Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DIY FI FlowBench (Assembly)

Caricato da

BespokeReader100%(1)Il 100% ha trovato utile questo documento (1 voto)

500 visualizzazioni11 pagineThis is the first of a series on building and using a fuel injector testing and cleaning machine. The machine is easily built, is based on an IBM-PC and can cost as little as $200 to build. The purpose of this machine is to allow you to measure and record all important parameters of an electronic fuel injector.

Descrizione originale:

Titolo originale

DIY FI FlowBench(Assembly)

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis is the first of a series on building and using a fuel injector testing and cleaning machine. The machine is easily built, is based on an IBM-PC and can cost as little as $200 to build. The purpose of this machine is to allow you to measure and record all important parameters of an electronic fuel injector.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

500 visualizzazioni11 pagineDIY FI FlowBench (Assembly)

Caricato da

BespokeReaderThis is the first of a series on building and using a fuel injector testing and cleaning machine. The machine is easily built, is based on an IBM-PC and can cost as little as $200 to build. The purpose of this machine is to allow you to measure and record all important parameters of an electronic fuel injector.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 11

Warning

The project described hereiD uses flam-

mable liquids and may present a fire

hazard .. Reasonable care has been exer-

cised in designing the flow bench. None"'

when you USe ga$olil)e as the

ouklooTsor With high

ventilation. A fire extinguisher

a l w ~ y s be kept on hand. We highly

recommend you employ a fan set up to

blow away vapors as they are emitted.

If you choose to build this device, you

accept all risks involved. Neither Perfor-

mance Engineerin Magazine nor its

staff accepts any liability if you hurt

yourself or others while using this de-

vice.

Photo 1 - The fuel

injecti on fl ow bench,

front & back vi ews.

4

By John De Armond

Introduction

This article is the first of a series on building and using a fuel

injector testing and cleaning machine. The machine is easily built,

is based on an IBM-PC and can cost as little as $200 to build. This

first article will show you how to build the machine and will

present some basics of testing. Subsequent articles will go into

considerable detail about using the machine in a high perfor-

mance environment.

The purpose of this machine is fairl y simple c To allow you to

measure and record all important parameters of an electronic fuel

injector. The design and construction of this machine is also fairly

simple. Some of the underlying concepts may not be. Of course,

that is why this magazine exists, to de-mystify this stuff.

Some Basics

What is the purpose of ' any fuel metering system? Keep it

simple now. That' s right, to create the optimum fuel/air mi xture

under all conditions. See, that was easy. This holds true

whether the device metering the fuel is fuel injection,

carburetion or someone pouring gas down the intake. As

with many things in life, while the theory is simple,

implementalion is quite complex.

Let's presume for a moment that the best mi xture under

all conditions is the chemically correct one, 14.7: 1 for

gasoline. That is, for everyone part by weight of gasoline,

there must 14.7 parts by weight of air to completely burn

the fuel. This is known as the stoichi ometri c mixture. I

tend to abbrevi ate this as "stach" , pronounced just like it

looks.

Achi eving this, particularly with fuel injection, should be

easy. Just measure the air flow, calculate a proportional

amount of fuel and shoot it in. Problem is, physics rears

its ugly head. Both air and fuel have the inconvenient

tendency to change properties with temperature and

pressure. Air is even worse because it changes density

with pressure. If we didn't have all these considerati ons,

a simple, all mechanical system such as the Hilborn would

work perfectly under all conditions. Reality dictates all the

fancy electronics we have today.

In order to confi gure any kind of fuel injection control

system, one must know the characteristics of the final

actuator, the fuel injector. That is, the tuner must know

how much fuel per unit time the injector will deliver, how

much delay after he commands the injector open before

the actual delive ry starts and how long after he commands

it shut it actually stops fl ow. See the sidebar for more

detail s on injector parameters.

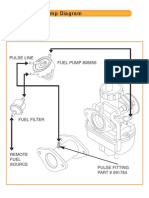

Pressure Regulator

Pressure Gauge

FuOl Injector

:f Undel Test

Catch Bowl

Figure 1 - Piping Di agram

Injector, Parameters

You might be asking yourself. "SO I've built the

tester. Now what do I testT Fortunately the

important parameters of the fuel injector are well

defined. The first thing you need to acquire is a

copy of the SAE sfandard on fuel injectors. This

is SAEJ1832, "Gasoline Fuel Injector Highway

Vehicle Recommended Practice." This docu-

ment can be ordered directly from the SAE and

can even be paid for on your credit card. See the

Resources Box for details. This standard is al-

most 50 pages long and covers injection mea-

surements in vastly greater detail than could any

magazine article so you should order this stan-

dard and have it available when reading this

section.

Flow

The most basic parameter is the fuel deUvery.

That is, how many units of fuel per time interval

the injector delivers. If the fuel pressure is held

constant, the amount of fuel injected is directly

proportional to the amount of time the injector

is open. The actual parameter is the mass per

second, typically grams per second. The reason

mass is needed is mixture is specified in terms of

the ratio of the masses of the air and fuel. The

rate of delivery is dependent on the fuel pressure,

the viscosity of the fluid and the dimensions of

the internal orifice. We'll standardize the test

pressure and the fluid so all injectors can be

compared against each other. You can either

measure the volume of the fuel delivered and,

using the density of the fuel, compute the mass,

or you can actuaUy measure the mass directly

with a lab balance. We'll be looking at both

methods.

