documento24 pagineGentle Yoga Volume 1gigyyyyfyigiyNessuna valutazione finora

- Tolerance Stack-Up AnalysisDocumento22 pagineTolerance Stack-Up AnalysisPraveen ShandigeNessuna valutazione finora

- Corrugated Fiberboard DesignDocumento39 pagineCorrugated Fiberboard DesignsudarshanNessuna valutazione finora

- Design For EnvironmentDocumento1 paginaDesign For EnvironmentsudarshanNessuna valutazione finora

- 2 CastingDocumento16 pagine2 Castinggubeguru100% (11)

- Global Ports and Warehousing StandardsDocumento81 pagineGlobal Ports and Warehousing StandardsUnais RahmanNessuna valutazione finora

- Asian Size Range PDFDocumento15 pagineAsian Size Range PDFWhite_rabbit2885764Nessuna valutazione finora

- Is 2062 - 2006 - Hot Rolled Low, Medium and High Tensile Structural Steel PDFDocumento13 pagineIs 2062 - 2006 - Hot Rolled Low, Medium and High Tensile Structural Steel PDFThenna ArasuNessuna valutazione finora

- 003 Steel Plate SHTDocumento26 pagine003 Steel Plate SHTFebri VictorNessuna valutazione finora

- Nimonic Alloy 80ADocumento24 pagineNimonic Alloy 80AdharmatejakademNessuna valutazione finora

- Carriage SteelDocumento38 pagineCarriage SteelbernardinodinoNessuna valutazione finora

- 1.1 Introduction - NotesDocumento12 pagine1.1 Introduction - NotesabhishekNessuna valutazione finora

- Angang 2013 2hDocumento231 pagineAngang 2013 2hHenry So E DiarkoNessuna valutazione finora

- S275JR PDFDocumento1 paginaS275JR PDFEmrahCayboylu100% (1)

- Bs en 10113 1 PDFDocumento23 pagineBs en 10113 1 PDFserdarNessuna valutazione finora

- Simufact BR Rolling 2015 E Web PDFDocumento2 pagineSimufact BR Rolling 2015 E Web PDFSamir KhNessuna valutazione finora

- Tesis LaminaciónDocumento98 pagineTesis LaminaciónTomás BonelloNessuna valutazione finora

- As 2400.13-1983 Packaging Tensional StrappingDocumento6 pagineAs 2400.13-1983 Packaging Tensional StrappingSAI Global - APACNessuna valutazione finora

- Publsihed Paper Root Cause Analysis of Formation of Black Brown Patch Defect On Cold Rolled Steel Sheet SurfaceDocumento9 paginePublsihed Paper Root Cause Analysis of Formation of Black Brown Patch Defect On Cold Rolled Steel Sheet SurfaceMuhammad BilalNessuna valutazione finora

- SAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFDocumento5 pagineSAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFMadirley PimentaNessuna valutazione finora

- 35CD4Documento2 pagine35CD4Tarun Kumar V MNessuna valutazione finora

- Mathematical Model For Cold Rolling and Temper Rolling Process of Thin Steel StripDocumento7 pagineMathematical Model For Cold Rolling and Temper Rolling Process of Thin Steel StripRhushikeshNessuna valutazione finora

- POSCO Case - History of PoscoDocumento5 paginePOSCO Case - History of PoscoBinod Kumar PadhiNessuna valutazione finora

- Steel Deformed and Plain Bars For Concrete Reinforcement: CNS Number Category NumberDocumento14 pagineSteel Deformed and Plain Bars For Concrete Reinforcement: CNS Number Category NumberTrọng Đẹp TraiNessuna valutazione finora

- Ding 2013 Fem Modeling of Dynamical RecrystalDocumento8 pagineDing 2013 Fem Modeling of Dynamical RecrystalЮрий ГаминNessuna valutazione finora

- Finland TankDocumento27 pagineFinland TankAhmed AkmalNessuna valutazione finora

- Mission - Company History - Management Team - Global Network - Our StrategyDocumento11 pagineMission - Company History - Management Team - Global Network - Our StrategymaulanaNessuna valutazione finora

- Bright Steel Bars PDFDocumento14 pagineBright Steel Bars PDFramanamurtytv7176Nessuna valutazione finora

- IS 1852 - 1985 - Reff2022Documento28 pagineIS 1852 - 1985 - Reff2022singaravelan narayanasamy100% (1)

- Is 1570 P1 - 1978Documento13 pagineIs 1570 P1 - 1978praveen_pattemNessuna valutazione finora

- Topic 3: Metal Forming & Shaping ProcessesDocumento115 pagineTopic 3: Metal Forming & Shaping ProcessesA TalkNessuna valutazione finora

- by DesignDocumento31 pagineby DesignShalini JhaNessuna valutazione finora

- TR7e:rur) : F?R:TTDocumento11 pagineTR7e:rur) : F?R:TTSrikanth SrikantiNessuna valutazione finora

- Indian Standards As On 17.01.2004 LatestDocumento19 pagineIndian Standards As On 17.01.2004 LatestSaravana KumarNessuna valutazione finora