As with many things, this simple concept gets

complicated in practice. What we referred to

above is the static flow rate or Qs (all variables will

be the ones used in J1832.) That is, if we apply

fuel and yank the injector open. how much will

it flow? Easy to measure. That is only peripher-

ally relatecl to actual operating conditions. In the

engine, the fuel flow is started and stopped once

or twice each power cycle. When the injector

opens, the fuel, having inertia like any other

matter, tal,es a bit of time to start moving.

Because of this delay. if the injector is open 50%

of the time, the flow will not quite be 50%. The

actuaL flow is known as the dynamic flow rdte or

(continued)

Pe rformance Engineering Magazine 5

Overview

What must an injector tester do? Not that much really.

It must supply the injector with a stable supply of fuel (or

other working fluid) at a known pressure. It must supply

the proper voltage for the injector. It must provide the

means to precisely and repeatedly actuate the injector.

Finally it must provide the facilities to measure the

injector's operating parameters. Thanks to the ubiqui-

tous IBM-style PC and a touch of hardware we will

fabricate or inexpensively buy, these requirements are

simply achieved.

In addition to a PC and the hardware we are going to

fabricate, you will need a couple of other pieces of

equipment. The most expensive is an oscilloscope. Since

we are dealing with relatively slow events, most any old

scope wi ll work. The cadillac of scopes for automotive

work is the digital storage scope. This instrument is really

a special purpose computer that digitizes the signal in

question and displays it on a screen. Because the signal

is stored in the scope's memory, it is visible until either

replaced with a new trace or erased. That means very

slow events such ignition or fuel injection cycles can be

viewed at will. It also means that with the right equip-

ment, hardcopy of the trace can be generated.

In the automotive context, the cadillac of digital storage

scopes (DSO) is the Fluke 97 Scope Meter. This hand-

held unit combines the functionality of a dual trace, 50

MHz oscilloscope and a digital voltmeter. See Photo 2.

All the scope traces and data presented in this series of

articles are generated from PE's Fluke 97. At $1795

retail, this scope is within the reach of the professional

Performance Engineer and even for many hobbyists.

Note that this scope is not necessary in order to build and

use the fuel injection tester. Nice but not necessary.

One of the tests you will perform on a fuel injector is

to measure the opening and closing time. This is done by

mounting an accelerometer on the injector and record-

ing the vibrations generated by the injector opening. See

Photo 3. An accelerometer is a device that converts

acceleration to an electrical signal. Typically the output

is specified in terms of signal magnitude per G of

acceleration. The accelerometer we use here at PE is a

fairly expensive commercial piezoelectric accelerometer

made by Endevco. These units typically cost $200 or

more. However, a very satisfactory accelerometer can be

constructed from an ordinary knock sensor.

Tester Description

The tester is pretty simple. A miniature fuel supply

loop, almost identical to that found on the car, is set up

under controlled conditions. The loop consists of a

standard FI fuel pump, filter, bypass regulator and pres-

sure gauge. See Fig. 1. The regulator pictured is a fixed

pressure unit from a Datsun 280Z. For a more general

purpose tester, use an adjustable regulator available from

Injector Parameters

(continued)

Q. Since the inertial delay is fixed, the shorter

JUld faster the opening pulse, the larger

proportion of the total flow interval is con-

sumed by the intertial interval.

The only way to determine the slope of this

dynamic flow curve is to actually pulse the

Injector under the same conditions and deter-

mine the flow rate vs pulse width.

Spray Pattern

The spray pattern is important because it

dictates where in the intake the injector is

placed and how well itwiU work. The ideal

configuration is for the injected fuel to spray

directly onto the head of the intake valve.

This gets the fuel as closlf as possible to the

combustion chamber and none is sprayed on

the intake walls. The .tester allows you to

observe and even measure the spray pattern.

J1832 details pattern testing in great detail.

(continued)

Photo 2 - The Fluke 97 Scopemeter

6

Performance Engineering Magazine

Photo 3 - Accelerometer and in-

jector clamping detail.

a variety of sources. See the Re-

source list.

The pump is supplied with 12

volts through a switch and a rheo-

stat. The rheostat is provided to

adjust the speed of the fuel pump

until the bypass regulator just starts

to bypass. The purpose is to intro-

duce as little heat to the fuel as

possible. Fuel is supplied to the

injector through a flex hose and is

secured via a homemade quick

action clamp. The injector is held

in the fi xture by a common wood-

working toggle-clamp. The accel-

erometer is attached to this clamp.

Photo 4 illustrates this assembly.

You will observe that there is a

small flowmeter in the line to the

injector. This meter is optional

and is not necessary to conduct

any test in this series. The meter

is convenient but very expensive

so the design was developed with-

out it.

Below the injector mount is a

spray catch-cup used to catch the

spray from the injector when

observing the spray pattern. It is

fabricated from a 4" CPVC pipe

endcap. It is designed so it can be

quickly moved out of the way for

tests so requiring. See photo 1. In

Performance Engineering Magazine

this photo the cup is

white so it will show up

better. It should be paint-

ed flat black with appli-

ance epoxy paint so the

spray pattern can be

more easily observed.

The cup hanger is fabri-

cated from a piece of

gas line flattened in a

vice and drilled for at-

tachment to the panel.

The bends are accom-

plished with an ordinary

tubing bender available

at the car parts store.

The loops that hold the

cup to the hanger are

ordinary nylon wire clamps avail-

able from Radio Shack or other

electronic supply houses.

A quick peek at the schematic in

Fig. 2 reveals the simplicity of the

electrical circuit. The reason this

circuit is so simple is that the PC

does all the work. The printer port

adapter is nicely buffered. The soft-

ware does all the actual testing.

Ain't PCs grand!?! The circuit pro-

vides the ability to test both saturat-

ed mode and peak-hold mode

injectors. Which mode is in effect is

strictly the function of the software.

The potentiometers are adjusted to

provide the proper peak and hold

current in peak-hold mode or VR-

Photo 4 - Regulator,

flowmeter, pressure gauge

and piping detail. Note the

homemade T-handle clamp

at bottom-center.

7

8

1 alone is used to set the saturated

current for saturated-mode opera-

tion. We'll cover this aspect in great

detail in the next issue.

Construction

The chassis of the tester is con-

structed from plywood. All joints

are glued, braced and screwed with

sheetrock screws. This makes a

very sturdy but easily "machined"

base. A heavy coat of aerosol ep-

oxy appliance paint provides a non-

stain finish. Control legends were

created by laying out the pattern in

CorelDraw and laser printing them

on overhead transparency film. The

legend is glued to the panel using

ultraviolet curable epoxy. If you

don't have such esoteric glue (Mine

waS stolen from Doreen's stained

glass studio), superglue will do fine.

The piping is three-eighths inch

brake line: [ used metal piping be-

cause it is sturdy and fireproof, a

consideration that should not be

underestimated. The return piping

should extend to below the surface

of the liquid in the reservoir in order

to minimize foaming and evapora-

tion. Be sure to plug the opening to

the reservoir with some fiberglass

cloth as shown. This a vapor barri-

er and a fire stop.

The electrical construction is sim-

plicity personified. See photo 6 for

details. Basically, everything is sim-

ply screwed to the wooden chassis.

The heatsinks on the transistors

are not necessary and were includ-

ed in an early stage of develop-

ment. They remain completely cool

to the touch. None of the wiring or

layout is critical. [ recommend us-

ing shielded wire for the lead to the

Pc.

Power for my tester is supplied

by a regulated power supply. This

is convenient and may be neces-

sary for some of the SAE

testing but is not required. A car

battery will work just fine. If you do

use a regulated power supply, be

sure to include an outboard filter

capacitor as illustrated on the sche-

matic and in Photo 60. This capac-

itor filters the switching transients

Performance Engineering Magazine

Opening and Closing De-

lay, Turndown Ratio

When the ECU applies a

pulse to the injector, not

oJ)?n immediately. The

tor coU inductance

Iy resists the flow of clll'i'ei1tiatl.d

the valve parts have inertia.

Both these faqj:ors

opening SJ)?ed of the injetbr.

It is important to mirlim12' this

delay. The reason is a parame-

tercaUed the "ilJmdown ratto".

That is, the ratio betweeti;t'he

maximum and minimWn open

time. Themaximumopent'lme

is .. set by how much a

pOwer cycletakes at maxirrrum

RPM. See F'Jgure 8. Forexam-

pie, if the engine's m

is lO,QOO RP

These injectors will be mafched

as to fuel delivery and opening

what ifene goes

Orgetsdlrty?Howdoyou

the .replacement to the Un-

less you buUd this macl:ilne or

about

a cbmmerciaUy buUt fuel '

tester, you don't.

The last benefit might not be

so obvious. This.tester lets you

get "down to thll! bare meti:ll. ,-

You'll be able to measure and

get the feel for almost Wery

oJ)?rating parameter of a fuel

injec::ror and you can quickl!l corn--

pare one injector design to an-

other. This level of experience

and understanding makes it much

easier to grasp the rest of the

injection system design process.

+ 12 Vol ts

(OvlIooXI!tvVolIOble)

j '

+12 Volts

Fuel InJectOf

VRI

l OOQ 20watt

Wirewound

Potentiometer

Clarostot or equi v.

VR3

200-20woM

Wirewound

Potentiometer

Clarosta! or equiv.

FuefPump

Fig. 2 - Schematic Diagram

created by firing the fuel injector. I

learned from experience that these

transients will burn out the power

supply unless trapped. Most any

value capacitor larger than about

30,000 uF will work fine.

The Software

The software is amazingly simple

considering what it allows us to do.

Its basic function is to turn the fuel

injector on and 6ff for precisely

timed intervals and to' total the

amount of time the injector is open.

The software uses the hardware

timer built into each Pc. The timer

is used in a high resolution mode

that gives us the ability to measure

time in microseconds. The actual

timer routines were taken from

some public domain code written

by David Kirschbaum. This soft-

ware is written to be as portable as

possible and has run on every type

of PC tested to date.

The operation is simple. Four

values must be specified. These

are:

The time the peak current flows.

T(peak)

The total on time. T(on)

i

u.J

T(hold)

l')

0

>

t

>--

z

u.J

'"

'"

:::J

U Coil Current

--------j""-- ---

i

z

u.J

"-

0

"'--If-_ ..... Motion

TIME

Fig. 3 - Idealized voltage

and current waveforms and

pintle motion for Peak/

Hold (solid lines) and

saturated driver (shaded

lines.)

Performance Engineering Magazine

9

A

B

The total cycle time. T(cycle}

The lotal number of cycles.

See Fig. 3 for del ails. Once

these parameters are spf'cified.

t he go command can be issued

to fire the injector. During each

cycle, both transistors (bits 0

and J) are fired for T(peak).

Then the peak transistor is

turned off (bit 0) and the injector

is held on for the time interval

equal to T(on) - T(peak}. The

hold transistor (bit 1) is turned

off for T(cycle) - T(on} and then

the cycle repeats until the total

number of cycles are run or a

key is pressed. A keypress ter

minates Ihe test. The lotal on

time is accll1111 il ated during test-

10

ing and is displayed at the end of

each cycle. This time is vital for

computing the fuel delivery of the

injector. This time accLm1ulator can

be reset at any time.

A second mode is the current!

purge mode. This mode simply

fires the injector continuously so

that the peak and hold current can

be set. Some caution must be used

because excessive current can quick-

ly burn out injectors. Because the

peak current is often many times

the rating of the injector, the peak

on-time is limited to one second at

a time. A second use of this mode

is to turn the injector on continu-

ously so air may be purged after an

injector change and to release pres-

sure prior to changing the injector.

Perfonnance Engineering MagaziJl e

c

D

Photo 6 - Wiring Details

A !l1ird mode is the software

calibration mode. Because every

computer requires a finite amount

of time to execute a sequence of

instructions and because the time

intervals we are dealing with are

very short, a compensation factor

must be developed for each ma

chine. The software ships with a

compensation value appropriate for

my 25 MHz 386sx laptop. The

calibration mode allows you to al

lernately generate a 0.5 ms and a

5 111S pulse from bit 0 while chang

ing the compensation factor. You

would place the program in this

mode and then observe the pulse

output on an osci lloscope while

dithering the compensation factor

until the pulse widths are exac!.

A 5V DC B 5V OFF

500ms/DIV SINGI E Trig A 1

r;ll

Off Time

I

Start

Cyc le Storts

of

End of

New

Cyc le

Cycle

"

Fnd Peak.

)

Begin Hold

I-

r.-..

-Fig. 4 - Lamp test waveform

Injector Parameters

(continued)

maximum amount of time avail-

able to inject is that taken by two

revolutions.

10,000 /60 =, 166.66 revs

per second.

1 / 166.66 RPS = 0.006

seconds per rev.

Two revolutions is 12 millisec-

onds

So we have 12 miUiseconds

maximum to supply the needed

fuel at full RPM. It is desirable to

size the Injector f10wrate such

that the injector is open almost

all the time. That

turndown ratio. It is

tant to note that the opening

delay must be accommodated In

thiS 12 ms interval. More accu-

rately, the opening delay minus

the closing delay must be ac-

commodated. The closing de-

lay. which is almost always

10..-

Performance Engineering Magazine

This compensati on factor onl y

matt ers when creating intervals

shorter t han about 2 ms. The value

vou develop may be polaced in an

va ri abl e ca ll ed

FITCOMP_ Sec the documenta-

tion thClt accompnni es the code for

detail s_ Pl ease refer to the Resollrce

I .i st for sohwi'lre Cl vail ahility .

Testing

I suggest you test the mechanicCl I

components first. Insli'lll i'ln injec-

tor. fill the tank with gasol ine and

fire off the pump at full speed.

Q'li ckly look for leaks and verify

the pressure wgulator is function-

ing. VClry I-he speed knob and veri fy

the pump chi'l nges speerL Tllm off

the pump and bl eed the pressure

by loosening the pipe , lamp on the

injector nnd all owing the gas to leak

into the cnl ch bowl.

Electrical tests are conducted with

]1

a small 12 volt, approxi-

mately 2 amp (taillight)

BNC Connector

)

on t he front panel

of the flow bench

r------.,

I I

, "/1

Acceleromet er

Iightbulb installed in place

of the injector. Connect

the PC and start the pro-

gram. This is important

because the first thing the

program does is reset the

parallel port. In my expe-

rience, about half the time

a parallel port will power

up with the output bits

set; i.e ... the transistors

I ' Chan A I

Chan B

I _: ..

I - - - - -- - - I "{T

fired. This could, of

course, burn out the in-

jector. Apply power and

verify there is 12-14 volts

- available at the injector

power switch. If that is in

order, turn on the injec-

tor power switch. The

lamp should be off. If nO,t,

check your wiring. Enter the cur-

rent/purge mode. Fire the peak

transistor. The lamp should light.

Turn thepeakpot. Thelightinten-

sity should vary. Turn the peak

transistor off and fire the hold tran-

sistor. The lamp should again light.

Turn the hold pot. The lamp in-

tensity should vary. In each case,

with the lamp at full brilliance (min-

imum resistance), verify that the

collector of the applicable transis-

tor is switched within about a half

volt of ground. If it is not, either the

transistor has low gain or your

parallel port has insufficient drive.

If insufficient drive is the problem,

'1

'J

Idddobi

D ==C'J

DDDDGJ

Od8m

00000

o

see the Resource List for a known

good parallel port card. Turn the

hold transistor off. Return to oper-

ate mode. Set the following pa-

rameters:

Total cycle interval 3000 ms

Peak interval 1000 ms

On interval 2000 ms

Repetitions 100

Peak potentiometer fully

counter-clockwise, maximum re-

sistance

Hold potentiometer fully clock-

wise, minimum resistance.

Run the test. You should see the

Fig. 5

Standard

connection

diagram

lamp come on dimly for a second,

go full intensity for a second and

turn off for a second. If you have a

scope connected to the monitoring

point, you should see a waveform

similar to Fig. 4. Testing is com-

plete. Press any key to terminate

the test.

Operation

This is going to be brief because

the majority of the next issue's

article will cover operation. This is

just enough to get you going.

Install an injector. Connect the

scope as illustrated in Fig. 5. Set the

A 5V DC B 500mV DC

Fig. 6

A 5V DC B 200mV DC

l msj DIV SINGLE Trig' A l 1 msj DIV SINGLE Tri g' A l

IT "\

'\

,

,

l'-

fI IT ...

tv "'-V'

rvv

A 1 It.

.....,

'\I"'U

v

Fig. 7

12

Performance Engineering Magazine

scope as follows:

Chan A - monitoring point, 2

volts per division

Chan B - accelerometer, full

sensitivity, usually 5 mv/division

Trigger - Chan A, DC cou-

pled, negative slope

Sweep - 1 ms/division, Normal

trigger.

Set the peakand hold pots fully

counter-clockwise {maximum resis-

tance}.

Start the software and apply pow-

er to the injector. Leave the fuel

pump off at this stage. Set the

following parameters for peaklhold

injectors:

Peak time 5 ms

Total cycle time 15 ms

On time 10 ms

Repetitions 10,000

Start the test. You should see

some activity on the scope. Adjust

the trigger level for a stable display

similar to Fig. 6. The injector may

be making some noise but probably

is not opening. Start turning the

peak pot clockwise. You should

hear the sound of the injector

change. At some point the change

will become marked: This will oc-

cur when the injector gets enough

)eak current to actually start open-

ing. You should see some activity

on channel B, the accelerometer.

You should see a vibration spike

shortly after the current is applied

and perhaps a second spike as the

injector closes when the peak cur-

rent turns off. If the injector closes

when the peak current turns off,

gradually tum the hold current pot

until the injector stays on for the

duration of the on time.

You have now determined the

approximate peak and hold cur-

rent requirements of that injector.

You can back the peak time off

until the injector fails to open. This

will determine the approximate

peak time required. This is normal-

Iyabout 1-2 ms Fig. 6 illustrates a

typical peak/hold waveform. You

may now go to current mode and

evaluate the currents you have set.

For Saturated Driver Injectors,

use the foll OWing parameters:

Peak time 0 ms

Total cycle time 15 ms

On time 10 ms

Repetitions 10,000

Start the test and observe the

scope. You should see a display

similar to Fig. 7. Start turning the

Hold pot clockwise. Atsome point

the injector should start opening.

The accelerometer should show

some activity and the sound should

change. Continue increasing the

current by further turning the hold

pot and observe the opening de-

lay. The delay should decrease

rapidly at first and then remain

fairly constant. Just a bit more

than what is necessary to tum the

delay "knee" is usually about right.

If the injector is a high impedance

{no ballast resistor} unit, the hold

pot should end up near zero ohms.

If a ballast resistor is used in an

existing install ation with low im-

pedance injectors, the pot should

end up near that value.

Since we don't have any fuel

flowing at this point , don't run

these tests for too long lest you

overheat the injector. Once you

get the approximate electrical pa-

rameters set, you may start the fuel

pump and actually inject some fuel!

Working Fluids

For most testing, you will want

to use the actual fuel you will be

burning in the engine. If you plan

on testing a lot of injectors, you

might want to consider using N-

Heptan e as outlined in SAE

J1832. It has a lower vapor pres-

sure than gasoline and is much

more stable over time. If you use

gasoli ne, you should use new gas-

oline each day. Pump the old gas

out and use it in your hotrod

lawnmower or something.

Performance Engineering Magazine

This tester is very effective in

cleaning dirty injectors. The work-

ing f1wi d I' ve found very effective is

a half-and-half mix of gasoline and

Chevron Techron fuel injector

cleaner. Simply clean the injector

on the outside and then connect it

to the tester. Run the injector at

about a 50')-(' duty cycle for 15

minutes. The vibration of firing the

injector appears to assist in the

cleaning operation. More on this

next issue.

In Closing

This just about wraps up the first

installment in this series. Use the

time to build your tester , acquire

the software, acquire a copy of

SAE J1832 and get everything

working.

Ordering Files by

Emall

If you are on the Internet or any of

connected.networks, you can request

the Software that accompanies this

article via -electronic mail. There is no

charge. lfyouare ona network other

than the Internet, consult

master tor for malIingfo

an Internet address. The..

ipstructions 3SS\ltM you

lritemet. .

Address the mail to

dlxie.com. This is an aut.:mJ.<mc.

server. There need not be.any Sub-

ject". In the. body of the message.

irlclude the following:

address <your mail

get help

The file will be returned to your

address in uuencoded format. You

wiD need a uudecoder in order to

process the fUe. These are widely

available from Bulletin Board sys-

lems, including Courts of Chaos list-

ed opposite.

13

---------- - - ------- ----- _._--- - - - -

14

Resource Guide

Software

The software may be obtained from the foll owing sources:

Courts of Chaos BBS

By e-Mail

By mail from PE Magazine_

Fuel Pressure Regulator

501 '3155-0059

Send request 10 Iistserv@dixie.lulTr

Send a LargeSASE and $S.OO

A stock regulator from your car of choice may be used or an adjustable regulator lTIay be

ordered from: Kenne Bell , 10743 Bell Courl. Rancho Cucarnonga. CA l) j 730. 7 14 941-

6646, 714941-0985 (tech sUPPOli)

Electronic Parts

Q1.Q2 TIP-120 Transistors

01 Diode, 6A, 50PIV

VR-1. 2 Rheostat, lOOn ,12. 5 IR l tt

VR-3 Rheostat, 20n ,25 walt

S1.S2 Toggle Switch, SPST. :3 amp

BNC- 1 BNC panelmount connector

TP-1 Dual Bananna Jack

Compatable Printer Pori Card

Toggle Clamp

Radio Shack P/N 276-2068

Radio Shack PIN 276-166 1

Newdrk PIN 871'3611-50 III

Newark PI N 87f6:390-20 12]

Radio Shack PI N 275-322

Radio Shack

Radio Shack

Magillonics PIN A-B10913]

This is a standard 1" woodworking toggle clamp available from most hardware

stores. An alternative supplier is Stone Mountain Power Tools in Stone Mowltain. GA_

404446-8390.

Accelerometer

The knock sensor mentioned is a standard automotive knock sensor. Mine is from

a Dodge Turbo Lazer. True accelerometers can be had horn:

SAE

Endevco

30700 Rancho Viejo Rd.

San Juan Capistrano, CA 92675

714661-7231

PCB Piezotronics Inc

716 684-0001

J1832 may be ordered from the SAE, 400 Cornmorl weLIlth Dr.. Warrel!ciale, I-'A 15096.

412 776-4970, 412776-0790 (FAX)

Hard-to-Find Parts

The above marked items are available from Rapid Deployment Systems Inc. PO Box

670386, Marietta, GA30066. 404 578 9547. Add $4 to each order forS/H. Allow 6 weeks

for delivery.

[lJ

[2J

[3J

VR-1,2 -

VR-3 -

Card -

$10.00 each.

$15.00 each.

$19.95 each.

Peljormance Engineering Magm:ille

Potrebbero piacerti anche

- Manual of Basic Air Flow BenchDocumento24 pagineManual of Basic Air Flow BenchPung Kang Qin100% (1)

- Superflow 110Documento34 pagineSuperflow 110dcapito4017100% (2)

- How To Build A Fuel LineDocumento15 pagineHow To Build A Fuel LineMech EngrNessuna valutazione finora

- Two Stroke AircraftDocumento10 pagineTwo Stroke AircraftVinti Bhatia100% (1)

- DIY Flowbench DesignDocumento15 pagineDIY Flowbench Designibis_pilot100% (2)

- Rewinding A BLDC MotorDocumento22 pagineRewinding A BLDC MotorUday WankarNessuna valutazione finora

- Champion Spark Plugs for Proven PerformanceDocumento7 pagineChampion Spark Plugs for Proven PerformanceMGD040452100% (1)

- Maximum BoostDocumento249 pagineMaximum BoostD.J.GuyNessuna valutazione finora

- 3 in 1 MachineDocumento5 pagine3 in 1 Machinemarandan85100% (1)

- A Simple Small Metalworking ShaperDocumento7 pagineA Simple Small Metalworking ShaperĐặng Ngọc Hùng100% (1)

- Building High Performance EnginesDocumento17 pagineBuilding High Performance Engineslone_anarchistNessuna valutazione finora

- Secrets of Exhaust and Intake DesignDocumento26 pagineSecrets of Exhaust and Intake Designrudey1867% (3)

- A New Generation of Two Stroke EngineDocumento11 pagineA New Generation of Two Stroke Engineshax001100% (2)

- Cylinder head porting guide: Improve engine efficiency through port modificationsDocumento10 pagineCylinder head porting guide: Improve engine efficiency through port modificationsdebugevdo75% (8)

- Secrets of A Cam DesignerDocumento40 pagineSecrets of A Cam Designerncampagna8134100% (2)

- The Design of Competition EnginesDocumento546 pagineThe Design of Competition EnginesAlex Kuznetsov95% (21)

- Cam DesignDocumento3 pagineCam DesignJoe KenyonNessuna valutazione finora

- Esslinger CatalogDocumento48 pagineEsslinger Catalogcircleline0% (4)

- Stirling Walking Beam EngineDocumento13 pagineStirling Walking Beam EngineTomescu PaulNessuna valutazione finora

- Deciding To Build A Type 1 Performance EngineDocumento10 pagineDeciding To Build A Type 1 Performance EngineRobert DennisNessuna valutazione finora

- Vincent TechnicalDocumento58 pagineVincent TechnicalCiprian MaiorNessuna valutazione finora

- Animal Carb TuningDocumento5 pagineAnimal Carb TuningRusty100% (1)

- Air Box DesignDocumento10 pagineAir Box DesignShailendra SinghNessuna valutazione finora

- Standard Abrasives - DIY Cylinder Head Porting Guide PDFDocumento14 pagineStandard Abrasives - DIY Cylinder Head Porting Guide PDFkristof2273100% (1)

- Carbtune PDFDocumento22 pagineCarbtune PDFndmvillocilloNessuna valutazione finora

- EFI Two StrokeDocumento6 pagineEFI Two StrokegkarthikeyanNessuna valutazione finora

- Engine Porting and PolishingDocumento8 pagineEngine Porting and Polishingmoparman1100% (10)

- Cylinder Kreidler TuningDocumento6 pagineCylinder Kreidler Tuningfzr67100% (1)

- Zundapp 2-Stroke Engine RepairDocumento61 pagineZundapp 2-Stroke Engine RepairqhunumbsNessuna valutazione finora

- In The Workshop: Duplex "Documento6 pagineIn The Workshop: Duplex "johnboy183Nessuna valutazione finora

- Radial Engine BalancingDocumento13 pagineRadial Engine BalancingAashi Rose100% (1)

- Whitepaper: Engine Intake OptimizationDocumento10 pagineWhitepaper: Engine Intake OptimizationgosculptorNessuna valutazione finora

- Isky - Valve Timing For Maximum Output - ExcerptsDocumento11 pagineIsky - Valve Timing For Maximum Output - ExcerptsgaragepunkfanNessuna valutazione finora

- Hub Centres SteeringDocumento29 pagineHub Centres SteeringSudheesh Kumar ENessuna valutazione finora

- Super Flow 110120260 FLOWBENCHDocumento206 pagineSuper Flow 110120260 FLOWBENCHAnderson ZambrzyckiNessuna valutazione finora

- Intake Pulse CalculationDocumento14 pagineIntake Pulse CalculationShrikant Khating100% (5)

- Higher - Compression - Two - Stroke PDFDocumento8 pagineHigher - Compression - Two - Stroke PDFImung Pernah SehatNessuna valutazione finora

- 2012 Comet Catalog Web PDFDocumento244 pagine2012 Comet Catalog Web PDFTEXASBAGMANNessuna valutazione finora

- HRP Motor Sports Products and Services CatalogDocumento16 pagineHRP Motor Sports Products and Services CatalogGus McGrathNessuna valutazione finora

- Cb750 Service 2Documento136 pagineCb750 Service 2gabimaier31Nessuna valutazione finora

- Engmod2T: The Multi-Cylinder Two-Stroke Engine SimulatorDocumento8 pagineEngmod2T: The Multi-Cylinder Two-Stroke Engine SimulatorByndy95Nessuna valutazione finora

- Camshaft Lobe DesignDocumento7 pagineCamshaft Lobe Designagandoel100% (1)

- Honda SOHC Four Lubritech Paint ScheduleDocumento4 pagineHonda SOHC Four Lubritech Paint Schedulesetthe0% (1)

- Intake Design For Maximum PerformanceDocumento8 pagineIntake Design For Maximum PerformanceCaio Paim100% (2)

- Selection and Tuning of Dellorto DHLA CarburettorsDocumento12 pagineSelection and Tuning of Dellorto DHLA CarburettorsMichael Mitchell0% (1)

- ZRP Catalog 2019 PDFDocumento68 pagineZRP Catalog 2019 PDFMichaelNessuna valutazione finora

- Shop - Metal - Gingery's Pipe Bending MachineDocumento1 paginaShop - Metal - Gingery's Pipe Bending MachinePutra Pratama100% (6)

- 08ZX10Rracing Kit ManualDocumento80 pagine08ZX10Rracing Kit ManualAriel MuñozNessuna valutazione finora

- Engine Intake Port Optimization in SculptorDocumento3 pagineEngine Intake Port Optimization in SculptorgosculptorNessuna valutazione finora

- Ron Iskenderian Cam Session - Minor Cam Timing Inaccuracies Do Not Lost HPDocumento3 pagineRon Iskenderian Cam Session - Minor Cam Timing Inaccuracies Do Not Lost HPgaragepunkfan100% (1)

- 2 Stroke TuningDocumento6 pagine2 Stroke TuningRahul NakheNessuna valutazione finora

- Jet Powered Models, Pulse JetsDocumento5 pagineJet Powered Models, Pulse JetsBalaji AeroNessuna valutazione finora

- Home Shop Machinist's Gears GuideDocumento8 pagineHome Shop Machinist's Gears Guidegaragepunkfan100% (1)

- Crankshaft ConstructionDocumento24 pagineCrankshaft ConstructionBharatiyulam100% (2)

- Construction and Manufacture of AutomobilesDa EverandConstruction and Manufacture of AutomobilesValutazione: 5 su 5 stelle5/5 (1)

- Telehander TL642 CAT PartsDocumento402 pagineTelehander TL642 CAT Partsrmatico1234100% (5)

- Fuel CellsDocumento5 pagineFuel CellsSatish KumarNessuna valutazione finora

- Nozzles Catalogue 2014-09Documento110 pagineNozzles Catalogue 2014-09Johmir Torres100% (1)

- Piston WordDocumento17 paginePiston Wordhi_mayank1Nessuna valutazione finora

- Bilge Ballast and SystemsDocumento72 pagineBilge Ballast and SystemsRENGANATHAN P100% (7)

- Jenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsDocumento4 pagineJenbacher JMS 616 GS-N.L Natural Gas Module Technical Specsmxnoxn100% (1)

- En 4J2 1F PDFDocumento634 pagineEn 4J2 1F PDFCristhian CazasNessuna valutazione finora

- Development of Combustion EnginesDocumento74 pagineDevelopment of Combustion EngineskristianNessuna valutazione finora

- 40KW Diesel Generator Datasheet J40u (English) PDFDocumento4 pagine40KW Diesel Generator Datasheet J40u (English) PDFojopoderosoNessuna valutazione finora

- Volkswagen Passat (B4)Documento2 pagineVolkswagen Passat (B4)Arūnas GiraitisNessuna valutazione finora

- Tabla de Capacidades Sany Stc-800sDocumento9 pagineTabla de Capacidades Sany Stc-800sAnonymous sqFTF5tuNessuna valutazione finora

- 7081 GCE O Chemistry MSC 20080807Documento36 pagine7081 GCE O Chemistry MSC 20080807MERCY LAWNessuna valutazione finora

- PMChecklist ReportDocumento9 paginePMChecklist ReportIbrahim AwadNessuna valutazione finora

- VSEP Membrane Separation Ethanol Application NoteDocumento12 pagineVSEP Membrane Separation Ethanol Application NoteHermawan Dwi AriyantoNessuna valutazione finora

- En Ruptela FLS Installation Instructions-1Documento47 pagineEn Ruptela FLS Installation Instructions-1Alexi TC100% (1)

- Astm E778Documento5 pagineAstm E778ThoharudinNessuna valutazione finora

- Technical Diary OF Stage-1 (UNIT-1&2) (PTPS, Panipat) : 2 X 110 MW Unit-I & Ii Panipat Thermal Power Station PanipatDocumento138 pagineTechnical Diary OF Stage-1 (UNIT-1&2) (PTPS, Panipat) : 2 X 110 MW Unit-I & Ii Panipat Thermal Power Station PanipatapsNessuna valutazione finora

- WH713 1 WH714 1 WH714H 1 WH716 SN 395F70001-Up PDFDocumento655 pagineWH713 1 WH714 1 WH714H 1 WH716 SN 395F70001-Up PDFdrmasster100% (1)

- Fisher 480 Series Actuator GuideDocumento12 pagineFisher 480 Series Actuator GuideSergio Figueroa MuñozNessuna valutazione finora

- SH210 5 SERVCE CD PDF Pages 1 33Documento33 pagineSH210 5 SERVCE CD PDF Pages 1 33Em sulistio87% (23)

- Benham RiseDocumento24 pagineBenham RiseRhea CelzoNessuna valutazione finora

- 930E Field Assembly CEAWD03300Documento174 pagine930E Field Assembly CEAWD03300Jorge Rodolfo Yanez EscuderoNessuna valutazione finora

- Hydraulic Excavator 325dl PDFDocumento32 pagineHydraulic Excavator 325dl PDFacarisimovic100% (1)

- Service-Manual Linhai Atv Europe 07.0Documento341 pagineService-Manual Linhai Atv Europe 07.0Stefan100% (3)

- Stainless Steels: Cost-Efficient Materials For The Global Biofuels IndustriesDocumento20 pagineStainless Steels: Cost-Efficient Materials For The Global Biofuels Industriessara95Nessuna valutazione finora

- ZVH GuideDocumento5 pagineZVH GuideJoaquin Ruben Lozano QuinteroNessuna valutazione finora

- Presentation On CFBC Technology by Cethar Vessels (P) LTDDocumento21 paginePresentation On CFBC Technology by Cethar Vessels (P) LTDRavi Chandar100% (3)

- Pressure TransducerDocumento17 paginePressure TransducerDian PramadiNessuna valutazione finora

- MAN Test CellDocumento12 pagineMAN Test CellavryoneNessuna valutazione finora

- Siestorage Catalog enDocumento28 pagineSiestorage Catalog ennguyenqlda0% (1)